Extrusion-type molecular-sieve denitration catalyst based on copper-iron mixing and preparation method of molecular-sieve denitration catalyst

A denitration catalyst, molecular sieve technology, applied in molecular sieve catalysts, separation methods, chemical instruments and methods, etc., can solve the problems of insufficient molecular sieve and carrier firmness, low molecular sieve catalyst loading, harsh preparation process conditions, etc. The effect of high temperature activity, reducing production cost and avoiding pore blocking problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

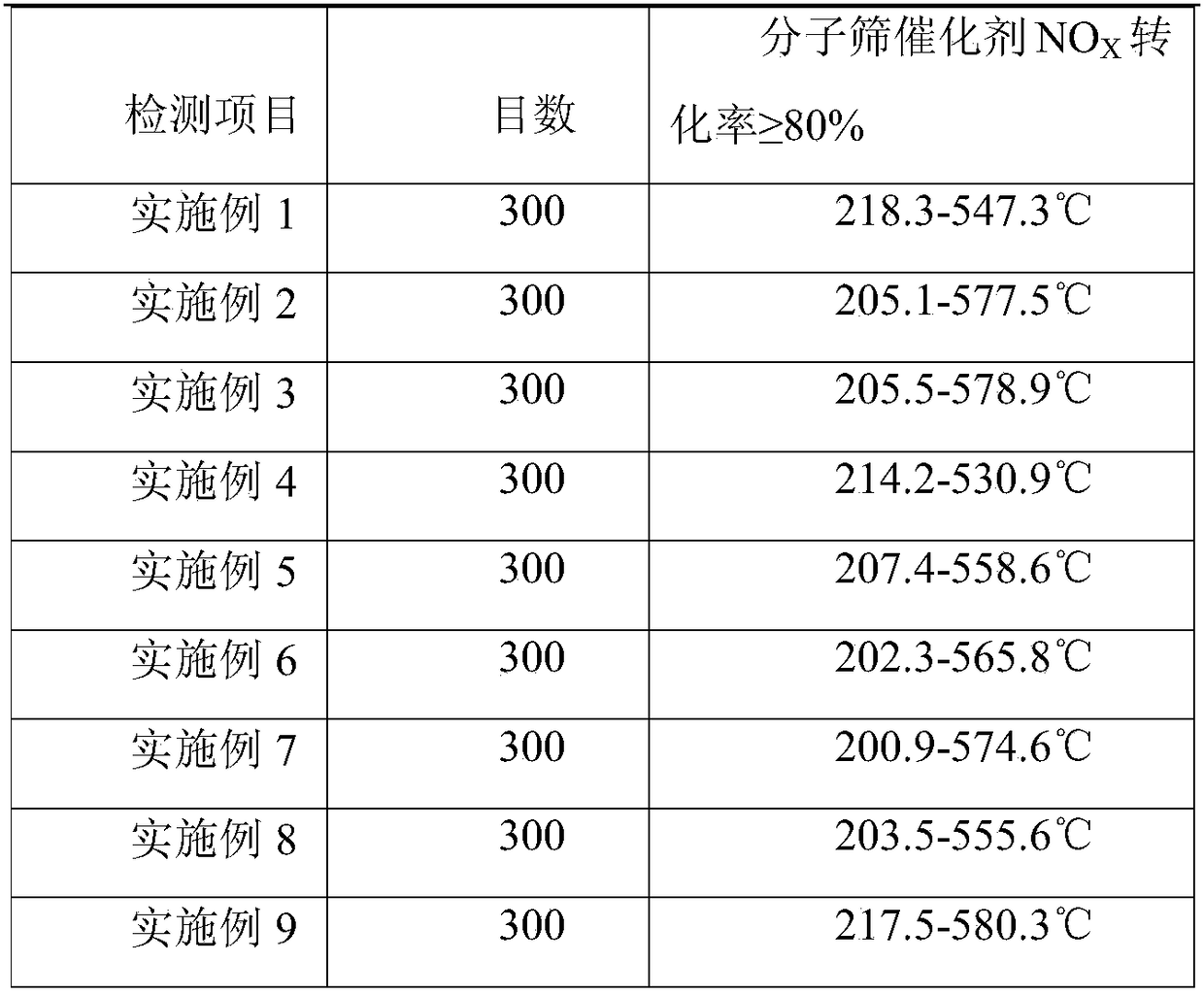

Examples

Embodiment 1

[0023] The extruded copper-iron mixed-base molecular sieve denitration catalyst for automobile exhaust gas treatment provided by the invention, the preparation method thereof comprises the following steps:

[0024] Weigh the following components by weight according to the following proportions: 100 parts of SSZ-13, 7 parts of talc, 2 parts of washed kaolin, 6 parts of calcined kaolin, 1 part of hydroxypropyl methylcellulose, polyethylene oxide (molecular weight is 5×10 5 ) 1 part, 4 parts of polyethylene glycol (PEG-400), 3 parts of lactic acid, 2 parts of stearic acid, 1 part of glass fiber (length-diameter ratio of 3~6:1), ferrous chloride (as per iron oxide) The amount of copper oxide is calculated as 1 part), copper nitrate (calculated as 1 part according to the amount of copper oxide).

[0025] (1) adding SSZ-13 molecular sieve, talc, water-washed kaolin, calcined kaolin into the mixer and mixing uniformly;

[0026] (2) then add hydroxypropyl methylcellulose, polyethyle...

Embodiment 2

[0035] The extruded copper-iron mixed-base molecular sieve denitration catalyst for automobile exhaust gas treatment provided by the invention, the preparation method thereof comprises the following steps:

[0036] Weigh out the following components in parts by weight according to the following proportions: 50 parts of ZSM-50 parts, 50 parts of SSZ-13, 15 parts of talc, 6 parts of washed kaolin, 13 parts of calcined kaolin, 5 parts of hydroxypropyl methylcellulose, Ethylene oxide (molecular weight 5×10 5 ) 3 parts, 6 parts of polyethylene glycol (PEG-400), 5 parts of lactic acid, 5 parts of stearic acid, 5 parts of glass fiber (length-diameter ratio of 3-6:1), ferrous chloride (as per iron oxide) The amount of copper oxide is calculated as 4 parts), copper acetate (calculated as 4 parts according to the amount of copper oxide).

[0037] (1) adding ZSM-50 and SSZ-13 molecular sieves, talc, water-washed kaolin, and calcined kaolin into the mixer to mix uniformly;

[0038] (2) ...

Embodiment 3

[0047] The extruded copper-iron mixed-base molecular sieve denitration catalyst for automobile exhaust gas treatment provided by the invention, the preparation method thereof comprises the following steps:

[0048] Weigh each component of the following parts by weight according to the following proportions: 100 parts of SSZ-13, 10 parts of talc, 5 parts of washed kaolin, 10 parts of calcined kaolin, 3 parts of hydroxypropyl methylcellulose, polyethylene oxide (molecular weight is 5×10 5 ) 2 parts, 5 parts of polyethylene glycol (PEG-400), 4 parts of lactic acid, 4 parts of stearic acid, 3 parts of glass fiber (length-diameter ratio of 3-6:1), ferrous chloride (by iron oxide) The amount of copper oxide is calculated as 2 parts), copper acetate (calculated as 3 parts according to the amount of copper oxide).

[0049] (1) adding SSZ-13 molecular sieve, talc, water-washed kaolin, calcined kaolin into the mixer and mixing uniformly;

[0050] (2) then add hydroxypropyl methylcellu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com