UV-resistant knitted fabric with quick drying and moisture absorption functions

A knitted fabric, quick-drying technology, applied in knitting, weft knitting, warp knitting, etc., can solve the problems of affecting the use effect of fabrics, easy peeling of coating, poor quick-drying and moisture absorption performance, etc., and achieves favorable adhesion The effect of preservation, convenient and fast evaporation, high quality anti-UV effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

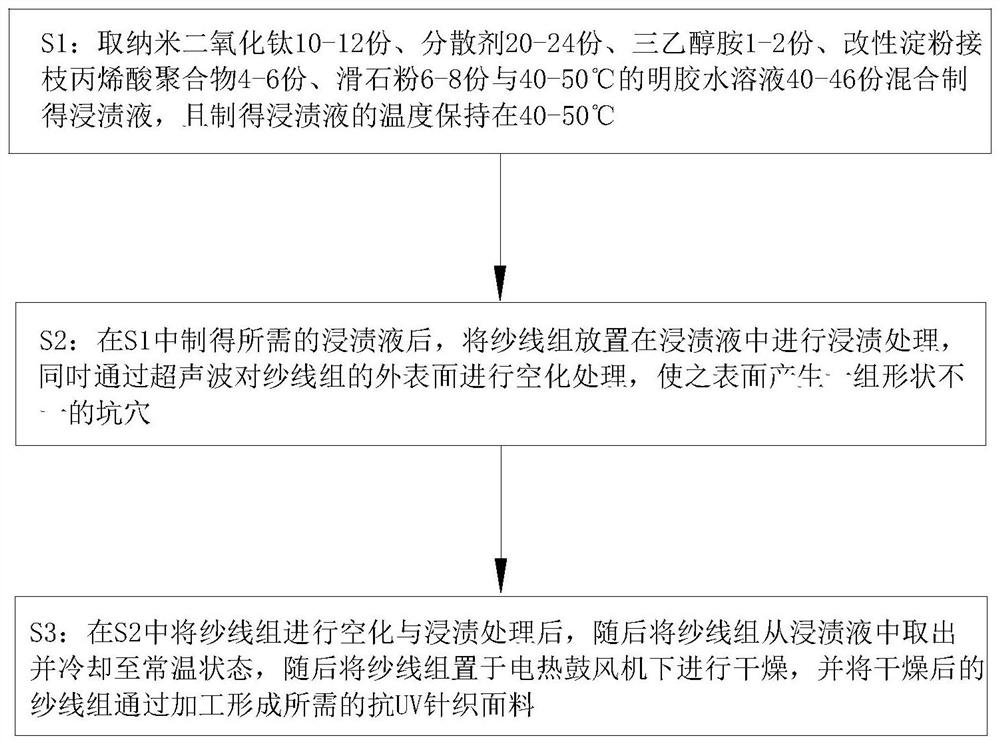

Method used

Image

Examples

Embodiment approach

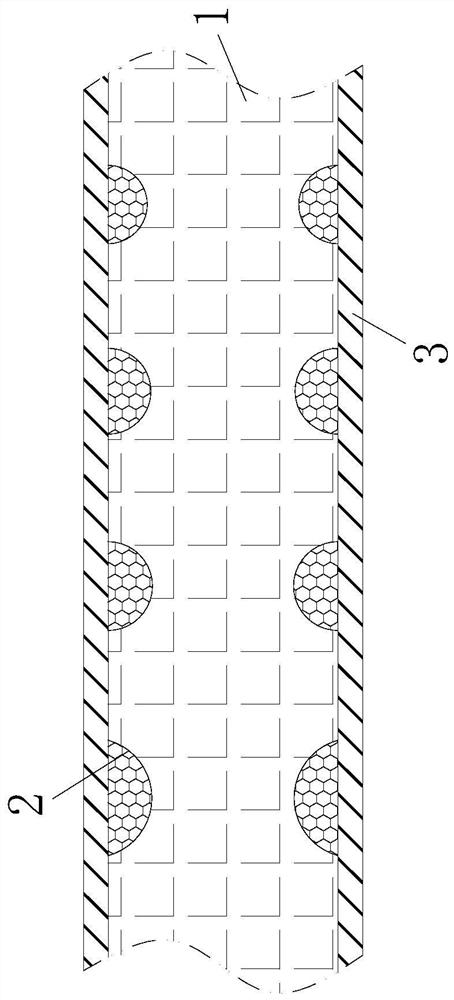

[0038] As an embodiment of the present invention, before the yarn group 1 is taken out from the dipping solution, the temperature of the dipping solution is lowered in advance; during operation, when the yarn group 1 is taken out immediately after the dipping process is completed, the yarn The liquid impregnation solution filled in the pit 2 on the outer surface of group 1 is easy to flow out from the interior of the pit 2, thereby affecting the forming quality of the gel in the pit 2. The cooling treatment makes the liquid impregnation liquid filled in the pit 2 preform a semi-solid preliminary gel under the action of the gel, so that the preliminary gel can be well preserved in the pit 2 without flowing out, effectively improving The impregnation quality of yarn group 1 is determined.

[0039] As an embodiment of the present invention, after the yarn group 1 is taken out from the immersion liquid, a layer of textile coating glue 3 is applied to the outer surface of the coole...

Embodiment 1

[0045] Take 10 kg of nano-titanium dioxide, 20 kg of dispersant, 1 kg of triethanolamine, 4 kg of modified starch grafted acrylic acid polymer, 6 kg of talcum powder and 40 kg of gelatin aqueous solution at 45°C to prepare the impregnating liquid, and obtain the impregnating liquid The temperature of the yarn group was kept at 45°C, and then the yarn group was placed in the dipping solution for immersion treatment, and the outer surface of the yarn group was subjected to cavitation treatment by ultrasonic waves, and then the yarn group was taken out of the dipping solution and cooled to room temperature state, and place the yarn group under an electric blower to dry, then process the dried yarn group to form the desired anti-UV knitted fabric, and record the anti-ultraviolet effect of the fiber fabric.

Embodiment 2

[0047] Take 12 kg of nano-titanium dioxide, 20 kg of dispersant, 1 kg of triethanolamine, 4 kg of modified starch grafted acrylic acid polymer, 6 kg of talcum powder and 40 kg of gelatin aqueous solution at 45°C to prepare the impregnation solution, and obtain the impregnation solution The temperature of the yarn group was kept at 45°C, and then the yarn group was placed in the dipping solution for immersion treatment, and the outer surface of the yarn group was subjected to cavitation treatment by ultrasonic waves, and then the yarn group was taken out of the dipping solution and cooled to room temperature state, and place the yarn group under an electric blower to dry, then process the dried yarn group to form the desired anti-UV knitted fabric, and record the anti-ultraviolet effect of the fiber fabric.

[0048] Wherein, the statistical results of Embodiment 1-Example 2 are shown in Table 1.

[0049] form one

[0050]

[0051] Table 1 shows that adding nano-titanium dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com