Membrane as well as preparation method thereof and lithium battery

A diaphragm and base film technology, which is applied in the field of lithium battery, diaphragm and its preparation, can solve the problems of liquid retention and plugging of blind holes, achieve good low-temperature capacity retention rate, uniform migration distribution, and improve low-temperature capacity retention rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

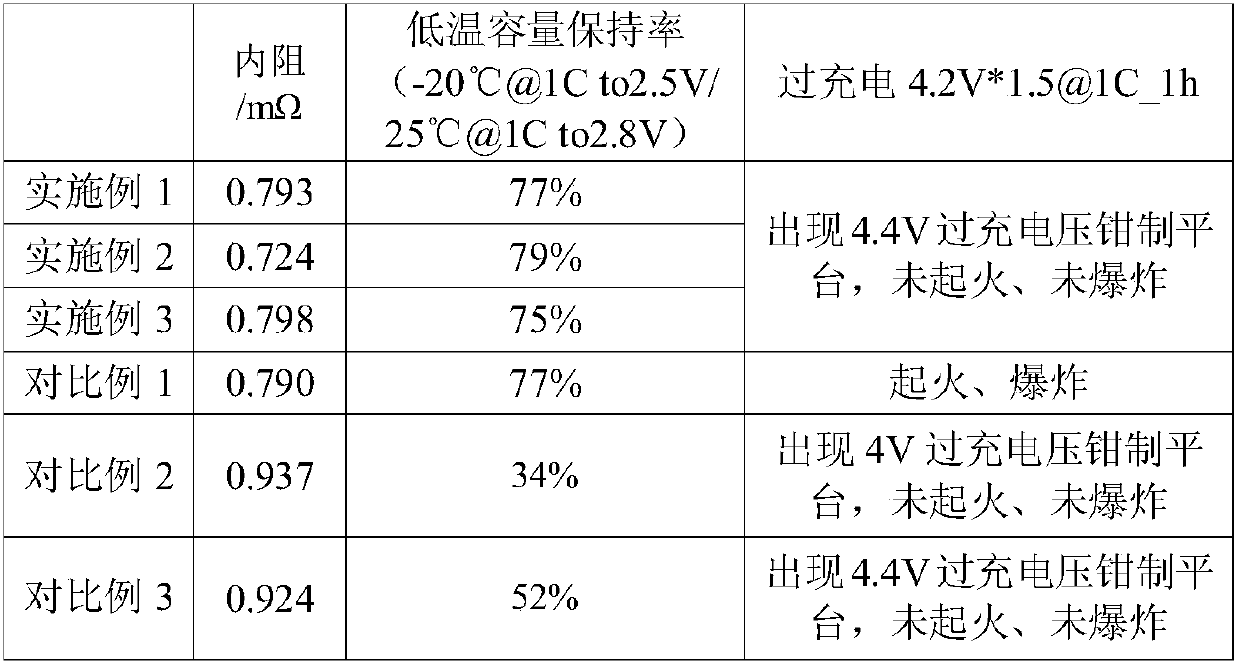

Examples

Embodiment approach

[0041] According to one embodiment of the separator of the present invention, the base film includes a polyolefin resin.

[0042] Generally speaking, the electrolyte solution of lithium battery adopts the organic solvent system, and the polyolefin resin selected in the present invention has the effect of resisting the organic solvent; in addition, the polyolefin resin also has excellent mechanical properties. In order to improve the mechanical properties of the separator, ultra-high molecular weight polyethylene is further preferred.

[0043] According to an embodiment of the diaphragm of the present invention, the thickness of the base film layer is 5-15 μm, the porosity of the base film layer is 30-60%, and the diameter of the pores in the base film layer is 40-80 nm.

[0044] In the diaphragm of the present invention, the thickness of the base film layer is preferably 5-15 μm, which not only ensures the mechanical strength of the diaphragm, but also does not affect other pr...

Embodiment 1

[0077] The preparation method of the diaphragm provided in this embodiment comprises the following steps:

[0078] Step S1: providing a base film layer containing a first electroactive polymer; specifically:

[0079] Uniformly mix ultra-high molecular weight polyethylene, polyphenylene and paraffin oil at a mass ratio of 3:3:1, heat and extrude at 180°C, cool and shape at 30°C, and simultaneously stretch longitudinally and horizontally to form a base film layer; The obtained basement film layer is subjected to the following post-treatment: the basement film layer is immersed in ethanol, and the paraffin oil in the basement film layer is extracted and washed away; and then heat-treated at 120° C. for 4 minutes. It has a thickness of 10 μm, a porosity of 45%, and a pore diameter of 60 nm.

[0080] Step S2: providing nanofiber slurry containing nanofibers and a second electroactive polymer, wherein the second electroactive polymer coats the nanofibers; specifically:

[0081] Ar...

Embodiment 2

[0085] The preparation method of the diaphragm provided in this embodiment comprises the following steps:

[0086] Step S1: providing a base film layer containing a first electroactive polymer; specifically:

[0087] Uniformly mix ultra-high molecular weight polyethylene, polyphenylene and paraffin oil at a mass ratio of 6:3:2, heat and extrude at 170°C, cool to form at 25°C, and simultaneously stretch longitudinally and horizontally to form a base film preparation layer; Immerse the obtained basement membrane preparation layer in ethanol, extract and wash off the paraffin oil in the basement membrane preparation layer; then heat-treat at 100°C for 4 minutes to obtain a basement membrane layer with a thickness of 5 μm, a porosity of 30%, and a pore size of 80 nm .

[0088] Step S2: providing nanofiber slurry containing nanofibers and a second electroactive polymer, wherein the second electroactive polymer coats the nanofibers; specifically:

[0089] Soak cellulose nanofibers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com