Energy-saving and environment-friendly high-strength epoxy resin concrete material

An epoxy resin, energy-saving and environment-friendly technology, applied in the field of construction concrete, can solve the problems of toughness and resistance to be improved, environmental protection, high production cost, etc., and achieve the effects of easy promotion and use, high production efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

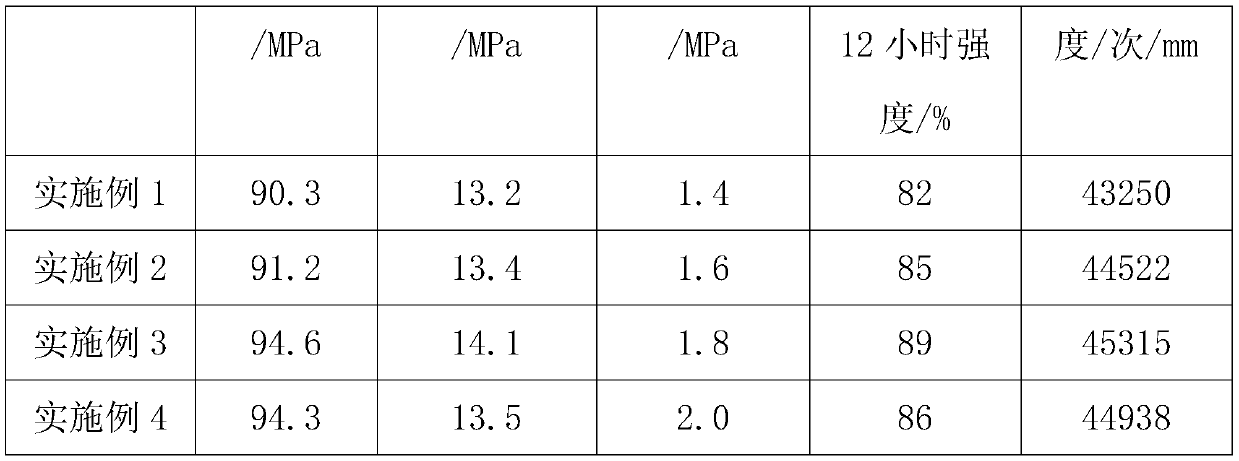

Embodiment 1

[0025] The invention provides an energy-saving and environment-friendly high-strength epoxy resin concrete material, wherein the main materials used include by weight: 70 parts of epoxy resin, 30 parts of base material, 8 parts of river sand and 10 parts of asbestos fiber. The auxiliary materials include by weight: 10 parts of corn starch, 8 parts of reactive diluent, 2 parts of defoamer, 15 parts of curing agent, and 6 parts of toughening agent.

[0026] Preferably, the base material is made by mixing gangue and limestone, and the mass ratio of gangue to limestone is set to 10:6.

[0027] Preferably, the epoxy resin is set to be glycidyl ester epoxy resin, and the curing agent is set to be diaminodiphenyl sulfone.

[0028] Preferably, the reactive diluent is set to propylene oxide phenyl ether, the toughening agent is set to aralkyl ether, and the defoamer is set to polyether modified silicone.

[0029] An energy-saving and environment-friendly high-strength epoxy resin conc...

Embodiment 2

[0037] The invention provides an energy-saving and environment-friendly high-strength epoxy resin concrete material, wherein the main materials used include by weight: 80 parts of epoxy resin, 35 parts of base material, 10 parts of river sand and 12 parts of asbestos fiber. The auxiliary materials include by weight: 11 parts of cornstarch, 9 parts of reactive diluent, 3 parts of defoamer, 18 parts of curing agent, and 7 parts of toughening agent.

[0038] Preferably, the base material is made by mixing gangue and limestone, and the mass ratio of gangue to limestone is set to 12:5.

[0039] Preferably, the epoxy resin is set to be glycidyl ester epoxy resin, and the curing agent is set to be diaminodiphenyl sulfone.

[0040]Preferably, the reactive diluent is set to propylene oxide phenyl ether, the toughening agent is set to aralkyl ether, and the defoamer is set to polyether modified silicone.

[0041] An energy-saving and environment-friendly high-strength epoxy resin concr...

Embodiment 3

[0049] The invention provides an energy-saving and environment-friendly high-strength epoxy resin concrete material, wherein the main materials used include by weight: 90 parts of epoxy resin, 35 parts of base material, 10 parts of river sand and 14 parts of asbestos fiber. The auxiliary materials include by weight: 11 parts of cornstarch, 9 parts of reactive diluent, 3 parts of defoamer, 22 parts of curing agent, and 7 parts of toughening agent.

[0050] Preferably, the base material is made by mixing gangue and limestone, and the mass ratio of gangue to limestone is set to 14:5.

[0051] Preferably, the epoxy resin is set to glycidyl ester epoxy resin, and the curing agent is set to m-aminomethylamine.

[0052] Preferably, the reactive diluent is polyglycidol, the toughening agent is aralkyl ether, and the defoamer is polyether-modified silicone.

[0053] An energy-saving and environment-friendly high-strength epoxy resin concrete material also includes a method for prepari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com