Secondary support grouting anchor rod with self-adaptive function

A technology for secondary support and grouting bolts, which is applied in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problems of not being able to bond the surrounding rock mass, not being able to anchor in the center, leaking air or even leaking mortar. , to achieve the effect of reducing the probability of mine disasters, good air tightness and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

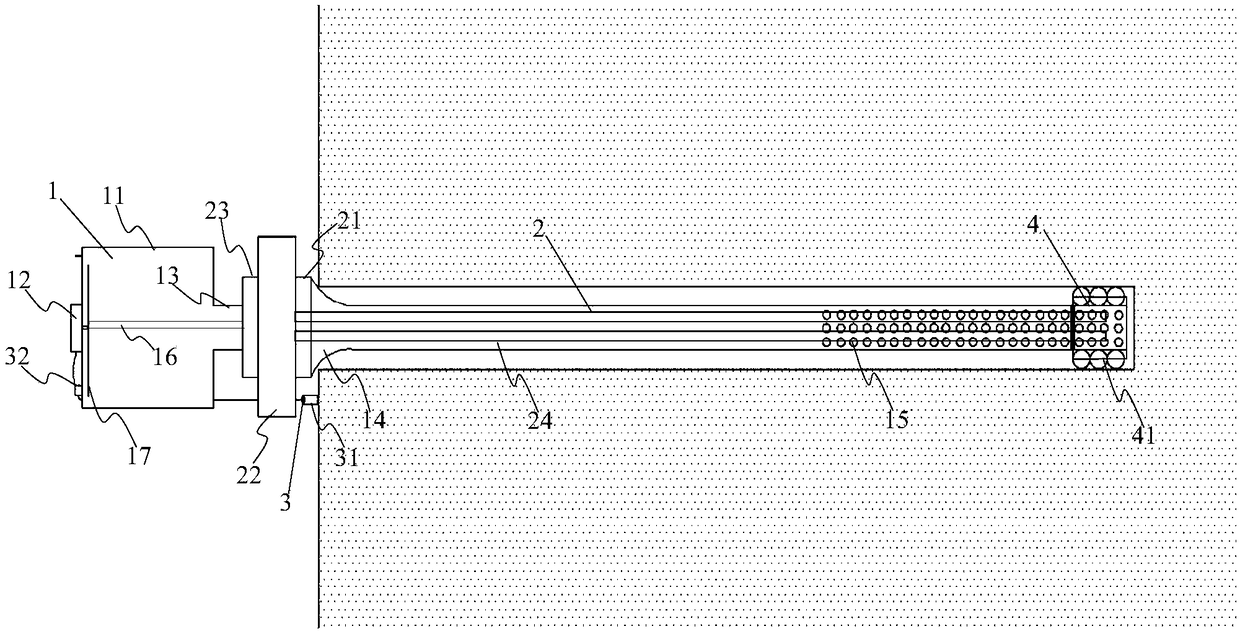

[0021] combine figure 1 with figure 2 As shown, an adaptive secondary support grouting bolt provided by the present invention and a method for bolt construction are implemented in the following manner.

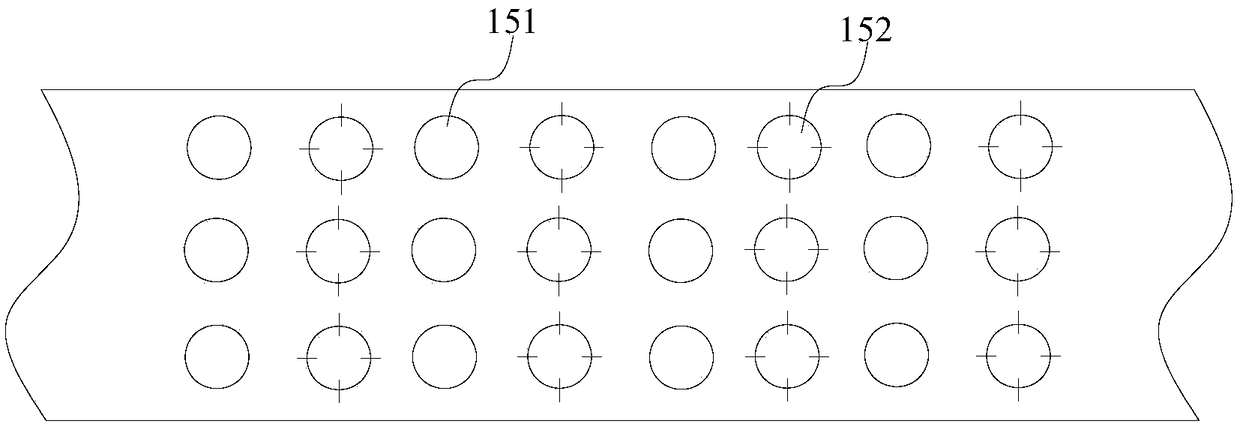

[0022] An adaptive secondary support grouting anchor specifically includes a grouting mechanism 1, an anchoring mechanism 2, a monitoring mechanism 3 and a positioning mechanism 4, such as figure 1 shown. The grouting bolt can be automatically grouted again according to changes in the mine pressure or the movement of the roadway surrounding rock, so that the hollow bolt body 24 can automatically perform grouting reinforcement when the roadway surrounding rock changes and the mine pressure change reach a certain limit, so that To achieve the purpose of secondary support, it can realize long-term stable and effective support for surrounding rocks, reduce the probability of mine disasters, and thus achieve higher safety performance and technical and economic benefits.

[0023...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com