Preparation method of battery diaphragm

A battery diaphragm and ceramic diaphragm technology, which is applied in the field of battery diaphragm preparation, can solve problems such as the inability to achieve industrialization of coating, plugging of spraying technology, complicated operation, etc., and achieve good battery capacity retention rate, good spraying stability, and simple method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Coating of ceramic coating solution

[0050] ①Add 25g of alumina ceramics to 100g of deionized water, add dispersant polyethylene glycol and 0.2g of octadecyltrimethylammonium chloride, and stir at 3000r / min for 4h at high speed; ②Add 0.6g of carboxymethyl fiber Add plain sodium and 0.5g polyvinylpyrrolidone one by one, stir until dissolved, the stirring speed is 1000r / min; ③Continue to add 1g tridecafluorooctyltriethoxysilane, stir and disperse evenly for 4h, the stirring speed is 1000r / min , to obtain a ceramic coating solution; ④ use a flat coater to coat the ceramic coating solution on the base film, and dry it for later use. Note that steps ③ and ④ are carried out under dark conditions; the thickness of the obtained ceramic separator is 16 μm.

[0051] 2. UV light

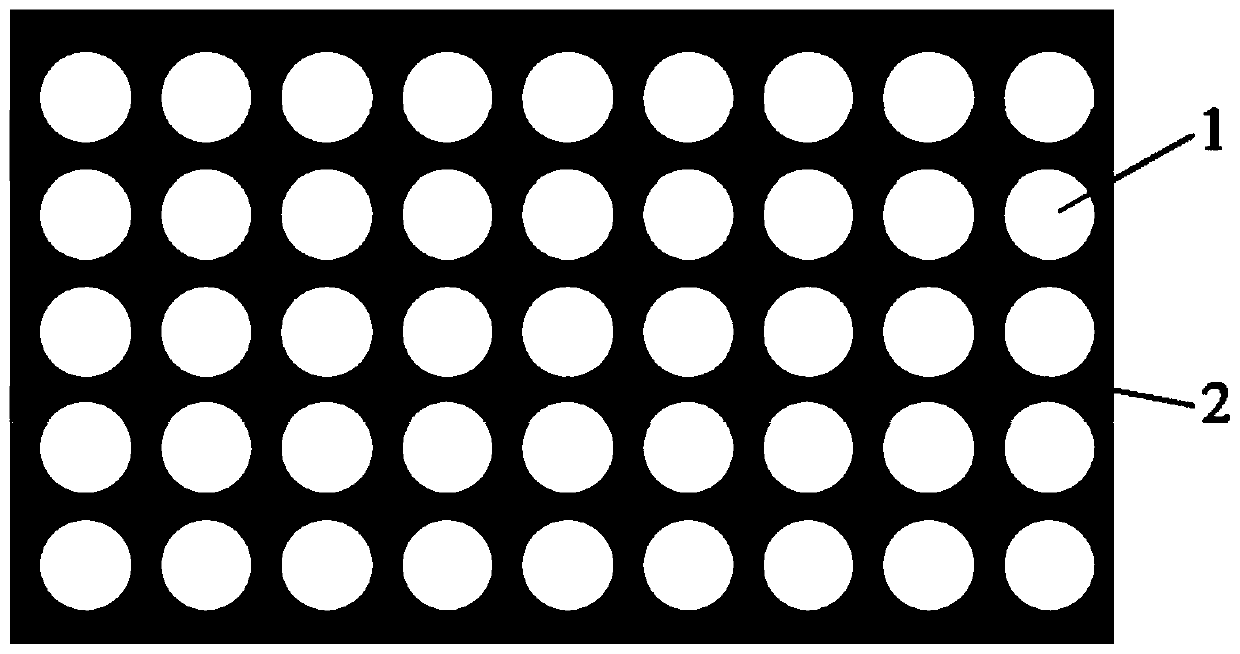

[0052] use figure 1 The mask plate shown (Cr PHOTO-MASK with photolithographic chromium version, circle diameter and spacing is 500μm) is subjected to UV light at an intensity of 250mj / cm 2 , the ...

Embodiment 2

[0056] 1. Coating of ceramic coating solution

[0057] ①Add 25g of alumina ceramics to 100g of deionized water, add dispersant polyethylene glycol and 0.2g of octadecyltrimethylammonium chloride, and stir at 3000r / min for 4h at high speed; ②Add 0.6g of carboxymethyl fiber Add plain sodium and 0.5g polyvinylpyrrolidone one by one, stir until dissolved, the stirring speed is 1000r / min; ③Continue to add 3g of octadecylfluorodecyltriethoxysilane, stir and disperse for 4h, the stirring speed is 1000r / min, get Ceramic coating solution; ④ Use a flat coater to coat the ceramic coating solution on the base film, dry it for later use, and pay attention to steps ③ and ④ under dark conditions; the thickness of the obtained ceramic separator is 16 μm.

[0058] 2. UV light

[0059] use figure 1 The mask plate shown (Cr PHOTO-MASK photolithographic chromium version, circle diameter and spacing is 500 μm) is subjected to ultraviolet light with an intensity of 350 mj / cm2 and a light time of ...

Embodiment 3

[0063] 1. Coating of ceramic coating solution

[0064] ①Add 25g of alumina ceramics to 100g of deionized water, add dispersant polyethylene glycol and 0.2g of octadecyltrimethylammonium chloride, and stir at 3000r / min for 4h at high speed; ②Add 0.6g of carboxymethyl fiber Add plain sodium and 0.5g polyvinylpyrrolidone one by one, stir until dissolved, the stirring speed is 1000r / min; ③ continue to add 5g heptadecafluorodecyltriethoxysilane, stir and disperse evenly for 4h, the stirring speed is 1000r / min, get Ceramic coating solution; ④ Use a flat coater to coat the ceramic coating solution on the base film, dry it for later use, and pay attention to steps ③ and ④ under dark conditions; the thickness of the obtained ceramic separator is 16 μm.

[0065] 2. UV light

[0066] use figure 1 The mask plate shown (Cr PHOTO-MASK photolithographic chromium version, circle diameter and spacing is 500 μm) is subjected to ultraviolet light with an intensity of 500 mj / cm2 and a light tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com