Shell lateral punching mold

A shell side, punching technology, applied in the direction of piercing tools, manufacturing tools, metal processing equipment, etc., can solve the problems of large burrs in parts holes, increased mold maintenance costs, damage to dies or punches, etc., to reduce waste products Produce, prolong service life and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

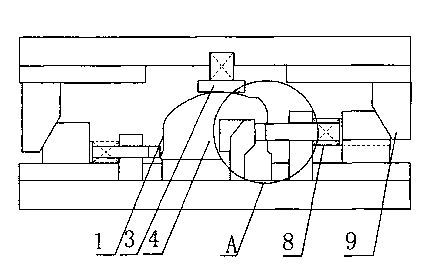

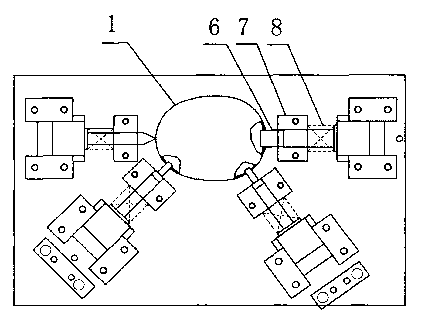

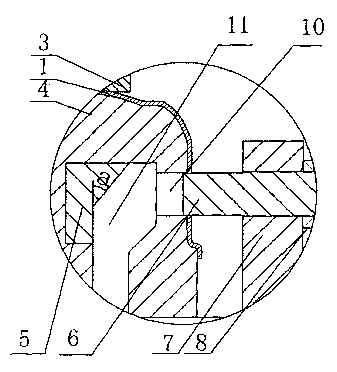

[0011] The structure of side punching die of the present invention is as Figure 1-Figure 3 As shown, the shell side punching die includes an upper die and a lower die, wherein the upper die mainly includes a clamping plate 3, an inclined die 9, and the lower die mainly includes a die 4, a slope-guided forced return structure 5, and a punch 6 , punch guide block 7, punch return spring 8; the die 4 is facing the punch 6 with a die hole 10, the outlet of the die hole 10 is connected to the vertically downward discharge hole 11, and the discharge hole 11 The position facing the punch is inlaid with a slope-guided forced return structure 5 with a slope, the angle between the slope and the vertical direction is a, and the angle a adopts the shape of the die 4 of 30°~60° and the shell 1 When punching, the casing 1 is set on the die 4, and the pressure plate 3 is pressed on the casing 1; the front end of the punch 6 is provided with a punch guide block 7 for the guidance of the punch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com