Evaporation source device used for evaporation

An evaporation source and evaporation technology, which is used in vacuum evaporation coating, sputtering coating, ion implantation coating, etc. The effect of plugging holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

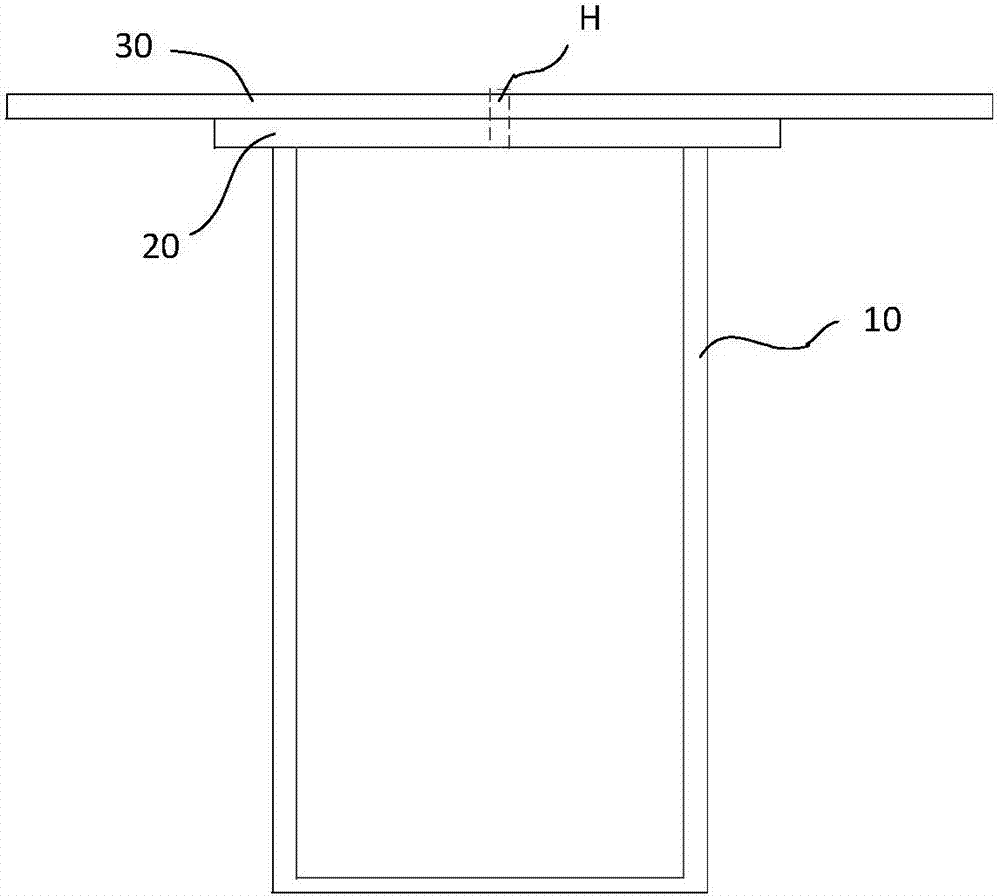

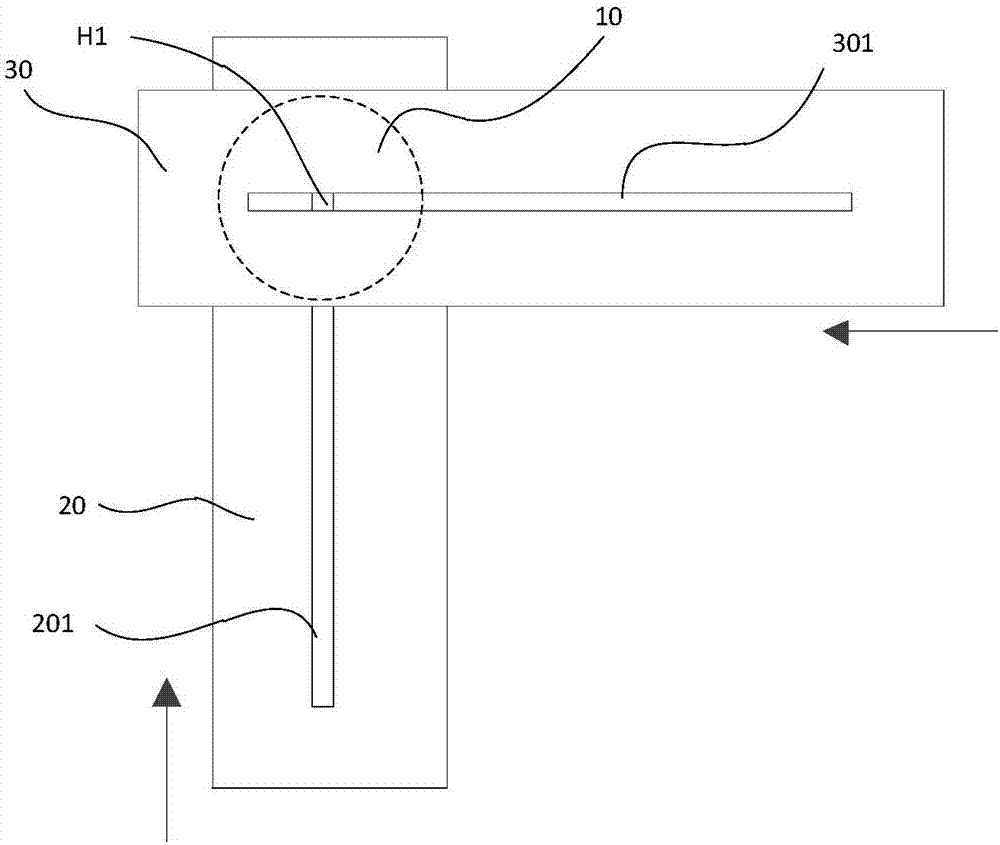

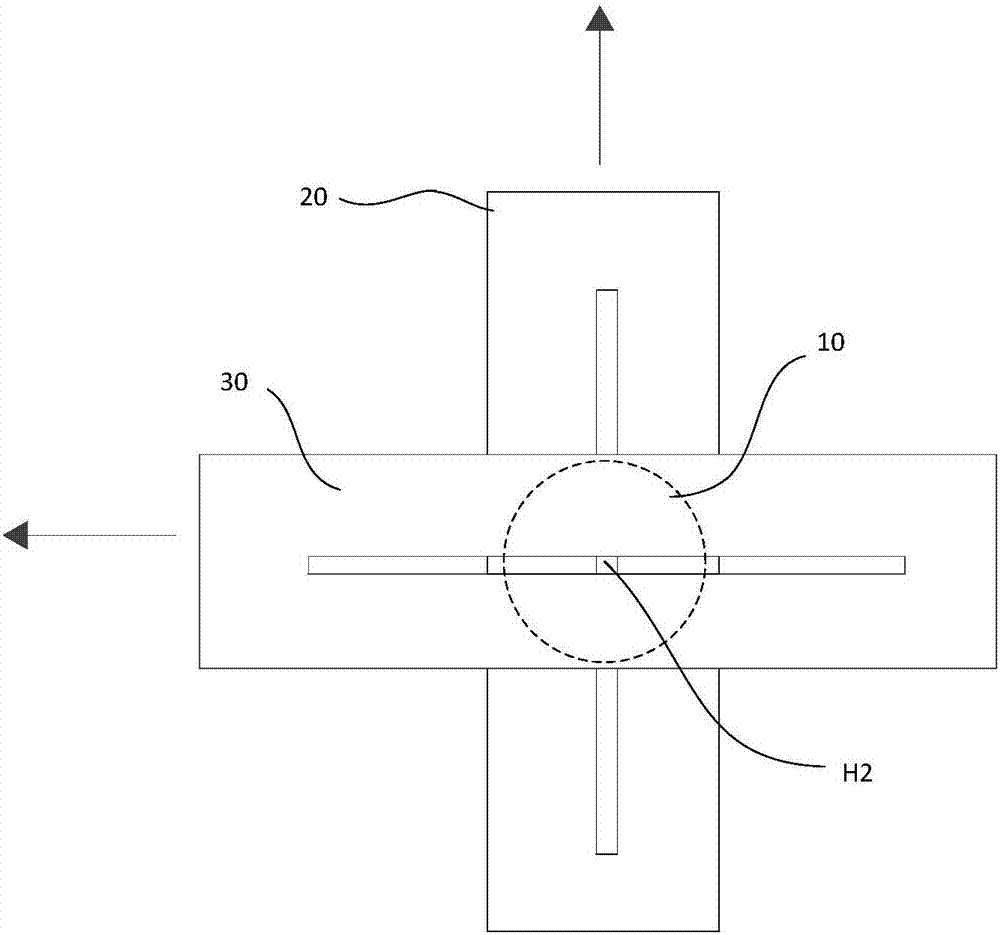

[0031] refer to figure 1 with figure 2 The evaporation source device of the present embodiment comprises a heating container 10 with an opening on the top surface and a first baffle plate 20 and a second baffle plate 30 covering the opening of the heating container 10. The heating container 10 is preferably a crucible, and the first baffle plate 20 and the second baffle plate 30 in the height direction of the heating container 10 (such as figure 1 The shown vertical direction) is stacked and the extension direction is crossed. The through holes on the first baffle plate 20 and the second baffle plate 30 are all strip-shaped holes extending along the length direction of the corresponding baffle plate, that is, the first A first strip-shaped hole 201 is opened on the baffle 20 , and a second strip-shaped hole 301 is opened on the second baffle 30 .

[0032] After being installed on the opening on the top surface of the heating container 10, the first baffle plate 20 and the s...

Embodiment 2

[0039] Such as Figure 5 As shown, different from Embodiment 1, the through holes on the first baffle plate 20 and the second baffle plate 30 of this embodiment are point-shaped through holes arranged at intervals in the length direction of the corresponding baffle plate, rather than one Overall strip hole.

[0040] During the process of moving the first baffle plate 20 and the second baffle plate 30, the dotted through holes of the first baffle plate 20 can cooperate with the corresponding dotted through holes of the second baffle plate 30 above it to form an evaporation channel H , when one of the point-shaped through holes of the first baffle plate 20 or the second baffle plate 30 is blocked, a new evaporation channel H can be formed by moving the baffle plate where the blocked point-shaped through-hole is located to replace the point-shaped through-hole.

[0041] It can be understood that, in other embodiments, the through holes on the first baffle plate 20 may be strip-s...

Embodiment 3

[0043] Such as Image 6 with 7 As shown, the difference from Embodiments 1 and 2 is that the first baffle plate 20 and the second baffle plate 30 of this embodiment are in the radial direction of the heating container 10 (ie figure 1 horizontal direction) adjacent to each other, the first baffle plate 20 and the second baffle plate 30 enclose the evaporation channel by splicing. Specifically, the first baffle 20 is provided with a plurality of first notches 200 arranged at intervals, and the second baffle 30 is provided with a plurality of second notches 300 arranged at intervals, and the second baffle 30 can Moving relative to the first baffle 20 , different first notches 200 cooperate with second notches 300 to form different evaporation channels.

[0044] Such as Image 6 , during the initial work, the first notch 200 on the edge of the first baffle 20 corresponds to the second notch 300 on the edge of the second baffle 30 one by one, and each first notch 200 is spliced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com