Manufacturing method of flexible circuit board

The technology of a flexible circuit board and a manufacturing method, which is applied in the direction of removing conductive materials by chemical/electrolytic methods, can solve problems such as dry film plugging, and achieve the effect of solving dry film plugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment is used to illustrate the preparation method of the flexible circuit board of the present invention.

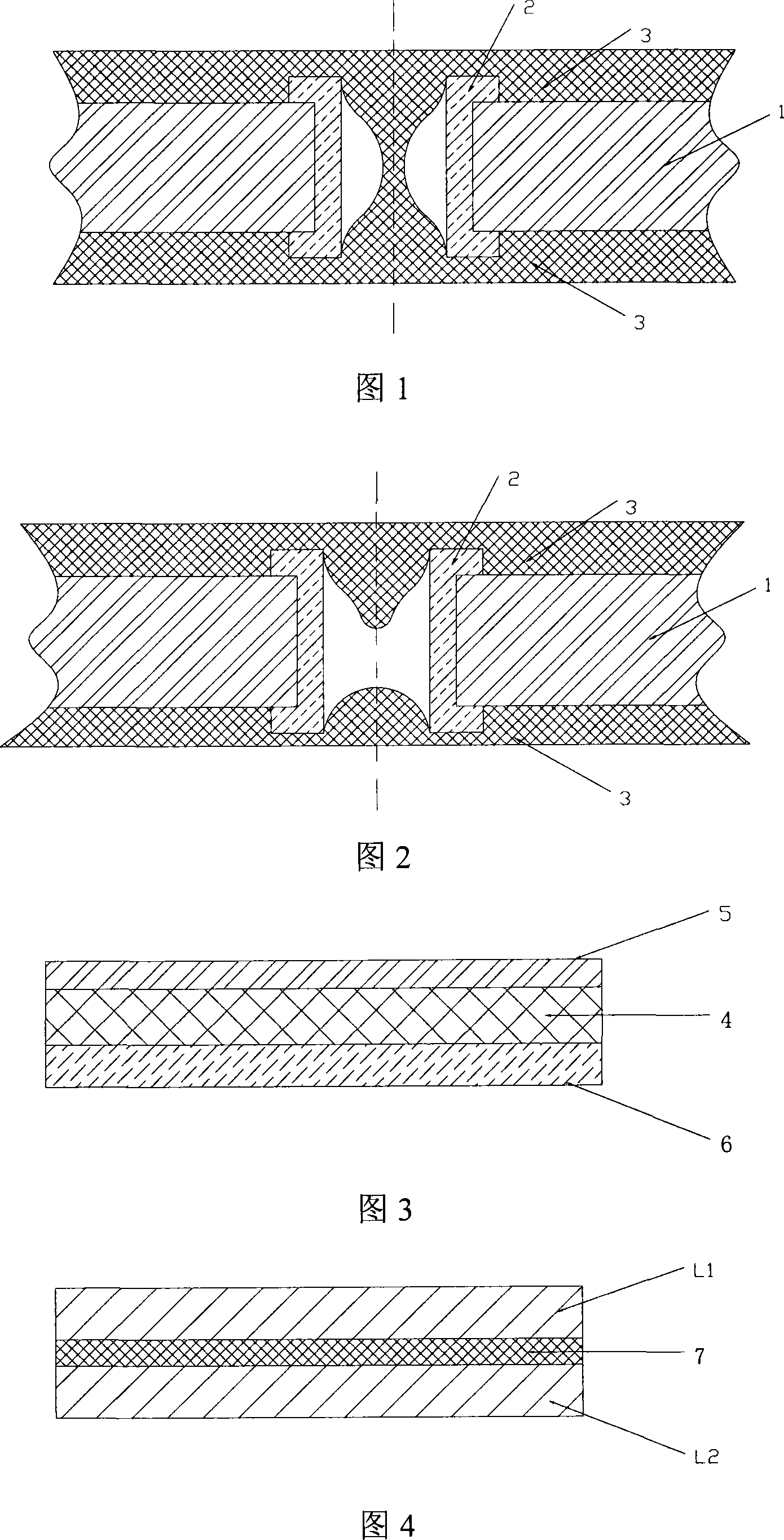

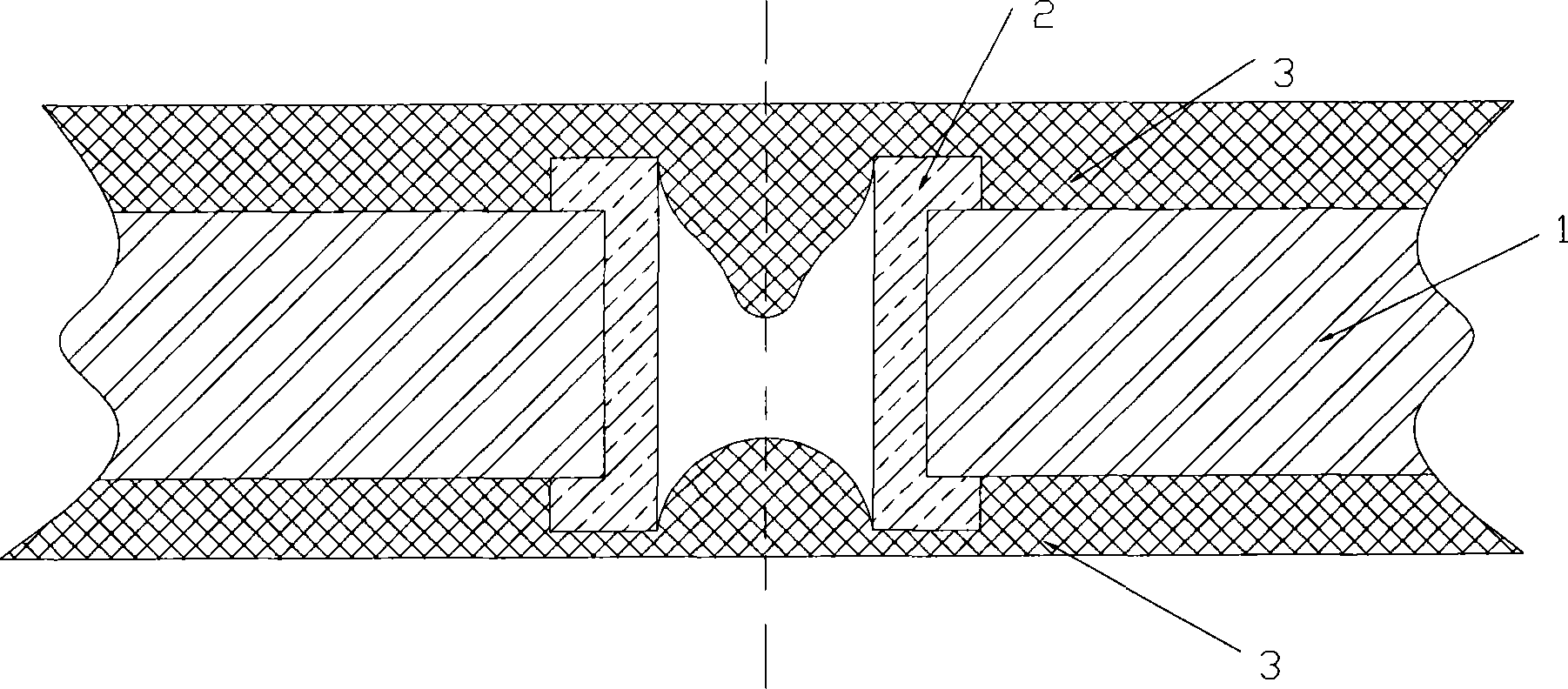

[0048] The structure of the selected copper-clad laminate is shown in Figure 4, in which the materials of the L1 and L2 surfaces are SL-12-12-EP of LG Company, and the material of the prepreg is BH-10 of Taihong Company.

[0049] Laminate YQ-40SD dry film (thickness: 40 microns) on the L1 surface, laminate AQ-20FA dry film (thickness: 20 microns) on the L2 surface; paste the negative film (Shenzhen Meike Silver Co., Ltd.) on the L1 surface with a thick dry film salt film) and exposed in a graphic manner with a 5 kW high-pressure mercury lamp, the L2 surface is directly exposed, and the exposure energy of the L1 surface is 50 mJ / cm2, and the exposure energy of the L2 surface is 30 mJ / cm2; the L1 surface Tear off polyester film; at 30°C with 1.0 wt% Na 2 CO 3 The solution was used to develop the L1 and L2 surfaces; at 48°C, with CuCl 2 / H 2 o 2 / HCl ...

Embodiment 2

[0052] This embodiment is used to illustrate the preparation method of the flexible circuit board of the present invention.

[0053] According to the same method as in Example 1, the difference is that the thickness of the dry film used is respectively: the thick dry film is 40 microns (YQ-40SD), and the thin dry film is 15 microns (SPG-152).

[0054] Prepare 400 sheets of the same flexible circuit board by the above method, and the product is marked as A2.

Embodiment 3

[0056] This embodiment is used to illustrate the preparation method of the flexible circuit board of the present invention.

[0057] According to the same method as in Example 1, the difference is that the thicknesses of the dry films used are: the thick dry film is 50 microns (YQ-50SD), and the thin dry film is 20 microns (AQ-20FA).

[0058] Prepare 400 sheets of the same flexible circuit board by the above method, and the product is marked as A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com