A method and device for continuous impregnation of materials

An impregnation device and material technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of impregnation impregnation, material bubbles, uneven impregnation of printing and dyeing, etc., to improve the impregnation speed, save energy, and shorten the drying time. The effect of dry time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

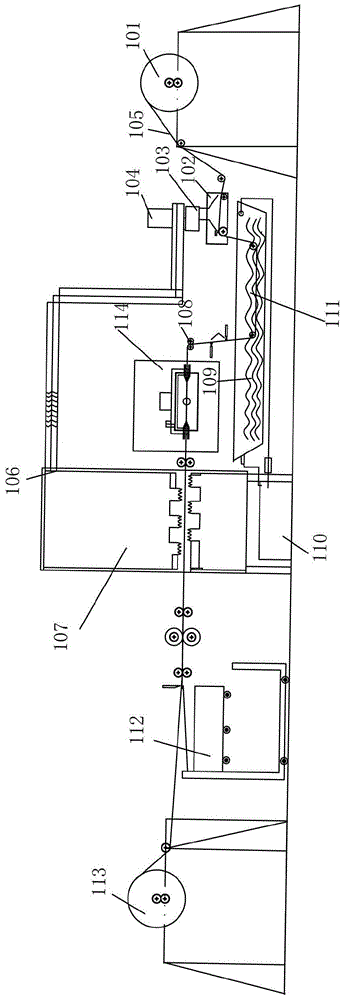

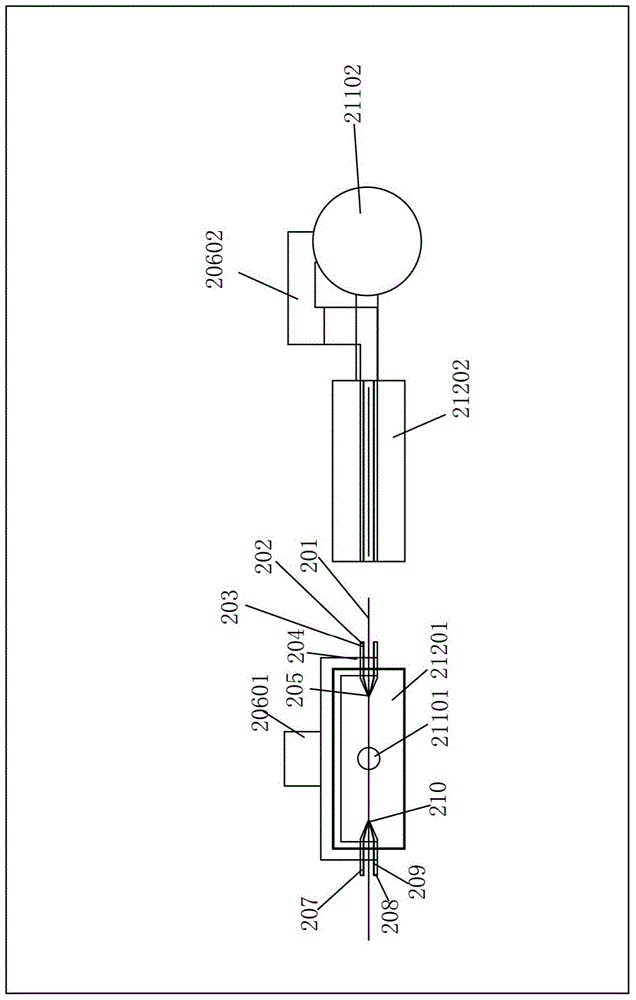

[0062] like figure 1 and figure 2 As shown in the figure, a method and device for continuous impregnation of materials provided by the present invention includes the following steps: the material passes through the conveying device 101, the impregnated material is placed in the unwinding station, and the material is introduced into the preheating and humidifying device by the roller. 102. Heat, humidify and spray the material, so that the material can be immersed more fully, and then the material enters the immersion tank 111 of the immersion device for immersion. It is dye, varnish, penetrating ink, wax liquid, and the impregnating liquid can also be glue, such as melamine glue, urine glue, transparent resin glue, dye such as ink, or resin, such as wear-resistant resin, etc. After impregnation Through the rollers of the conveying device 101, it is transferred to the positive pressure or negative pressure device, see figure 2, This embodiment adopts an airflow air knife pr...

Embodiment 2

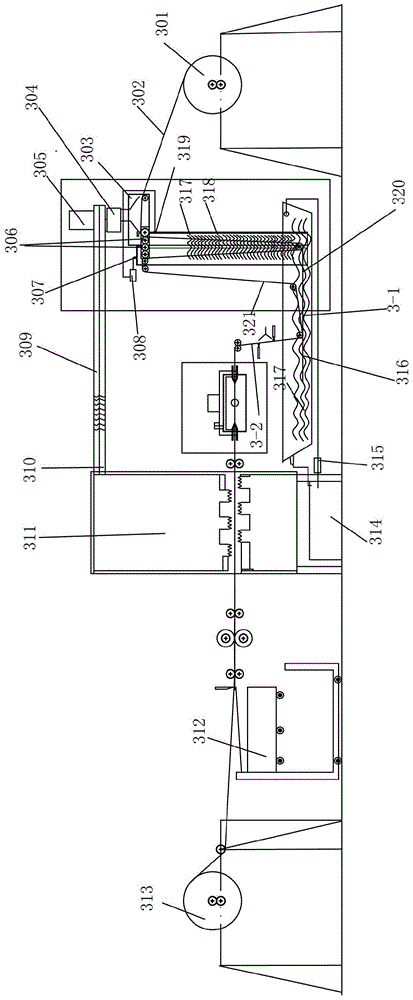

[0065] like image 3 , Figure 4 and Figure 5 , as shown, a method and device for continuous negative pressure impregnation provided by the present invention, the material is completed through the following steps and in the device, the main difference is that the negative pressure treatment step is completed before the impregnation step, and the negative pressure used in this embodiment is The processing device is a device for pressing rollers to seal negative pressure, and the specific steps are as follows: the material 302 passes through the conveying device, and the material is placed in the unwinding station 301, and the material is introduced into the preheating and humidifying device 303 by the roller to heat and humidify the material, In this way, the material can be impregnated more fully, and then the material enters the liquid storage chamber 318. The liquid storage chamber is vertical, and the liquid storage tank 316 is horizontal. The immersion liquid 317 is pla...

Embodiment 3

[0067] This embodiment is the combination of Embodiment 1 and Embodiment 2, and the details are as follows:

[0068] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention provides a continuous impregnation method and device, the material is completed through the following steps and in the following device, the main difference is that the negative pressure treatment step is completed before the impregnation step, and the negative pressure treatment used in this embodiment is The device is a device that seals negative pressure with a pressure roller, such as Figure 5 , the specific steps are as follows: the material passes through the conveying device, the material is placed in the unwinding station, the material is introduced into the preheating and humidifying device 501 by the roller, and the material is heated and humidified, so that the material can be impregnated more fully, and then The material enters the liquid storage cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com