Patents

Literature

31results about How to "Increased dipping speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

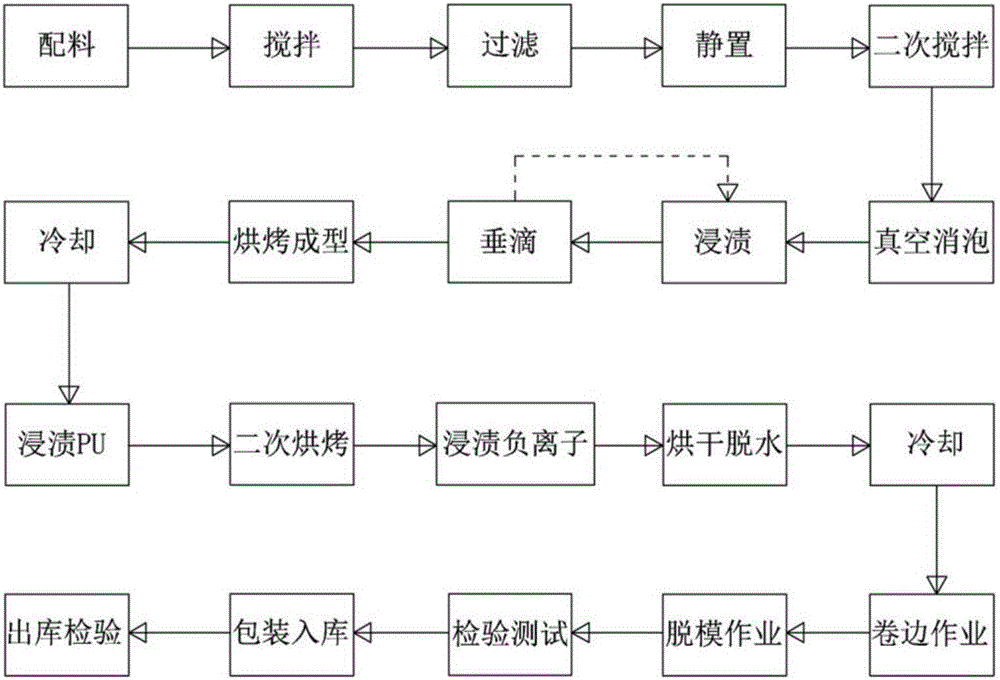

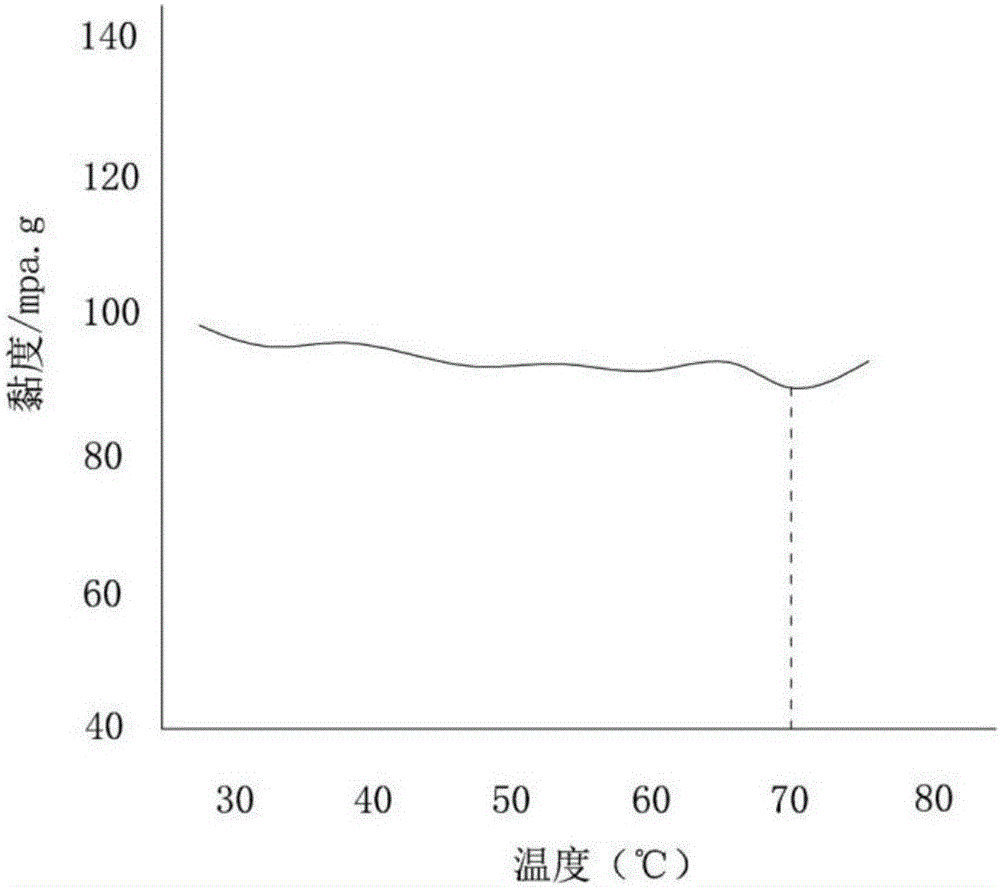

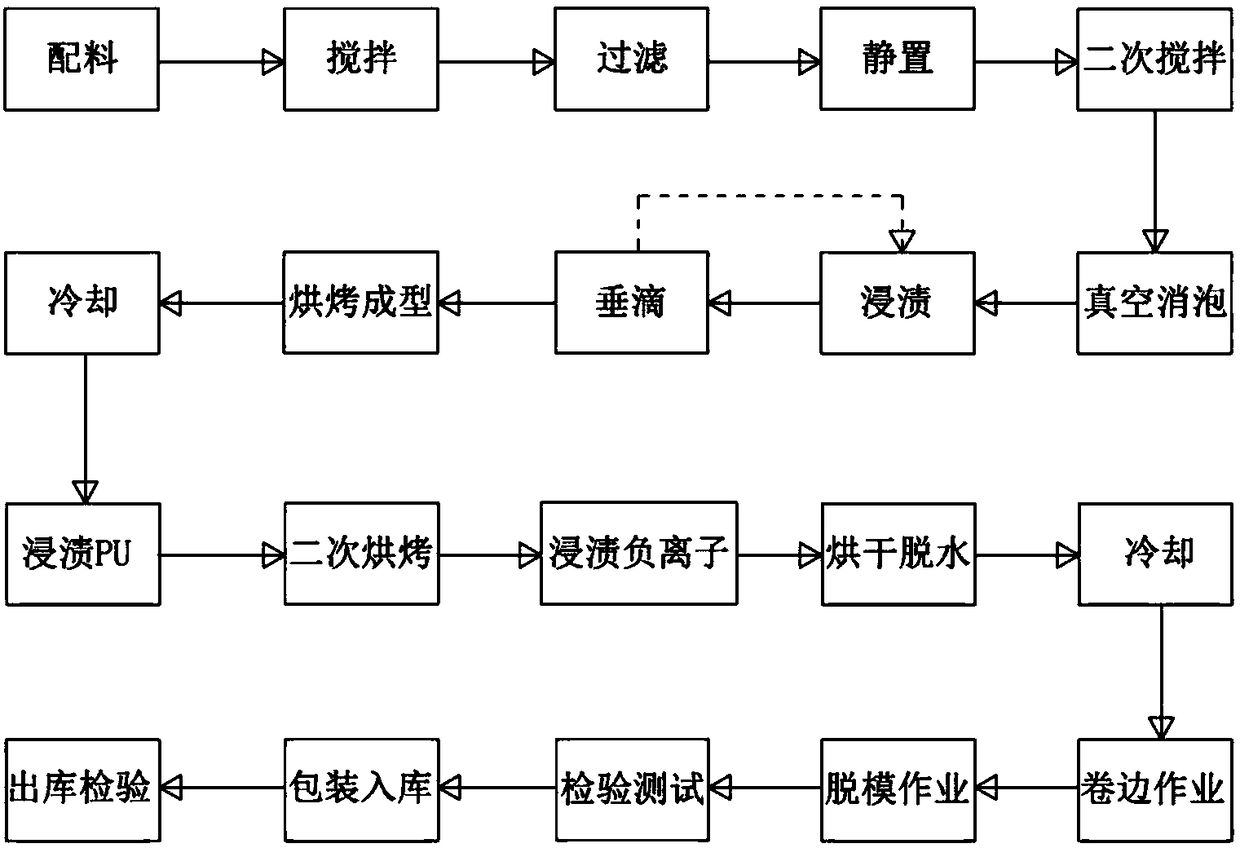

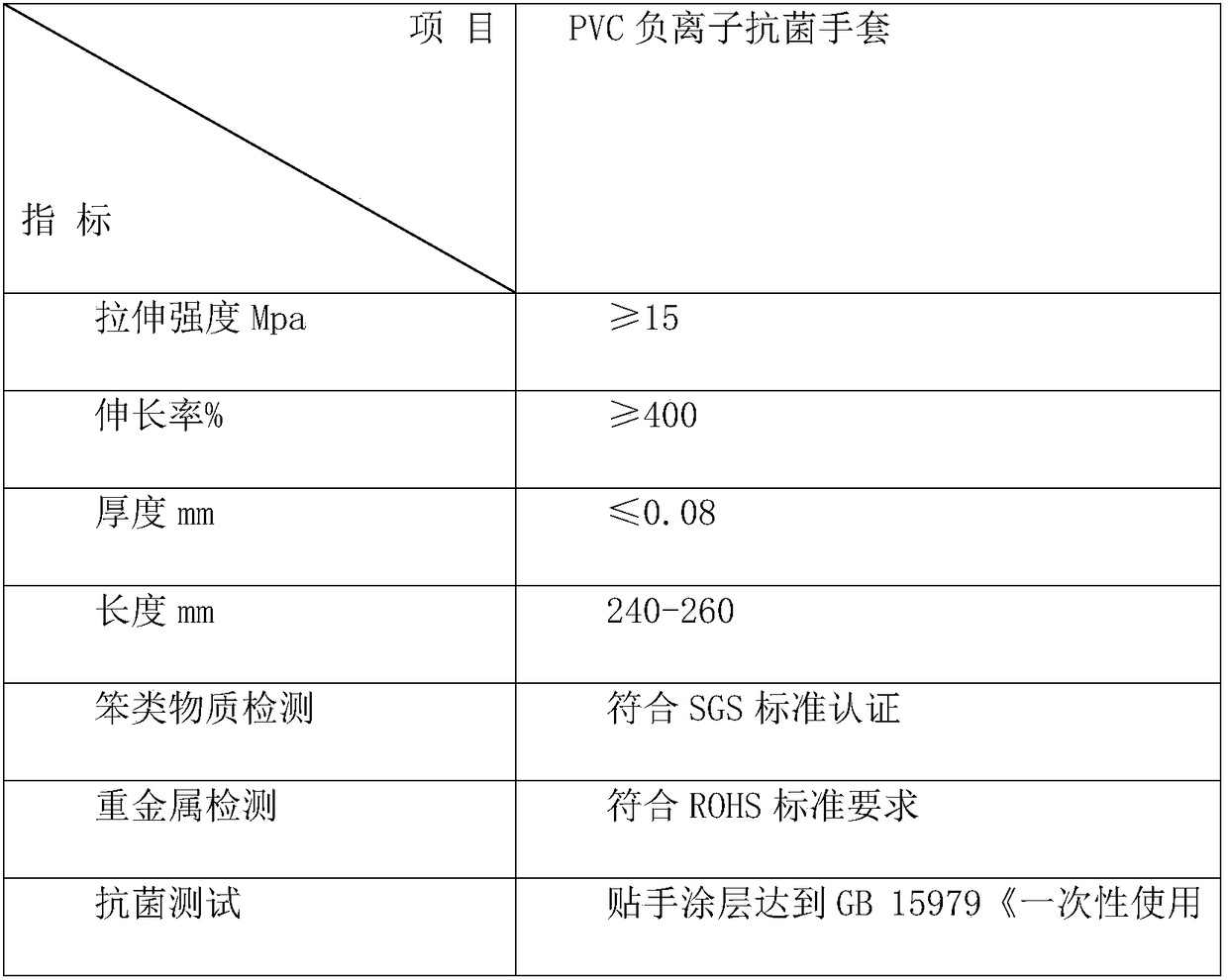

PVC (polyvinyl chloride) negative ion antibacterial glove and manufacturing process thereof

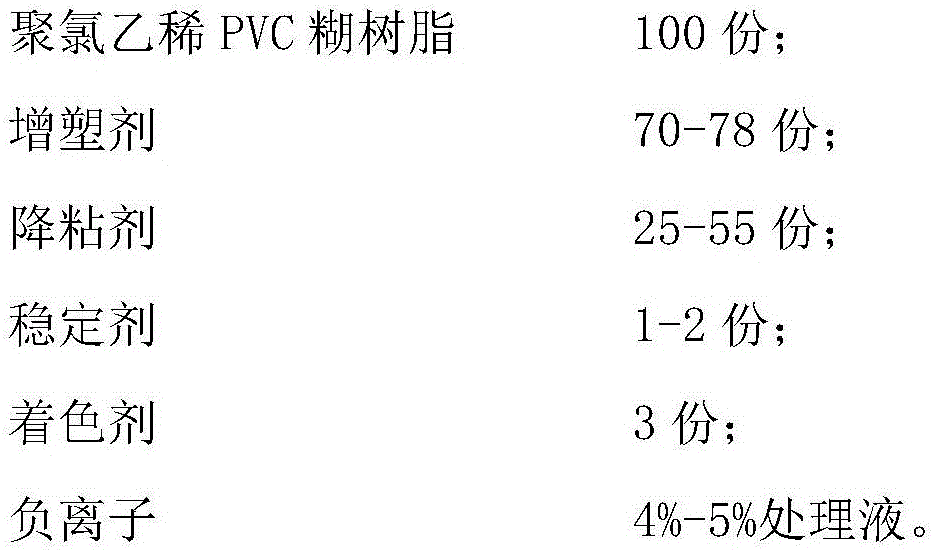

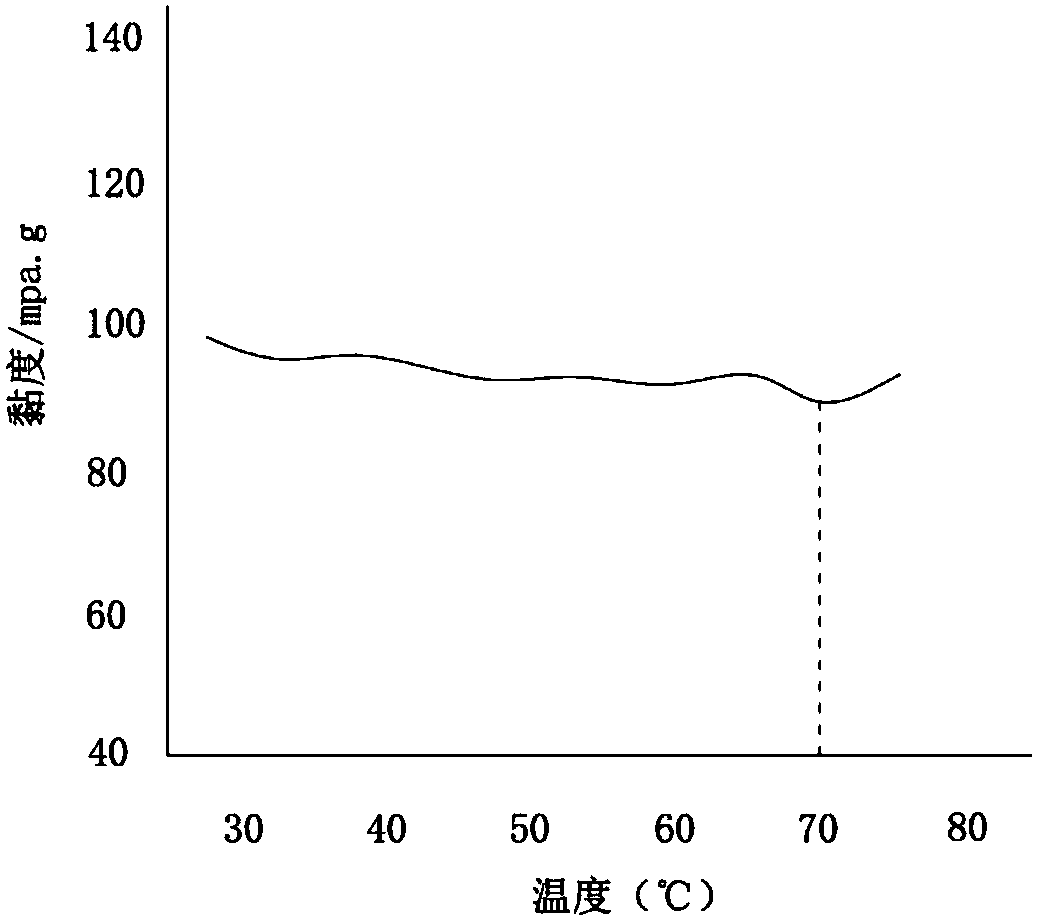

The invention discloses a PVC (polyvinyl chloride) negative ion antibacterial glove, relates to the field of glove manufacturing and aims at solving the problem that existing PVC gloves don't have capability of resisting and killing bacteria. The PVC negative ion antibacterial glove is composed of 100 parts of PVC paste resin, 70-78 parts of plasticizer, 25-55 parts of viscosity reducer, 1-2 parts of stabilizer, 3 parts of colorant and treatment liquid with 4-5% of negative ions. By adding the treatment liquid with 4-5% of negative ions, the PVC glove is endowed with capability of resisting and killing bacteria. The invention further discloses a manufacturing process of the PVC negative ion antibacterial glove.

Owner:淄博鸿烨上勤医疗科技有限公司

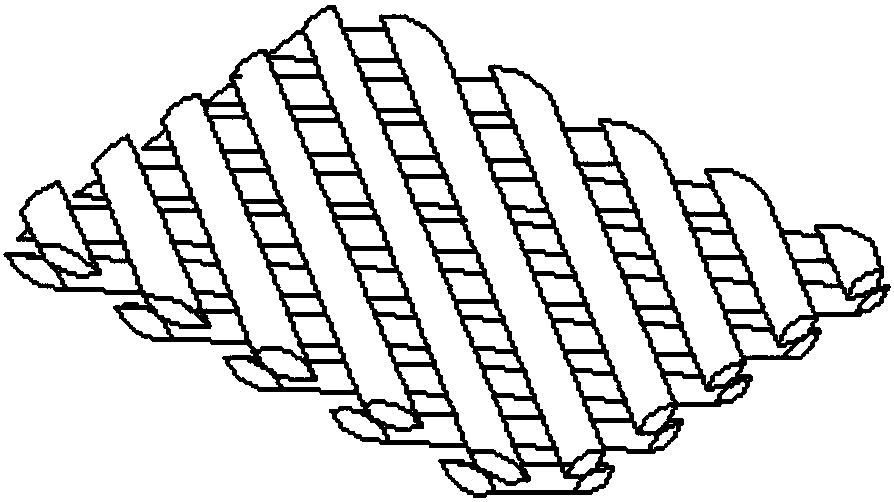

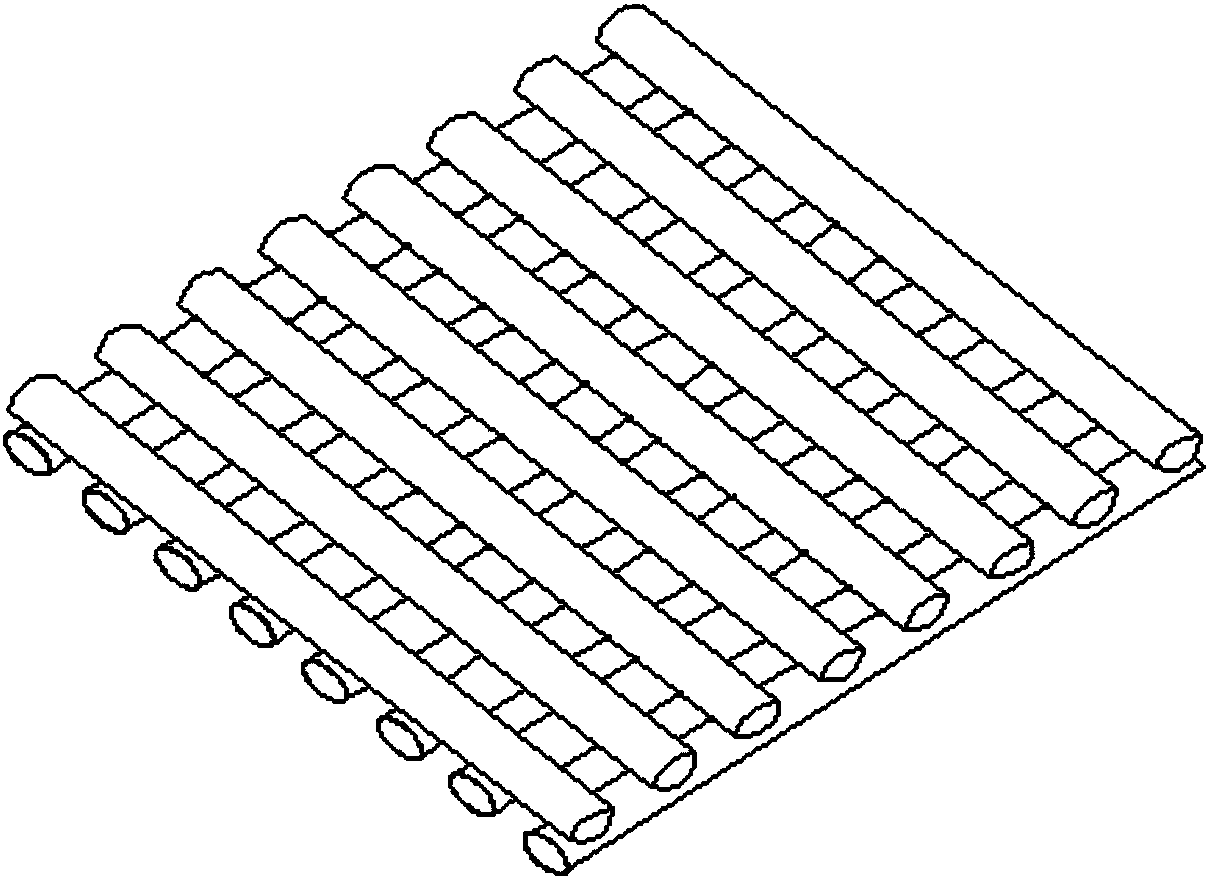

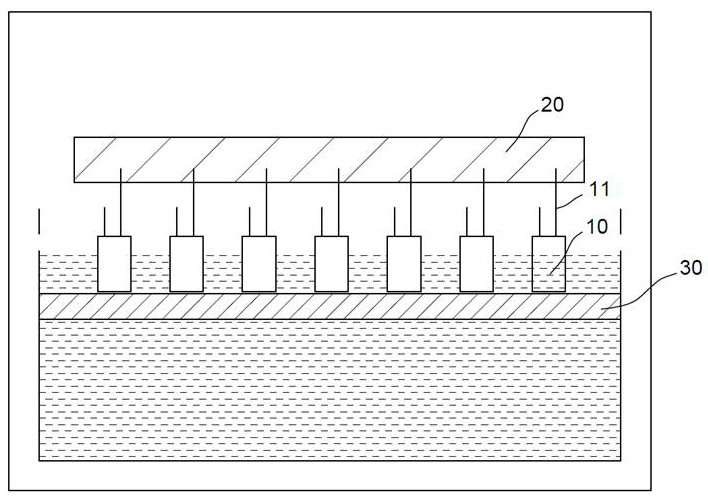

Embedded part, preparation method and composite structure including embedded part

The invention discloses a composite embedded part, a preparation method and a composite structure including the embedded part. The embedded part is of a sparse meshed or flaky structure formed by fiber bundles formed by steeping and solidifying resin in one way or in multiple directions; composite and super-hybrid composite parts can be manufactured by embedding the embedded part into a fiber laying layer through a resin introduction technology; the embedded part provides a flowing way for resin flowing in the composite molding process, and the resin steeping effect is improved; the embedded part forms a uniform entirety with a composite after being molded, and the properties of the composite are not reduced. The embedded part is embedded into a fabric and then introduced into the resin, and the embedded part has the advantages that the resin wetting speed is high, bubbles which are not discharged or remain in the resin are extremely easy to discharge, and dry spots are eliminated. Theembedded part also can be applied to the aspects of one-time pouring molding of other pre-molded parts and fabric laying layers used for blocking resin flow guiding, laminated molding of metal and glass fiber super-hybrid composites and the like.

Owner:BAMSTONE NEW MATERIAL TECH (WUHAN) CO LTD

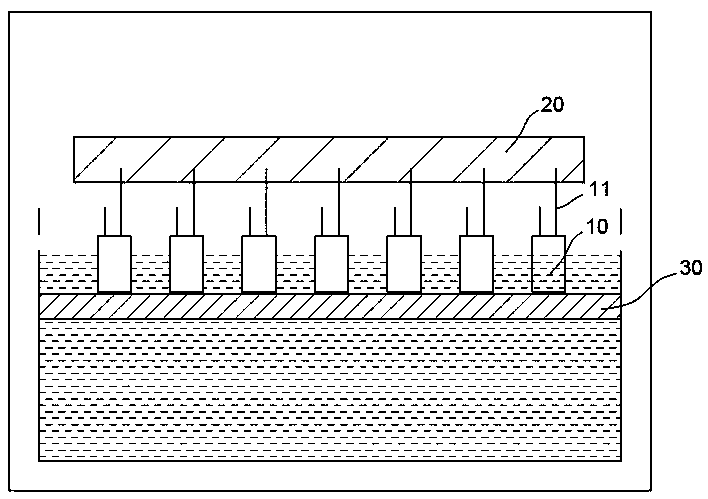

Solid state capacitor impregnation method

ActiveCN110364362AEasy accessIncreased dipping speedSolid electrolytic capacitorsDrying/impregnating machinesVacuum pumpingVacuum pump

The invention discloses a solid state capacitor impregnation method, which comprises the following steps: (1) an element is suspended, dry vacuum pumping for 5 to 10 s is carried out, and a vacuum degree is made to be negative pressure; (2) the element is lowered and is immersed in an impregnation liquid, the pressure is held for 5 to 20 s, the vacuum degree is negative pressure, and the vacuum degree is equal to that in the first step; (3) the element is kept in the impregnation liquid and is deflated to a normal pressure state; (4) the above steps (1) to (3) is a cycle, the cycle is executedfor at least two times, and in the case of multiple cycles, the vacuum degree of vacuum impregnation is gradually increased; and (5) the element is suspended, dry vacuum pumping is carried out, the vacuum degree is negative pressure, and the vacuum degree is greater than any above vacuum degree. The solid state capacitor disclosed in the invention has the advantages that the impregnation time isreduced, the impregnation effects are improved, and the element center can be impregnated thoroughly.

Owner:ZHAOQING BERYL ELECTRONICS TECH

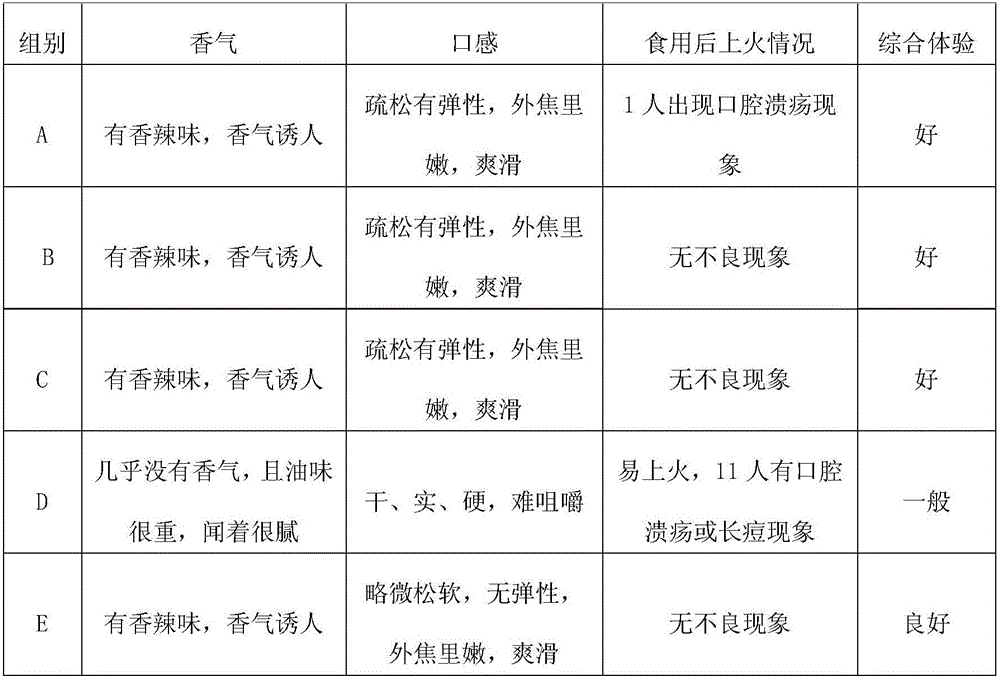

Preparation method of dried pork

The invention belongs to the technical field of the processing of dried meat, and particularly relates to a preparation method of dried pork. The preparation method of the dried pork comprises the following steps of (1) selecting materials: carefully selecting lean meat, and performing mincing so as to obtain minced lean meat; (2) performing pickling: uniformly mixing the minced lean meat in the step (1) with marinade to obtain a mixture, sealing the mixture by preservative films, enabling the mixture sealed by the preservative films to stand for 10-20 min, then enabling the mixture after standing for 10-20min to stand in a vacuum environment of 35-50 DEG C for 20-40 min, and finally, enabling the mixture after standing for 20-40min to stand in a vacuum environment of minus 3-0 DEG C for 100-150 min; (3) performing blanching: putting the pickled minced lean meat obtained in the step (2) in boiling water for 2-5s for rapid blanching; (4) performing baking: baking the blanched lean meat at 90-110 DEG C for 2-4 min, then baking the baked lean meat at 400-500 DEG C for 4-7s, and then putting the baked lean meat in a drying machine for drying; and (5) performing forming and packaging: performing forming, performing sterilizing, and performing vacuum packaging. The preparation method disclosed by the invention is simple in operation, the prepared dried pork is tempting in fragrance, loose and chewy, tender with a crispy crust, and smooth, and has no coarse sense, and after eating the dried pork, a person is not liable to suffer from excessive internal heat.

Owner:GUANGXI UNIV

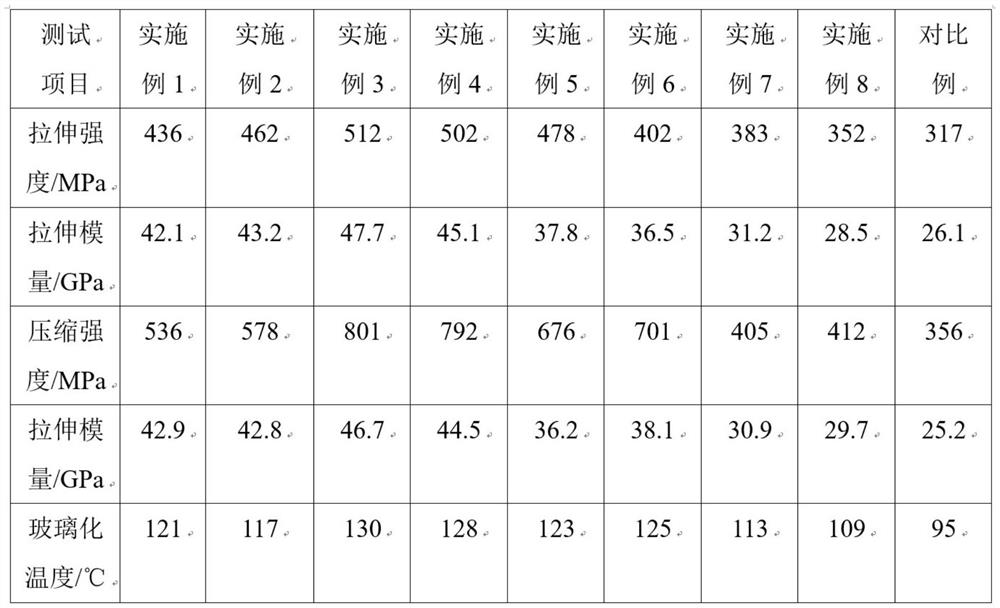

Epoxy resin composition capable of being rapidly cured at medium and low temperatures, epoxy resin-based composite material and preparation method thereof

ActiveCN113292819AFast medium and low temperature curing speedHigh glass transition temperaturePolymer scienceFirming agent

The invention provides an epoxy resin composition capable of being rapidly cured at medium and low temperatures, an epoxy resin-based composite material and a preparation method thereof. The epoxy resin composition capable of being rapidly cured at medium and low temperatures comprises the following components in parts by weight: 100 parts of epoxy resin, 0.1-5 parts of an imidazole accelerant, 2-40 parts of filler, 30-200 parts of an anhydride curing agent, 1-40 parts of a toughening agent and 0.5-10 parts of a release agent. According to the epoxy resin composition capable of being rapidly cured at medium and low temperatures, the epoxy resin-based composite material and the preparation method of the epoxy resin-based composite material, the medium and low temperature curing time of the epoxy resin-based composite material can be obviously shortened through cooperation of the anhydride curing agent, the imidazole accelerant and other raw materials in the epoxy resin composition; meanwhile, the pultrusion speed of the composite material in a pultrusion process is remarkably improved, and the composite material is excellent in mechanical property and high in glass transition temperature.

Owner:北玻院(滕州)复合材料有限公司

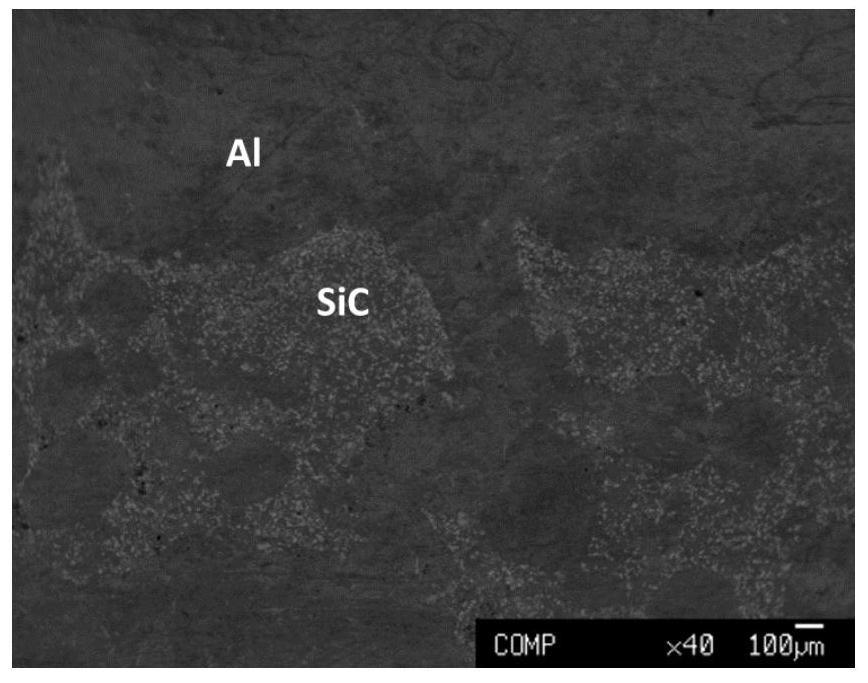

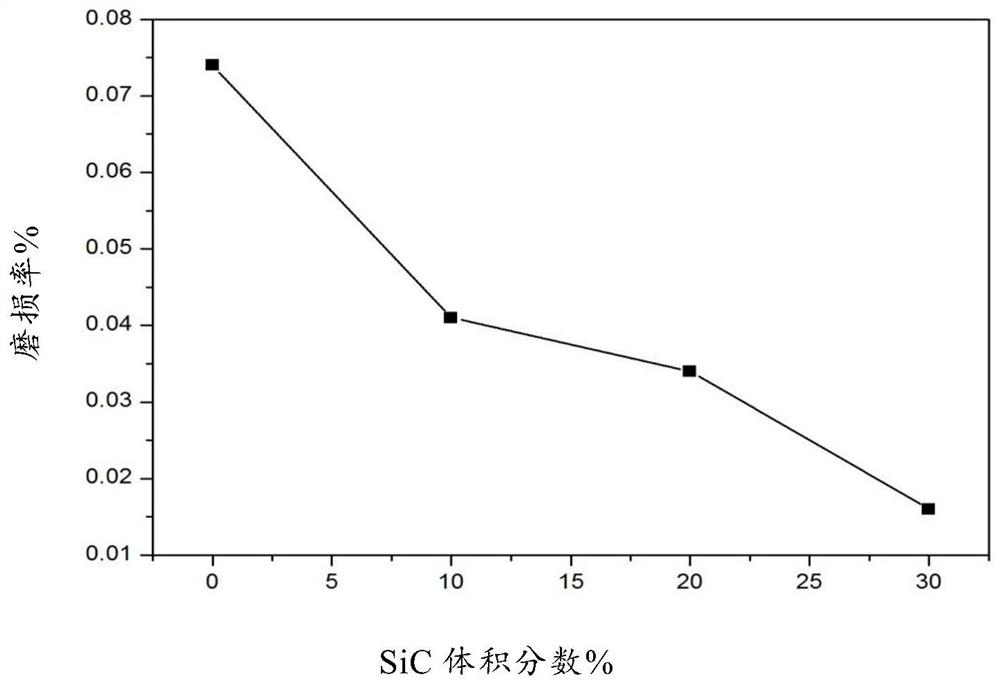

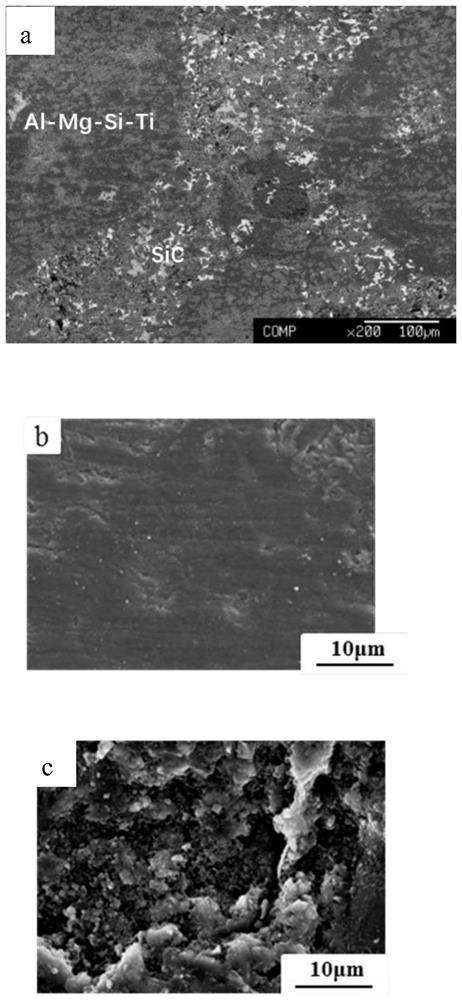

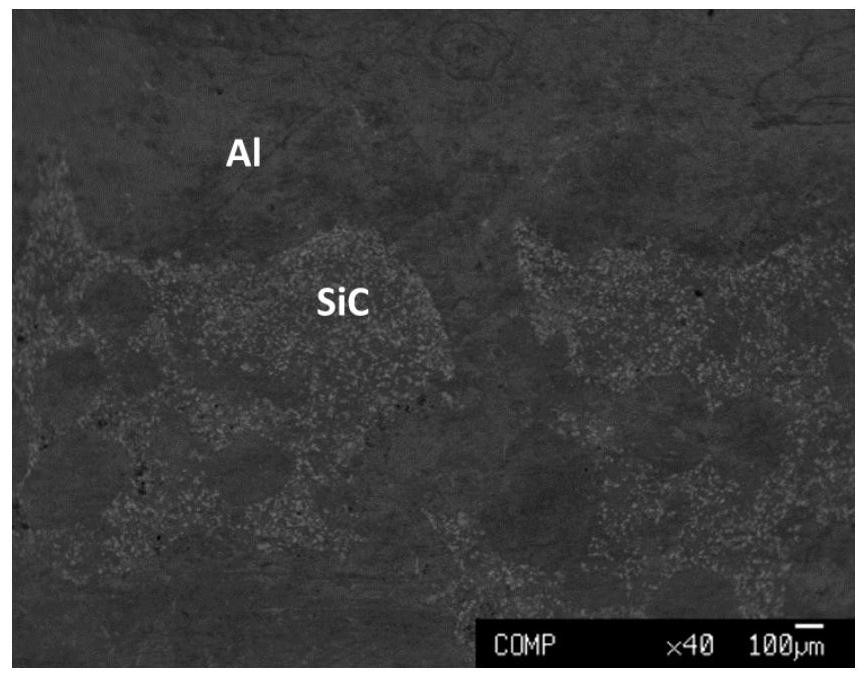

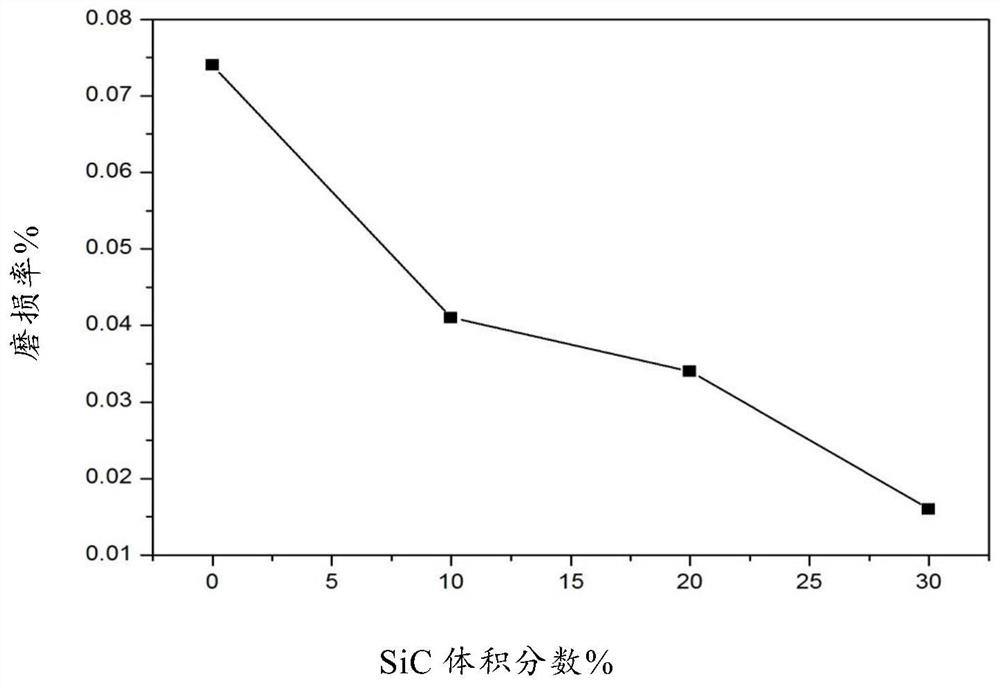

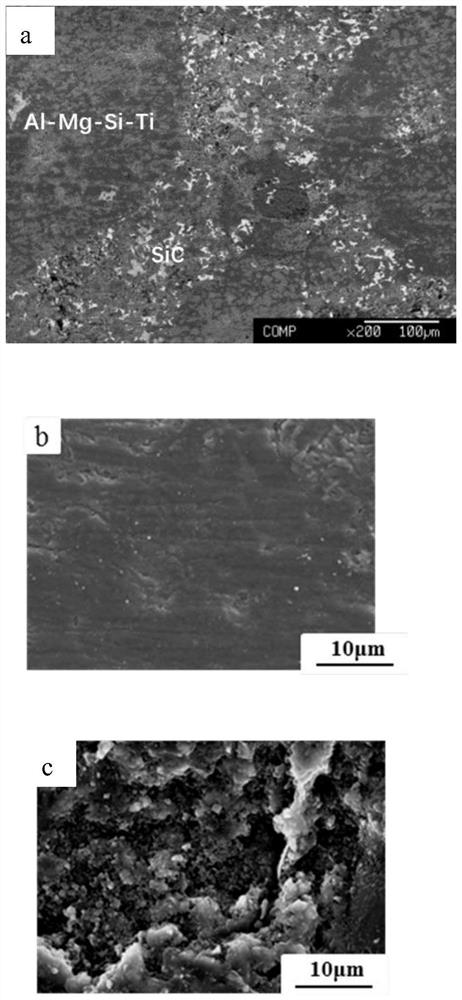

Preparation method of metal ceramic composite material

The invention discloses a preparation method of a metal ceramic composite material. The method comprises the following steps: (1) sequentially carrying out crushing, ultrasonic cleaning and drying onfoamed SiC ceramic according to the procedures of primary crushing, secondary crushing and tertiary crushing to obtain an ellipsoidal SiC ceramic block with the size of 2 mm to 15 mm; (2) carrying outpre-oxidation, pre-corrosion and cleaning on the ellipsoidal SiC ceramic block obtained in the step (1) to obtain a foamed SiC ceramic reinforcement; and (3) mixing the foamed SiC ceramic reinforcement obtained in the step (2) with metal, putting the mixture into a mold, performing heating and applying pressure in a nitrogen atmosphere, performing cooling, solidifying, demolding and polishing toobtain the metal ceramic composite material.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

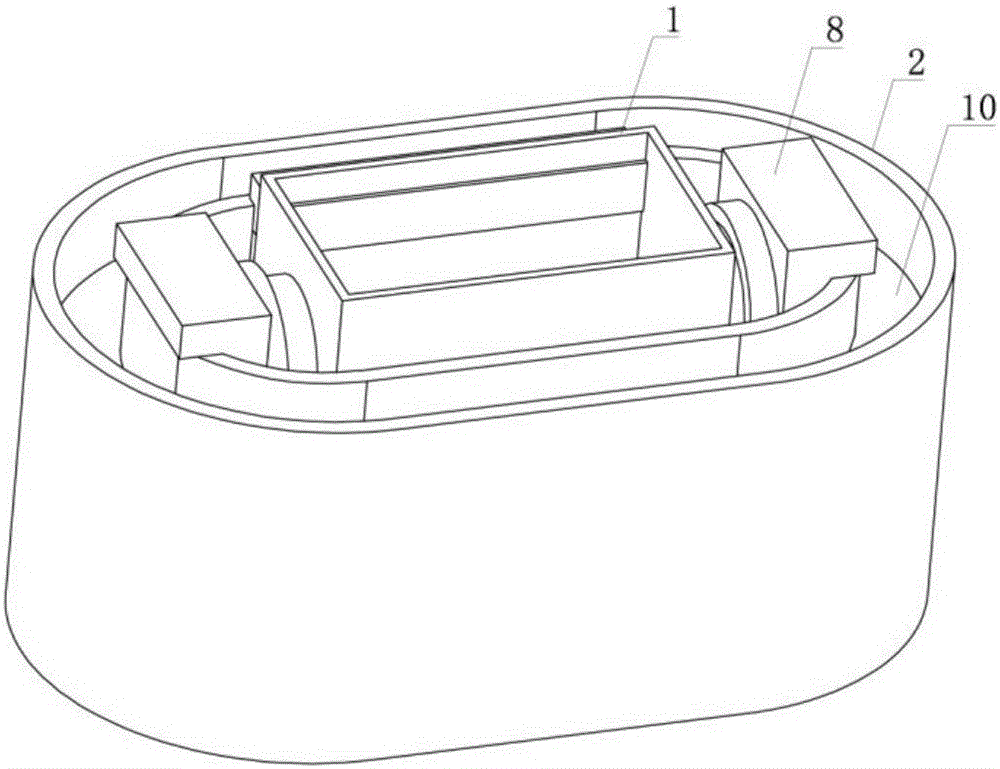

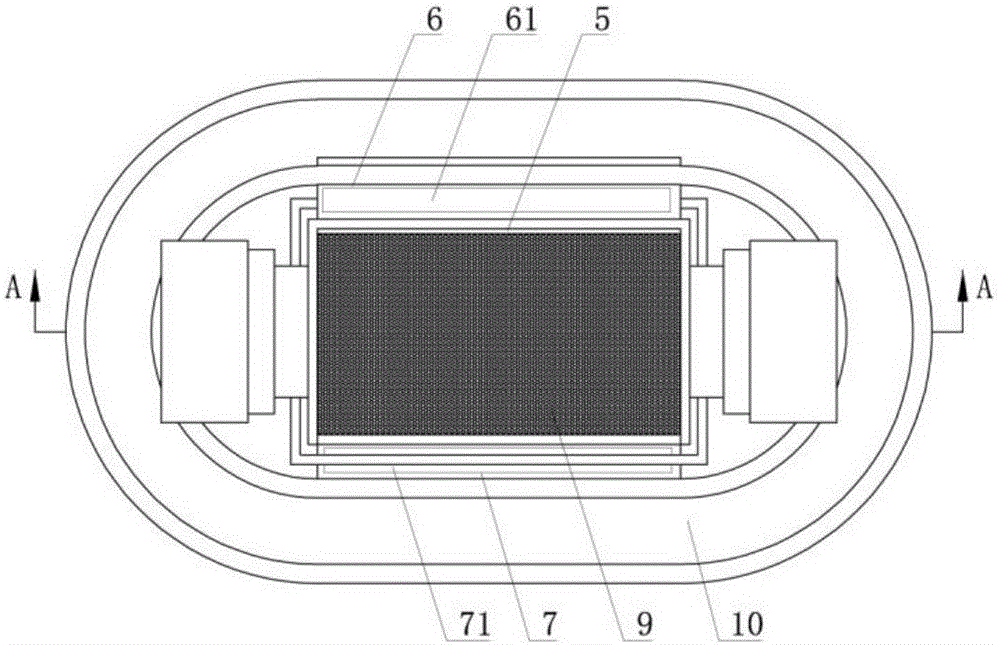

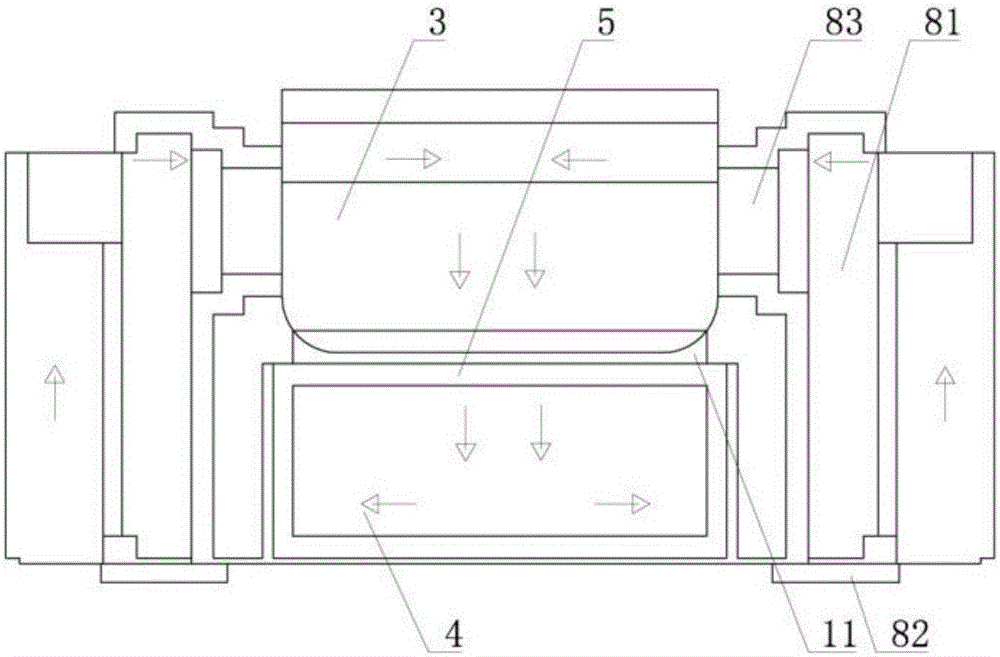

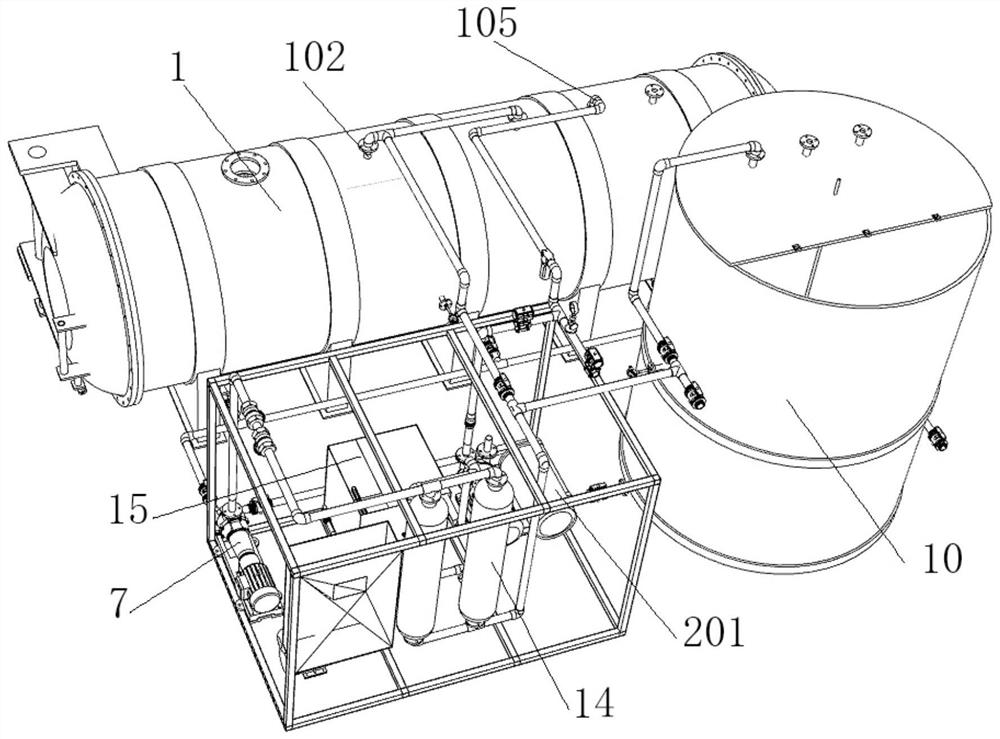

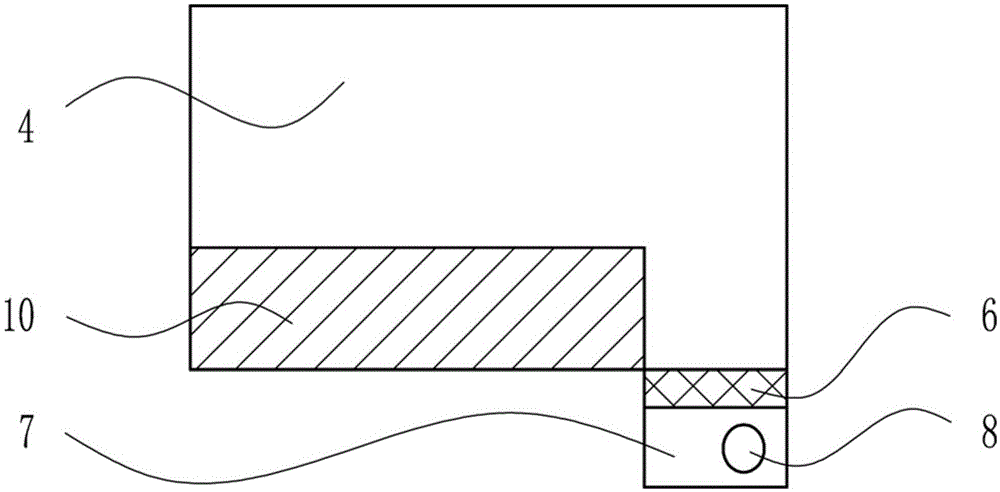

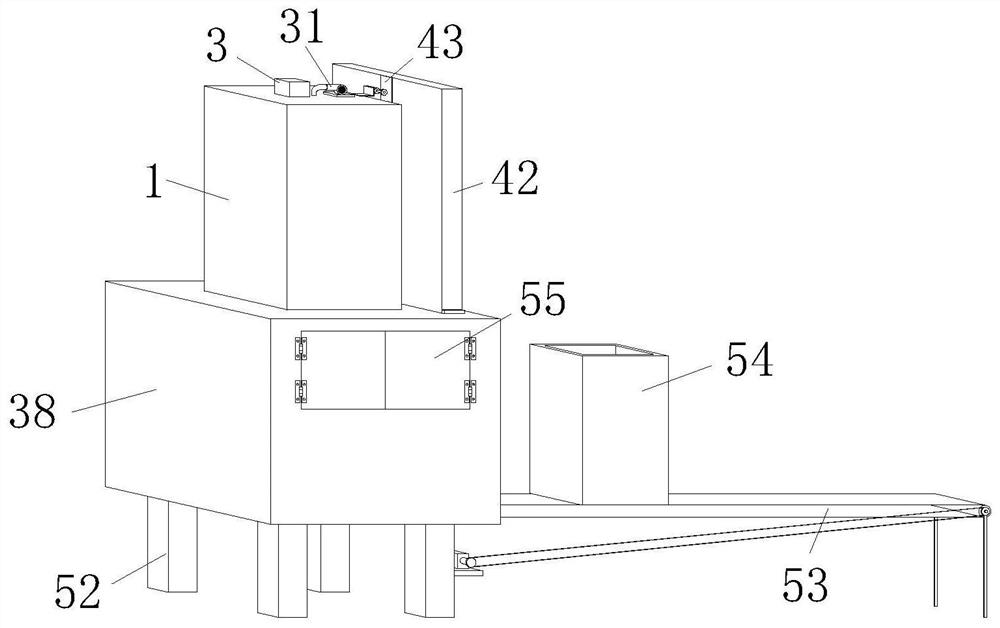

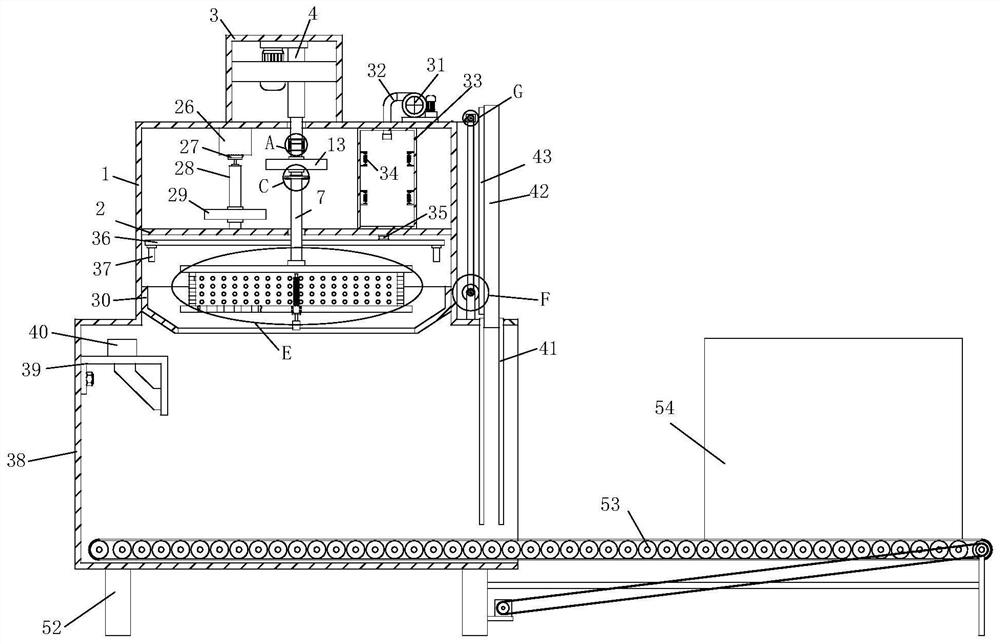

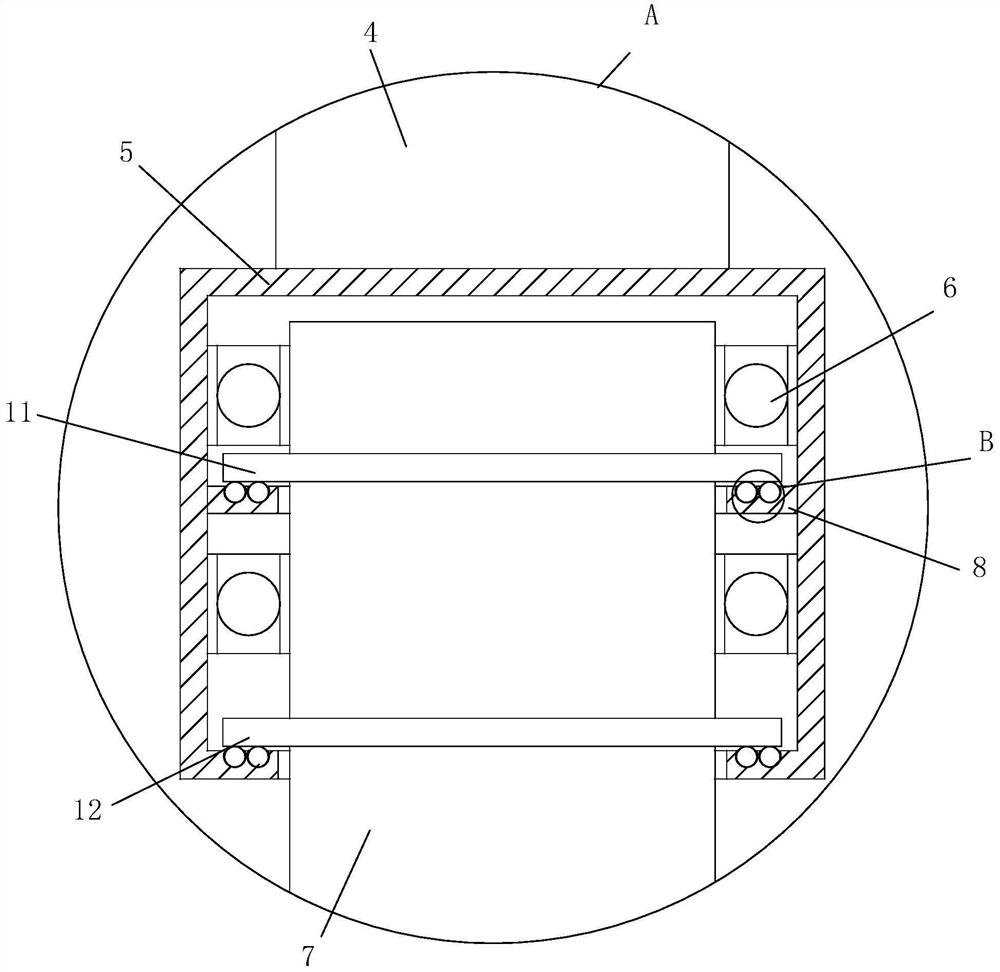

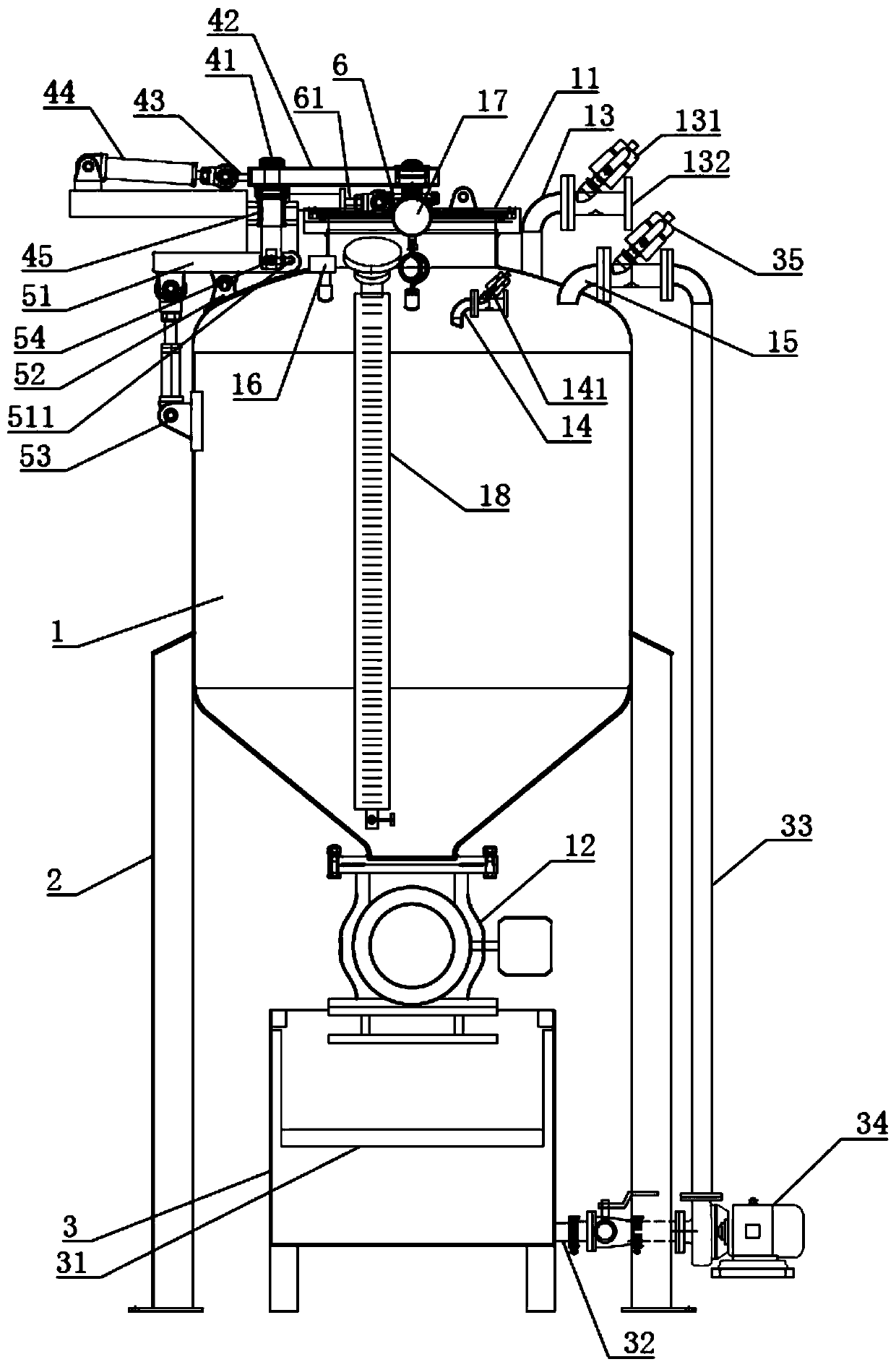

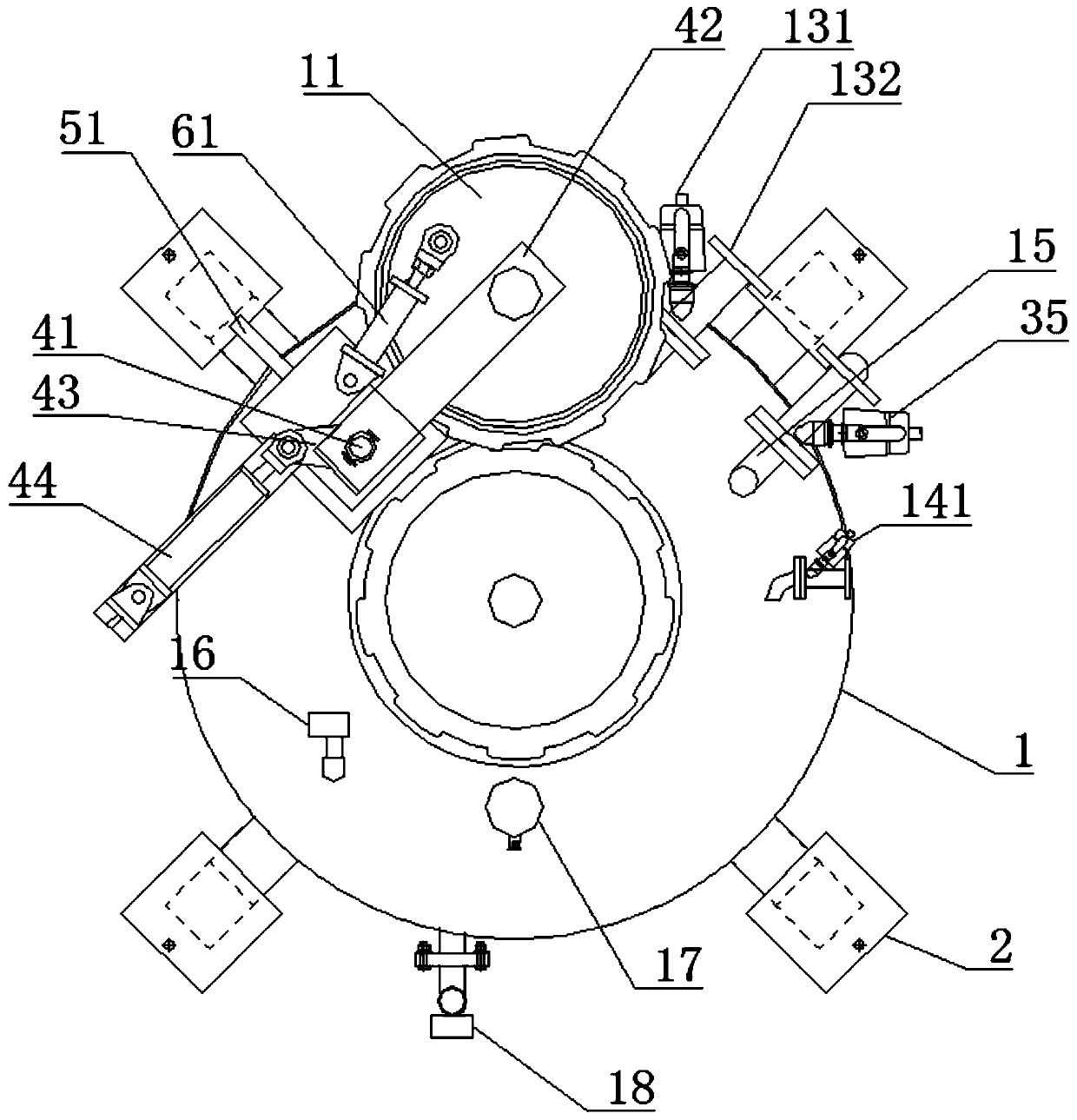

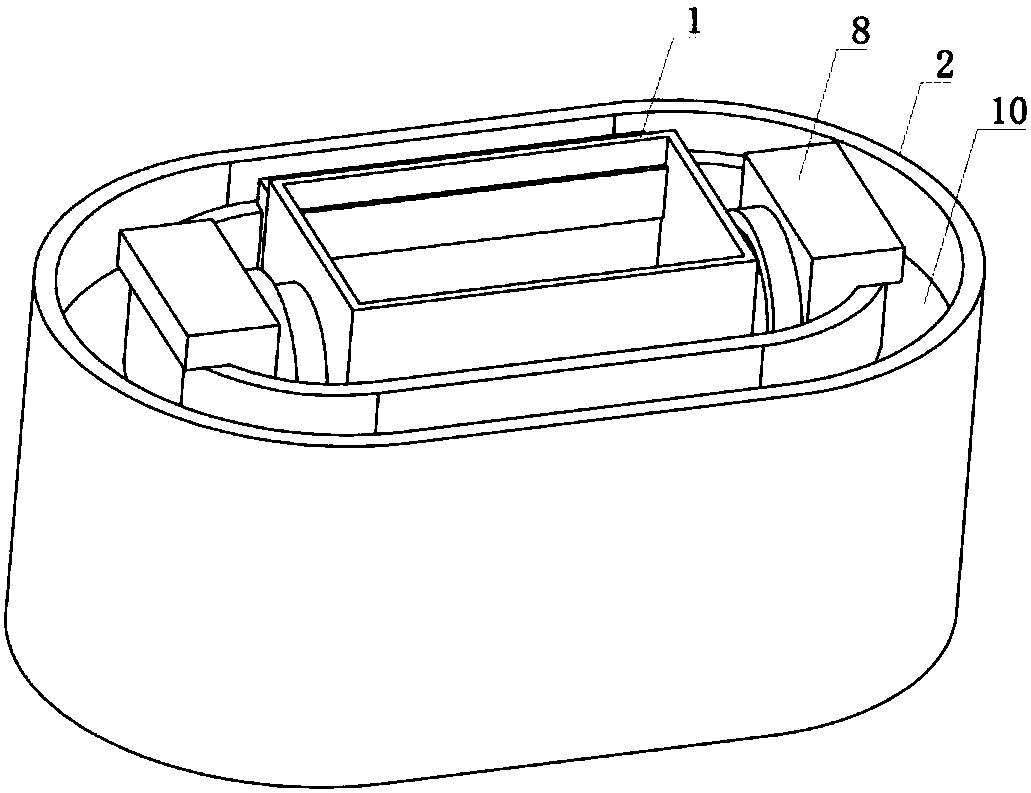

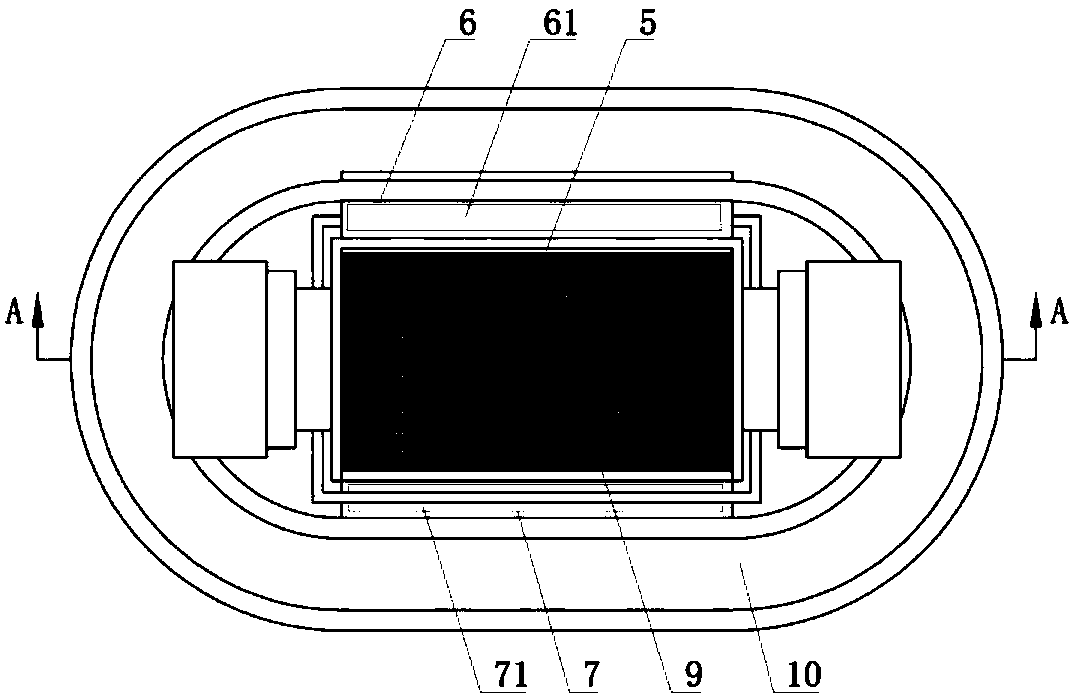

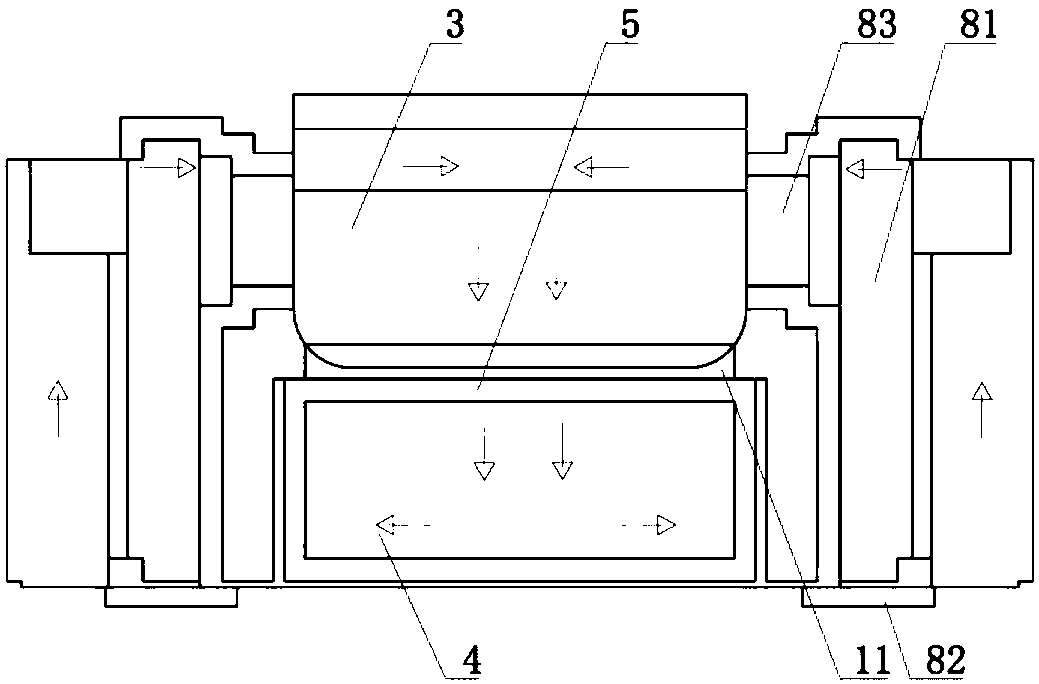

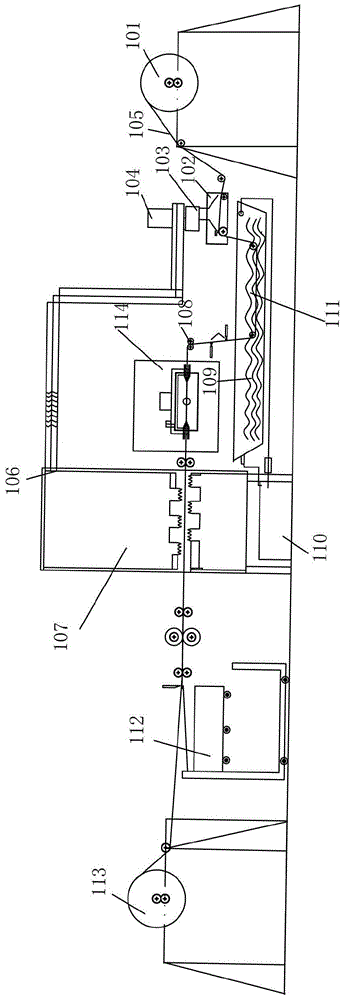

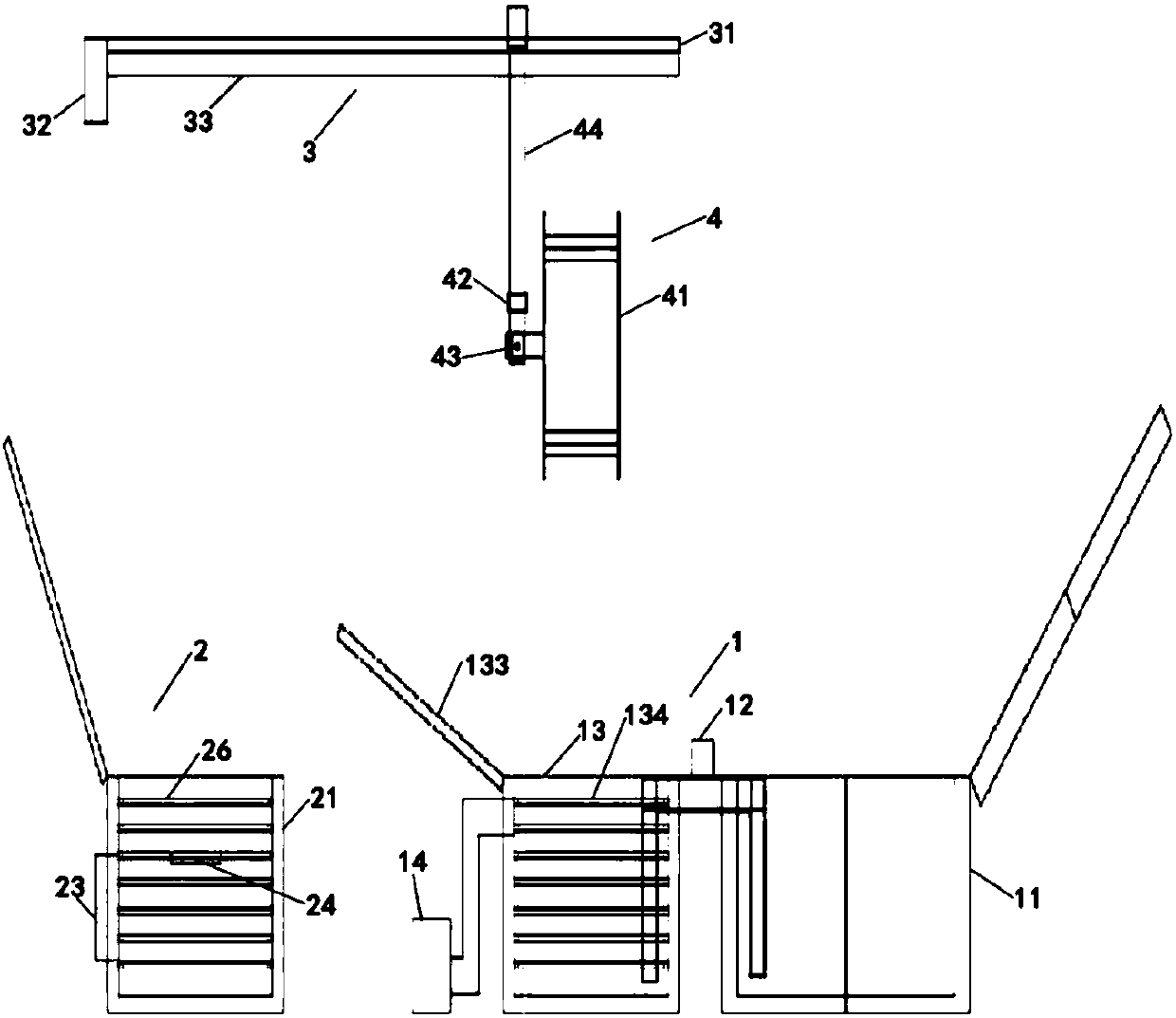

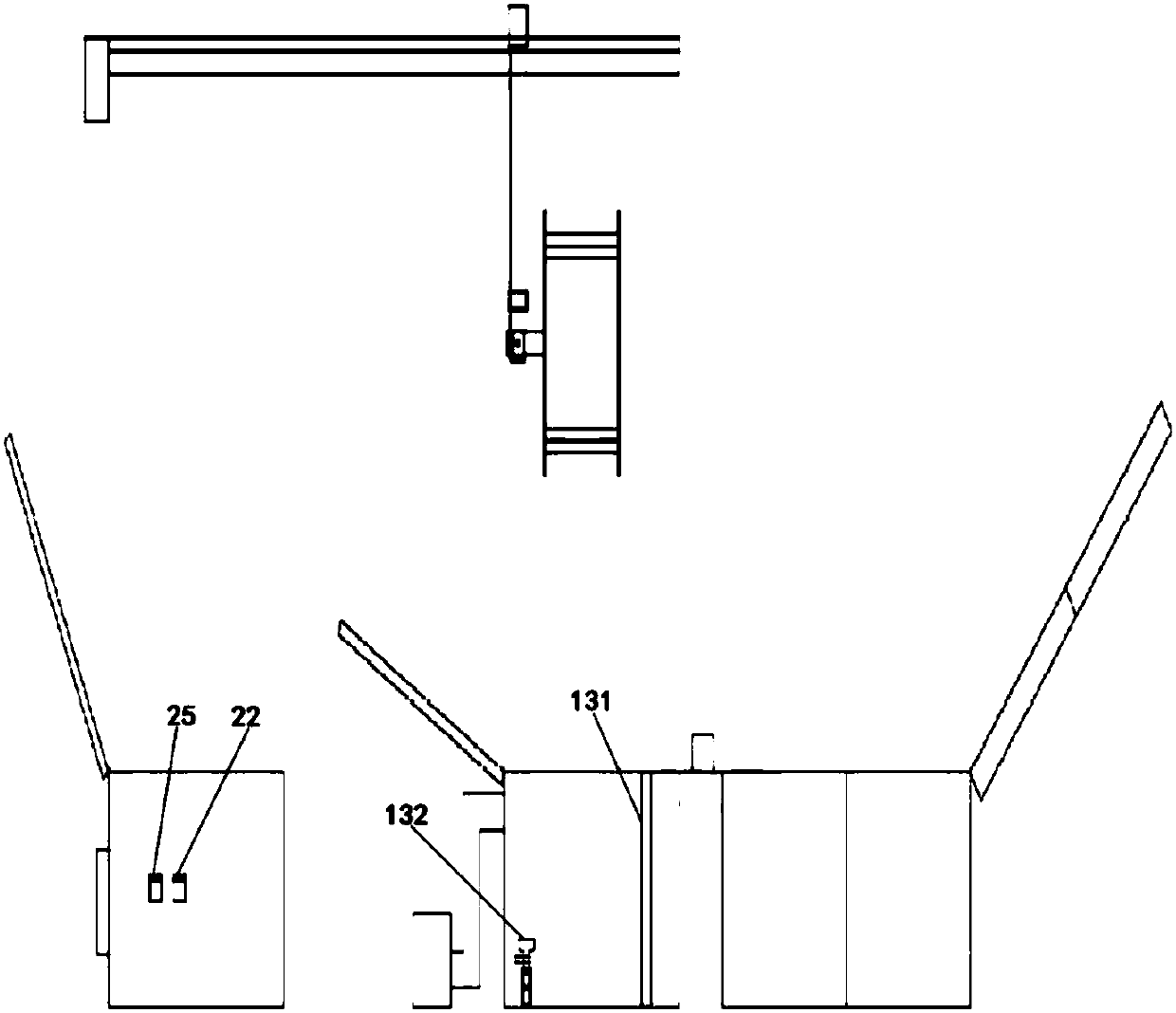

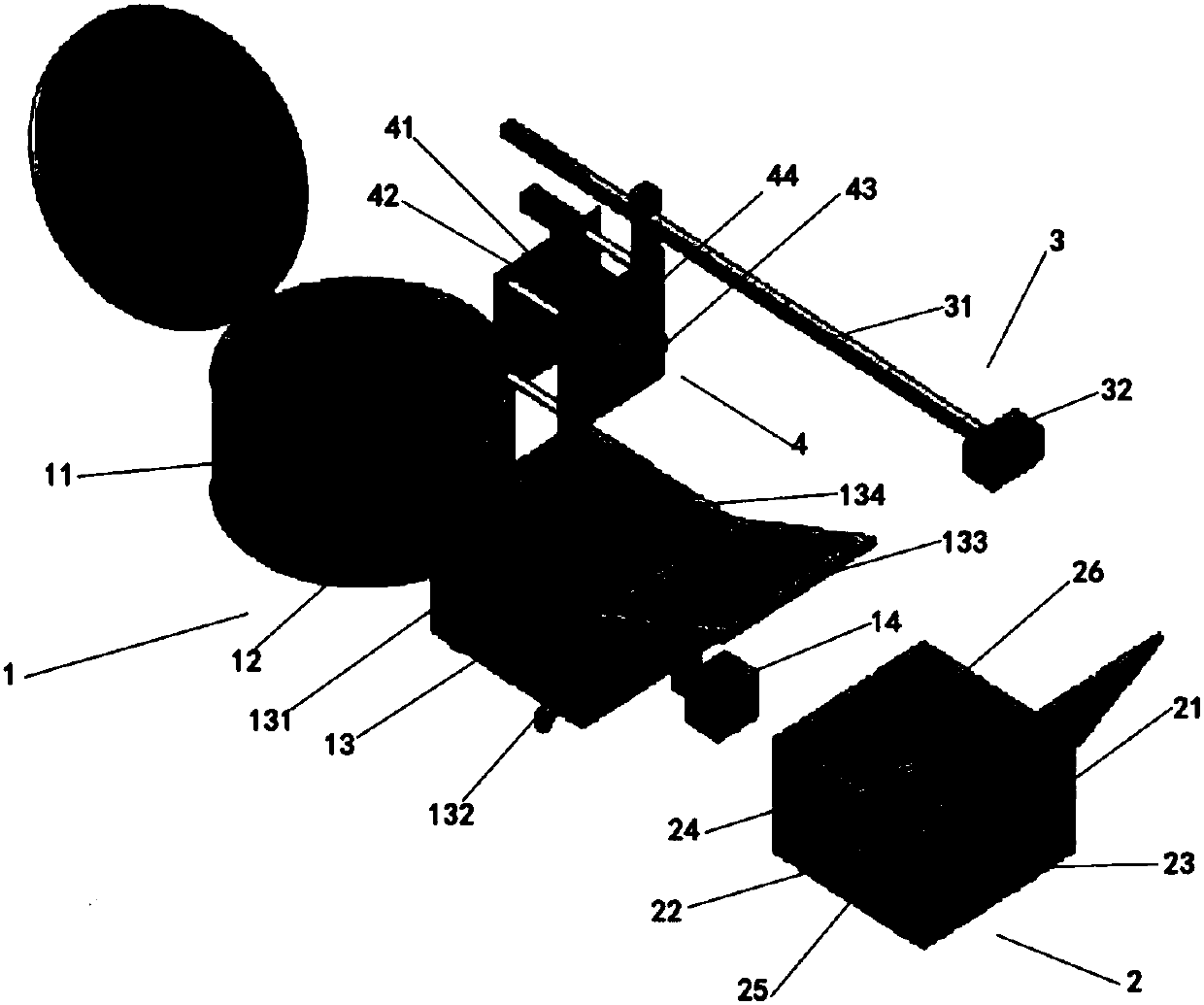

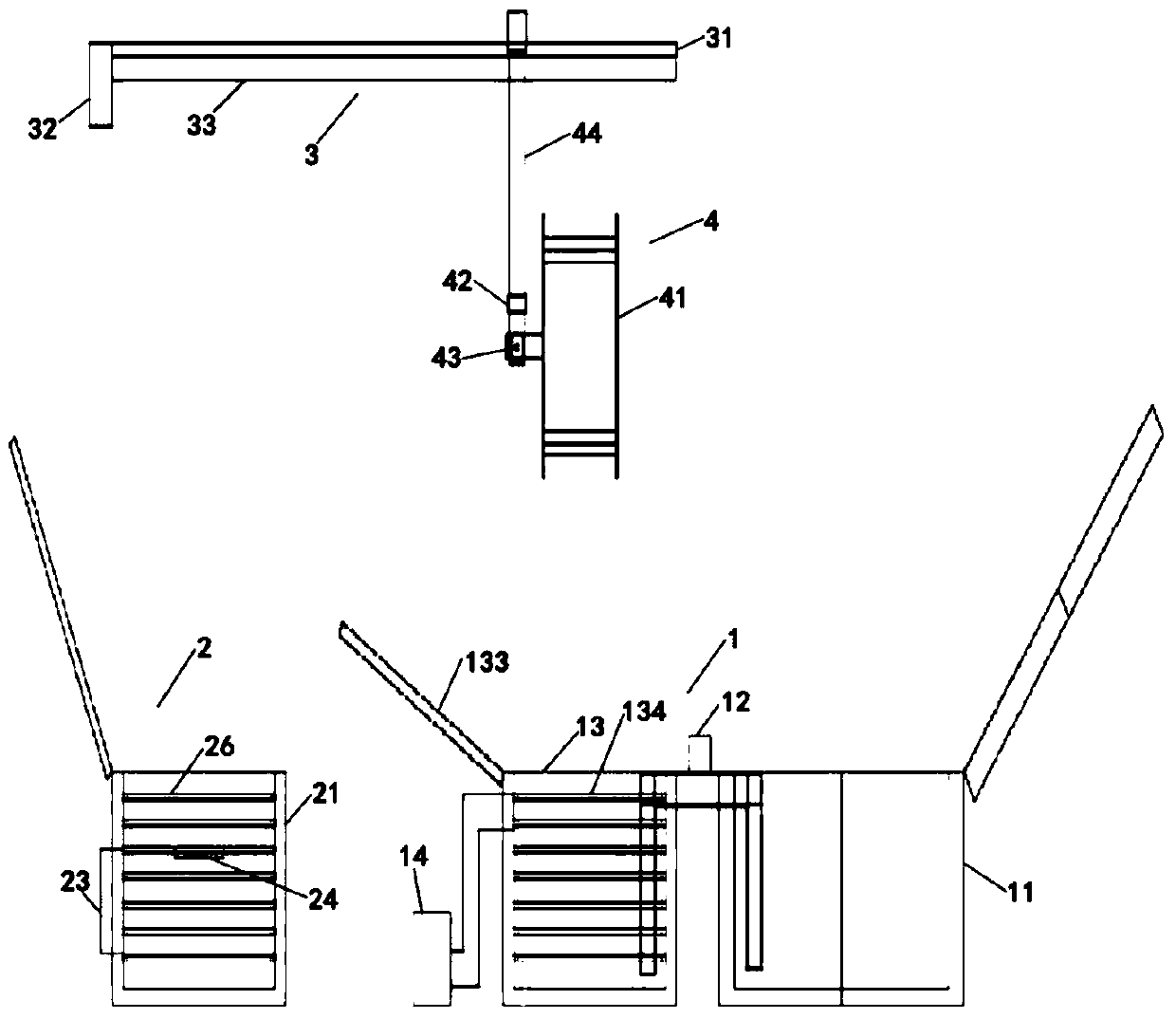

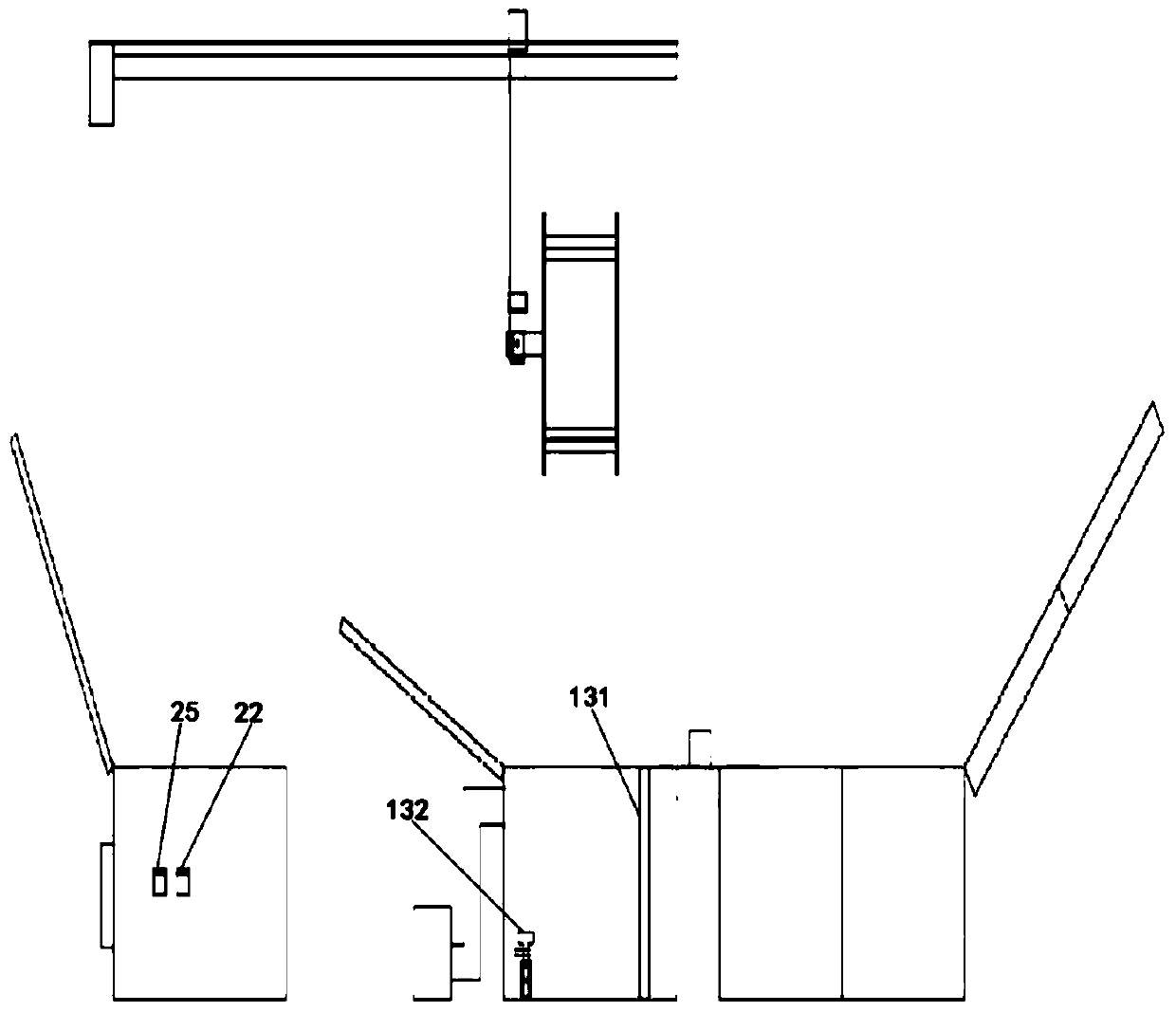

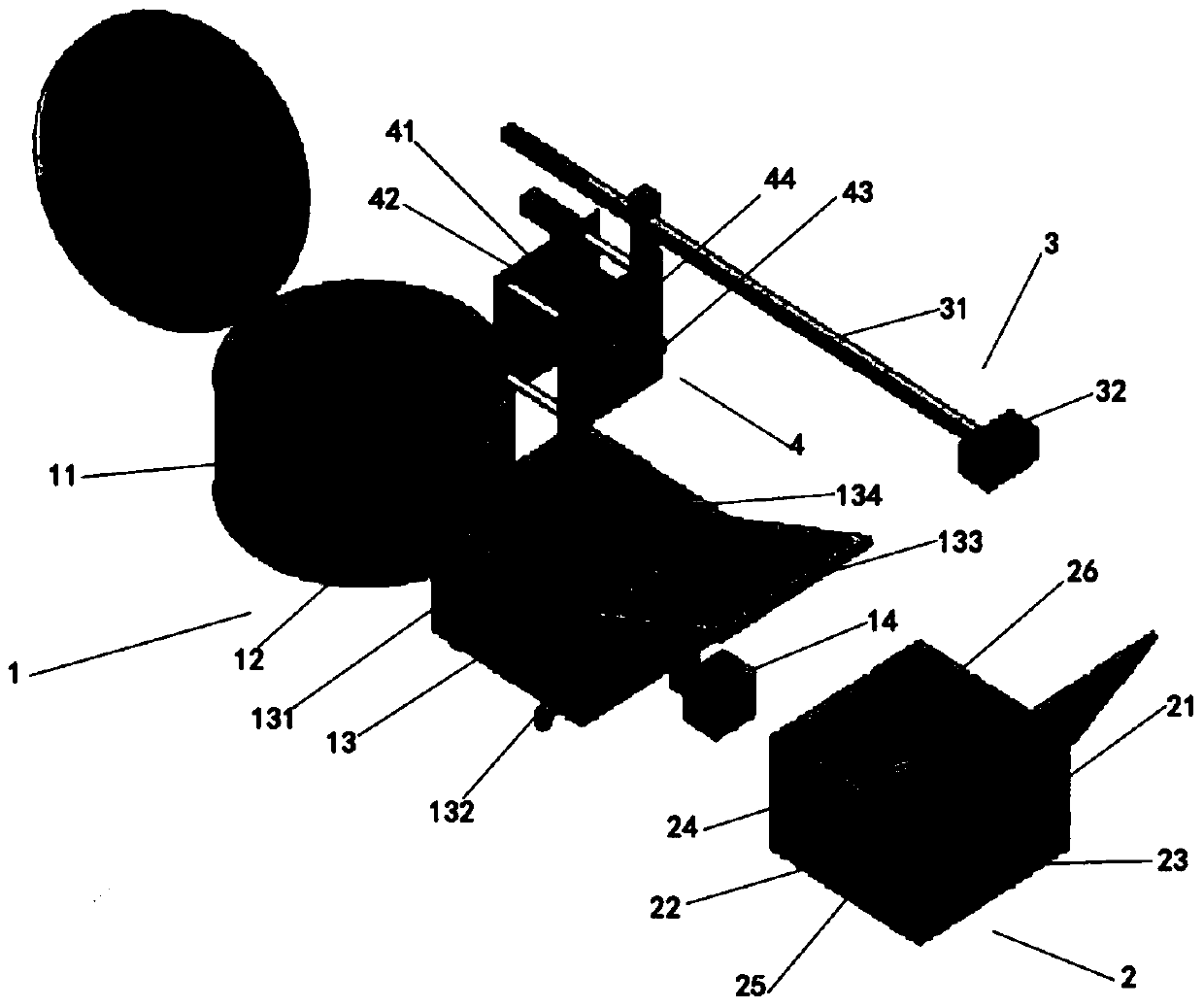

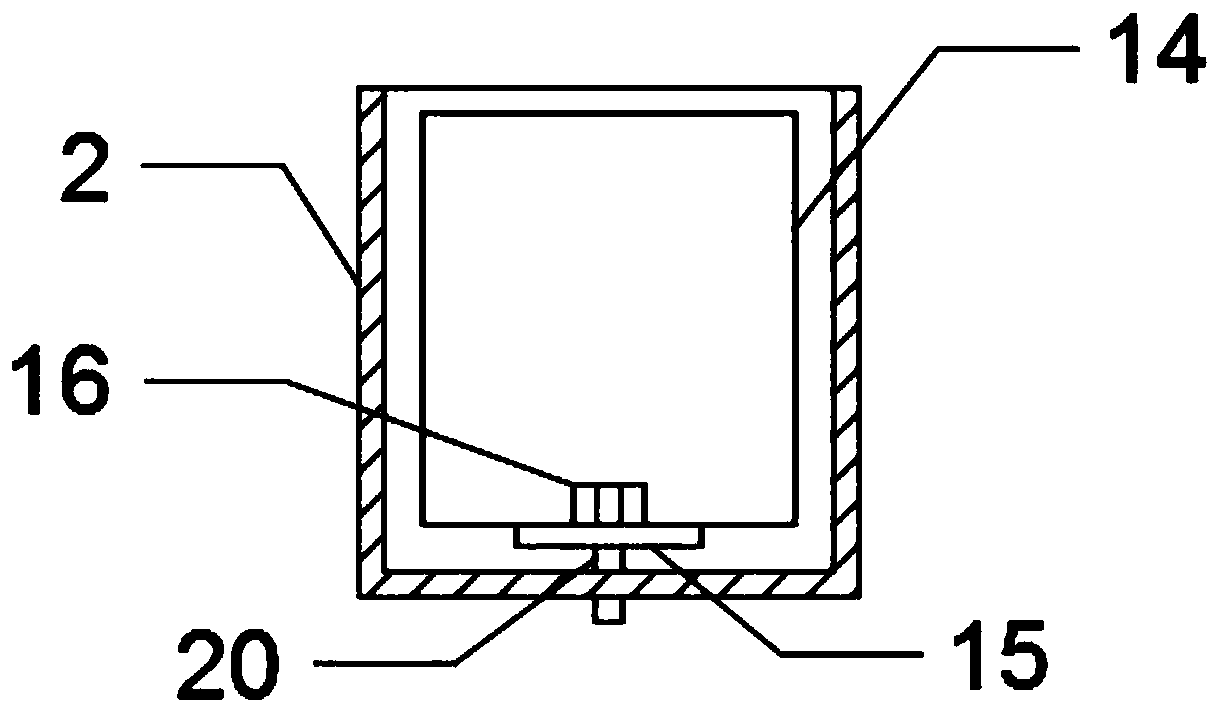

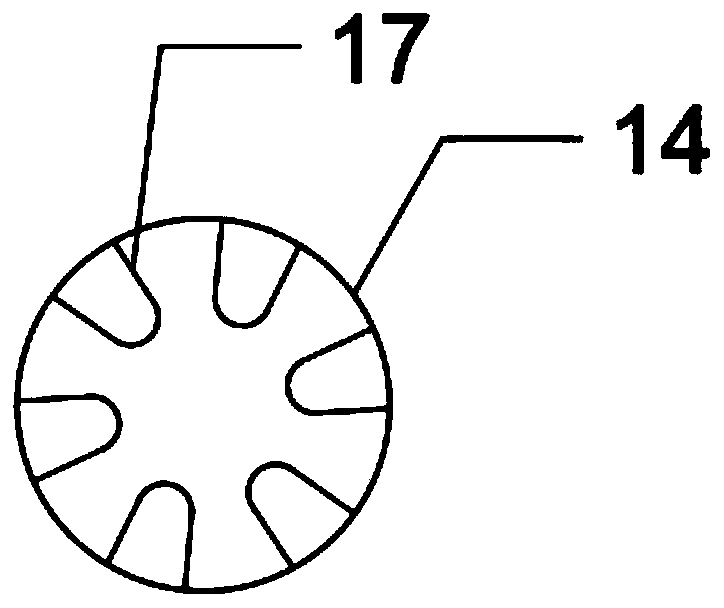

Special dipping equipment for PVC negative ion antibacterial gloves and dipping process thereof

ActiveCN105922484AShorten the soaking timeIncreased dipping speedDomestic articlesCoatingsSlurryEngineering

The invention discloses special dipping equipment for PVC negative ion antibacterial gloves, relates to the field of gloves manufacturing, and is used for solving the problem that traditional PVC gloves have no bacterial resisting and bacterial killing capacity. The equipment comprises a slurry tank, and a guide groove positioned in the outer circle of the slurry tank; the slurry tank includes a dipping pool, a precipitating pool positioned below the dipping pool, a separation plate, a feed channel and a discharge channel; support frames for supporting the slurry tank are arranged on two sides of the slurry tank; the separation plate is positioned between the dipping pool and the precipitating pool, and is embedded with a filter bag; the guide groove is annular; a conveying belt and a driving motor for driving the conveying belt to act are arranged in the guide groove; the back end of the conveying belt is higher than the front end; and the driving motor controls the conveying belt to circularly act. The equipment performs dipping through flowing of latex slurry, and gives the bacterial resisting and bacterial killing capacity to the PVC gloves. The invention further discloses a dipping process of the special dipping equipment for the PVC negative ion antibacterial gloves.

Owner:淄博鸿烨上勤医疗科技有限公司

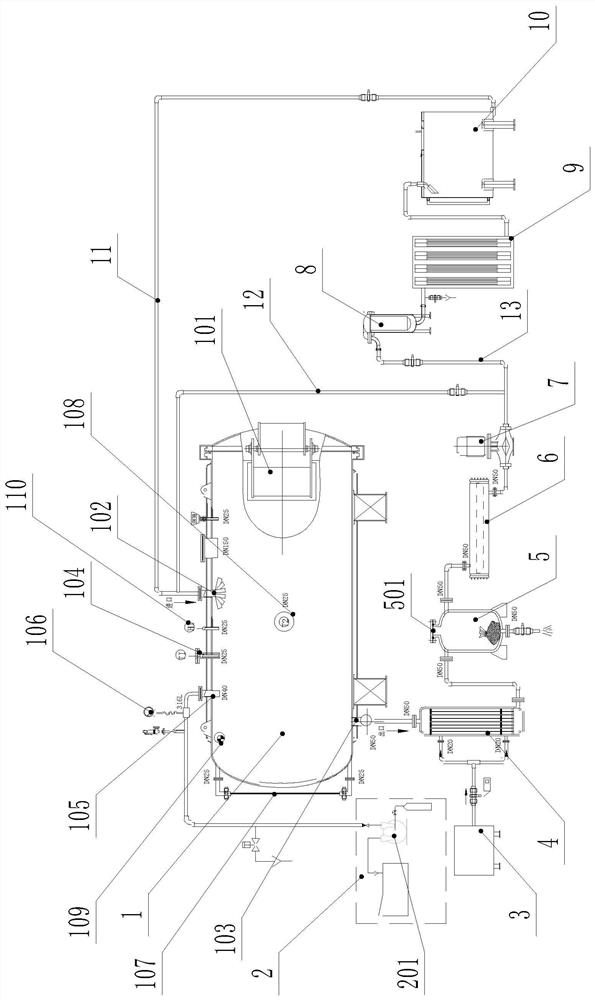

Salted egg pickling system and pickling process

InactiveCN113180201AIncrease temperatureIncreased osmotic diffusion abilityMeasurement devicesTreatment involving filtrationProcess engineeringWaste management

The salted egg pickling system comprises a pickling cylinder, and an outlet of a salt liquid temporary storage tank is communicated with a salt liquid inlet of the pickling cylinder through a liquid supply pipeline; a negative pressure system is communicated with the extraction opening of the pickling jar through a negative pressure extraction pipe; a heat exchange device is communicated with a salt liquid outlet of the pickling jar through a liquid discharge pipeline; a heat exchange device is connected with a heat exchange medium supply system for carrying out heat exchange on the salt liquid; a liquid inlet formed in the salt supplementing tank is communicated with the heat exchange device; a liquid outlet of the salt supplementing tank is communicated with an inlet of the salt liquid buffer tank; and a conveying pump is arranged on a pipeline on a salt liquid flowing path. In addition, the invention also discloses a salting method using the salting system, the salted eggs are salted in batches by adopting a decompression method, parameters in the salting process can be monitored, the salting time is shortened, and the quality and uniformity of the salted eggs are improved.

Owner:张家港鼎固自动化设备有限公司

Bitter taste-free Shatian pomelo peel and its production method and use

ActiveCN103976313AIncreased dipping speedShorten the soaking timeFood preparationFood safetyBitter taste

The invention relates to the field of foods and discloses a bitter taste-free Shatian pomelo peel and its production method and use. The production method comprises the following steps of preparing a Shatian pomelo peel bitter taste removal liquid from tea, putting Shatian pomelo peel and the Shatian pomelo peel bitter taste removal liquid into a vacuum impregnation tank together, carrying out vacuum impregnation for 3-5h, carrying out dehydration, carrying out immersion again, and repeating the above processes multiple times until a bitter taste is removed. The production method utilizes natural tea extract as a bitter taste removal agent, is green, does not contain an additive, is safe and healthy, has obvious effects, satisfies food safety requirements, retains a Shatian pomelo nutrition value on the premise of Shatian pomelo bitter taste removal and is suitable for industrial production.

Owner:广西容县锦香食品有限公司

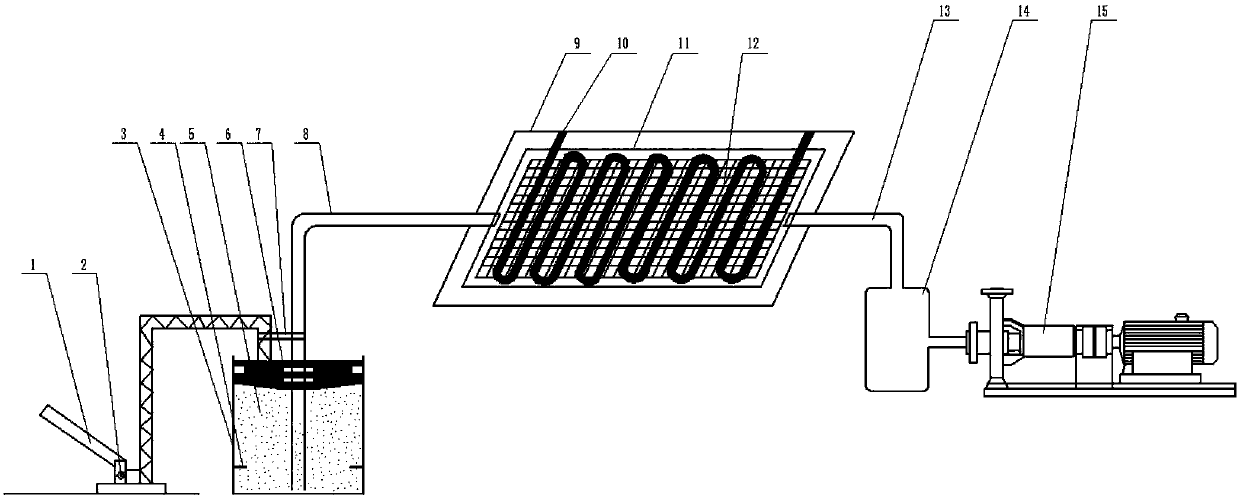

RTM hot-pressing auxiliary forming device and operation method

The invention provides an RTM hot-pressing auxiliary forming device and an operation method, belonging to the technical field of composite forming. The RTM hot-pressing auxiliary forming device comprises a pressure control system, a resin containing device, a limiting valve, a gel, a rubber plug, a fixing pipe device, a resin feeding pipe, a heating mold, a clip-shaped heating pipe, a high-temperature film, an enhanced material, a resin discharging pipe and a backflow bottle. After the device is mounted, the temperature of the heating mold is adjusted according to the resin characteristics andthe liquidity of the resin is kept to be in the optimal state; the suitable pressure scope is confirmed according to the volume of the gel and the area of the enhanced material; the pressure value isincreased under the combined action of a jack and a vacuum pump, and the dipping speed, namely, flowing speed, of the gel is increased. The invention provides the device and the method for increasingthe RTM forming efficiency and is capable of realizing the increasing of the dipping speed and greatly shortening the forming time.

Owner:DALIAN UNIV OF TECH

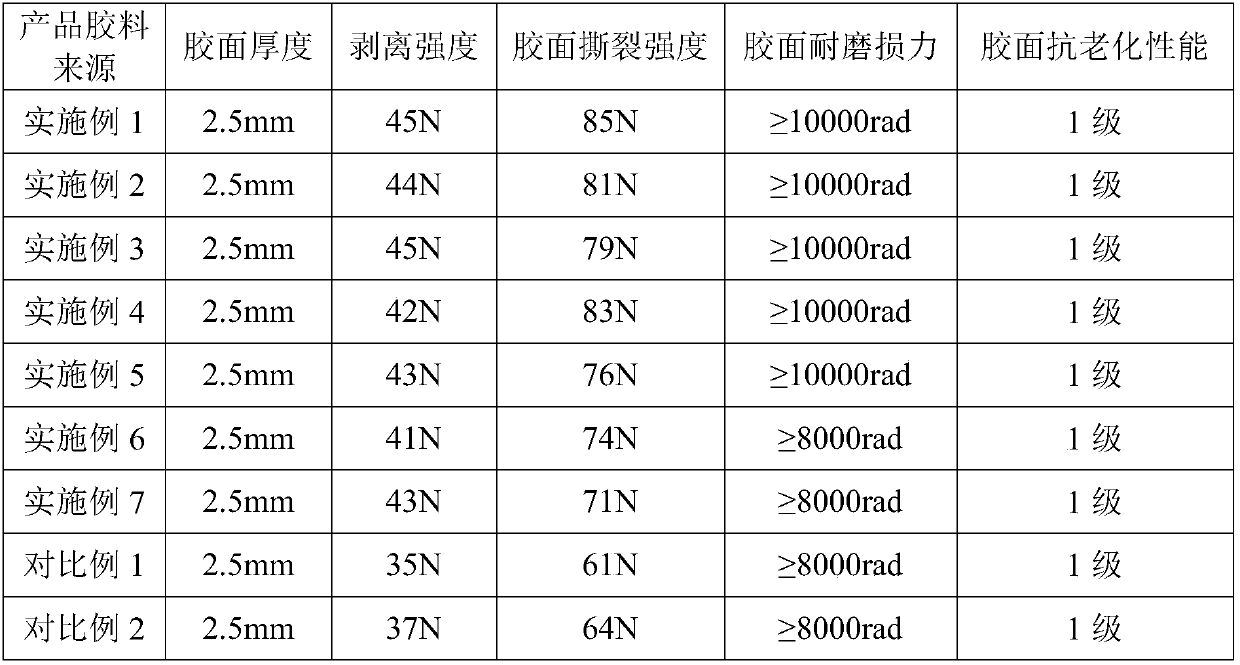

Nitrile rubber compound and preparation method thereof

The invention discloses a nitrile rubber compound and a preparation method thereof. The nitrile rubber compound is prepared from the following components in parts by weight: 80-150 parts of nitrile rubber, 0.5-8 parts of reinforcing filler, 10-30 parts of foaming agent, 0.5-5 parts of anti-aging agent, 1-15 parts of plasticizer, and 15-50 parts of negative ion stock solution, wherein the negativeion stock solution is prepared by mixing a water-soluble negative ion crystal and water in a weight ratio of (2-10):100. The nitrile rubber compound of the invention contains the added negative ion stock solution, the nitrile rubber compound containing a negative ion component is impregnated to prepare a negative-ion antibacterial glove, so that the glove is endowed with antibacterial ability; andalso with utilization of the characteristic that the a large amount of heat energy is released during a thermal motion process of the negative ion component, the impregnation time is shortened and the impregnation speed is improved. The nitrile rubber compound of the invention has the advantages of strong adhesion and good wear resistance, and is conducive to prolonging the service life of the glove and improving the protective effect.

Owner:GUANGZHOU ESEN PERSONAL PROTECTIVE EQUIP TECH CO LTD

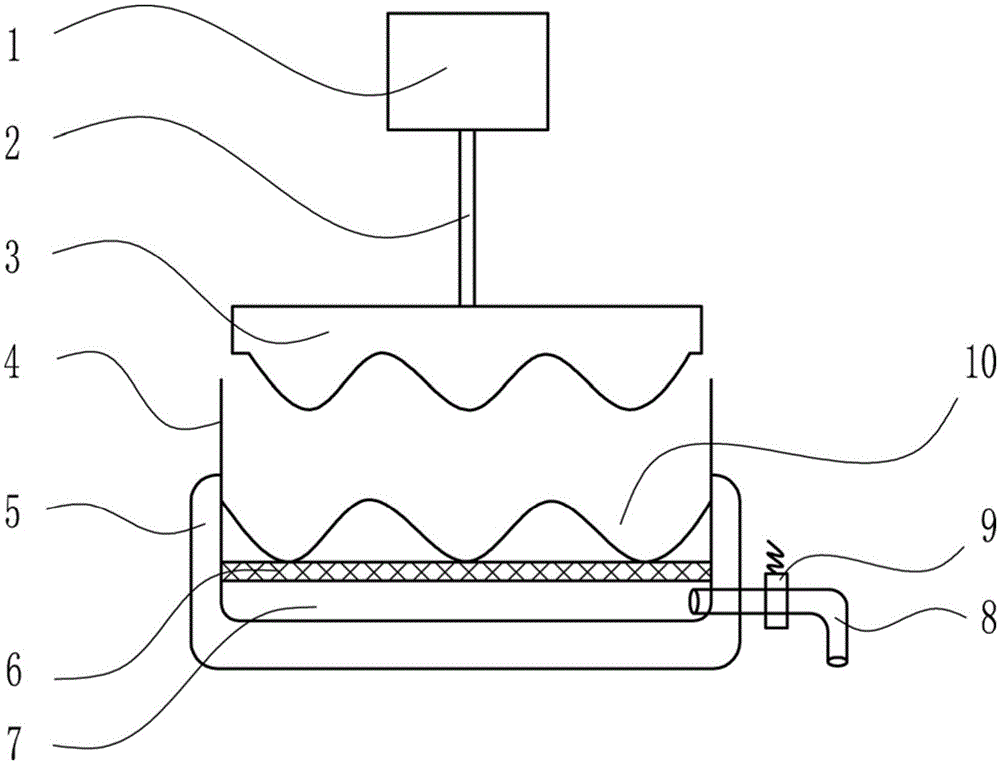

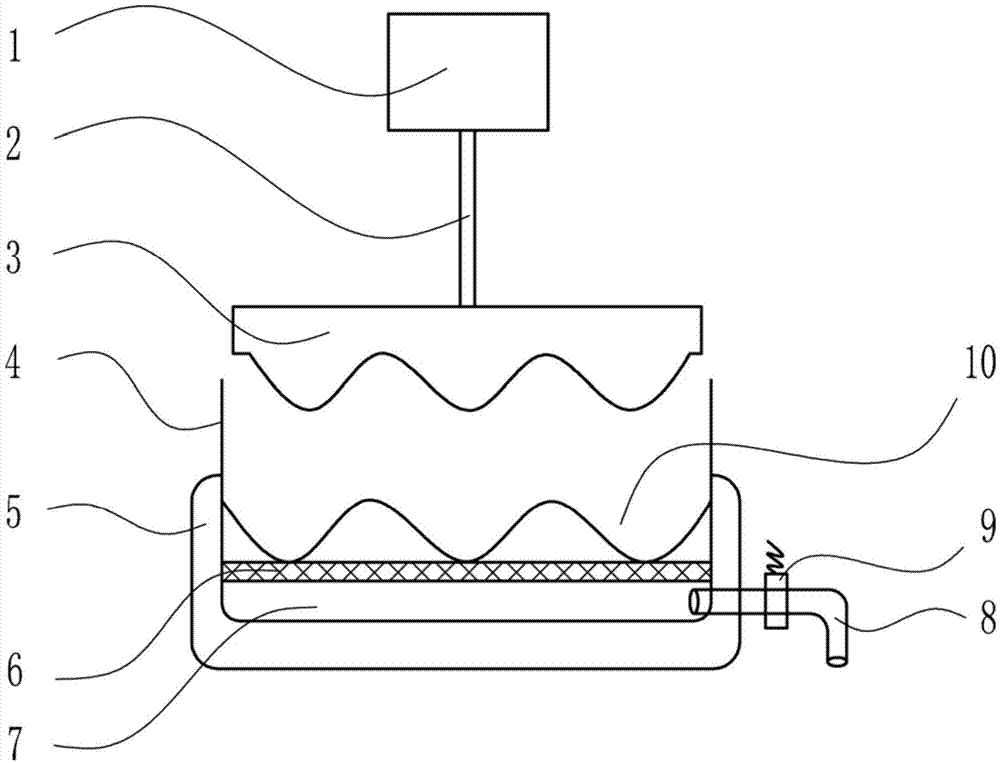

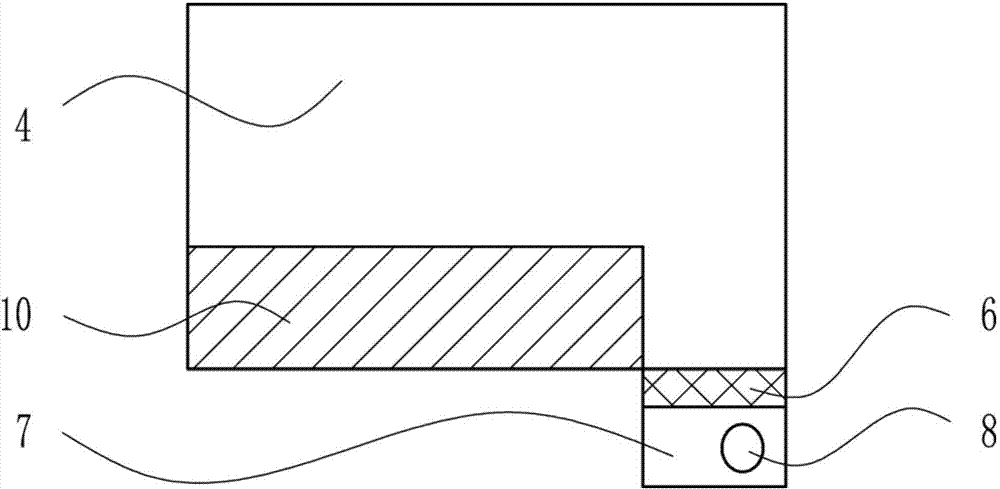

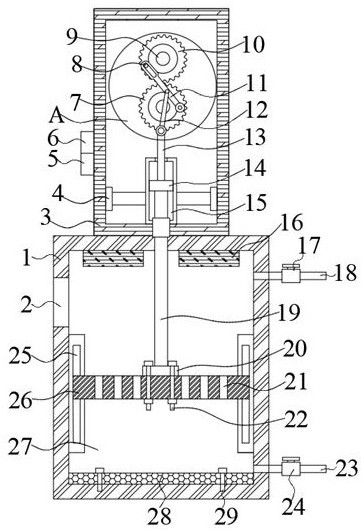

An immersion type traditional Chinese medicine liquid extraction device

InactiveCN104759115BHigh extraction purityImprove reaction efficiencySolid solvent extractionMedicineWater tanks

The invention relates to an extraction device, and particularly relates to an impregnation-type traditional Chinese medicine liquid extraction device. The invention aims at providing an impregnation-type traditional Chinese medicine liquid extraction device. The impregnation-type traditional Chinese medicine liquid extraction device comprises an upper air cylinder, a lower air cylinder, a waveform pressure head, a medicine pot, a water tank and a filter net; the upper air cylinder and the lower air cylinder are connected with a connecting rod; the connecting rod is connected with the waveform pressure head; the waveform pressure head is movably connected with the medicine pot; the medicine pot is provided with a waveform pot bottom, and the waveform pressure head is matched with the waveform pot bottom; a filter net and a front groove are arranged in front of the waveform pot bottom, the filter net is arranged above the front groove, and the filter net is connected with the front groove; and the height of the front groove corresponds to a valley position of the waveform pot bottom, and the position of the filter net corresponds to the valley position of the waveform pot bottom. According to the impregnation-type traditional Chinese medicine liquid extraction device, the bottom of the medicine pot is provided with the waveform pot bottom, so that the heat conduction efficiency can be improved, and the impregnation speed can be increased.

Owner:山西复盛公药业集团有限公司医药分公司

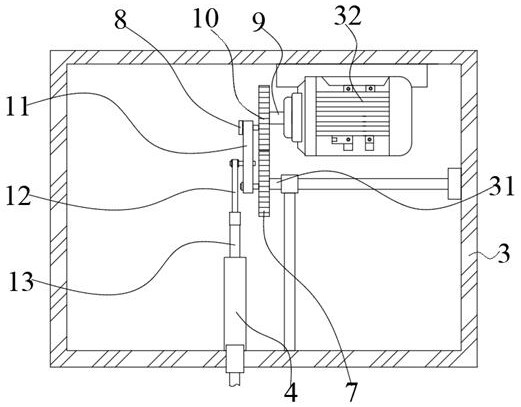

Production method of carbon fibers

PendingCN111826842AIncreased dipping speedSave sizing timeLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalElectric machineryWall plate

The invention relates to a production method of carbon fibers, and belongs to the technical field of carbon fiber production. A device comprises a power box, a partition plate, a push rod box, an electric push rod, a connecting sleeve, bearings, a transmission shaft, limiting rings, first grooves, first balls, first supporting plates, a second supporting plate, a driven gear, a limiting plate, second grooves, second balls, a top plate, side wall plates, filtrate holes, a bottom plate, a fixing cylinder, a supporting rod, a limiting block, a spring, a handle, a case, a first motor, a transmission rod, a driving gear, a flow gathering cylinder, a fan, a flow guide pipe, a heating box, heating wires, a short pipe, a transverse pipe, nozzles, a treatment box, a stop plate, a temperature control switch, sliding rails, a sliding door, a rack, a driving gear, supports, a driving shaft, a driven belt wheel, a transmission belt, a driving belt wheel, a second motor, a rack, supporting posts, aconveyor, a liquid storage barrel and discharging doors. Through rotation of the top plate, the side wall plates and the bottom plate, uniform sizing can be realized, and fast drying is also realized.

Owner:王康辉

Impregnation-type traditional Chinese medicine liquid extraction device

InactiveCN104759115AExtended service lifeImprove wear resistanceSolid solvent extractionTraditional medicineChinese herbology

The invention relates to an extraction device, and particularly relates to an impregnation-type traditional Chinese medicine liquid extraction device. The invention aims at providing an impregnation-type traditional Chinese medicine liquid extraction device. The impregnation-type traditional Chinese medicine liquid extraction device comprises an upper air cylinder, a lower air cylinder, a waveform pressure head, a medicine pot, a water tank and a filter net; the upper air cylinder and the lower air cylinder are connected with a connecting rod; the connecting rod is connected with the waveform pressure head; the waveform pressure head is movably connected with the medicine pot; the medicine pot is provided with a waveform pot bottom, and the waveform pressure head is matched with the waveform pot bottom; a filter net and a front groove are arranged in front of the waveform pot bottom, the filter net is arranged above the front groove, and the filter net is connected with the front groove; and the height of the front groove corresponds to a valley position of the waveform pot bottom, and the position of the filter net corresponds to the valley position of the waveform pot bottom. According to the impregnation-type traditional Chinese medicine liquid extraction device, the bottom of the medicine pot is provided with the waveform pot bottom, so that the heat conduction efficiency can be improved, and the impregnation speed can be increased.

Owner:山西复盛公药业集团有限公司医药分公司

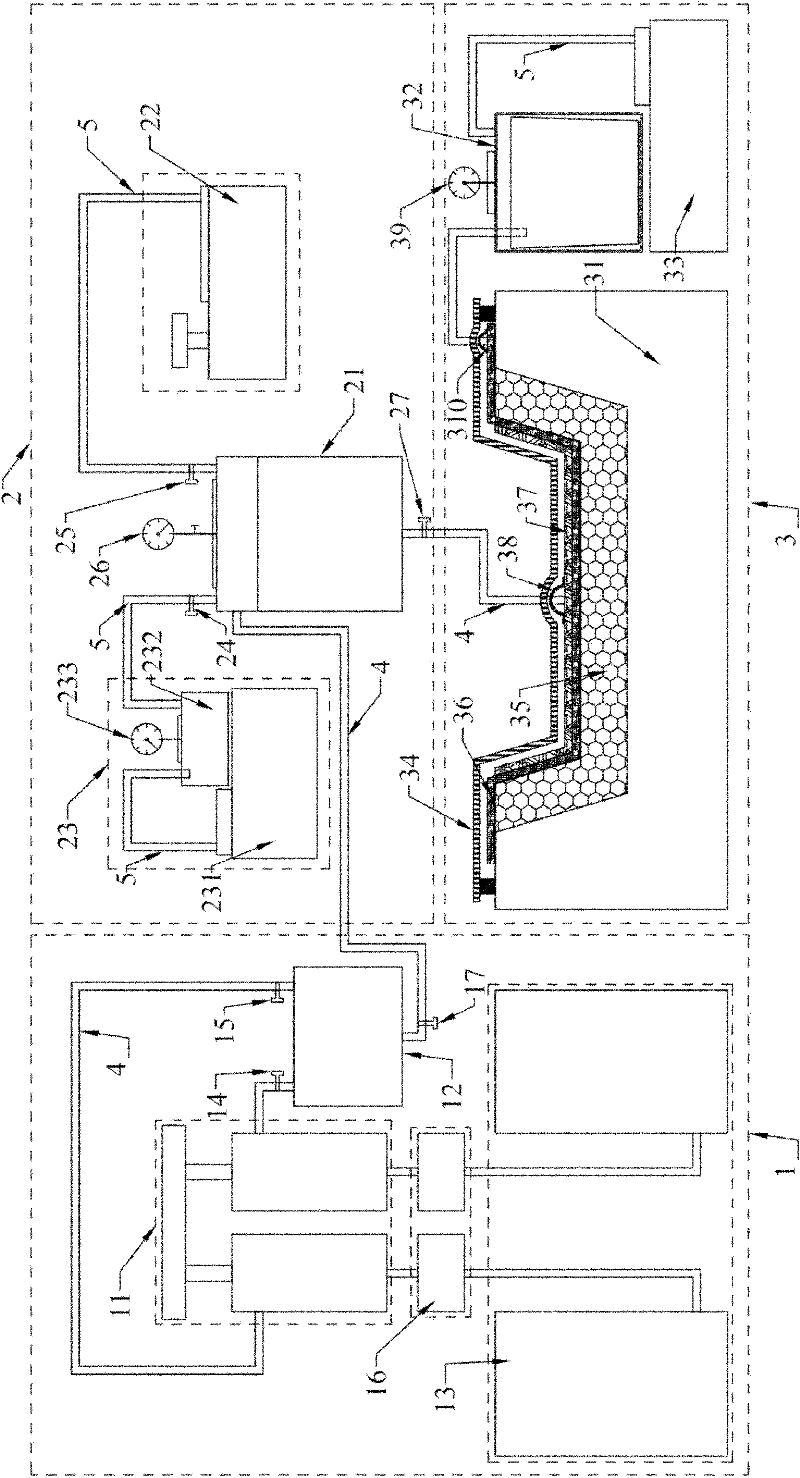

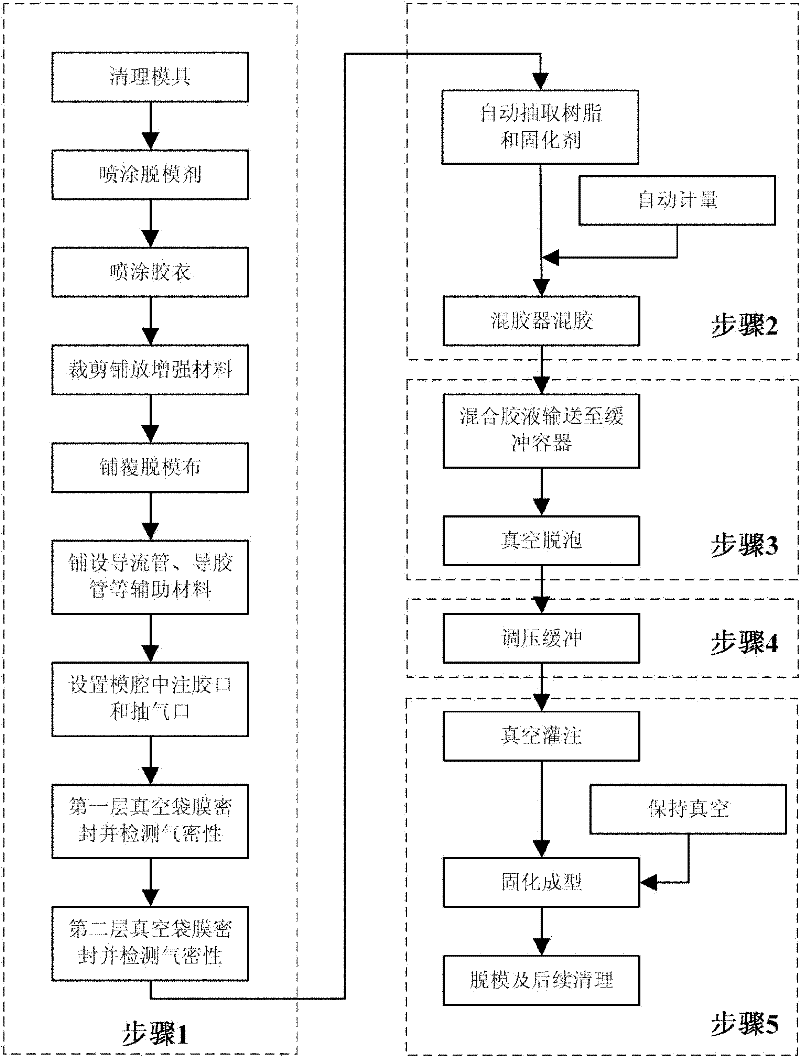

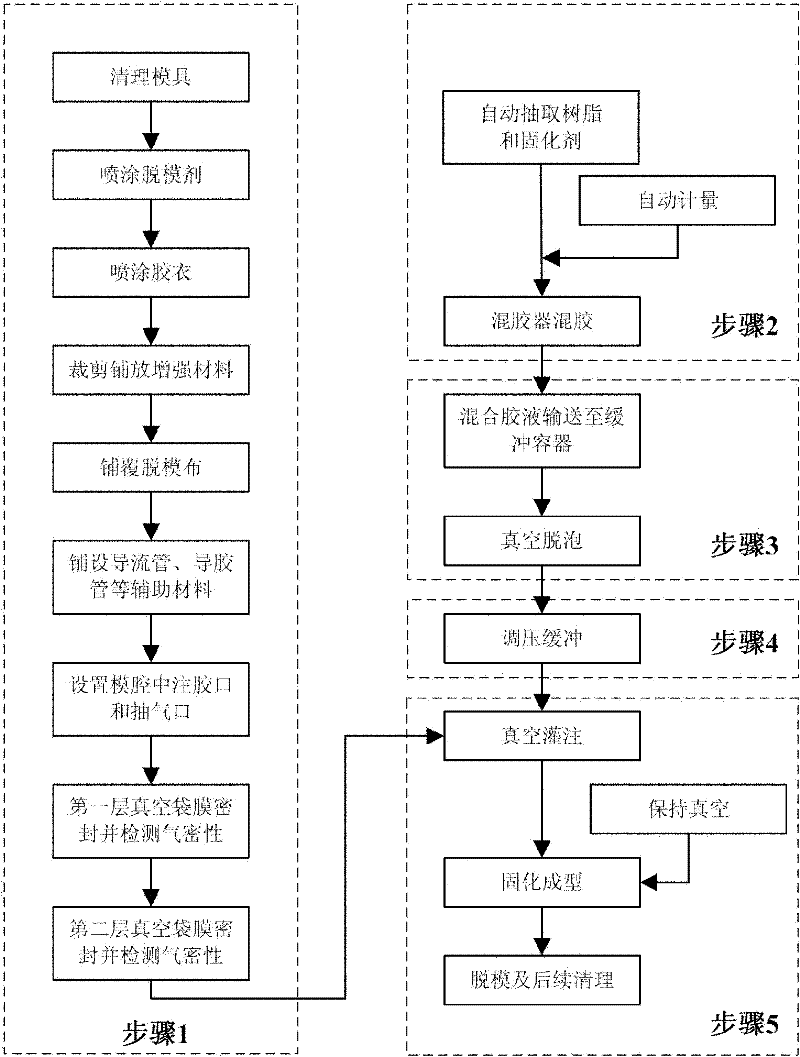

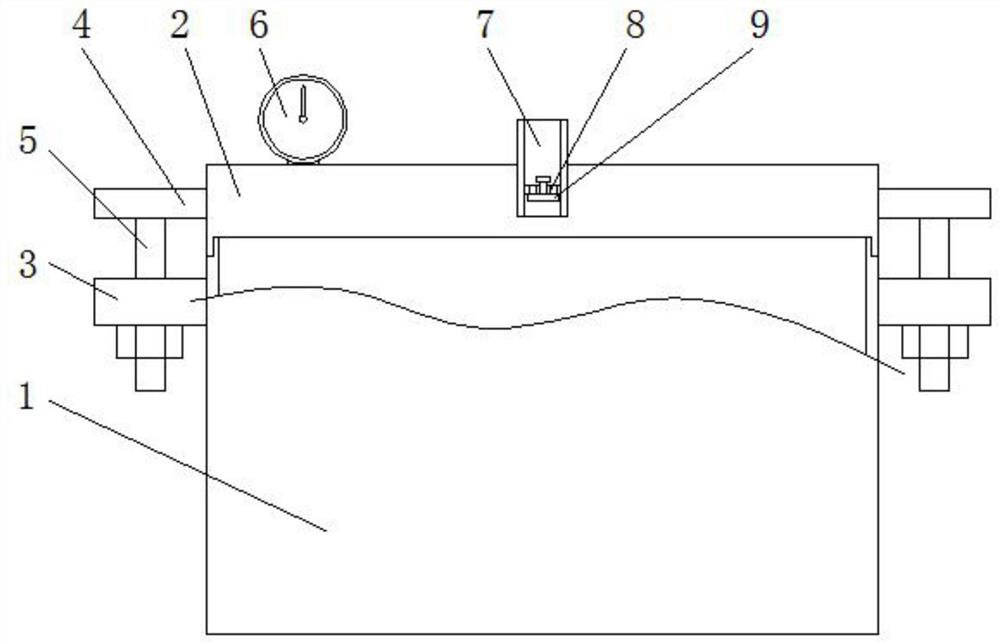

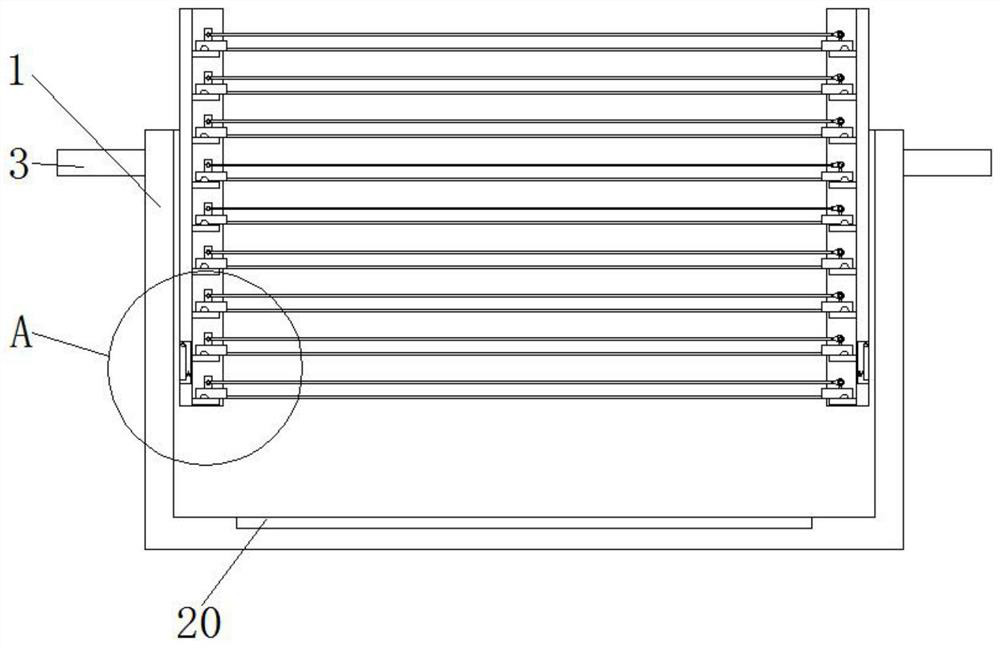

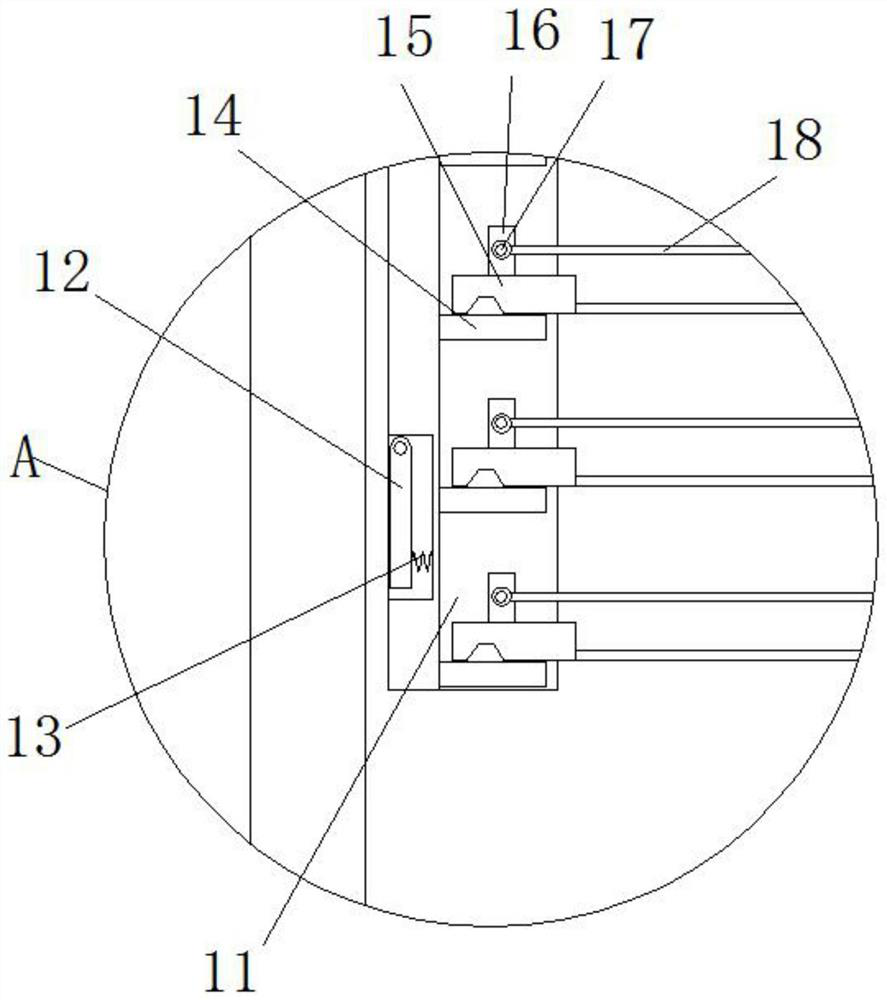

Integral molding technique and molding system for supersized composite material member

The present invention discloses an integral molding technique and molding system for a supersized composite material member. the integral molding technique includes five steps of vacuum bottling pretreatment, automatically mixing glue, vacuum defoamation, pressure regulating buffering and vacuum bottling, the corresponding molding system includes a automatic glue-mixing system, a debubbling pressure regulating buffering system and a vacuum bottling system. The debubbling pressure regulating buffering system includes a vacuum defoamation system, a pressure regulating pump and a buffering container, the automatic glue-mixing system and the vacuum bottling system are communicated with the buffering container through conveying tubes respectively, the vacuum defoamation system and the pressureregulating pump are communicated with the buffering container through air ducts respectively, each conveying tube and air duct are all provided with valves separately; the mixing glue solution after automatically mixing glue is injected to the buffering container and then is injected to a mould for the integral molding with dual pressures of a positive pressure and a vacuum negative pressure in the buffering container. The molding technique of the invention has advantages of raw material saving, high efficiency, strong serviceability, good product effect, safety, environment protection, etc.

Owner:NAT UNIV OF DEFENSE TECH

Straddle plate type peanut impregnator

PendingCN113100419AGuaranteed impregnation effectIncreased dipping speedFood shapingEngineeringStructural engineering

The invention relates to the technical field of peanut impregnation, in particular to a straddle plate type peanut impregnator, and solves the defects that peanut impregnation needs to consume a lot of time and peanuts cannot be in full contact with an impregnation solution. The straddle plate type peanut impregnator comprises an outer box body, a box cover is clamped at the top of the outer box body, insertion plates are welded on two sides of the outer box body, and connecting plates are welded on two sides of the box cover. The insertion plates are welded to the bottom of the connecting plates, a pressure gauge is installed on the upper surface of the box cover, an air nozzle is welded on the upper surface of the box cover, a partition plate is welded to the inner side of the air nozzle, a plug is clamped in the middle of the partition plate, a three-section rail is fixed to the inner side of the outer box body through screws, one side of the three-section rail is connected with the inner box body through screws, and the outer side of the inner box body is connected with a supporting plate through a rotating shaft; springs are welded to one sides of the supporting plates, bottom plates are welded to the interiors of the two sides of the inner box body, and storage baskets are clamped to the tops of the bottom plates, peanuts are fixed in a layered mode and soaked, the peanuts make complete contact with the soaking solution, and the peanut soaking effect is guaranteed.

Owner:青岛宝芝泉精密机械制造有限公司

A kind of preparation method of metal-ceramic composite material

The invention discloses a preparation method of a cermet composite material. The method includes: (1) sequentially crushing the foamed SiC ceramics according to the procedures of primary crushing, secondary crushing and tertiary crushing, ultrasonic cleaning, and drying to obtain an ellipsoidal SiC ceramic block with a size of 2 mm-15 mm; (2) Pre-oxidize and pre-corrode the ellipsoidal SiC ceramic block obtained in step (1), and obtain a foamed SiC ceramic reinforcement after cleaning, (3) mix the foamed SiC ceramic reinforcement obtained in step (2) with metal, and put it into a mold , under nitrogen atmosphere, heating and applying pressure, lowering the temperature, solidifying, demolding, and polishing to obtain the metal-ceramic composite material.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

A kind of debittering Shatian pomelo peel and its production method and application

ActiveCN103976313BIncreased dipping speedShorten the soaking timeFood scienceFood safetyBitter taste

The invention relates to the field of foods and discloses a bitter taste-free Shatian pomelo peel and its production method and use. The production method comprises the following steps of preparing a Shatian pomelo peel bitter taste removal liquid from tea, putting Shatian pomelo peel and the Shatian pomelo peel bitter taste removal liquid into a vacuum impregnation tank together, carrying out vacuum impregnation for 3-5h, carrying out dehydration, carrying out immersion again, and repeating the above processes multiple times until a bitter taste is removed. The production method utilizes natural tea extract as a bitter taste removal agent, is green, does not contain an additive, is safe and healthy, has obvious effects, satisfies food safety requirements, retains a Shatian pomelo nutrition value on the premise of Shatian pomelo bitter taste removal and is suitable for industrial production.

Owner:广西容县锦香食品有限公司

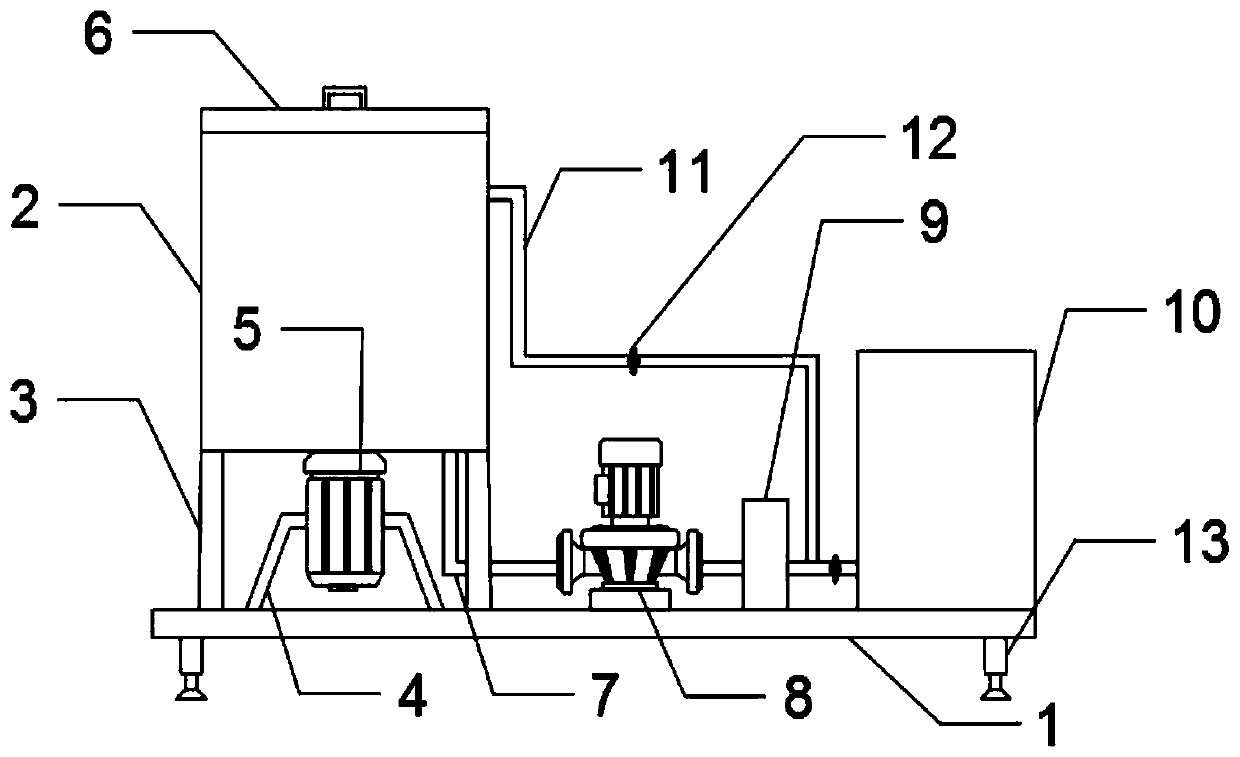

Full automatic vacuum impregnation device

PendingCN110742292ARealize automatic openingRealize automatic feeding processFood treatmentInlet valveEngineering

The invention relates to a full automatic vacuum impregnation device. The full automatic vacuum impregnation device comprises a vacuum impregnation tank, wherein a feeding door is arranged at the topof the tank; a material outlet valve is arranged at the bottom of the tank; a vacuumizing pipe opening, an atmosphere communicating pipe and an impregnation liquid inlet are also formed / arranged in / atthe top of the tank; a negative pressure sensor and a liquid level sensor are also mounted in the tank; an impregnation liquid tank is arranged below the discharging opening; a conveyer belt is arranged in the impregnation liquid tank; a draining opening is formed in the bottom of the impregnation liquid tank; an impregnation liquid conveying pipeline is arranged between the draining opening andthe impregnation liquid inlet; and a sanitary pump and a liquid inlet valve are mounted on the impregnation liquid conveying pipeline. Through the adoption of the full automatic vacuum impregnation device disclosed by the invention, the feeding door can be automatically opened, so thatautomatic charging, automatic discharging and automatic impregnation liquid injecting can be realized; the impregnation speed is increased through vacuumizing with the vacuum pump, so that the production speed of products is increased, and the working efficiency is improved; and labor is not needed to participatein the whole impregnation working procedure, so that the automation degree is high, and labor cost is saved.

Owner:诸城市中远机械有限公司

Special impregnation equipment and impregnation process for pvc negative ion antibacterial gloves

ActiveCN105922484BShorten the soaking timeIncreased dipping speedDomestic articlesCoatingsEngineeringSlurry

The invention discloses special dipping equipment for PVC negative ion antibacterial gloves, relates to the field of gloves manufacturing, and is used for solving the problem that traditional PVC gloves have no bacterial resisting and bacterial killing capacity. The equipment comprises a slurry tank, and a guide groove positioned in the outer circle of the slurry tank; the slurry tank includes a dipping pool, a precipitating pool positioned below the dipping pool, a separation plate, a feed channel and a discharge channel; support frames for supporting the slurry tank are arranged on two sides of the slurry tank; the separation plate is positioned between the dipping pool and the precipitating pool, and is embedded with a filter bag; the guide groove is annular; a conveying belt and a driving motor for driving the conveying belt to act are arranged in the guide groove; the back end of the conveying belt is higher than the front end; and the driving motor controls the conveying belt to circularly act. The equipment performs dipping through flowing of latex slurry, and gives the bacterial resisting and bacterial killing capacity to the PVC gloves. The invention further discloses a dipping process of the special dipping equipment for the PVC negative ion antibacterial gloves.

Owner:淄博鸿烨上勤医疗科技有限公司

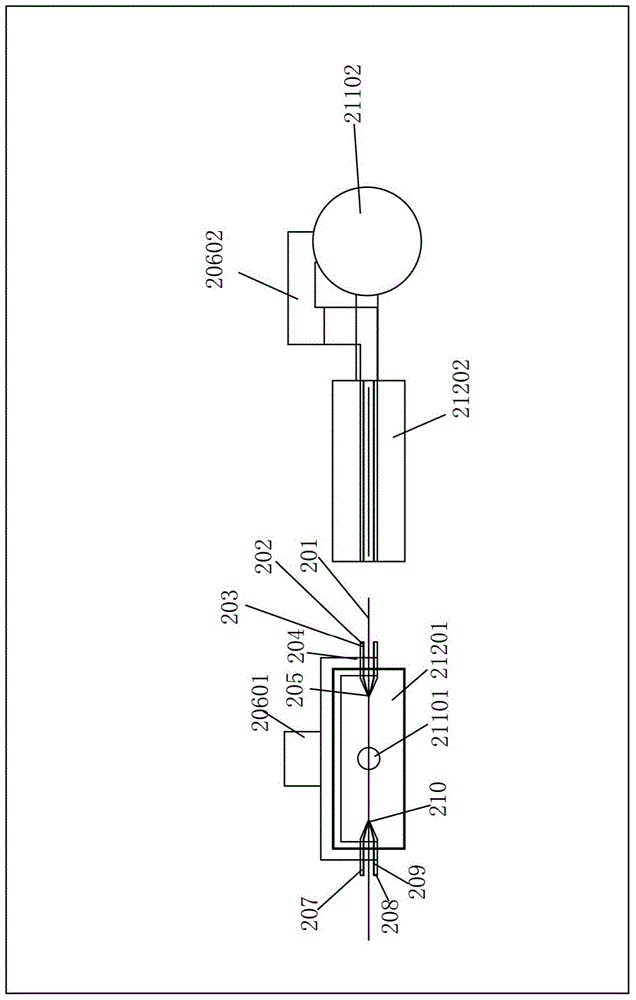

A method and device for continuous impregnation of materials

ActiveCN103639094BImproving the quality of impregnationIncreased dipping speedLiquid surface applicatorsCoatingsPositive pressureMaterials science

The invention provides a method for continuous impregnation of materials. The method comprises the following steps: material conveying; material impregnation; material drying; material shearing; and material winding including positive pressure treatment and / or negative pressure treatment. The invention also provides a device for the material continuous impregnation method. The device includes a material conveying device, a negative pressure device, a dipping device, a drying device, a cutting device and a winding device, and the devices are connected in sequence. The material dipping device or the back thereof is provided with a positive pressure device and or the negative pressure device, so that various materials especially thick or special materials contain less air bubbles after impregnation and has better effect. The device achieves continuous vacuum impregnation and dyeing of various materials and has the advantage of no hurt to the materials. A complete casing design realizes the processes of material dipping, liquid immersion, paraffin immersion and double-side dyeing soaking without opening the casing.

Owner:向明强

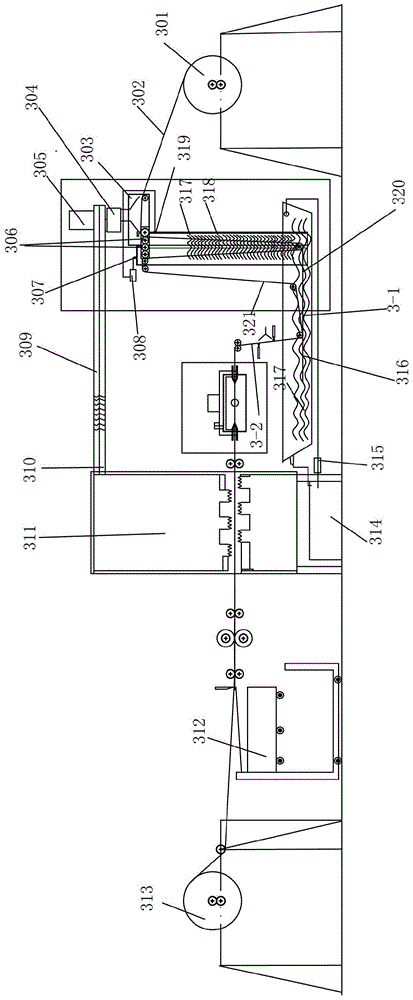

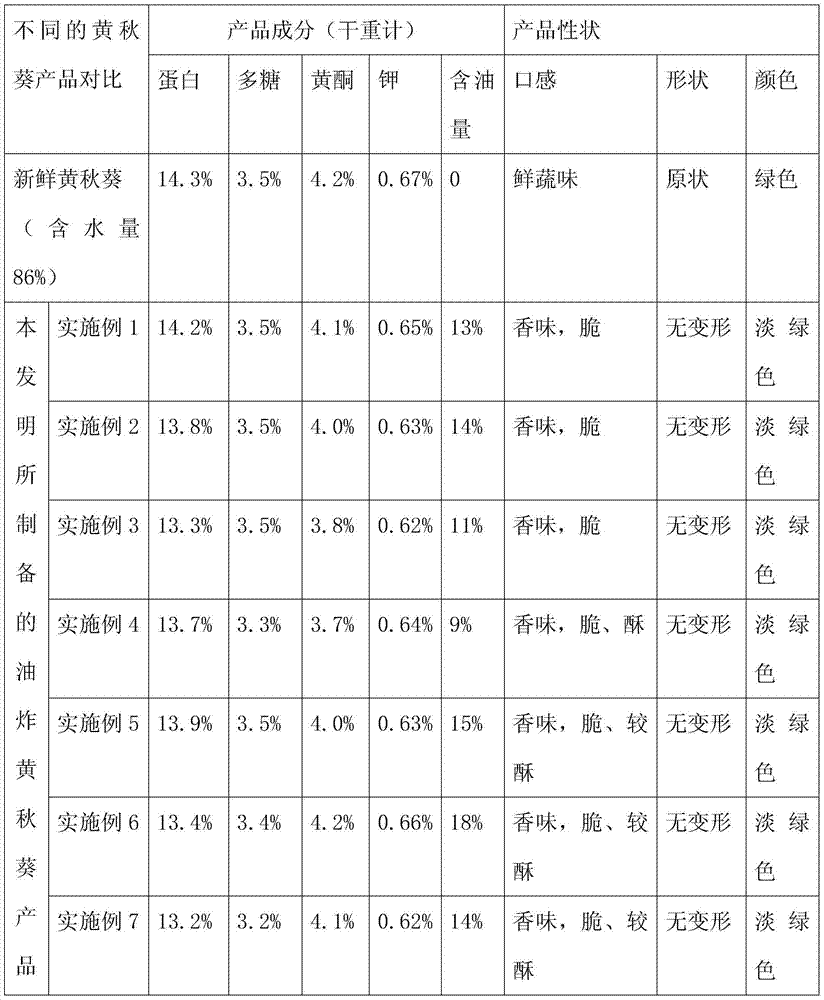

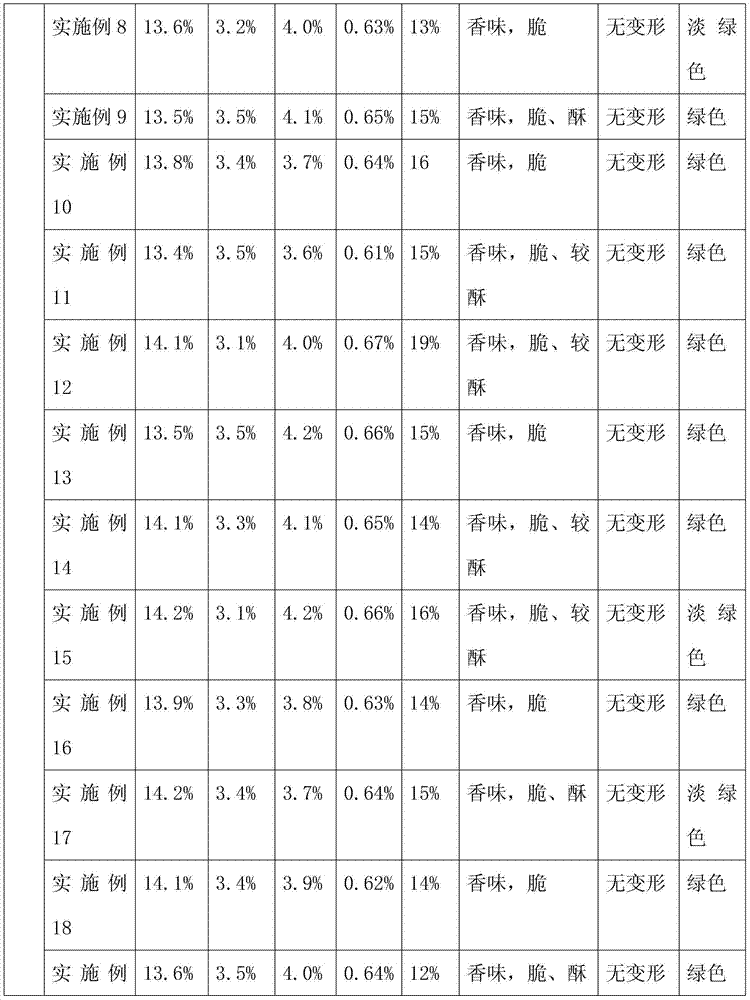

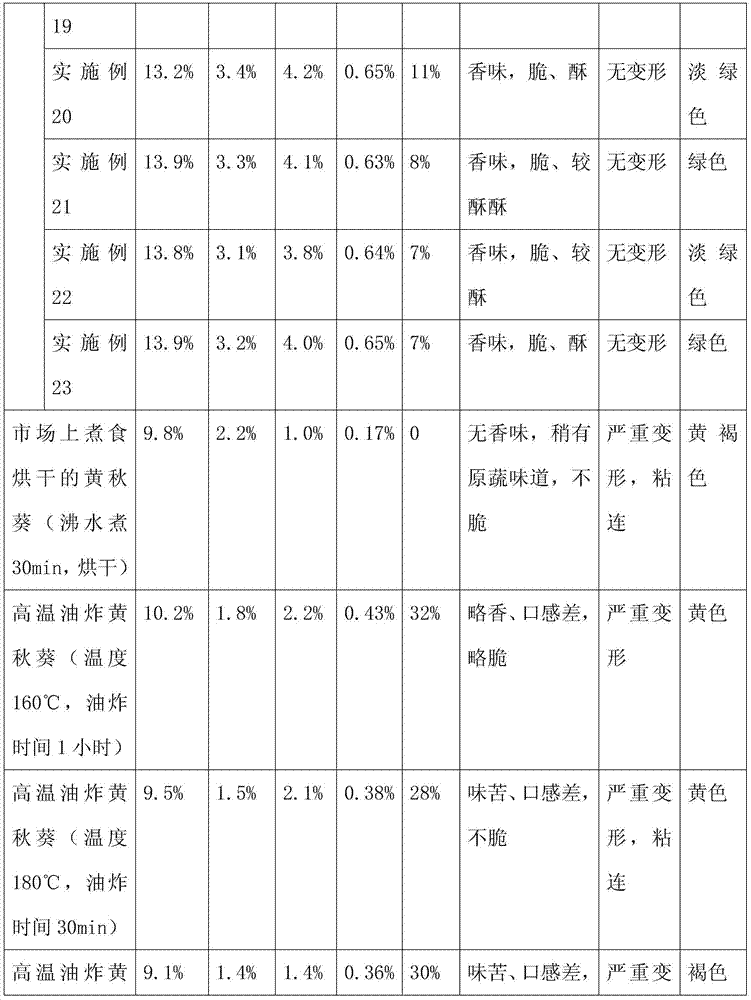

A production process of vacuum low-temperature frying okra with different flavors

ActiveCN103919074BSignificant positive effectReduce deformationFood freezingFood thermal treatmentFlavorFood item

The invention discloses a production process for frying abelmoschus esculentus with different tastes at low temperature in vacuum. The production process comprises the following steps: blanching washed abelmoschus esculentus in hot water; cooling and putting the abelmoschus esculentus into an instant freezer to be instantly frozen; putting the frozen abelmoschus esculentus into a seasoning solution to be immersed in vacuum; leaching and putting the abelmoschus esculentus into the instant freezer to be instantly frozen; carrying out vacuum low-temperature frying on the frozen abelmoschus esculentus; centrifuging and removing oil to obtain a product. The instant abelmoschus esculentus food prepared by the invention keeps the color, aroma, taste and nutritional components of the abelmoschus esculentus; meanwhile, the fried abelmoschus esculentus with different tastes are prepared and are suitable for different crowds including children, youngsters, middle-aged and aged people, diabetes mellitus patients and the like.

Owner:LAIYANG HENGRUN FOODSTUFF

Resin impregnation and curing device

ActiveCN107617537ARealize continuous operationDip curing effect is stableLiquid surface applicatorsCoatingsCooking & bakingAutomatic control

The invention discloses a resin impregnation and curing device. The resin impregnation and curing device comprises an impregnation device, a curing device, a conveying device and a fixing device. Theconveying device comprises a transfer bar, a motor and a conveying medium. The fixing device comprises a clamping device used for fixing workpieces and a connecting rod. The connecting rod and the transfer bar are in sliding connection through the conveying medium. The conveying device moves the fixing device in a sliding mode and further controls ascending, descending and the stop position of theclamping device through the connecting rod. The resin impregnation and curing device is simple in structure and reasonable in design, continuous operation of three main working procedures including resin pre-baking, impregnation and curing is realized, automatic control over the impregnation speed, lifting speed, curing time and test sample or motor winding turnover is achieved, the resin impregnation and curing effect is stable, the insulation life of test samples or motor windings is prolonged, and the resin insulation testing effect consistency is improved. Moreover, the resin impregnationand curing device is convenient to operate, manpower and material resources are greatly saved, and working efficiency is improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

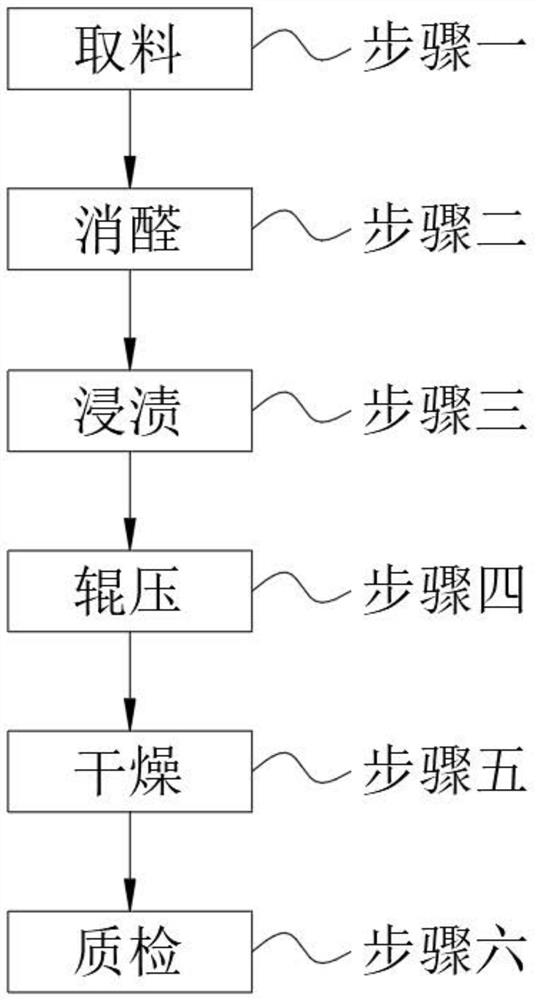

Resin-impregnated functionalized wood and processing technology

ActiveCN113414851ASpread evenlyLow free formaldehyde contentWood treatment detailsPressure impregnationPulp and paper industryWater soluble

The invention discloses resin-impregnated functionalized wood and a processing technology. The formula comprises finished wood, water-soluble low-molecular-weight phenolic resin, a defoaming agent, a formaldehyde eliminating agent, a dispersing agent, a coupling agent, an insect-resist agent and a curing agent. The weight parts of the components are as follows, 82-90 parts of the finished wood, 40-48 parts of the water-soluble low-molecular-weight phenolic resin, 1-3 parts of the defoaming agent, 5-9 parts of the formaldehyde eliminating agent, 2-4 parts of the dispersing agent, 1-3 parts of the coupling agent, 6-10 parts of the insect-resist agent and 1-3 parts of the curing agent. According to the processing technology, redundant gas in wood pores is thoroughly removed through ultrasonic impregnation and vacuum rolling, the impregnation speed of resin is increased, diffusion is uniform, reaction is sufficient, the wood modification time is shortened, the functional improvement effect of the wood is improved, formaldehyde removal treatment is conducted on the resin, the body health of personnel is guaranteed, pollution to the environment is reduced, and the diffusion degree of the resin in the wood pores is ensured.

Owner:A ZENITH HOME FURNISHINGS CO LTD

A resin impregnation curing device

ActiveCN107617537BRealize continuous operationDip curing effect is stableLiquid surface applicatorsCoatingsAutomatic controlTest sample

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

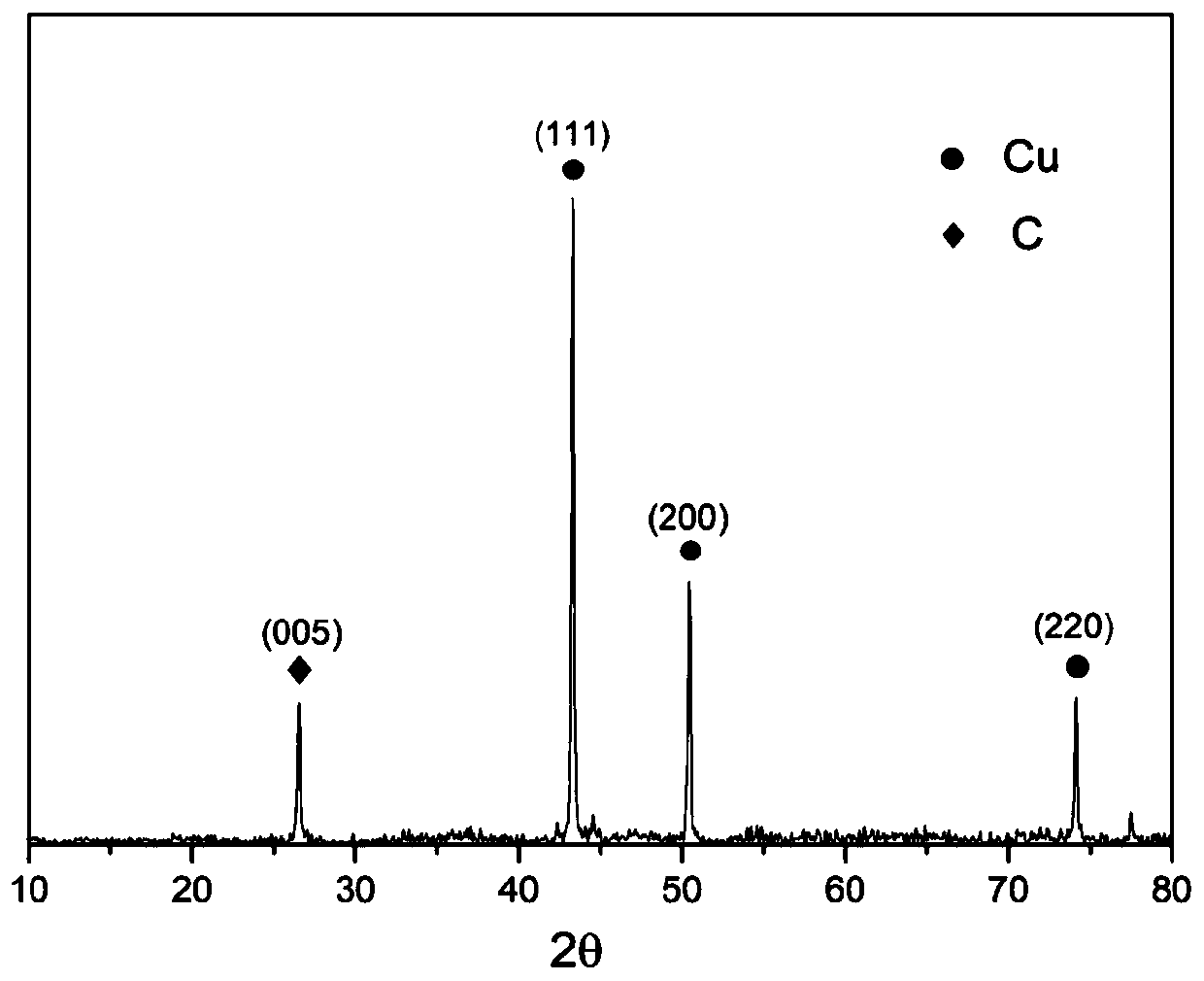

A kind of preparation method of copper-graphite-polytetrafluoroethylene composite material

ActiveCN109762282BReduce coefficient of frictionExtended service lifeTetrafluoroethyleneGraphite substrate

The invention discloses a preparation method of a copper-graphite-polytetrafluoroethylene composite material, and belongs to the technical field of powder metallurgy. The preparation method comprisesthe following steps: (1) a copper graphite substrate is prepared; (2) the copper graphite substrate is sequentially put into acetone and absolute ethyl alcohol for ultrasonic treatment, and after drying, a pretreated copper graphite substrate is obtained; (3) under the high temperature and high pressure, the pretreated copper graphite substrate is immersed into a polytetrafluoroethylene dispersionliquid; and (4) the immersed copper graphite substrate is plasticized at the high temperature, and the copper-graphite-polytetrafluoroethylene composite material is obtained. A polytetrafluoroethylene immersed layer can protect the copper graphite substrate against being corroded and oxidized at the room temperature and in a working state, due to the abrasion resistance and self-lubrication characteristics of polytetrafluoroethylene, a friction coefficient between contact surfaces during workpiece working can be decreased, the abrasion loss is reduced, and the service life of a workpiece is prolonged. The immersing speed of the polytetrafluoroethylene can be increased through high-temperature and high-pressure immersing, multi-time immersing is not needed, one-step in place is achieved, the preparation cycle is shortened, and the production efficiency is improved.

Owner:CENT SOUTH UNIV

pvc negative ion antibacterial gloves and its production process

The invention discloses a PVC (polyvinyl chloride) negative ion antibacterial glove, relates to the field of glove manufacturing and aims at solving the problem that existing PVC gloves don't have capability of resisting and killing bacteria. The PVC negative ion antibacterial glove is composed of 100 parts of PVC paste resin, 70-78 parts of plasticizer, 25-55 parts of viscosity reducer, 1-2 parts of stabilizer, 3 parts of colorant and treatment liquid with 4-5% of negative ions. By adding the treatment liquid with 4-5% of negative ions, the PVC glove is endowed with capability of resisting and killing bacteria. The invention further discloses a manufacturing process of the PVC negative ion antibacterial glove.

Owner:淄博鸿烨上勤医疗科技有限公司

A kind of solid capacitor impregnation method

ActiveCN110364362BEasy accessIncreased dipping speedSolid electrolytic capacitorsDrying/impregnating machinesPhysical chemistryEngineering

The invention discloses a method for impregnating a solid capacitor, comprising the following steps: (1) suspending the element, and dry vacuuming for 5 to 10 seconds to make the vacuum degree negative; ~20s, the degree of vacuum is negative pressure, and the degree of vacuum is equal to the degree of vacuum in step (1); (3) keep the elements in the impregnation solution, and deflate to normal pressure; (4) the above steps (1)~( 3) It is one cycle; execute this cycle at least twice, and the vacuum degree of vacuum impregnation gradually increases during multiple cycles; (5) Suspend the element in the air, dry vacuum, the vacuum degree is negative pressure, and the vacuum degree is greater than the above any degree of vacuum. The solid capacitor of the invention reduces the impregnation time and improves the impregnation effect; the center of the element can be thoroughly impregnated.

Owner:ZHAOQING BERYL ELECTRONICS TECH

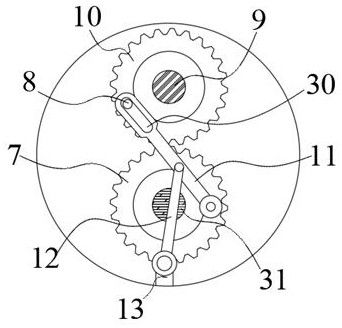

Activated carbon dipping tank with microwave enhanced heating

PendingCN111926479AIncreased dipping speedHigh speedSolid sorbent liquid separationTextile treatment machine arrangementsActivated carbonRotational axis

The invention discloses an activated carbon dipping tank with microwave enhanced heating. The activated carbon dipping tank comprises a dipping box, the upper surface of the dipping box is fixedly connected with a driving box, the inner wall of the top face of the driving box is provided with a motor, the outer wall of the left side of the motor is slidably connected with one end of a rotating shaft, and the other end of the rotating shaft is fixedly connected with the inner side wall of a gear A, the outer wall of the left side of the gear A is connected with a connection shaft, and the outersurface of the connection shaft is slidably connected with the inner side wall of a connection hole arranged in one end of a connection rod A. According to the activated carbon dipping tank with themicrowave enhanced heating, by means of the manner that the motor runs to drive the rotating shaft to rotate, a sliding block can be driven to slide along a sliding groove under coordination rotatingof the gear A and a gear B, and then a supporting shaft and a horizontal plate can be driven to perform vertical moving, the fact that cloth materials inside the dipping tank can be stirred back and forth is realized, meanwhile, water flow inside the dipping tank can be heated in coordination with running of microwave generators, improvement of the cloth material dipping speed and dipping efficiency is realized, and the activated carbon dipping tank with the microwave enhanced heating is suitable for being widely popularized and used.

Owner:贵州省万山银河化工有限责任公司

Active carbon fiber pretreatment reactor

InactiveCN111424338AIncreased dipping speedIncrease profitTextile treatment machine arrangementsFibre chemical featuresFiberCarbon fibers

The invention discloses an active carbon fiber pretreatment reactor, and belongs to the technical field of active carbon fiber pretreatment equipment. The active carbon fiber pretreatment reactor comprises a pedestal. A pretreatment reaction tank is arranged above the pedestal. A pretreatment reaction rotating stand is arranged inside the pretreatment reaction tank. A plurality of net cages are arranged inside the pretreatment reaction rotating stand. An acceleration motor is arranged at the lower end of the pretreatment reaction tank. A circulating pipeline connected with the pretreatment reaction tank is arranged on the right side of the acceleration motor. One end of the circulating pipeline is connected with a circulating pump, and the right end of the circulating pump is connected with a filter tank through a circulating pipeline. The right end of the filter tank is connected with a storage tank and a reflux pipeline. According to the active carbon fiber pretreatment reactor disclosed by the invention, the dipping speed is increased through the pretreatment reaction rotating stand, the circulating pump and the filter tank are used for cycling filtration of pretreatment liquid,and hence the purposes of shortening the dipping time and increasing the utilization rate of the pretreatment liquid are achieved.

Owner:安徽欣冉碳纤维环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com