Compound base of precious metal nanometer array and single layer graphene and preparation method thereof

A single-layer graphene and nanoarray technology, applied in the field of nanomaterials, can solve the problems of difficulty in obtaining large-area composite materials, reduced graphene performance, poor controllability, etc. less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

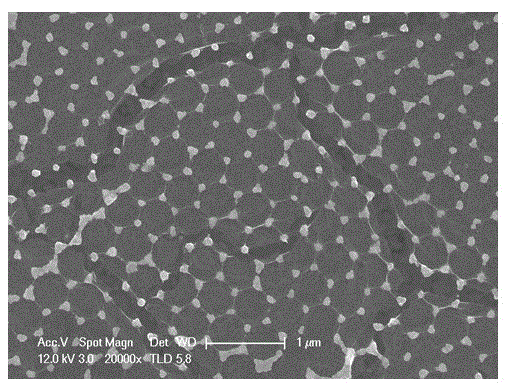

[0046]On a single-sided finely polished single-crystal silicon wafer, polystyrene nanospheres with a diameter of 460 nm were prepared by a liquid surface self-assembly method to form a single-layer closely arranged mask. Using a vacuum coating machine, a 10 nm thick Cr film was first evaporated on a polystyrene nanosphere mask, and then a 60 nm thick Ag film was evaporated to obtain a substrate. The substrate was sonicated in chloroform for 20 seconds and allowed to stand for 10 minutes to remove the polystyrene microspheres to obtain Ag nanoarrays, which were then washed in alcohol and deionized water in sequence.

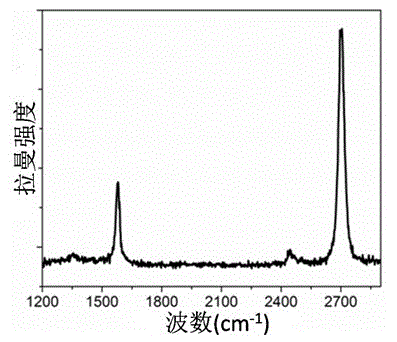

[0047] The Cu foil with a thickness of 25 μm was treated by chemical mechanical polishing to ensure that the surface of the Cu foil was clean and smooth; then, at 1020 ° C, in a mixed gas atmosphere of methane and hydrogen, the treated Cu foil was grown on the treated Cu foil by chemical vapor deposition. layer graphene, during the graphene growth process, the flo...

Embodiment 2

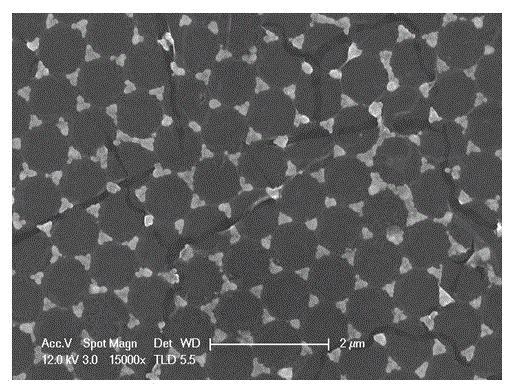

[0051] On a single-sided finely polished single-crystal silicon wafer, polystyrene nanospheres with a diameter of 800 nm were prepared by liquid surface self-assembly method to form a single-layer closely arranged mask. Using a vacuum coating machine, a 10 nm thick Cr film was first evaporated on a polystyrene nanosphere mask, and then a 60 nm thick Ag film was evaporated to obtain a substrate. Sonicate the substrate in chloroform for 20 seconds, let it stand for 10 minutes, remove the polystyrene nanosphere mask, and clean it in alcohol and deionized water in turn.

[0052] The Cu foil with a thickness of 25 μm was treated by chemical mechanical polishing to ensure that the surface of the Cu foil was clean and smooth; then, at 1020 ° C, in a mixed gas atmosphere of methane and hydrogen, the treated Cu foil was grown on the treated Cu foil by chemical vapor deposition. layer graphene, during the graphene growth process, the flow rates of methane and hydrogen were controlled to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com