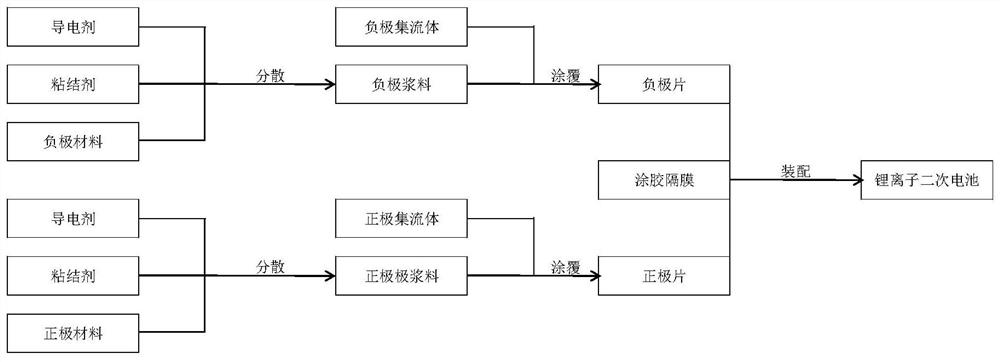

Aqueous binder and preparation method thereof, glued diaphragm and preparation method thereof, and lithium ion secondary battery

A technology for water-based binders and diaphragms, applied in the fields of water-based binders, preparation methods, preparations, glue-coated diaphragms, and lithium-ion secondary batteries. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

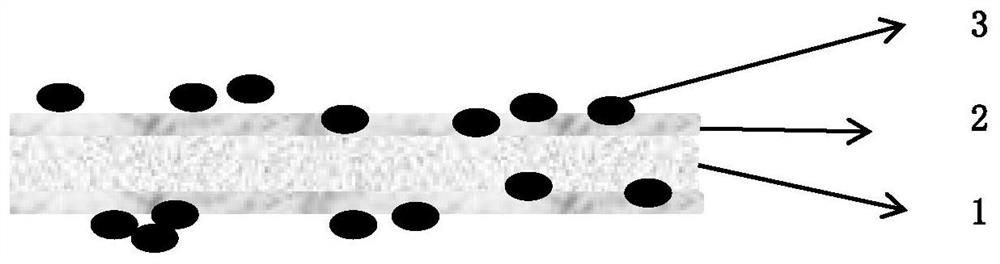

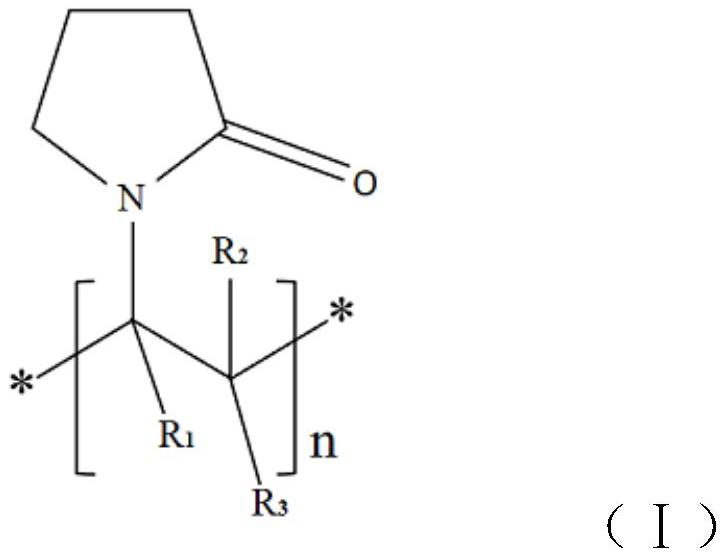

[0072]This embodiment provides a water-based adhesive. The raw materials of the water-based adhesive include point-bonded polymers, surface-bonded polymers, and polymer lithium salts. The point-bonding polymer is a granular polymer with a D50 particle size of 0.5um; the surface-bonding polymer is polyacrylic acid with a molecular mass of 200,000 and a glass transition temperature of 70°C; the polymer lithium The salt is lithium carboxymethyl cellulose;

[0073]The point-bonding polymer accounts for 75% of the total dry basis mass of the water-based binder raw materials, and the surface-bonding polymer accounts for 20% of the total dry basis mass of the water-based binder raw materials; the polymer lithium salt accounts for the total dry mass of the water-based binder raw materials. 5% of the base mass.

[0074]This embodiment also provides a method for preparing the water-based adhesive, including:

[0075](1) Prepare the first glue solution and the second glue solution of the surface-bondin...

Embodiment 2

[0083]This embodiment provides a water-based adhesive. The raw materials of the water-based adhesive include point-bonded polymers, surface-bonded polymers, and polymer lithium salts. The point-bonding polymer is a granular polymer with a D50 particle size of 1.5um; the surface-bonding polymer is polyacrylamide with a molecular mass of 1 million and a glass transition temperature of 100°C; the polymer The lithium salt is a lithium polyacrylate;

[0084]The point-bonding polymer accounts for 85% of the total dry-based mass of the water-based binder raw materials, and the surface-bonding polymer accounts for 13% of the total dry-based mass of the water-based binder raw materials. 2% of the base mass.

[0085]This embodiment also provides a method for preparing the water-based adhesive, including:

[0086](1) Prepare the first glue solution and the second glue solution of the surface-bonding polymer and polymer lithium salt respectively;

[0087](2) Stir the first glue solution, revolution 15r / min...

Embodiment 3

[0094]This embodiment provides a water-based adhesive. The raw materials of the water-based adhesive include point-bonded polymers, surface-bonded polymers, and polymer lithium salts. The point-bonding polymer is a granular polymer with a D50 particle size of 3um; the surface-bonding polymer is a polyamide with a molecular mass of 500,000 and a glass transition temperature of 120°C; the polymer lithium salt Lithium carboxyethyl cellulose;

[0095]Point-bonding polymer accounts for 92% of the total dry basis mass of water-based binder raw materials, and surface-bonding polymer accounts for 7% of the total dry-based mass of water-based binder raw materials; polymer lithium salt accounts for the total dry mass of the water-based binder 1% of the base mass.

[0096]This embodiment also provides a method for preparing the water-based adhesive, including:

[0097](1) Prepare the first glue solution and the second glue solution of the surface-bonding polymer and polymer lithium salt respectively;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com