Impregnation formula for punched Nomex paper honeycomb and use method thereof

A technology of paper honeycomb and formula, which is applied in the field of materials, can solve the problems of honeycomb cell wall hole plugging, etc., and achieve the effect of improving efficiency and improving impregnation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) At room temperature, weigh 1g of BYT-306N silicone surface additive and add it to 100g of honeycomb dipping glue phenolic alcohol varnish, stir and dissolve for later use;

[0020] (2) After the Nomex paper honeycomb core board is cut into strips, holes are drilled in each blank space between the core strip glues perpendicular to the lamination direction. The diameter of the holes can be 0.8mm. (1) Put in the prepared glue solution for 1 min, then extract the honeycomb and turn it over to dry, let it dry for 4 hours, and then put it in an oven for pre-baking before use.

Embodiment 2

[0022] (1) At room temperature, weigh 0.05g of BYT-141N silicone defoamer and add it to 100g of honeycomb dipping glue phenolic alcohol varnish, stir and dissolve for later use;

[0023] (2) After the Nomex paper honeycomb core board is cut into strips, a hole is drilled in each blank space between the core strip glue perpendicular to the lamination direction. The diameter of the hole can be 1.5mm. (1) Put the prepared glue in the solution for 5 minutes, then extract the honeycomb and turn it over to dry, let it dry for 8 hours, and then put it in an oven for pre-baking before use.

Embodiment 3

[0025] (1) At room temperature, weigh 0.56g of BYT-066N silicone defoamer and add it to 100g of honeycomb dipping glue phenolic alcohol varnish, stir and dissolve for later use;

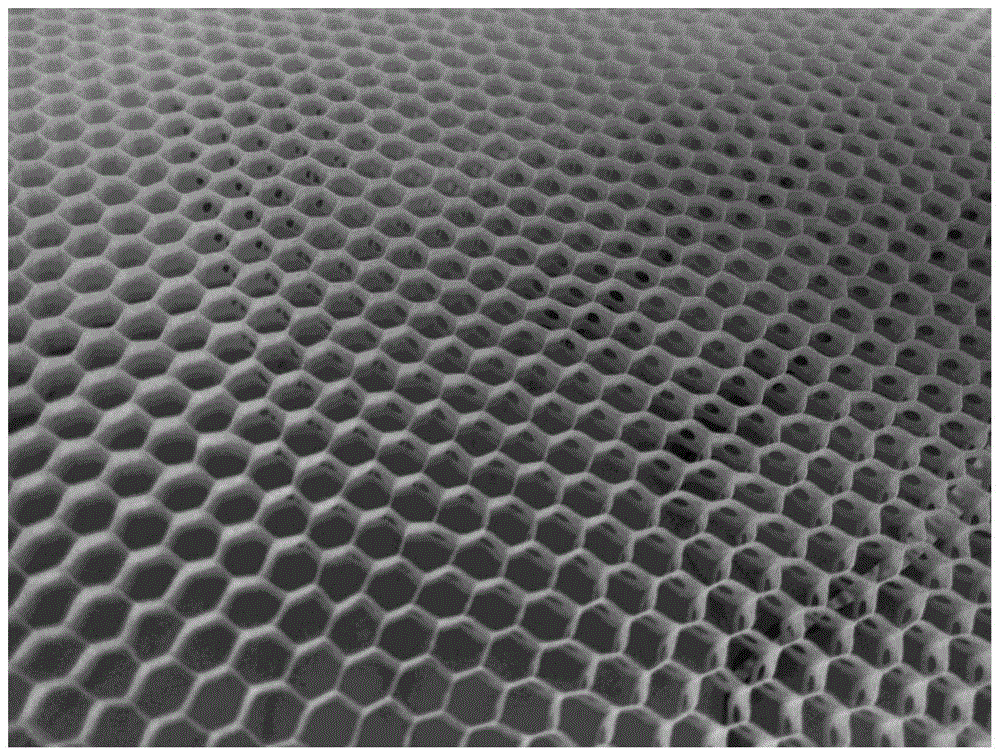

[0026] (2) After the Nomex paper honeycomb core board is cut into strips, holes are drilled in each blank space between the core strip glues perpendicular to the lamination direction. The diameter of the holes can be 1.0mm. (1) Put the prepared glue in the solution for 4 minutes, then extract the honeycomb and turn it over to dry for 6 hours, then put it in an oven for pre-baking before use. figure 1 It is a photo of the Nomex paper honeycomb core board after being impregnated with glue. It can be seen from the photo that there are small holes in the honeycomb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com