Coal mine underground grouting drill rod and using method

A technology for drill pipes and coal mines, which is applied in the direction of drill pipes, drill pipes, mining equipment, etc., and can solve problems such as increasing the workload of grouting filling, blocking holes, and affecting the penetration of grouting pipes into boreholes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

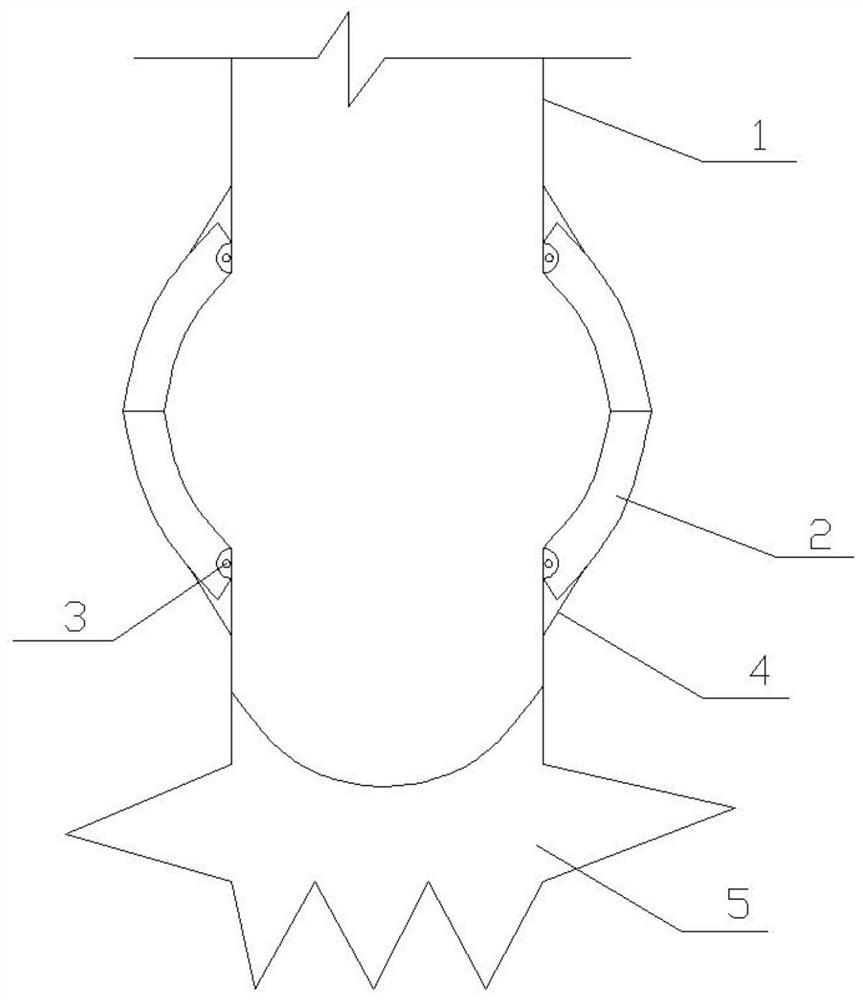

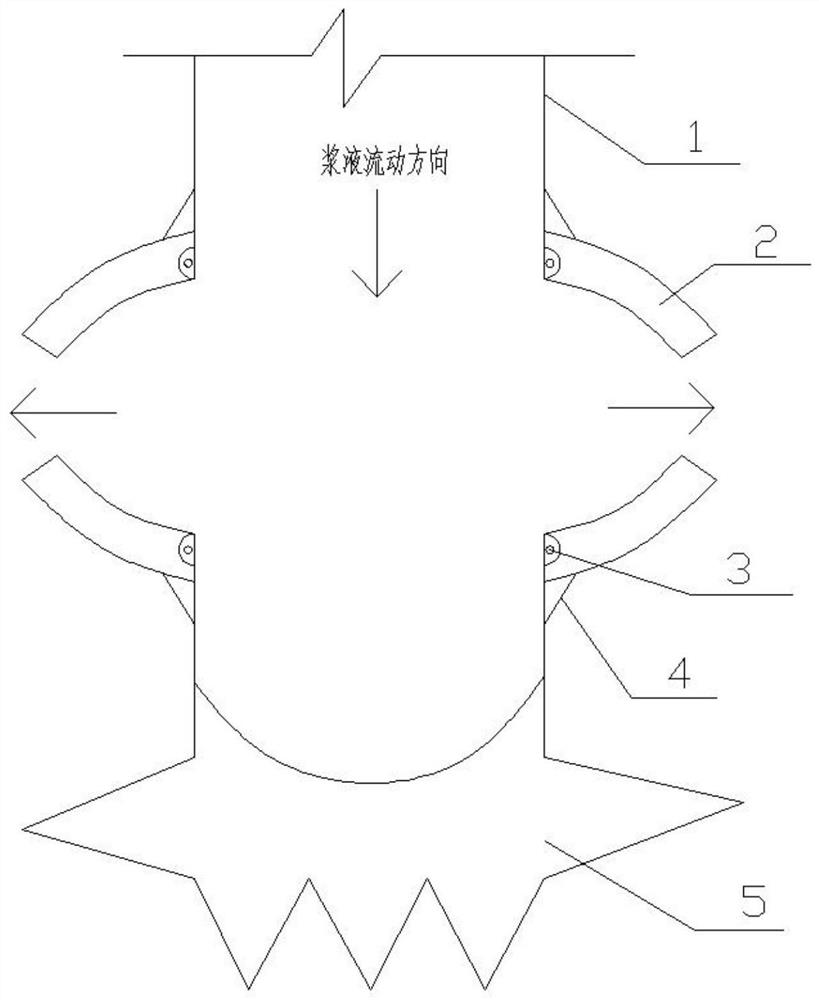

[0015] see figure 1 and 2 , an underground coal mine grouting drill pipe, the device is mainly composed of a drill pipe body 1, a one-way switch 2, a rotary connector 3, a shield 4, a drill bit 5 and other components. The drill pipe body 1 is designed to have a diameter of 5-10 cm according to the actual situation of the filling site, and is made of steel material. A high-strength drill bit 5 is welded at the end of the drill rod, and the drill bit 5 is made of a metal material with higher hardness, which is enough to drill through rocks of general hardness. The size of drill bit 5 is generally greater than the maximum height when one-way switch 2 is fully opened 1-2cm, so that when drill bit 5 drills rock mass holes, give one-way switch 2 sufficient opening and closing space. The one-way switch 2 is made of two halves of arc-shaped hard steel sheets. According to the geological conditions of the grouting site, its length is designed to be 3-5cm, the protruding height is des...

Embodiment 2

[0017] A coal mine underground grouting drill pipe. The specific use method of the device is as follows: step 1, connect the drill pipe body 1 to the drilling rig, align the drill bit with the grouting site, start the drilling rig, rotate the drill Drill into the grouting site; step 2, stop drilling after the drill pipe is drilled into the grouting area to a suitable length, start the grouting work, start the filling pump, pump the slurry into the drill pipe body 1 and push the slurry Flow to the drill bit 5; step 3, when the slurry reaches the position of the drill bit 5 at the front end of the drill pipe, the one-way switch 2 opens outward under the huge pressure of the slurry, and the slurry flows from the opening of the one-way switch 2 Injection outwards, start to fill the broken rock mass or gangue; step 4, when the slurry pressure in the drill pipe body 1 increases and the slurry consumption speed slows down, reduce the pumping pressure, rotate backwards and retract For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com