Salted egg pickling system and pickling process

A salted egg and process technology, applied in the field of salted egg pickling system, can solve the problems of inaccurate control of parameters, lack of safe production, long salted egg pickling cycle, etc., to achieve a suitable pickling environment, faster dipping speed, The effect of improving the quality of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below through specific examples.

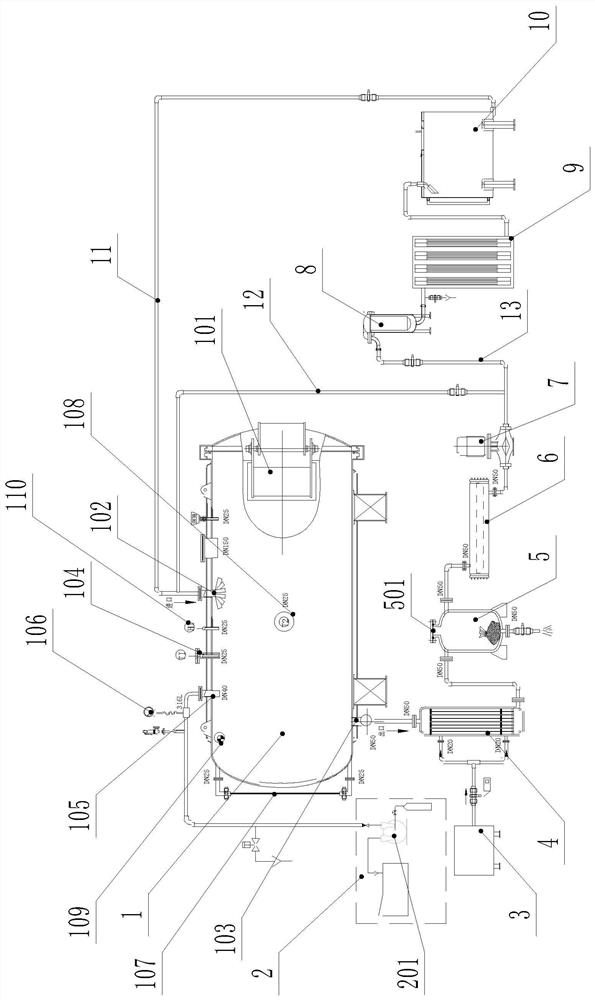

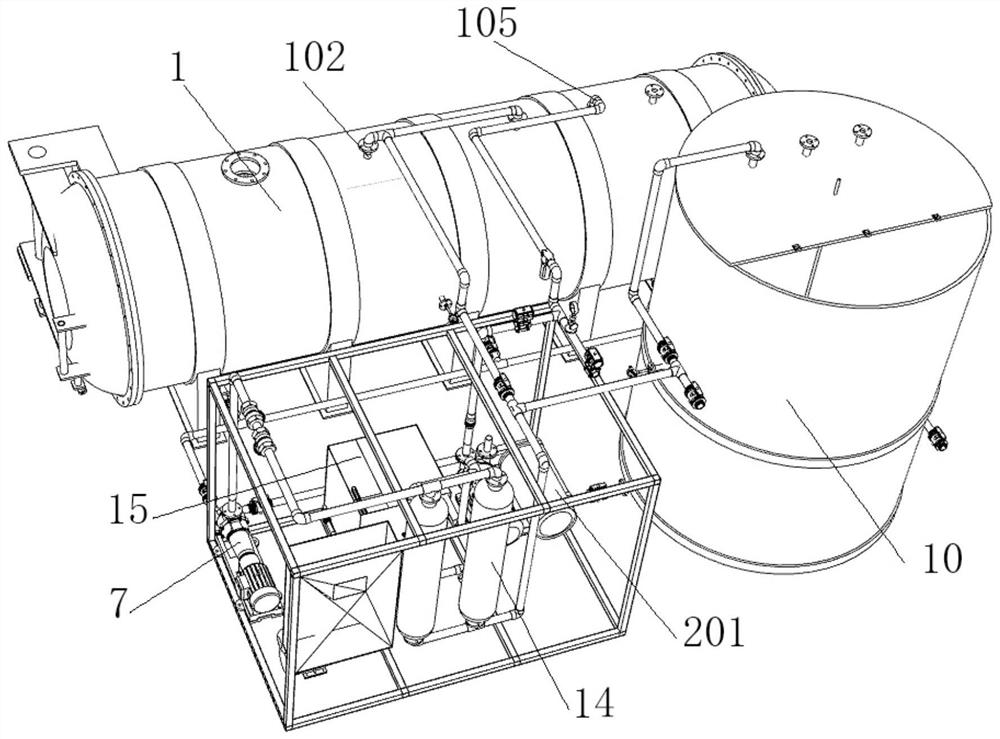

[0037] Such as figure 1 Shown, a kind of salted egg pickling system comprises

[0038] Pickling cylinder 1, described curing cylinder 1 comprises cylinder body and the cylinder head 101 that opening and closing is installed in the opening of cylinder body, described cylinder body and cylinder head 101 are all made of glass fiber reinforced plastics made of PPH, uniformly distributed in the cylinder body Reinforcing ribs to avoid deformation under transportation and vacuum conditions, good anti-corrosion performance, high strength, good thermal insulation and anti-aging performance, the rear head of the cylinder body and the tank door adopt a double-layer structure, the outer side is a blunt arc structure, and the inner side is a blunt arc structure. It is a flat cross-section with a hole in the upper part. It is pressurized by the blunt arc structure, and the brine is restricte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com