Preparation method of high-conductivity graphene powder

A technology of graphene powder and high conductivity, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of uncontrollable number of graphene layers, uncontrollable size, expensive price, etc., achieve high yield, The effect of low defect rate and simple feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

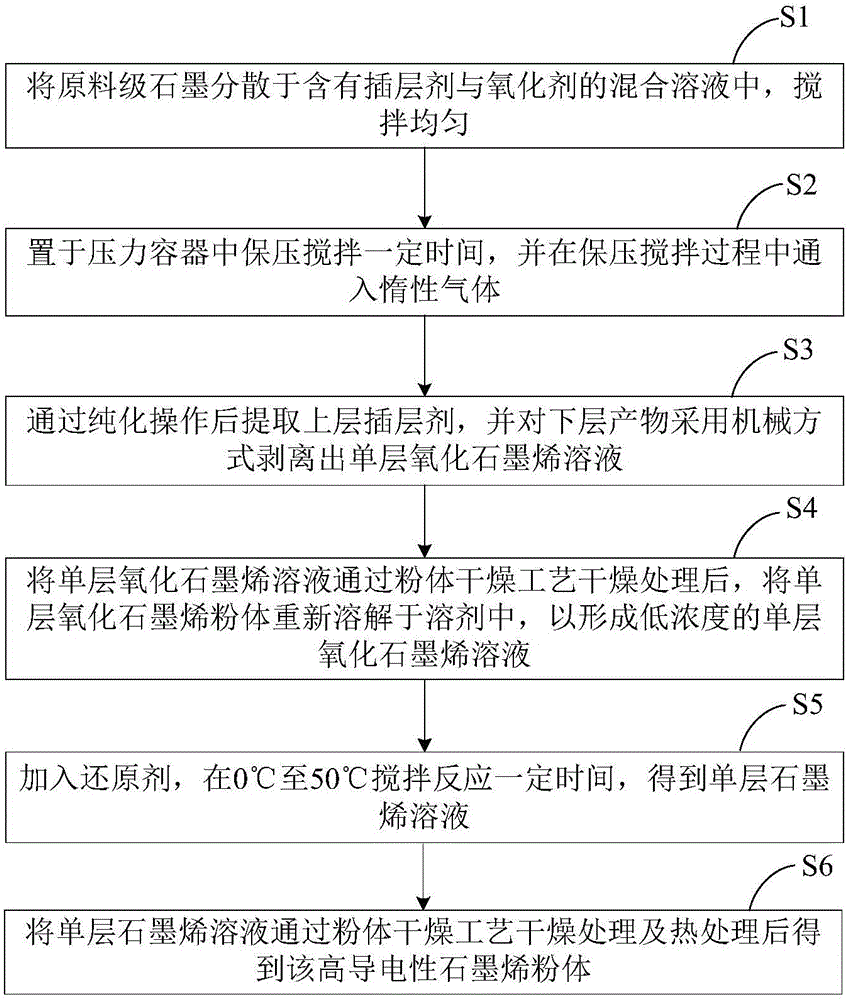

[0045] Such as figure 1 Shown, the preparation method of highly conductive graphene powder comprises the following steps:

[0046] First perform step S1, disperse the raw material grade graphite in the mixed solution containing the intercalation agent and the oxidizing agent, and stir evenly;

[0047] Then perform step S2, place in a pressure vessel and keep stirring for a certain period of time, and pass inert gas during the process of keeping pressure and stirring;

[0048] Then perform step S3, extract the upper intercalation agent after the purification operation, and mechanically peel off the single-layer graphene oxide solution from the lower product;

[0049] Then perform step S4, after drying the single-layer graphene oxide solution through a powder drying process, re-dissolving the single-layer graphene oxide powder in the solvent to form a low-concentration single-layer graphene oxide solution;

[0050] Then perform step S5, add a reducing agent, and stir and react...

Embodiment 1

[0058] Mix 1.0 g of 1000-mesh flake graphite (natural graphite) with 3.5 g of potassium permanganate, add it into a 100 mL pressure vessel, and add a magnetic rotor into the pressure vessel. 30 mL of concentrated sulfuric acid (concentration: 98 wt%) at 0°C was added.

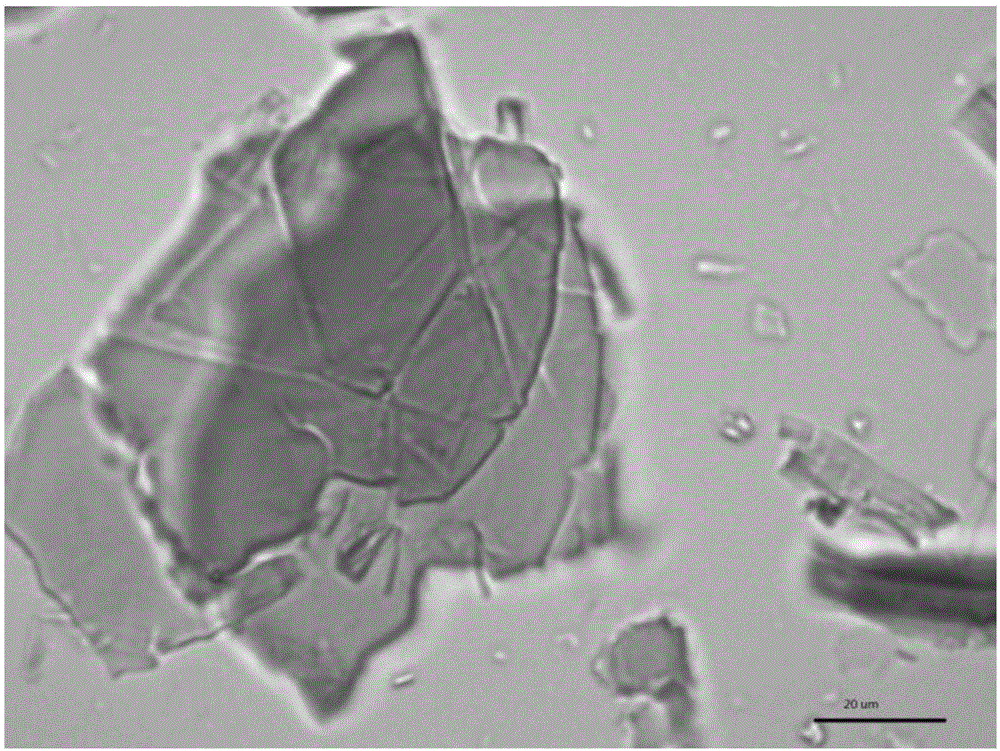

[0059] Put the autoclave into the autoclave, and seal the autoclave. A magnetic stirrer is arranged below the autoclave. Argon gas was introduced into the autoclave until the pressure reached 50 bar and the pressure was maintained. Turn on the magnetic stirrer and stir with the magnetic rotor for 5 min, so that the reactants are fully mixed. Then the reaction kettle was reacted at 5°C for 48h, and the pressure kettle was opened after the pressure was released. The obtained reaction product was placed in a centrifuge and centrifuged at a speed of 5000rmp for 5min. The intercalation agent in the upper layer was recovered as a clear liquid, and the muddy product in the lower layer was poured into 50mL of deioni...

Embodiment 2

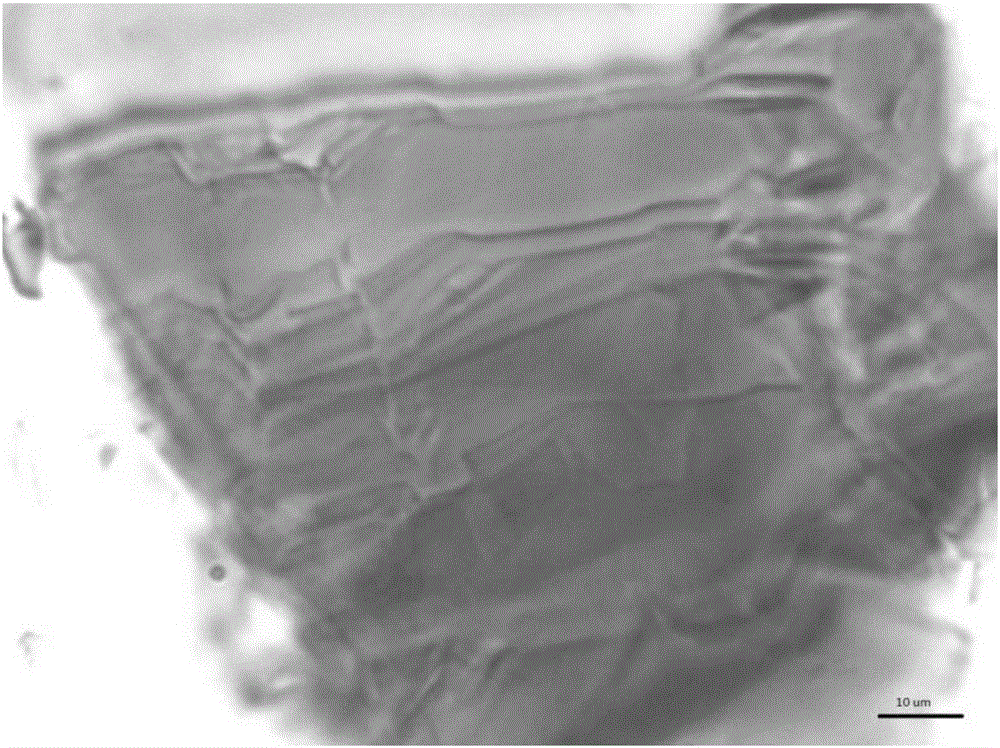

[0063] Mix 1.0g of 5000 mesh artificial graphite with 3.0g of ammonium persulfate and 1.0g of phosphorus pentoxide, add it into a 100mL pressure vessel, and add a magnetic rotor into the pressure vessel. 10 mL of concentrated sulfuric acid (concentration: 98 wt%) at 0°C was added.

[0064] Put the autoclave into the autoclave, and seal the autoclave. A magnetic stirrer is arranged below the autoclave. Introduce argon until the pressure reaches 100 bar and maintain the pressure. Turn on the magnetic stirrer and stir with the magnetic rotor for 5 min, so that the reactants are fully mixed. Then the reaction kettle was reacted at 0°C for 24h, and the pressure kettle was opened after the pressure was released. Centrifuge at 5000rmp for 5min in a centrifuge. The intercalation agent whose upper layer was clarified liquid was recovered and used, and the muddy product of the lower layer was poured into 50 mL deionized water for dilution, and the clear liquid was removed by centrif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com