Four-shaft non-anharmonic vibrating screen and screening method thereof

A vibrating screen and anharmonic technology, applied in the field of four-axis anharmonic vibrating screen and its screening, can solve the problems of high maintenance equipment cost, complex equipment structure, large maintenance workload, etc., and achieve low noise and low operating temperature. , The effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

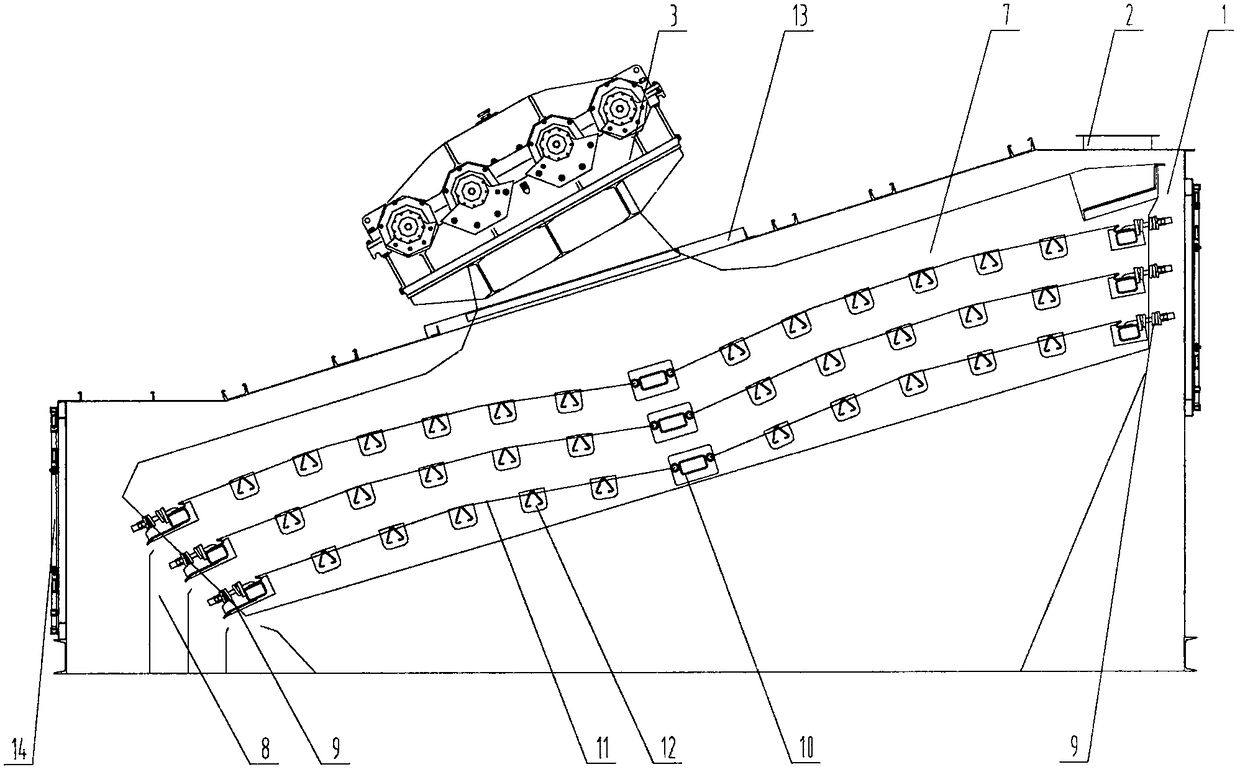

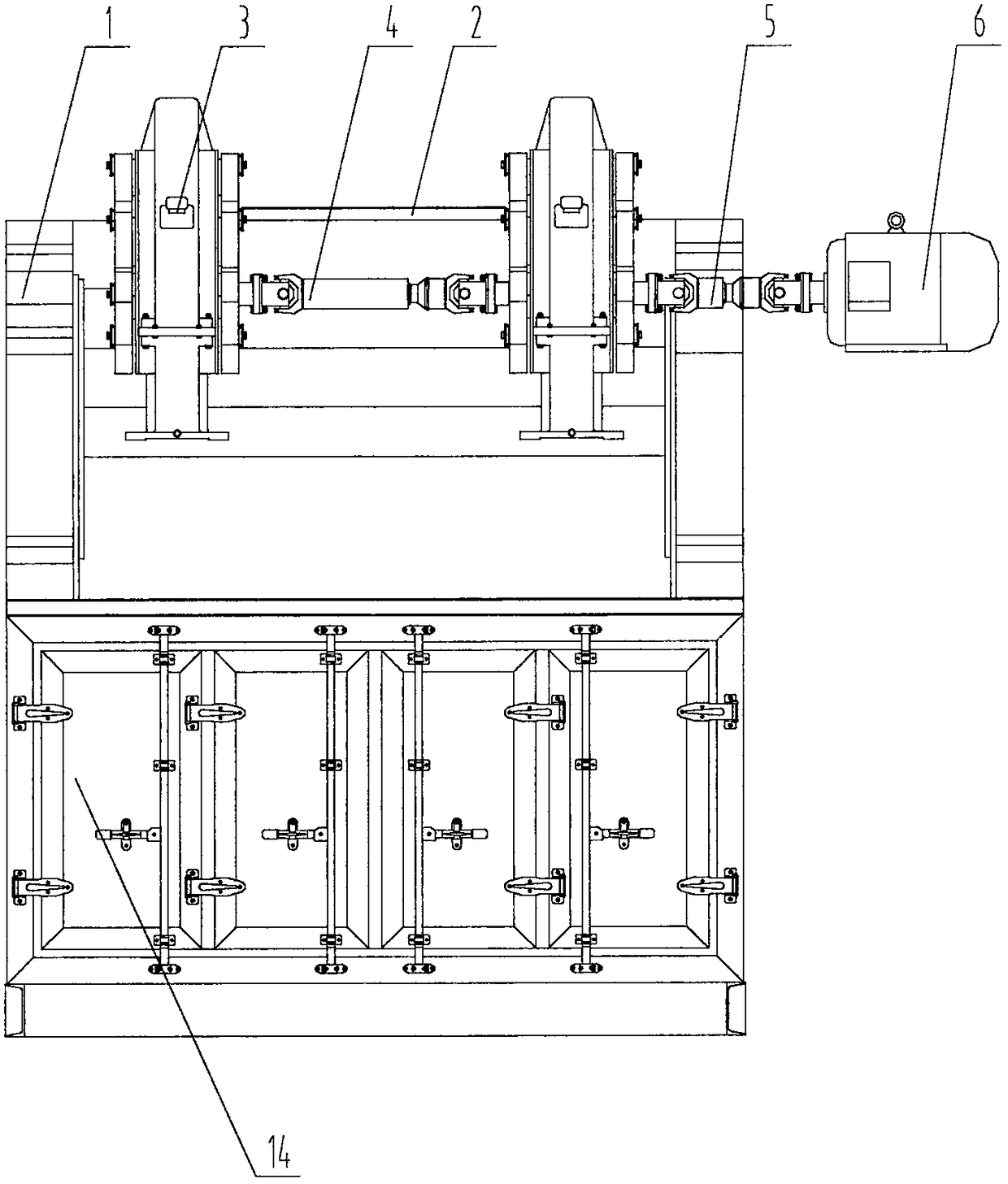

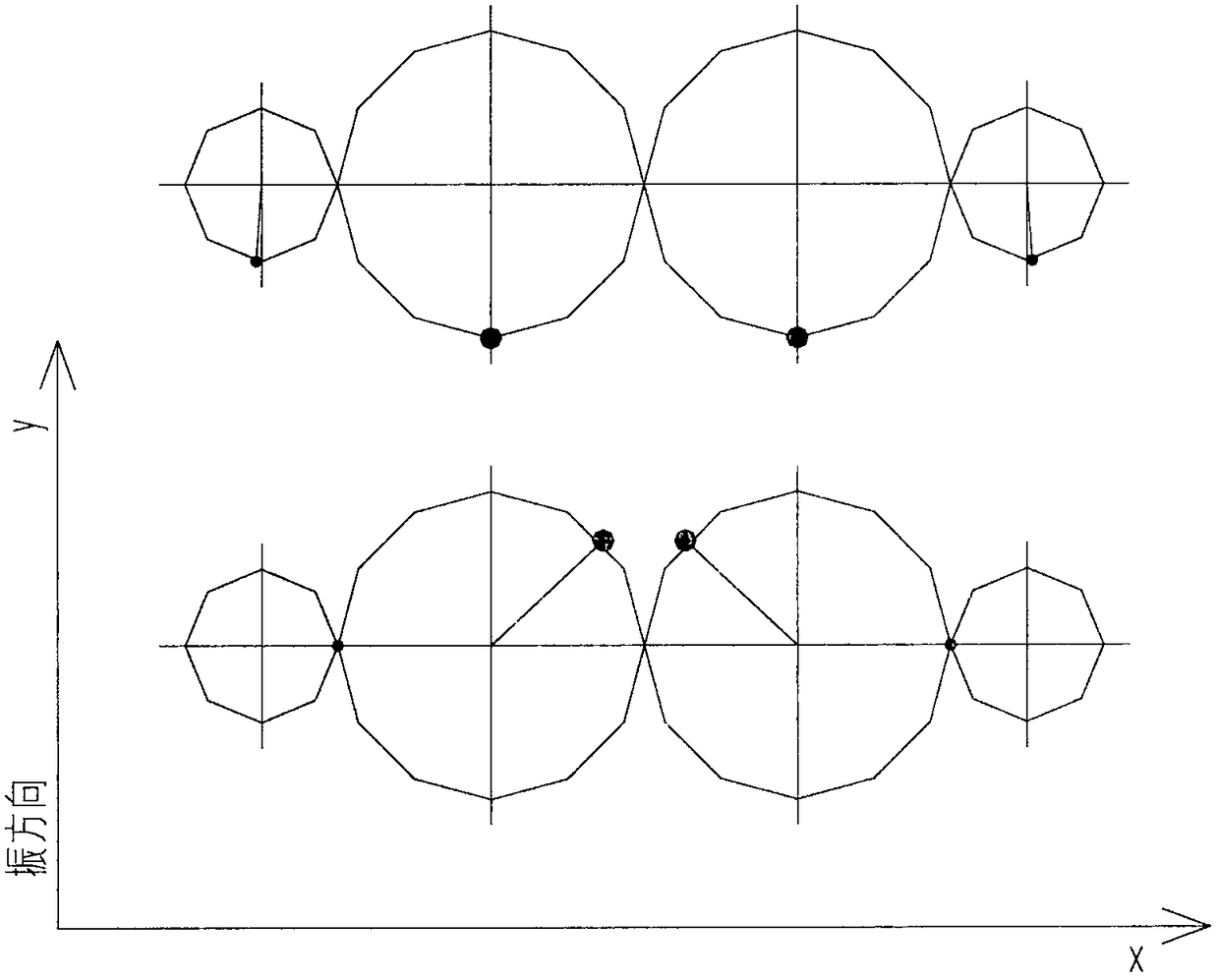

[0044] A four-axis non-harmonic vibrating screen, including a box body 1, a top of one end of the box body 1 is provided with a feed inlet 2, a screen body 7 is provided on the box body 1, and the screen body 7 has a slope with a large upper part and a small lower part. The two ends of the screen body 7 are respectively fixed with several groups of screen tensioning devices 9 from top to bottom. The screen tensioning devices 9 are provided with intermediate beams 10, the screen tensioning devices 9 and the middle beams There is a screen 11 between 10, the bottom of the screen 11 is provided with a number of support beams 12, the bottom of the box body 1 is provided with a number of discharge ports 8, between the upper middle of the screen body 7 and the box body 1. A screen cover 13 is provided. The top of the screen body 7 is provided with two four-axis thin oil exciters 3, and an intermediate shaft 4 is arranged between the driving shafts 21 of the two four-axis thin oil excit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com