Novel biomimetic surface-enhanced Raman spectroscopy substrate and its preparation method

A surface-enhanced Raman and substrate technology, applied in the field of Raman spectroscopy and nanomaterials, can solve the problems of difficulty in large-scale production, low density of substrate hot spots, and complicated production process, and achieves strong stability, convenient material acquisition, and simple processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of gold-coated two-dimensional biomimetic surface-enhanced Raman spectroscopy substrate

[0026] 1) Raw material pretreatment: select clean and transparent black grasshopper (Cryptotympanaatrata Fabricius) forewings, ultrasonically clean them with ultrapure water for 5 minutes, dry them in the air, remove the veins of the cicada wings with a scalpel, and cut them into 4×4 square millimeters Then use tweezers to fix the small piece on a glass slide with double-sided adhesive tape, blow it flat with the ear washing ball, and use it as a biological template.

[0027] 2) Substrate preparation: Put the prepared biological template into a DC ion sputtering apparatus (ETD-3000), use high-purity argon (99.999%) as the protective gas, and use high-purity gold (99.99%) as the target material, and sputter The air pressure is 10 Pa, the sputtering current is 4 mA, the sputtering rate is 3.0-4.0 nanometers per minute, preferably 3.6-4.0 nanometers per minute, ...

Embodiment 2

[0029] Example 2: Preparation of silver-coated two-dimensional biomimetic surface-enhanced Raman spectroscopy substrate

[0030] 1) Pretreatment of raw materials: same as step 1) in Example 1.

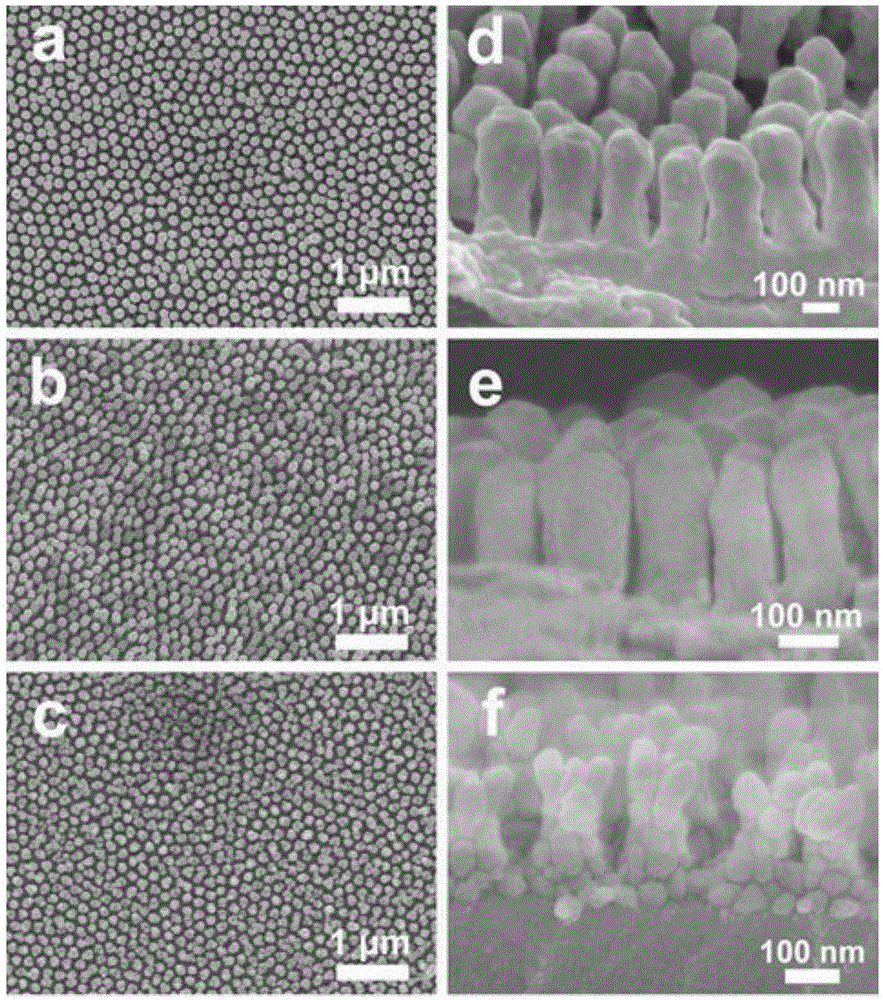

[0031] 2) Substrate preparation: the sputtering conditions and methods are the same as those described in step 2) in Example 1. The gold layer is intermittently sputtered for 2 cycles, and then the high-purity silver (99.99%) target is used, and the microstructure of the silver-coated layer can be adjusted by sputtering for 12 to 14 cycles. Such as figure 2 As shown in b and 2e, after 13 cycles of silver sputtering, a columnar two-dimensional biomimetic surface-enhanced Raman spectroscopy substrate with a silver-coated gap of less than 10 nm (ie, a two-dimensional silver-coated substrate) was prepared. In contrast, under the conditions of sputtering pressure of 6 Pa and sputtering current of 6 mA, 8 cycles of intermittent sputtering can also prepare pure silver-coated two-dimensiona...

Embodiment 3

[0033] Example 3: Preparation of silver particle-modified three-dimensional biomimetic surface-enhanced Raman spectroscopy substrate

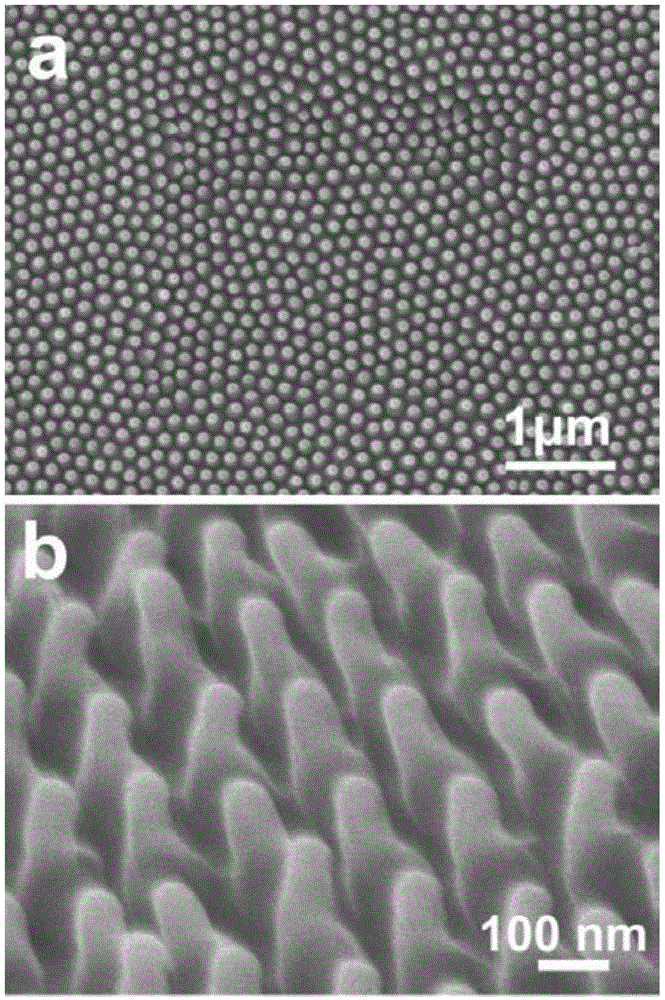

[0034] 1) Pretreatment of raw materials: same as step 1) in Example 1. Because the surface of the cicada wing of the black grasshopper has quasi-regular chitin nano-columnar array knots, its chitin columns are wide at the top and narrow at the bottom, with a diameter of about 60 nanometers at the top, a diameter of about 120 nanometers at the bottom, and a height of about 180 nanometers. The gap between them is about 80 nm. This special microstructure facilitates the formation of silver particles during the preparation of silver particle-modified 3D biomimetic surface-enhanced Raman spectroscopy substrates.

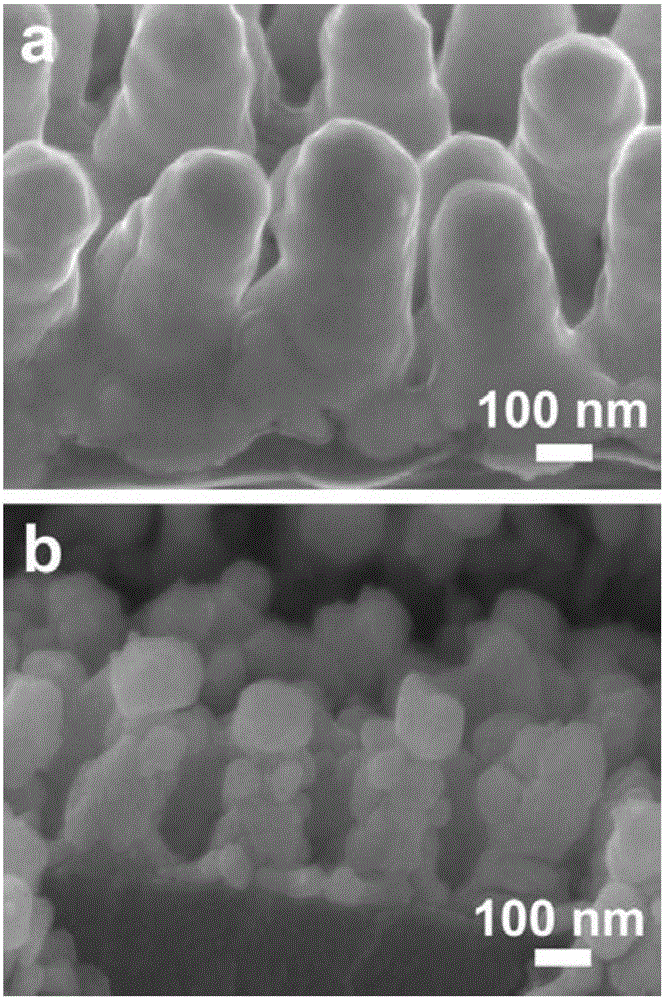

[0035] 2) Substrate preparation: the sputtering conditions and methods are the same as those described in step 2) in Example 1. The microstructure of the silver nanoparticle layer can be adjusted by direct sputtering with the silver targ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com