Patents

Literature

35results about How to "Guaranteed impregnation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving high-temperature performance of alumina-base ceramic core

InactiveCN101955353AHigh apparent porosityGuaranteed impregnation effectTurbine bladeRoom temperature

The invention discloses a method for improving the high-temperature performance of an alumina-base ceramic core, which comprises the following steps of: firstly, preparing an alumina-base ceramic core blank by adopting a gel casting molding process; secondly, preparing an alumina-base ceramic core prefabricated body with a plurality of holes and certain room-temperature anti-bending strength by freezing, drying and pre-sintering; thirdly, allowing penetrating fluid to seep into the alumina-base ceramic core prefabricated body under the conditions of vacuum and external pressure, drying, removing gel and soaking under vacuum and at pressure for three times; and finally, sintering at a high temperature to obtain the required alumina-base ceramic core. The alumina-base ceramic core prepared by the invention has high high-temperature performance and high core-removing property, can meet the process requirements of a hollow turbine blade on directional casting and single-crystal casting and guarantees the qualification rate of blade castings.

Owner:XI AN JIAOTONG UNIV +1

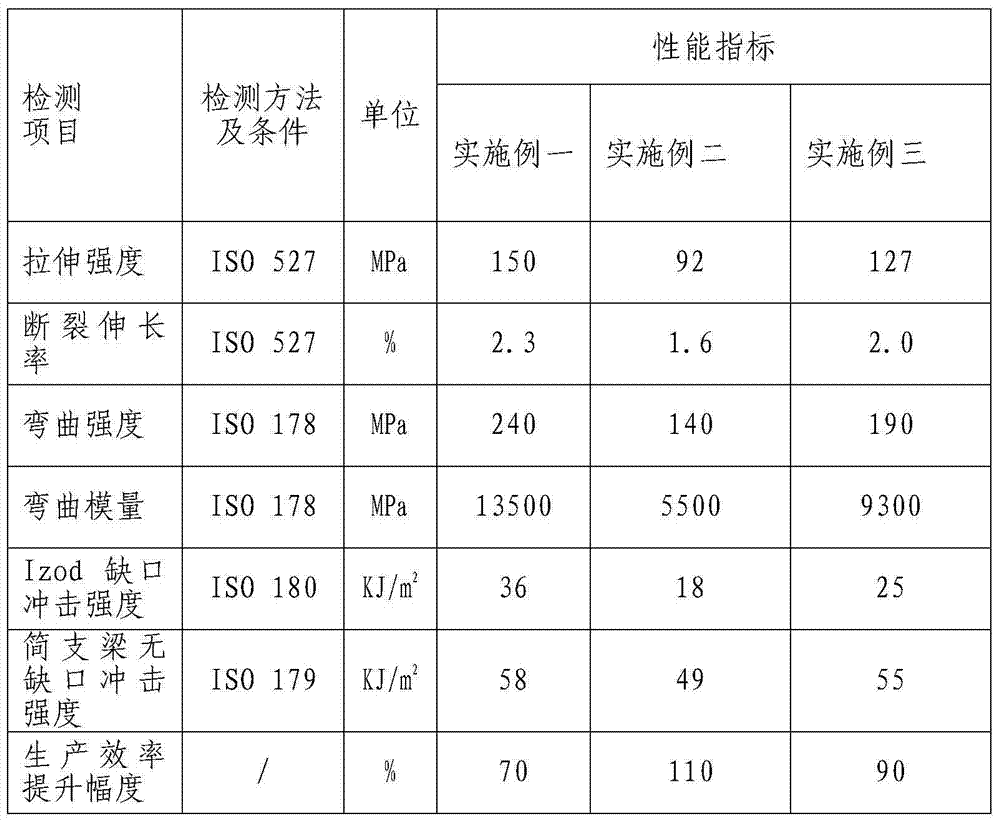

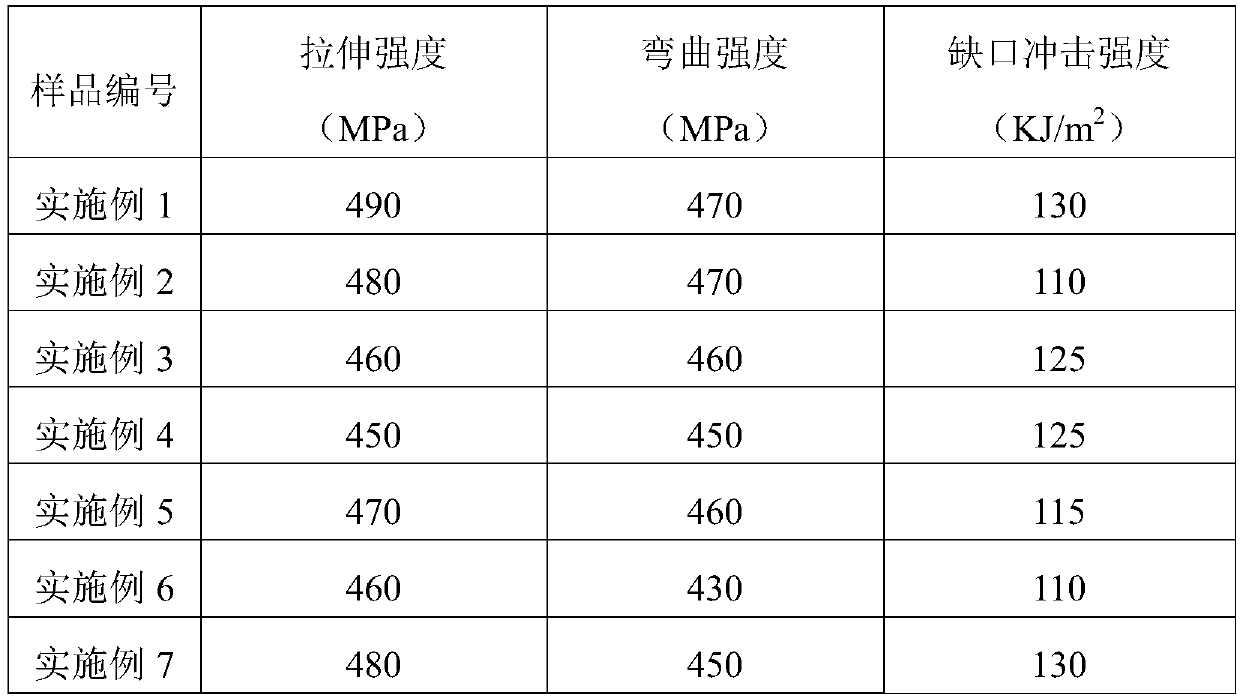

Long glass fiber reinforced polypropylene material adopting foaming technique and preparation method thereof

The invention relates to a material and a preparation method thereof, and particularly relates to a long glass fiber reinforced polypropylene material adopting a foaming technique and a preparation method thereof, belonging to the technical field of materials. The long glass fiber reinforced polypropylene material comprises the following components by mass percent: 30-75wt% of polypropylene, 20-60wt% of long glass fiber, 0.5-5wt% of chemical foaming agent and 1-5wt% of compatibilizer. The viscosity of the resin is further reduced by adopting a micro-foaming technology, meanwhile, the chance that a glass fiber strong dispersing device reduces or avoids direct contact of a glass fiber bundle and a roller or a convex part is reduced, the damage to the glass fiber is reduced, and the traction resistance of a material bar is reduced. The long glass fiber reinforced polypropylene material has the beneficial effects that the product performance, quality stability and production efficiency are improved when the impregnation effect on the glass fiber caused by polypropylene resin is ensured.

Owner:NANJING JULONG SCI&TECH CO LTD

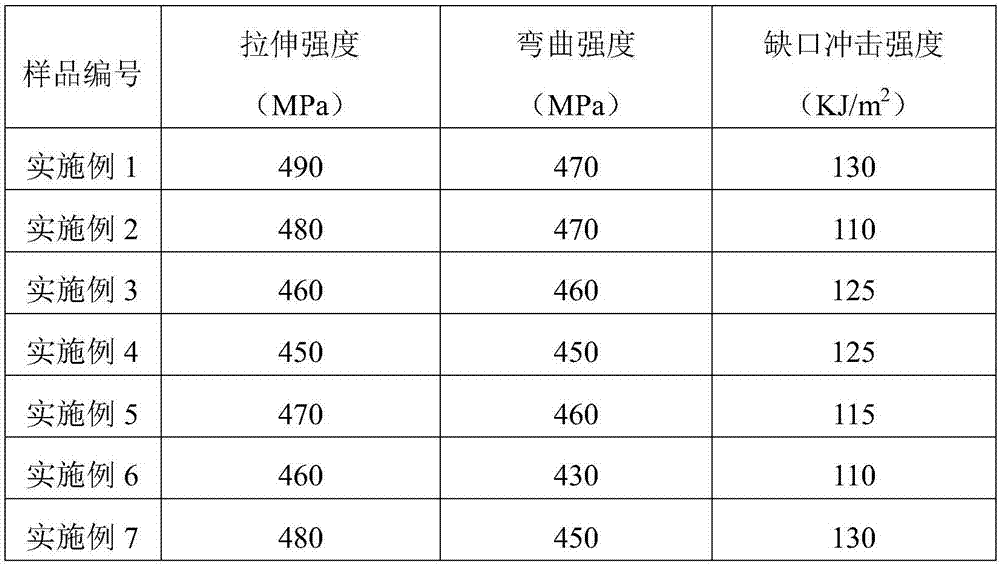

Preparation method of continuous fiber reinforced nylon-6 composite material

The invention discloses a preparation method of a continuous fiber reinforced nylon-6 composite material, which comprises the following steps: (1) separately storing caprolactam molten masses containing a catalyst and a catalyst promoter in a constant-temperature constant-speed liquid feeding tank; (2) placing a continuous fabric in a mold of an injection molding machine; (3) starting the injection molding machine and a constant-temperature liquid feeding device separately, adding the caprolactam molten masses containing the catalyst and the catalyst promoter into the feeding hole of the injection molding machine through the liquid feeding device at a same temperature and a same speed, mixing and injecting in the mold injection machine, and injecting the caprolactam molten masses containing the catalyst and the catalyst promoter into the mold paved with the continuous fabric; and (4) initiating caprolactam negative ring-opening polymerization in the mold. The preparation method disclosed by the invention can effectively prevent caprolactam from polymerization before entering the mold, so as to ensure good impregnation of fiber and caprolactam to obtain the continuous fiber reinforced nylon-6 composite material with more excellent mechanical properties.

Owner:江苏易元新材料科技有限公司

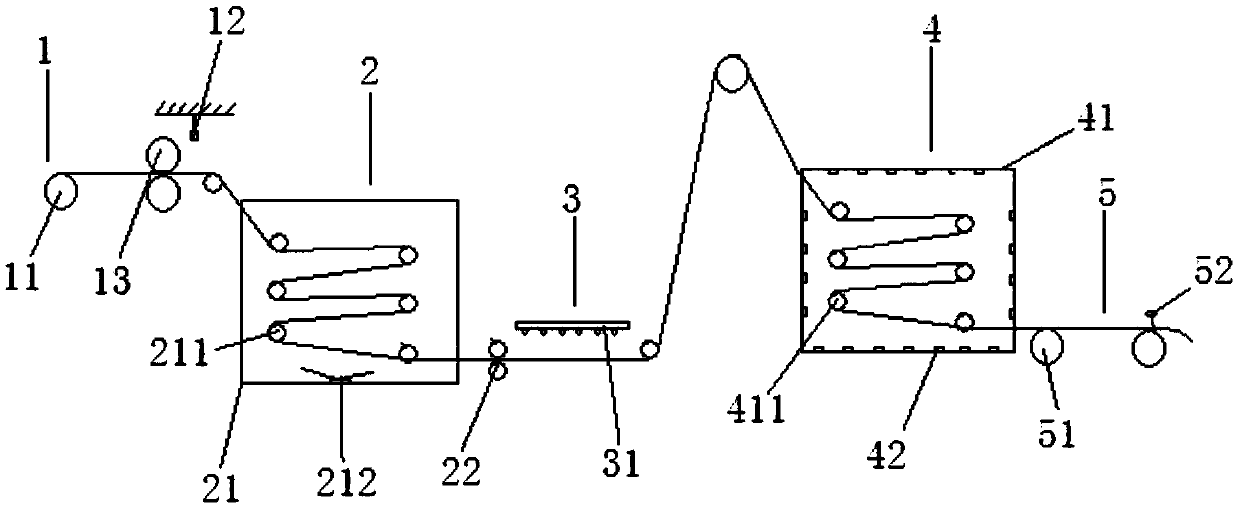

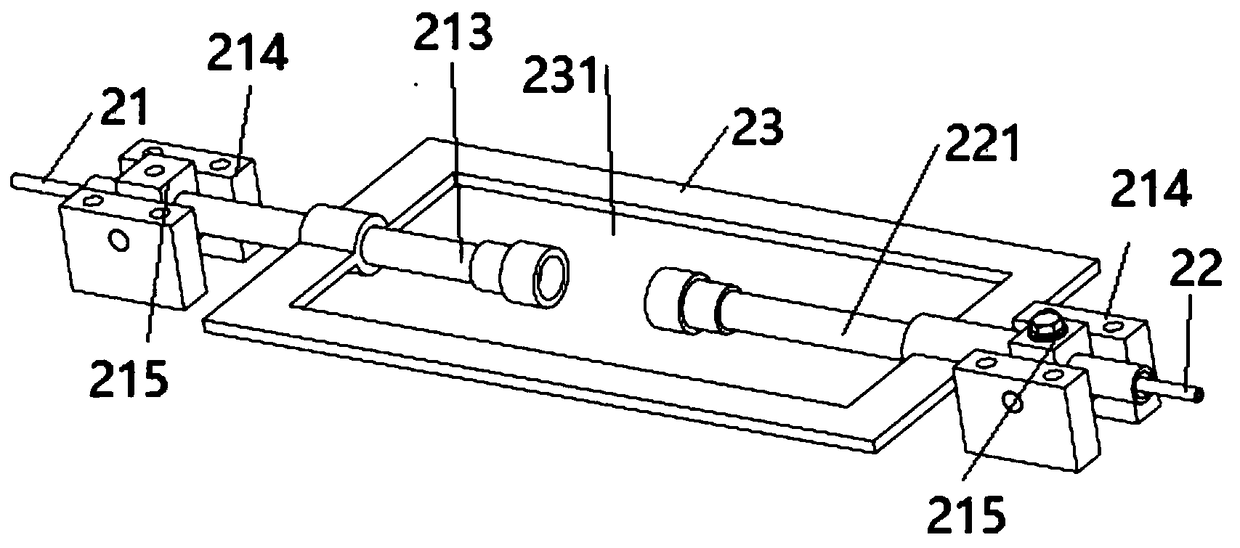

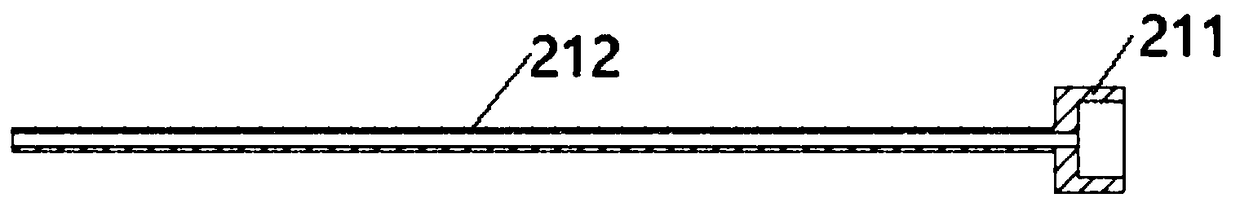

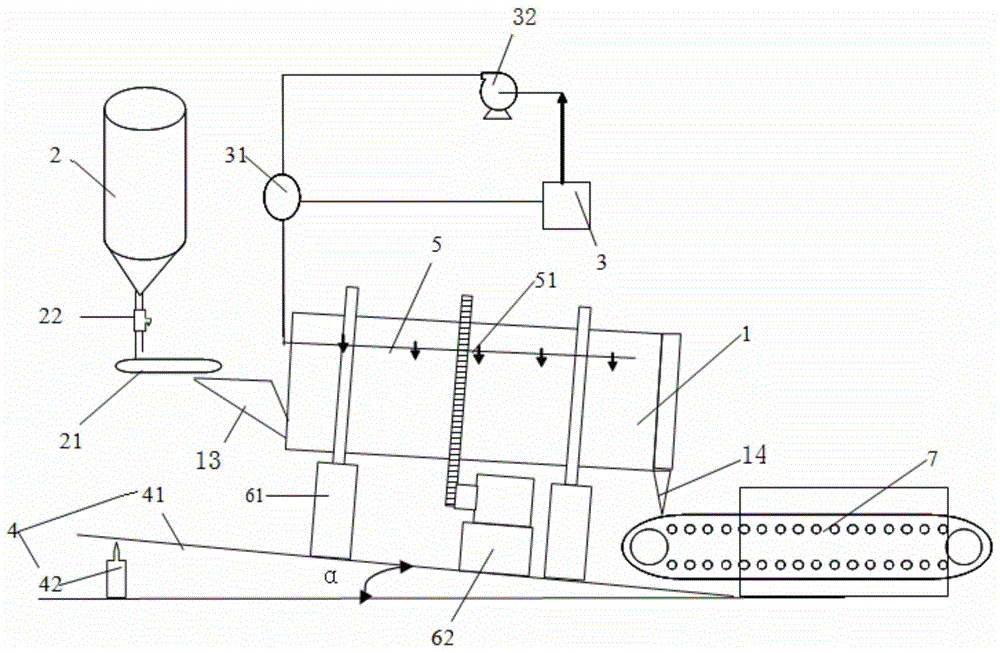

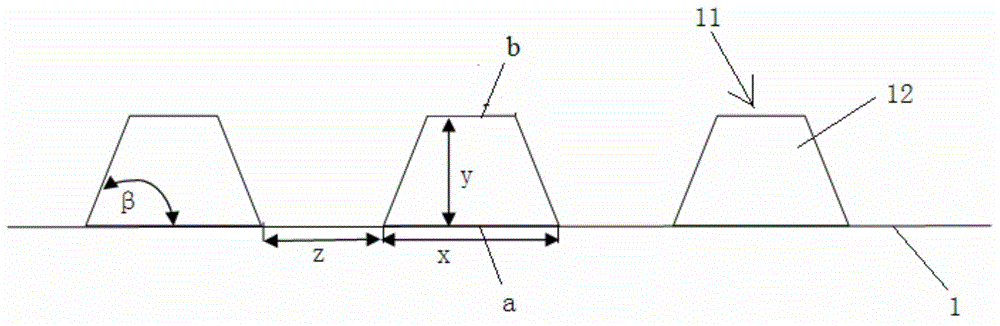

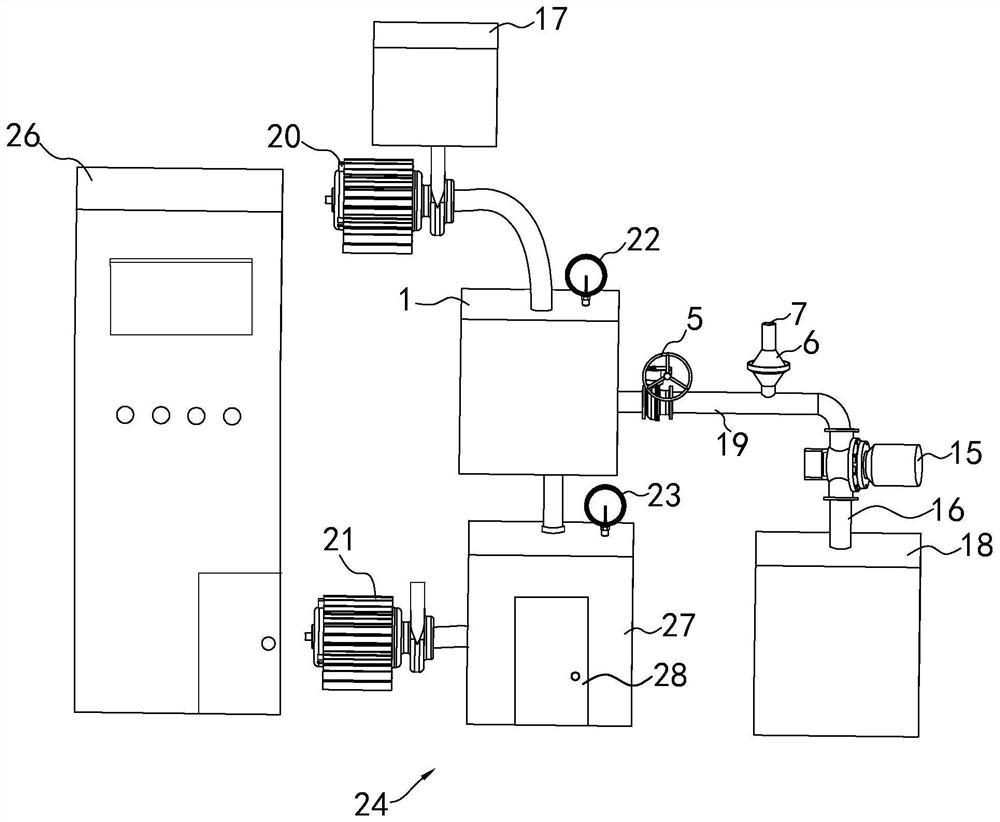

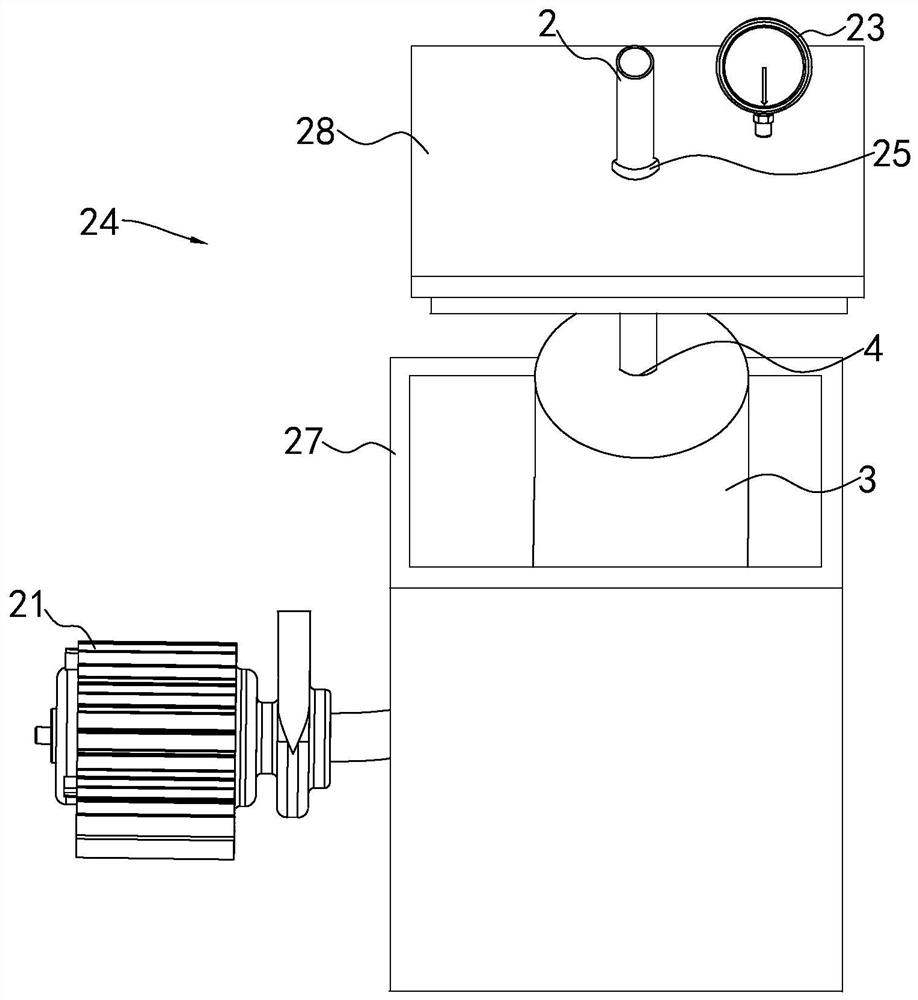

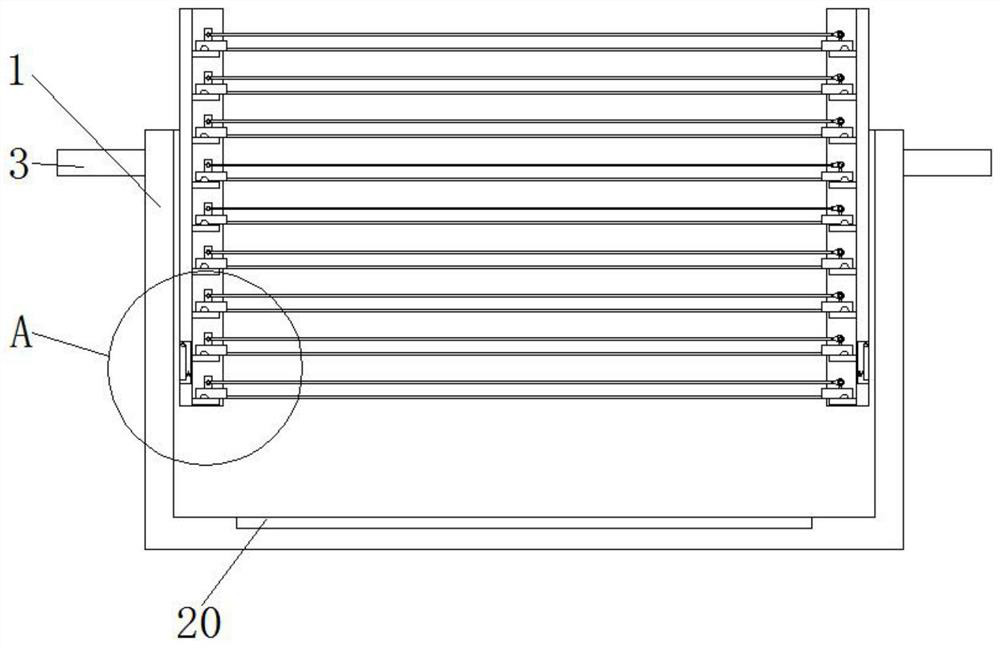

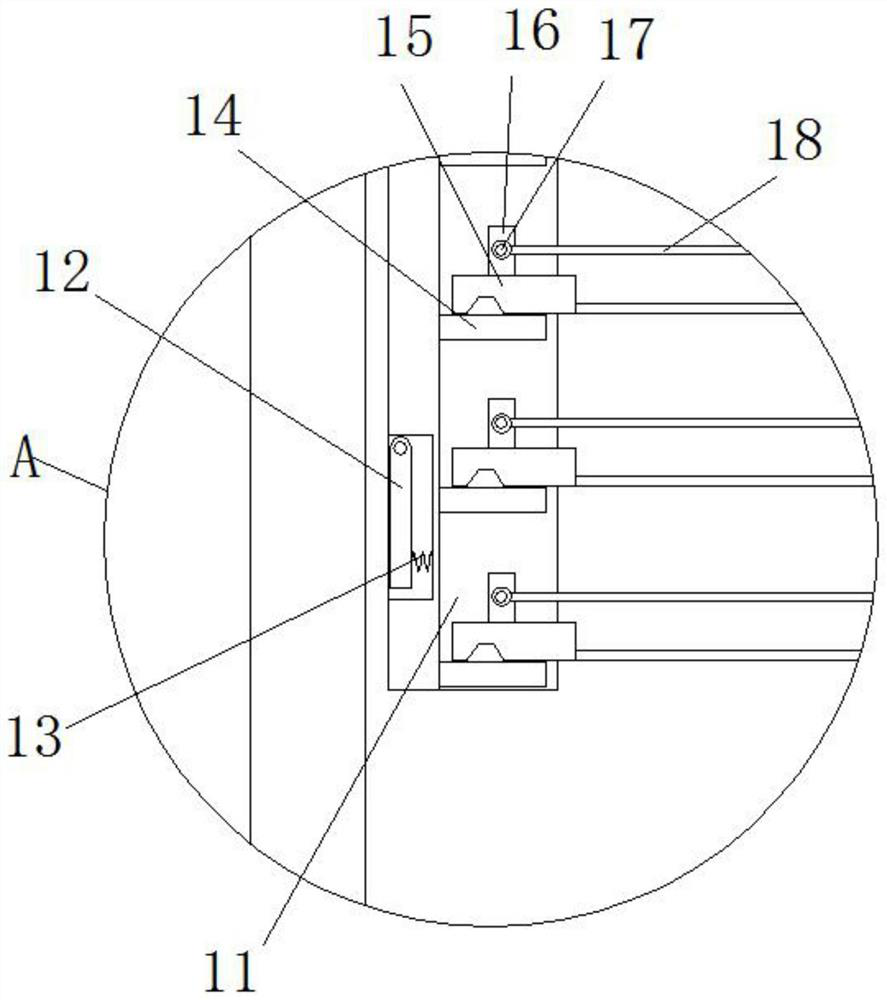

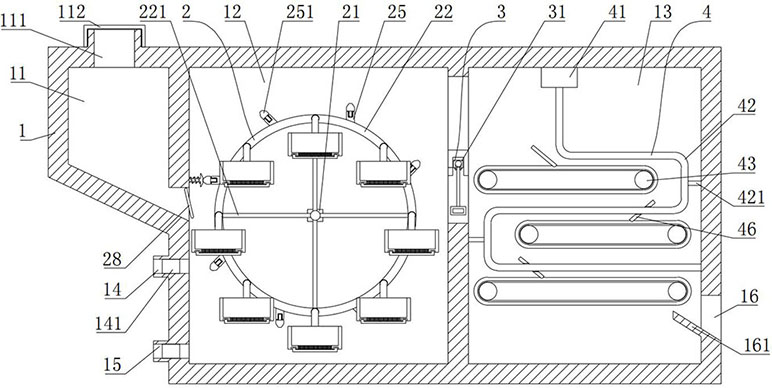

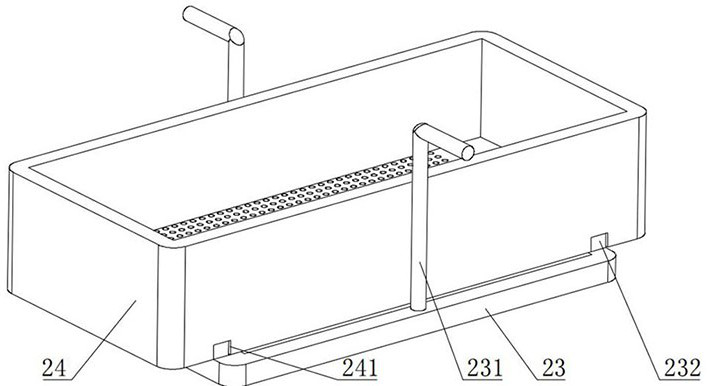

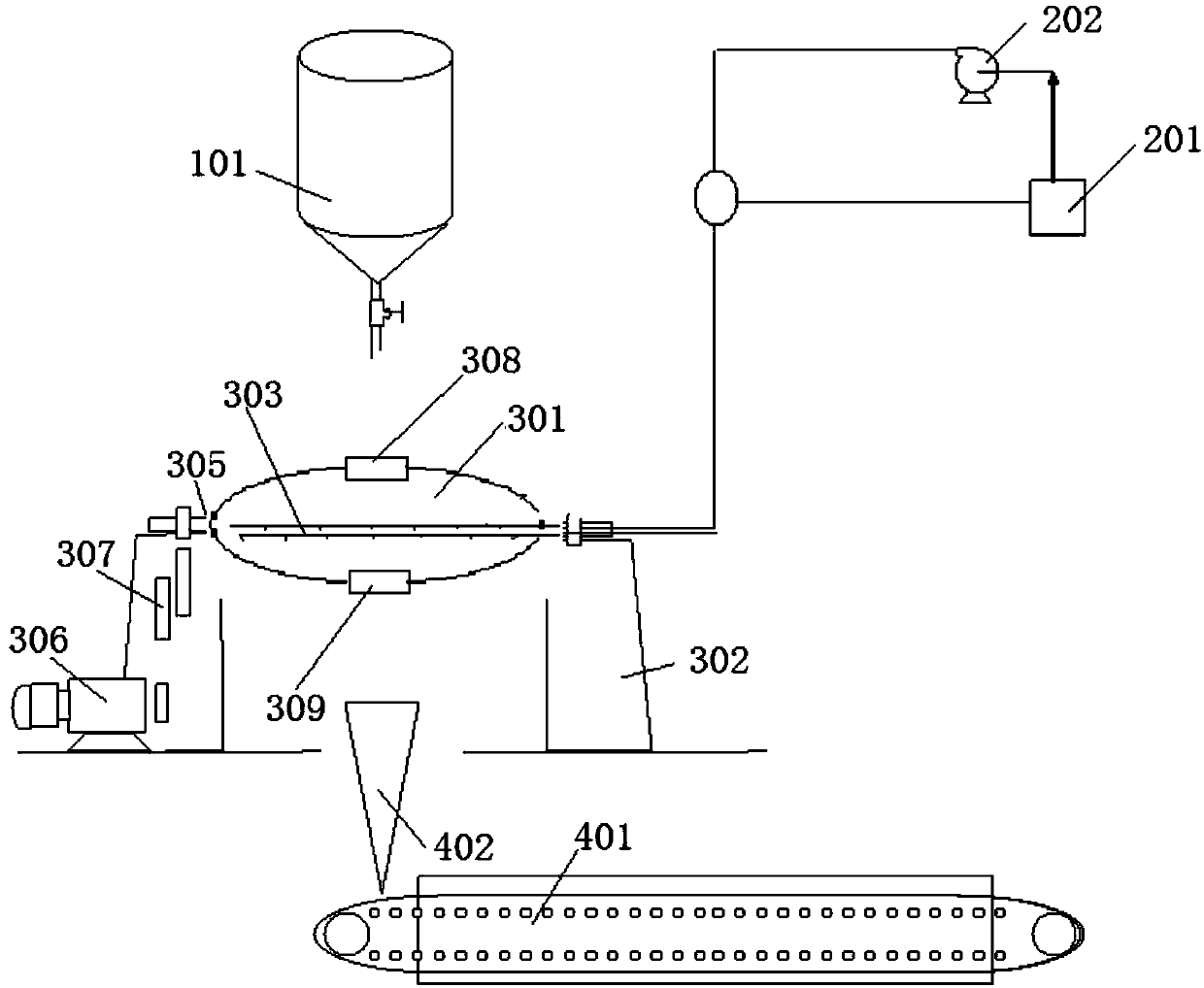

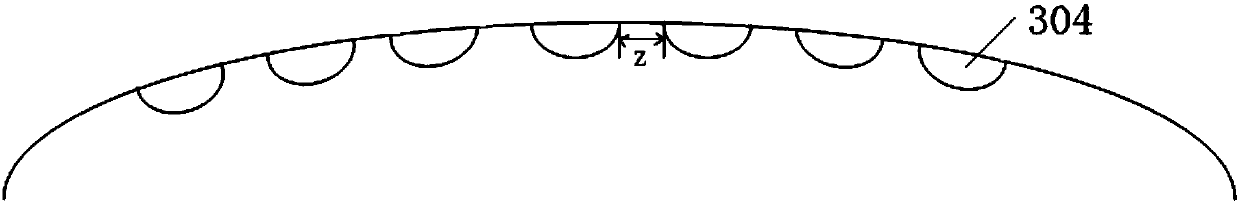

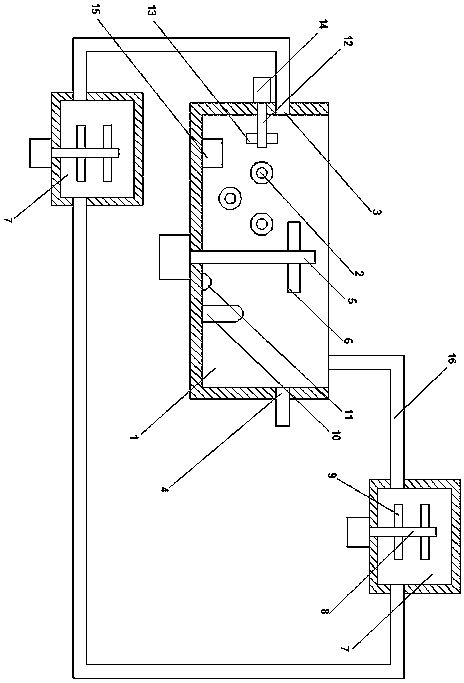

Padding and drying integrated machine

InactiveCN107604558AImprove work efficiencySpeed up the processTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsConveyor beltAir heater

A padding and drying integrated machine comprises a leading-in mechanism, a dipping device, a preheating device and a drying device which are successively connected via a conveyor belt. The dipping device comprises a dipping tank and a squeezing mechanism, two rows of staggered dipping rolls are disposed in the dipping tank, and the dipping rolls are successively connected via the conveyor belt. The preheating device comprises an air heater, the fabric squeezed by the squeezing mechanism is heated by hot air of the air heater, and water in the fabric is further removed. The drying device comprises a sealed oven, two rows of staggered heating rolls are disposed in the sealed oven, the heating rolls are successively connected via the conveyor belt, and inner walls of the sealed oven are uniformly distributed with hot air outlets. The dipping device and the drying device are integrated, efficiency of dipping and drying in a dyeing and finishing process can be effectively improved, and thetechnological process can be accelerated. The preheating device is disposed between the dipping device and the drying device, the water in the fabric can be blow-dried in advance, and drying efficiency of the sequent drying device can be improved.

Owner:太仓市芸芸化纤有限公司

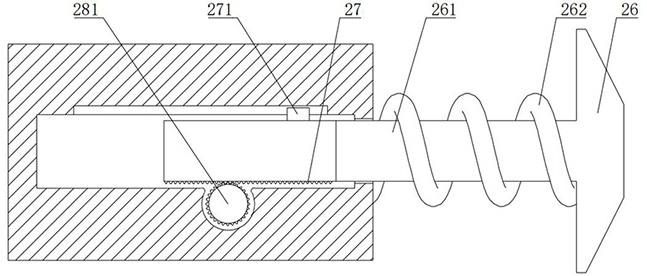

Low temperature valve low temperature test clamping device and method thereof

ActiveCN108871741AGuaranteed impregnation effectGuaranteed accuracyMachine part testingWork holdersMechanical engineeringEngineering

Owner:SHANGHAI MICROPOWERS

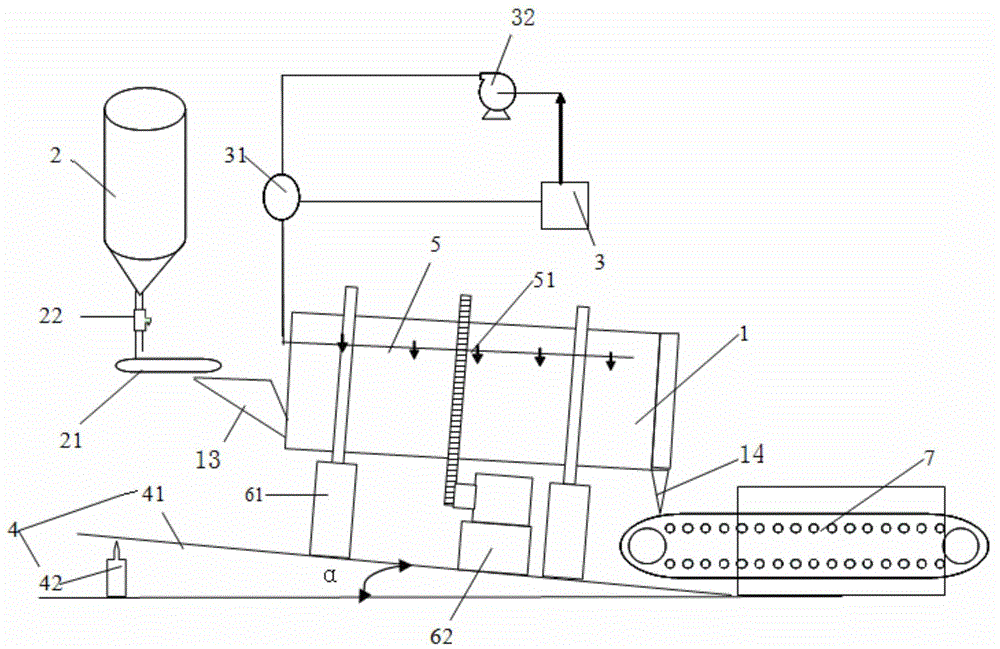

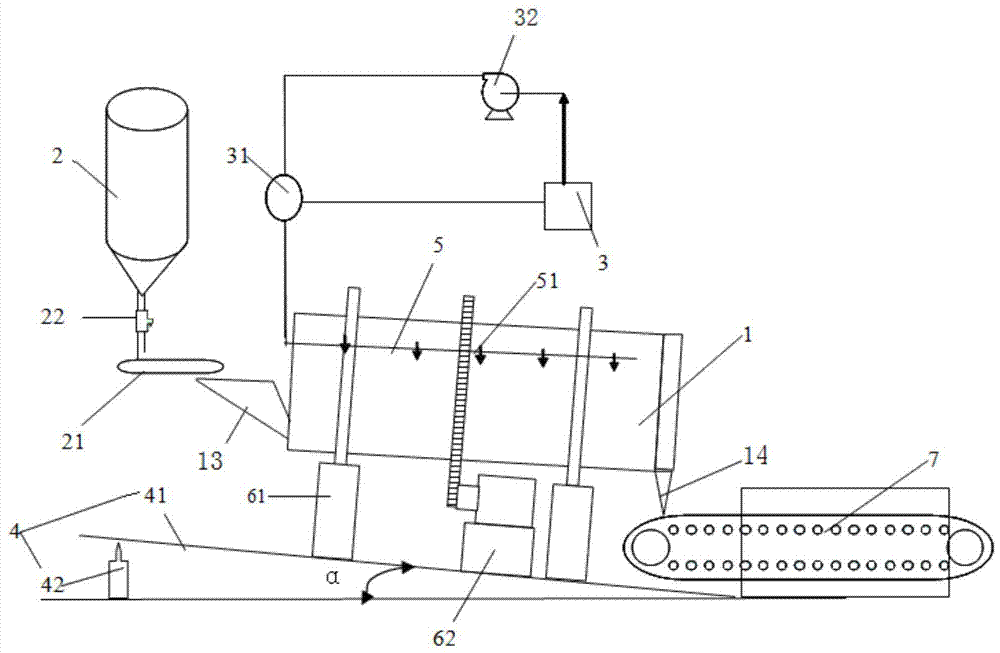

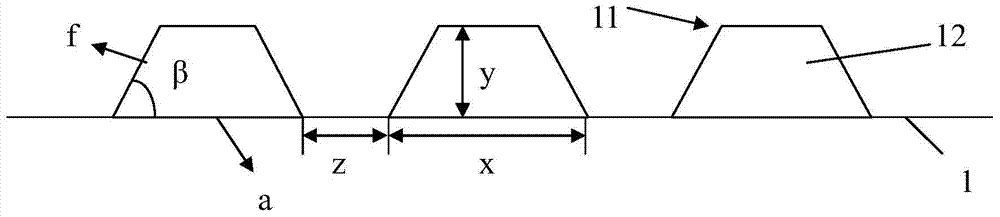

Catalyst preparation system

InactiveCN104368396ADip evenlyImpregnation uniform or non-uniformCatalyst activation/preparationActive componentEngineering

The invention discloses a catalyst preparation system. The catalyst preparation system comprises a carrier storage device, a solution storage device and a rotary drum, wherein the carrier storage device is used for storing a catalyst carrier; the solution storage device is used for storing a solution containing active components; the rotary drum is inclined; the carrier storage device and the solution storage device are respectively communicated with the rotary drum; the solution containing the active components is sprayed into the rotary drum from the solution storage device in an atomizing form; a material turning piece is arranged on the side wall of the rotary drum and is used for turning the catalyst carrier which enters the rotary drum from the carrier storage device during the rotation of the rotary drum. According to the catalyst preparation system provided by the invention, the rotary drum which is used for impregnating the catalyst carrier can be inclined. Therefore, the catalyst carrier can move from the charge end to the discharge end when being impregnated by the solution containing the active components, so that a catalyst can be continuously prepared; moreover, by arranging the material turning piece on the side wall of the rotary drum, the catalyst carrier can be turned by the material turning piece during the rotation of the rotary drum, so that the effective contact effect of the catalyst carrier and active substances is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid state capacitor impregnation method

ActiveCN110364362AEasy accessIncreased dipping speedSolid electrolytic capacitorsDrying/impregnating machinesVacuum pumpingVacuum pump

The invention discloses a solid state capacitor impregnation method, which comprises the following steps: (1) an element is suspended, dry vacuum pumping for 5 to 10 s is carried out, and a vacuum degree is made to be negative pressure; (2) the element is lowered and is immersed in an impregnation liquid, the pressure is held for 5 to 20 s, the vacuum degree is negative pressure, and the vacuum degree is equal to that in the first step; (3) the element is kept in the impregnation liquid and is deflated to a normal pressure state; (4) the above steps (1) to (3) is a cycle, the cycle is executedfor at least two times, and in the case of multiple cycles, the vacuum degree of vacuum impregnation is gradually increased; and (5) the element is suspended, dry vacuum pumping is carried out, the vacuum degree is negative pressure, and the vacuum degree is greater than any above vacuum degree. The solid state capacitor disclosed in the invention has the advantages that the impregnation time isreduced, the impregnation effects are improved, and the element center can be impregnated thoroughly.

Owner:ZHAOQING BERYL ELECTRONICS TECH

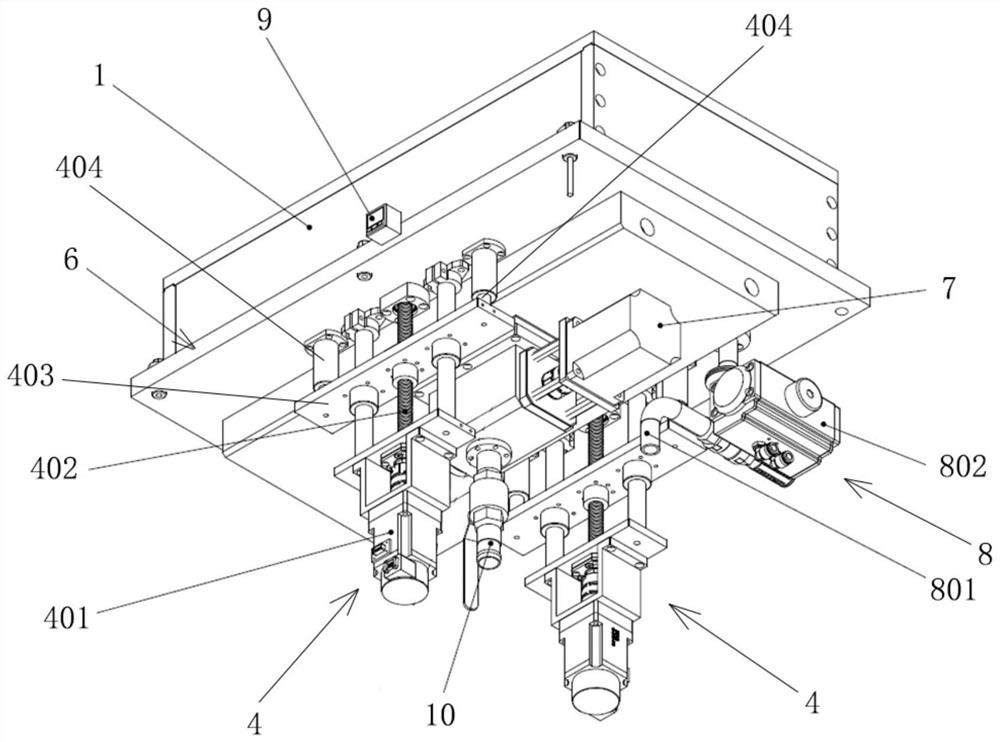

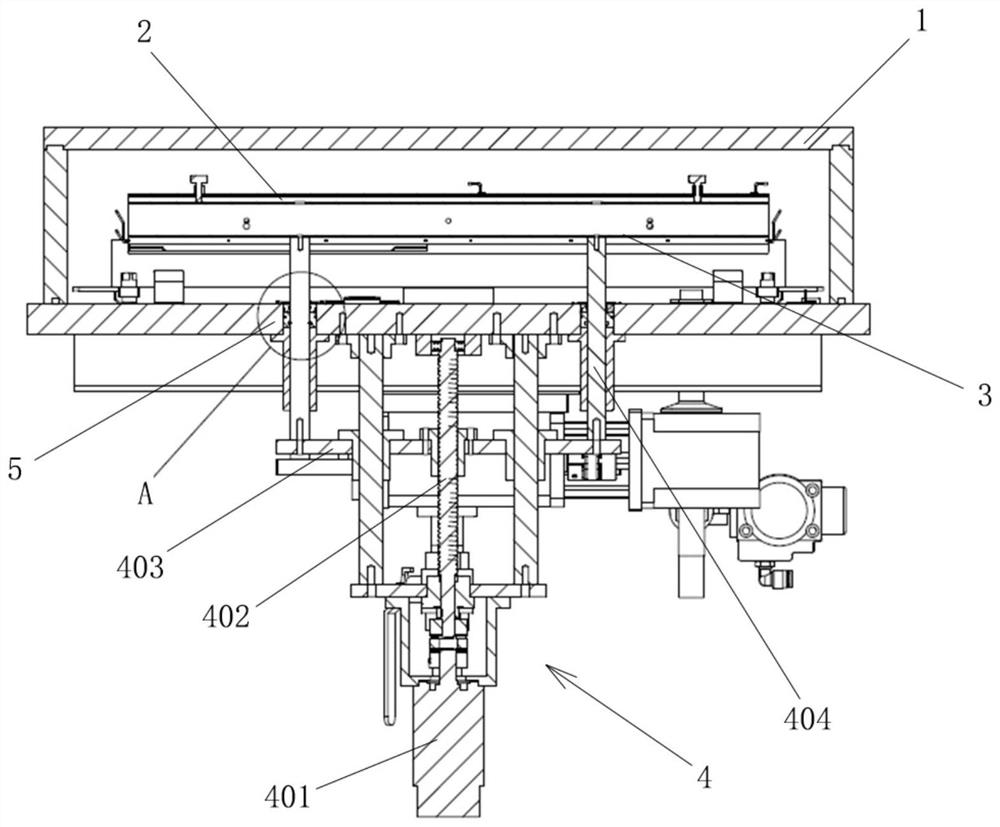

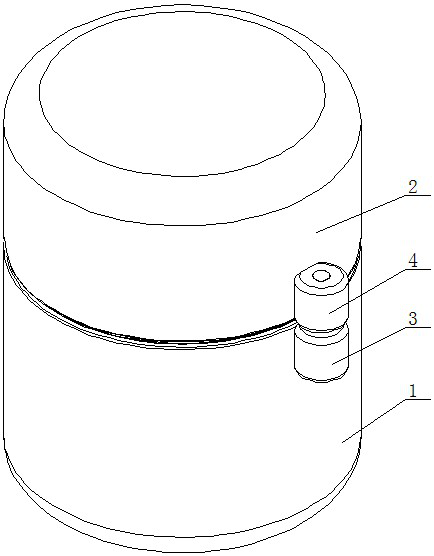

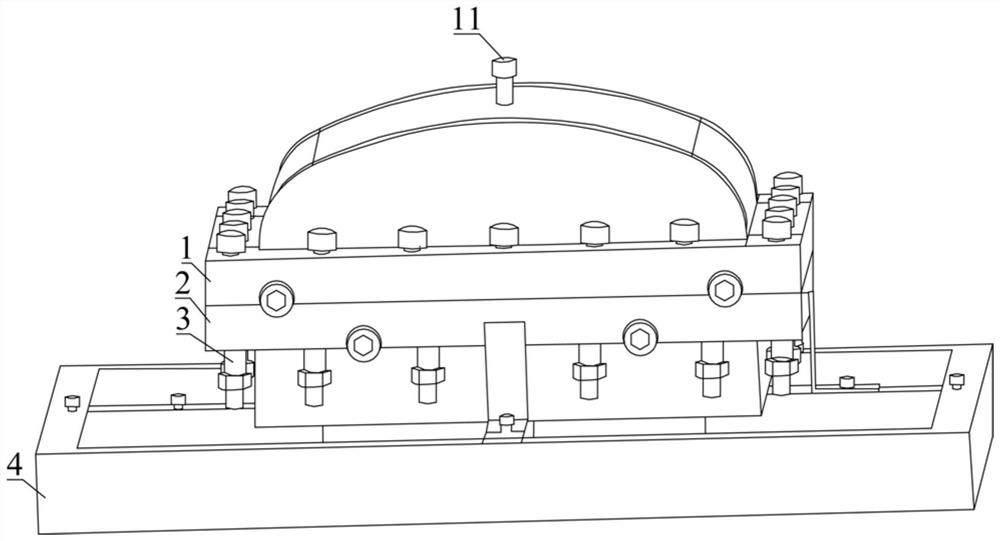

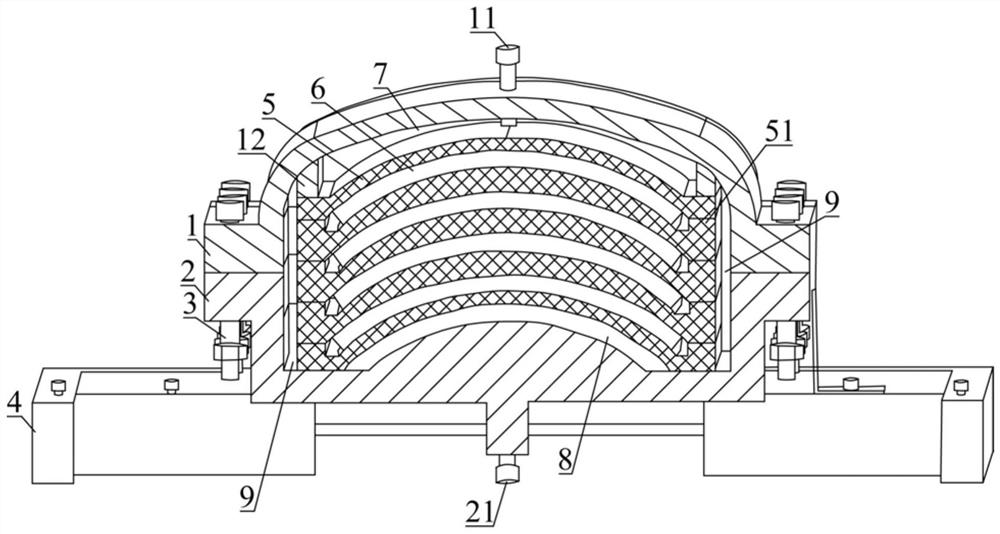

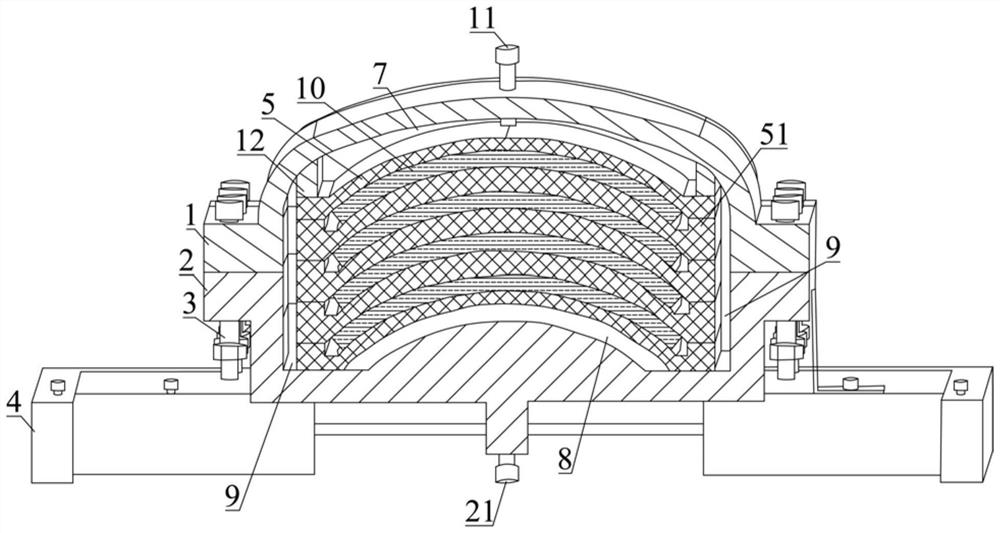

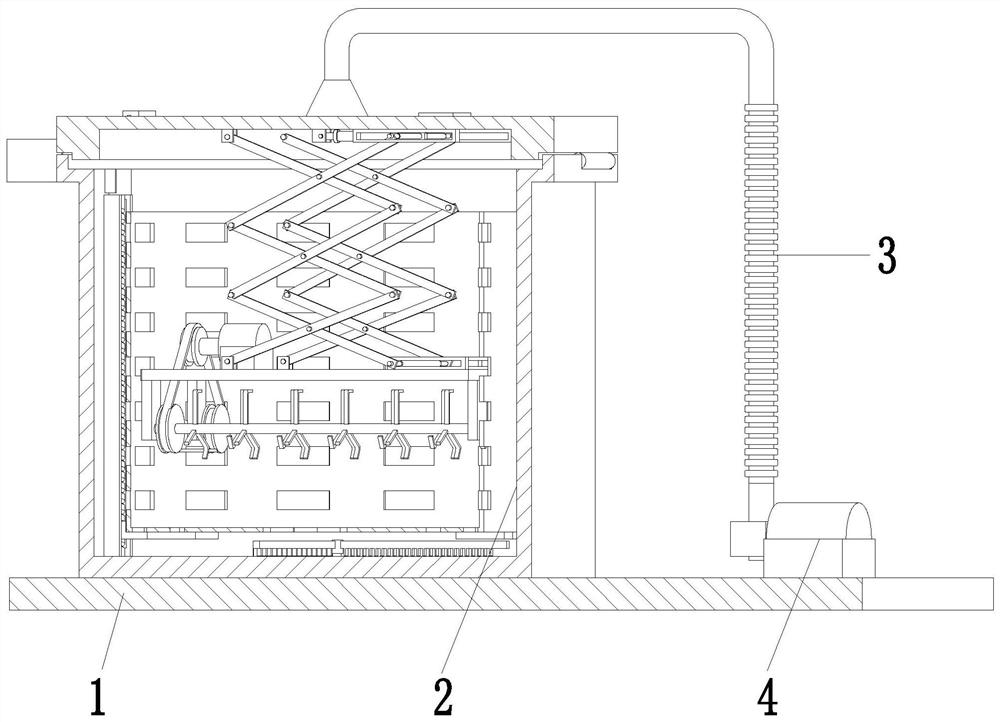

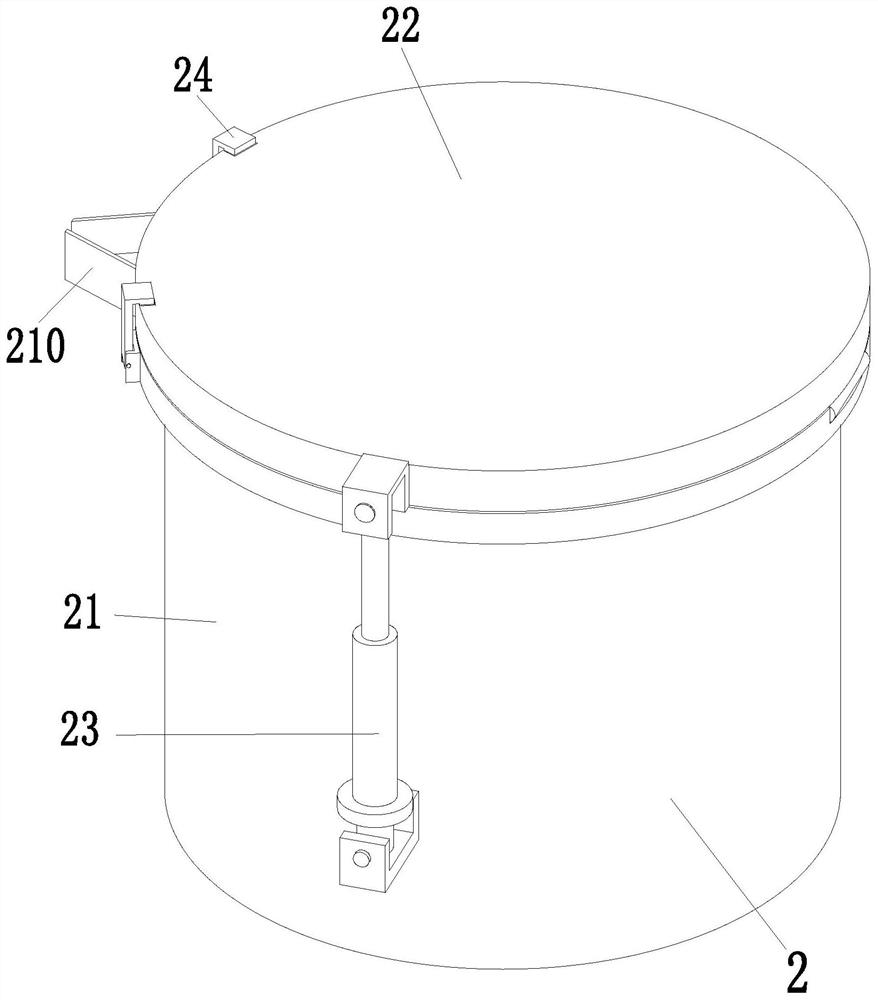

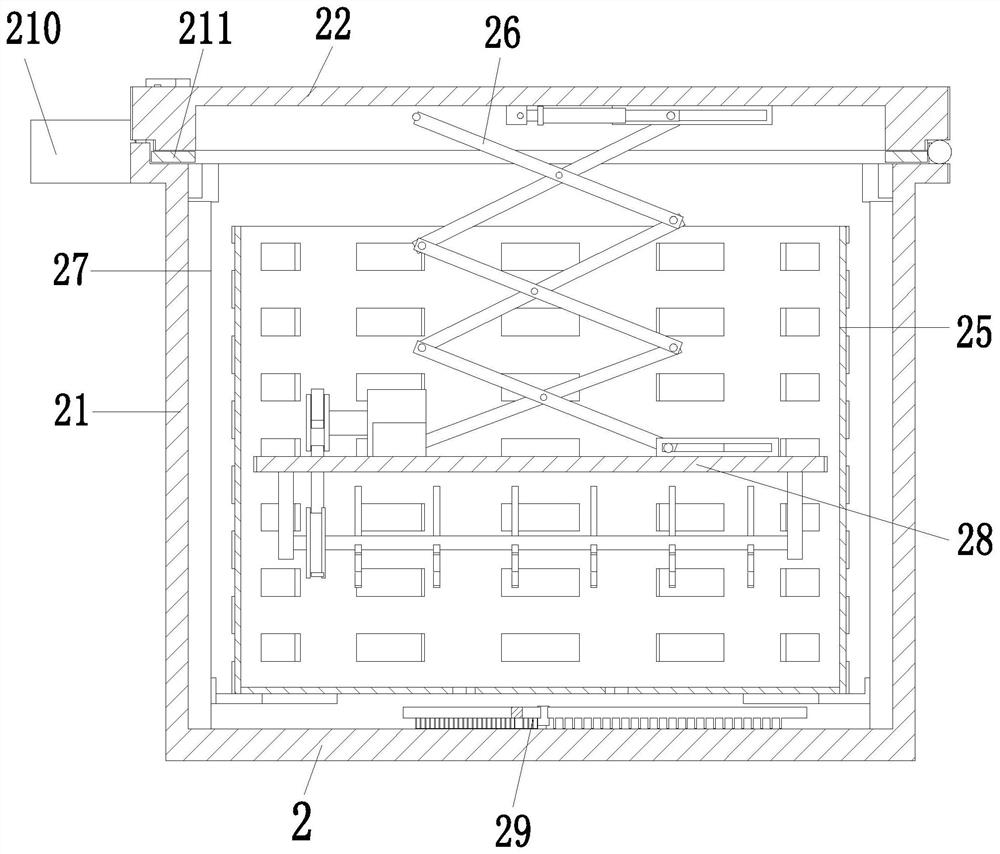

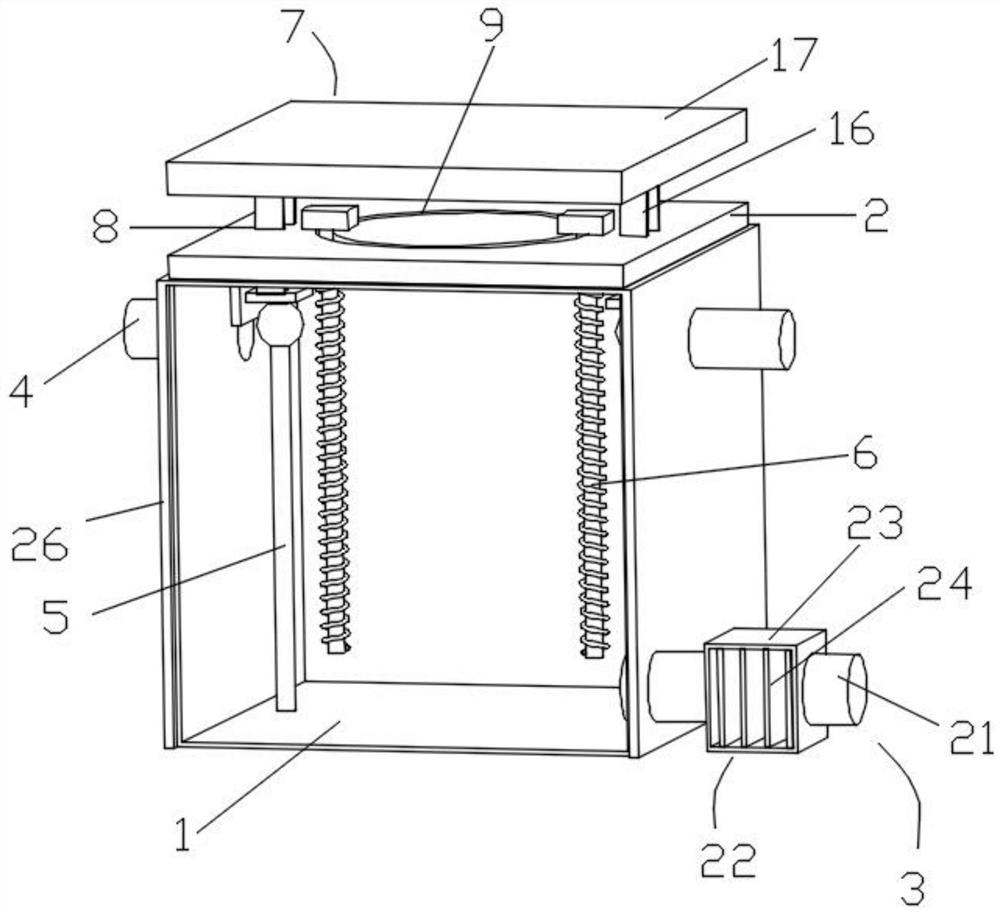

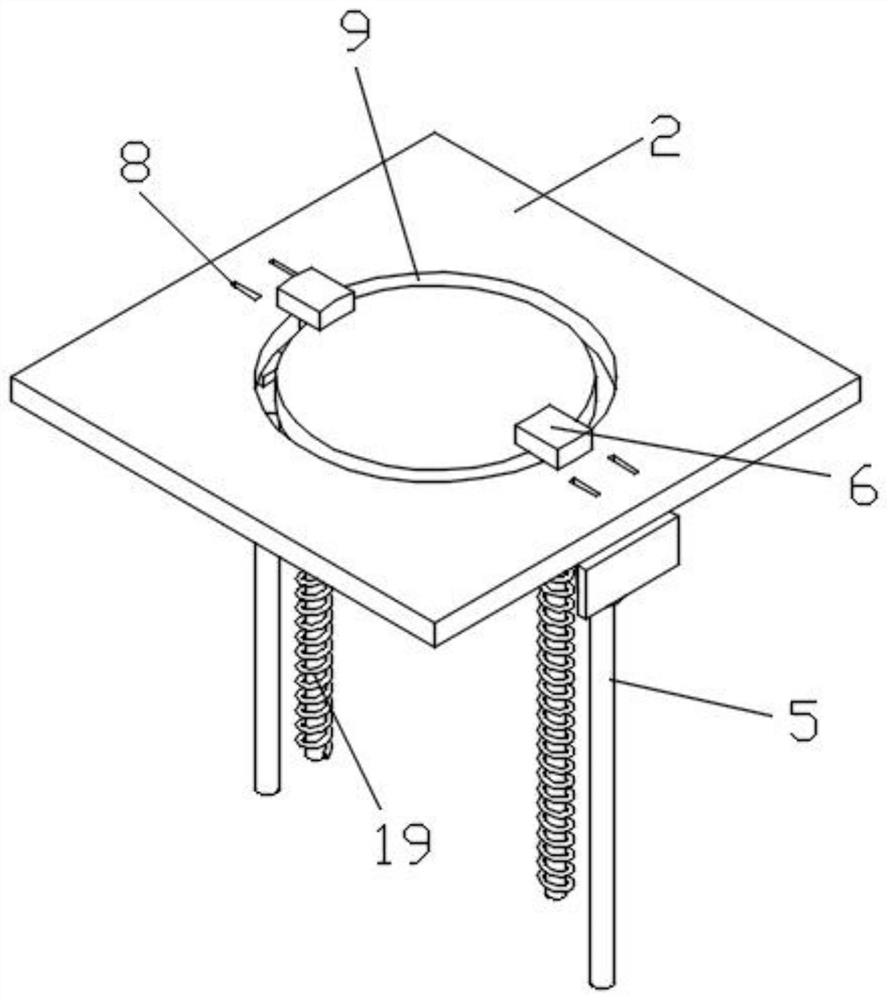

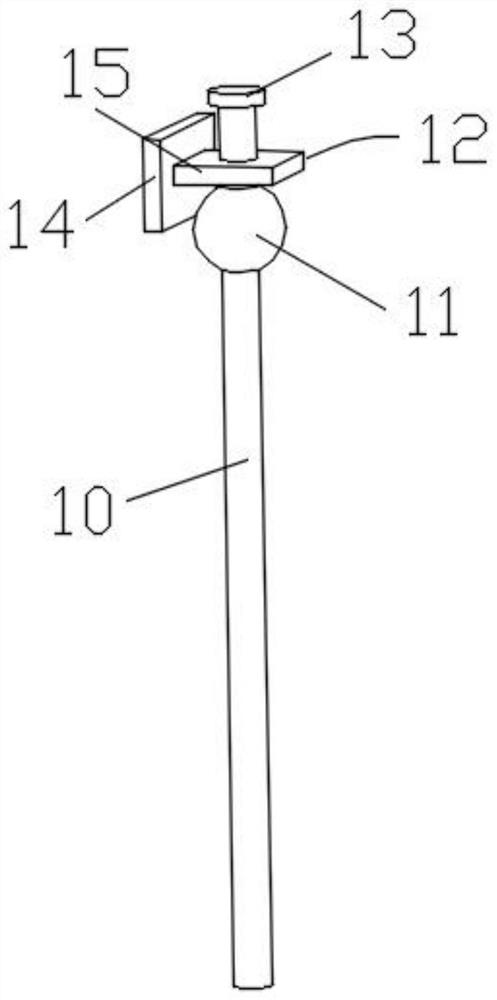

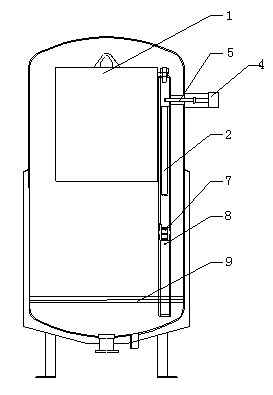

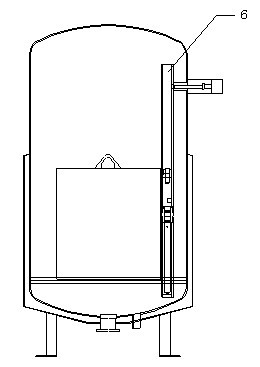

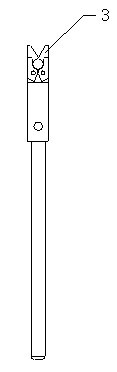

Vacuum impregnation device

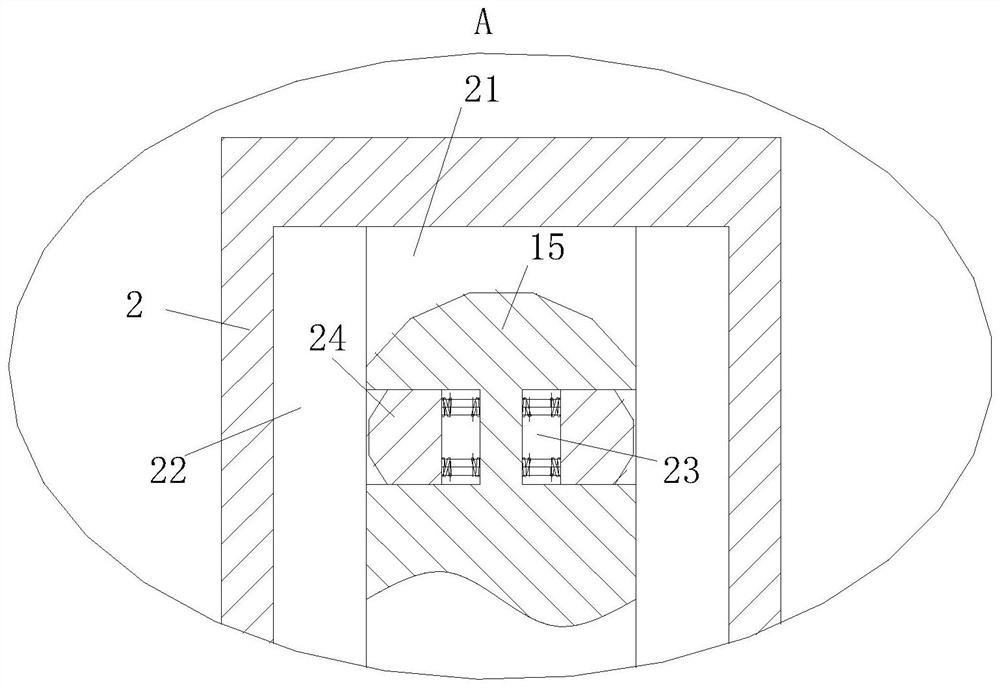

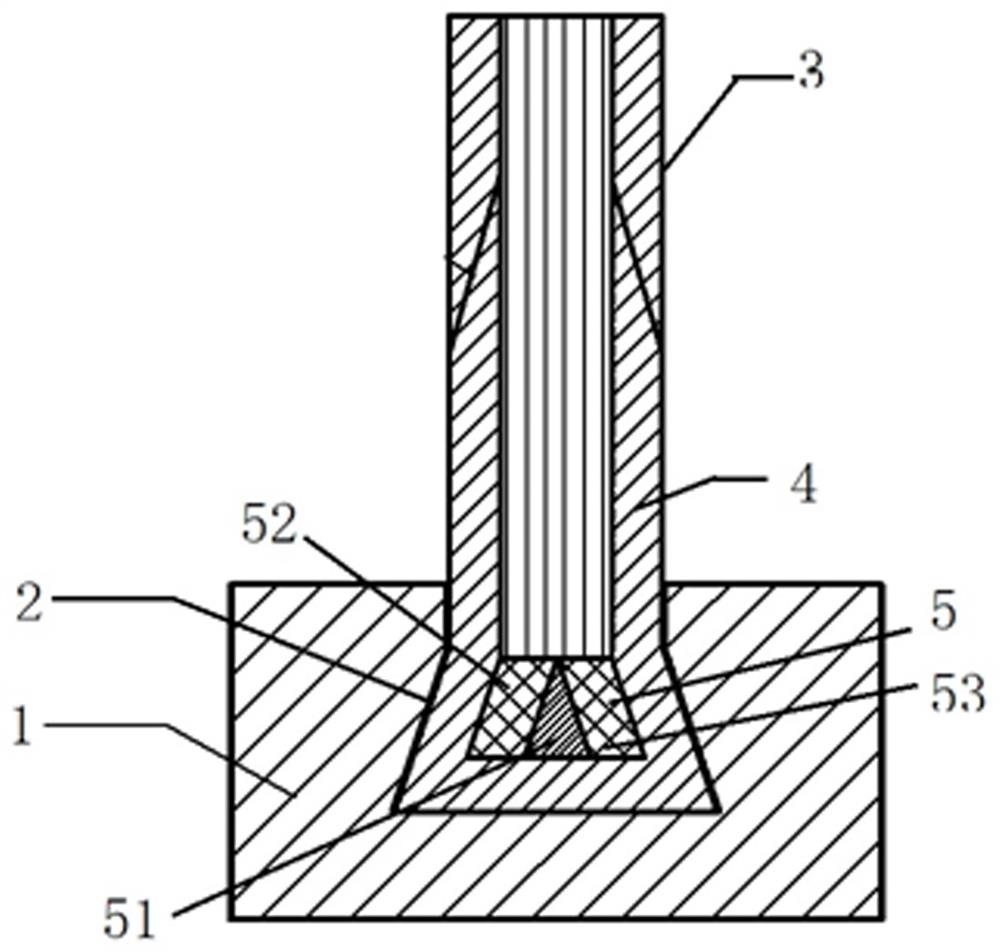

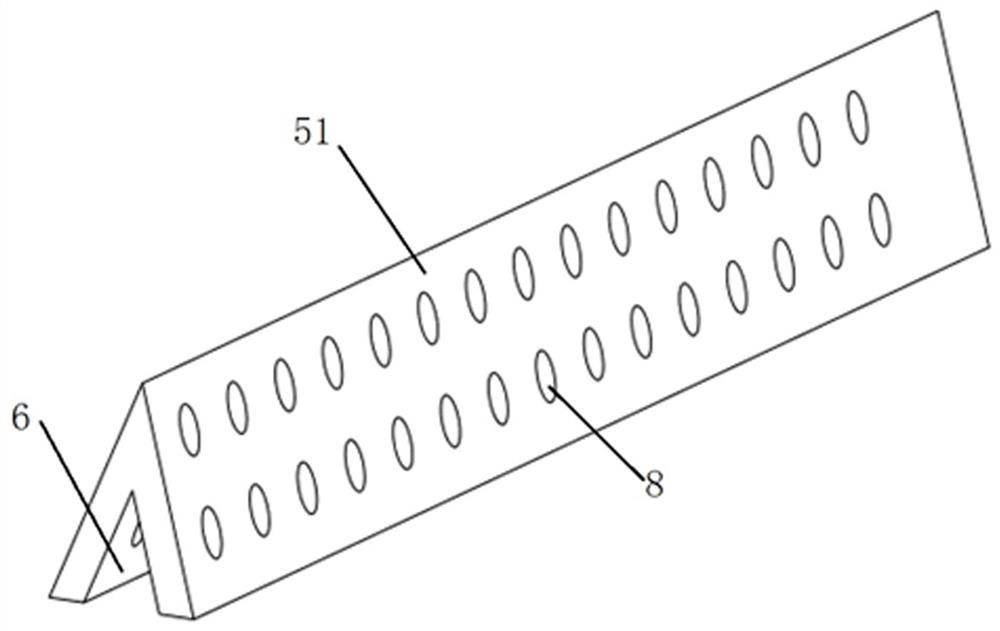

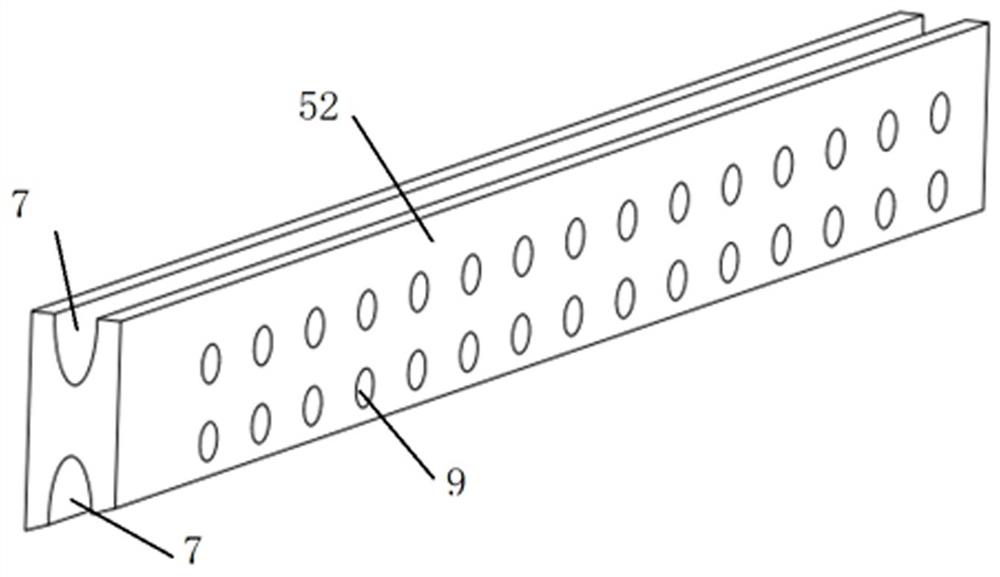

ActiveCN113192770AGuaranteed stabilityGuaranteed impregnation effectDrying/impregnating machinesMechanical engineeringPhysics

The invention relates to a vacuum impregnation device, and the device comprises a vacuum box body (1), an impregnation tank (2) and a knife edge structure (3) which are located in the vacuum box body (1), and a driving mechanism (4) which penetrates through the vacuum box body (1), is connected with the knife edge structure (3) and is used for driving the knife edge structure (3) to move back and forth in the direction close to and away from the impregnation tank (2); a through hole (101) for the driving mechanism (4) to penetrate through is formed in the vacuum box body (1), and a movable sealing structure (5) is arranged in the through hole (101). According to the scheme, the impregnation environment can be always kept to be a vacuum environment, on the basis of the vacuum impregnation environment, continuous circulation of the impregnation liquid in the impregnation process is achieved, the permeation effect of the impregnation liquid is better, manual box opening and other operations are not needed in the impregnation process, automatic material impregnation and automatic impregnation liquid supplement are achieved in the whole process, the cost in all aspects is effectively saved, and meanwhile, the operation and production efficiency is remarkably improved.

Owner:贵阳立特精密机械有限公司

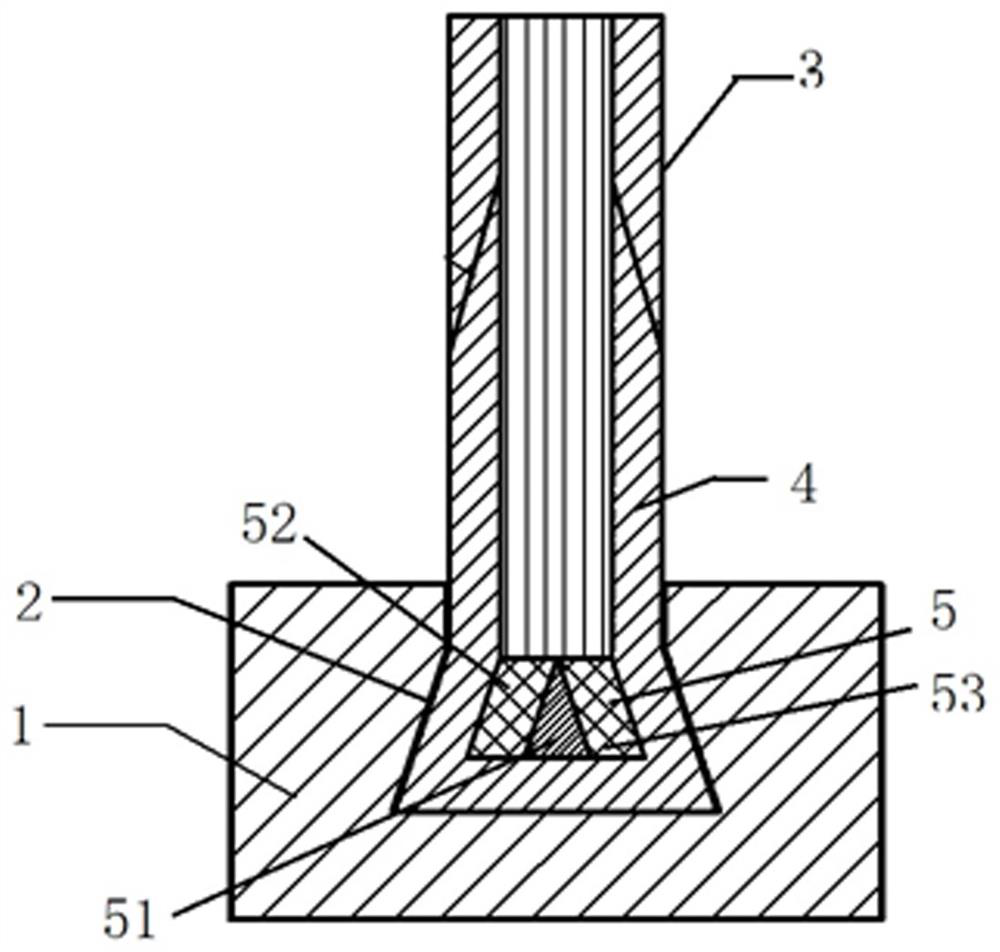

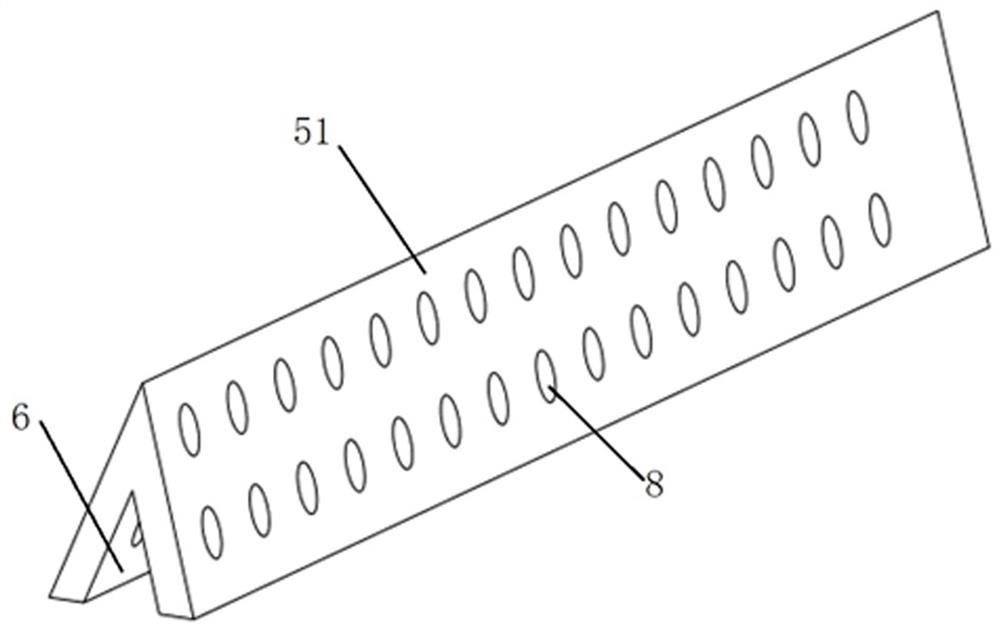

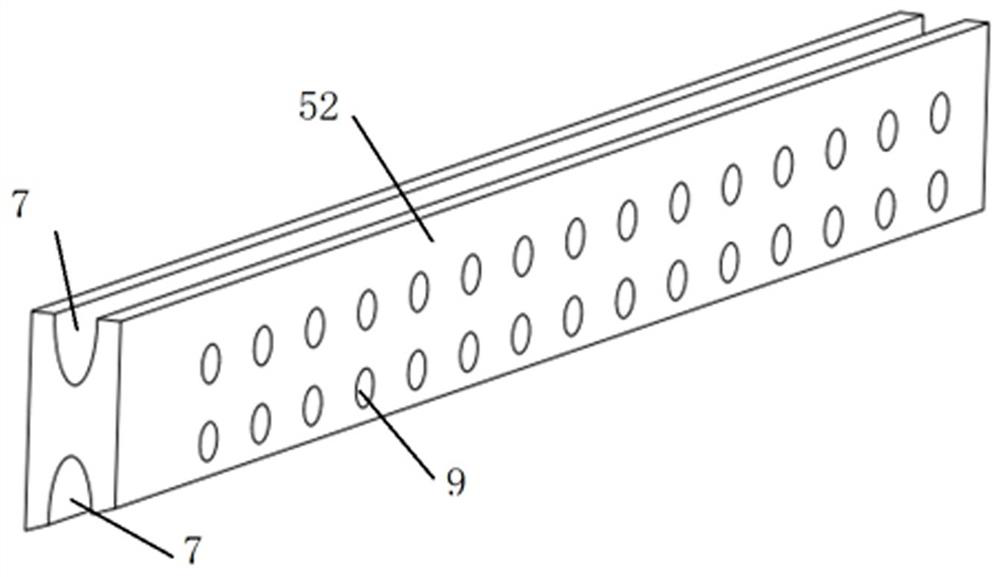

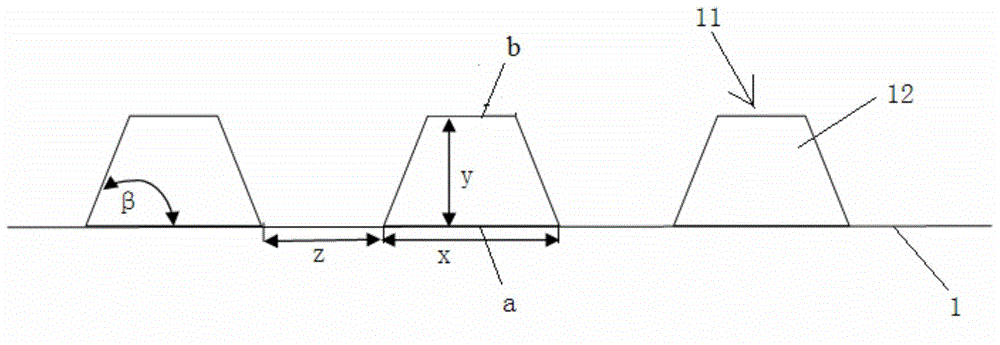

Composite material and metal component dovetail groove integrated forming connection structure and method

The invention provides a composite material and metal component dovetail groove integrated forming connection structure and method. The structure comprises a metal component, a composite material component and a composite material prefabricated block; the metal component is provided with a dovetail groove; the composite material component comprises a composite material body and a composite material connection part, the composite material connection part comprises a composite material forming structure which is arranged in the dovetail groove, the outer surface of the composite material forming structure is attached to the inner surface of the dovetail groove, and the composite material forming structure and the composite material body are integrally formed; and the composite material prefabricated block is used for fixing the position of a reinforcing material of the composite material forming structure in the dovetail groove and is arranged in the composite material forming structure in a filling manner, and the outer surface of the composite material prefabricated block is attached to the inner surface of the composite material forming structure. According to the structure and the method, before a composite material is formed, the reinforcing material and the dovetail groove are firstly effectively combined, then integrated forming is carried out, so that the connection structure has the connection strength and the sealing function of the composite material and metal at the same time, and many defects of mechanical connection and adhesive connection of the composite material and the metal component are avoided.

Owner:北京玻钢院复合材料有限公司

Preparation method for catalyst

InactiveCN104368397ADip evenlyUniform dipping stepCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentEngineering

The invention discloses a preparation method for a catalyst, which is characterized in that in a dipping step, a catalyst carrier and a solution containing the active components are respectively input in an aslant arranged rotating cylinder, a material turning piece is arranged on the sidewall of the rotating cylinder, an active solution is injected in the rotating cylinder in an atomization mode, through the rotation of the rotating cylinder, under dipping by the active solution, and the catalyst carrier is capable of moving from a charging end at high position to a discharging end at low position of the rotating cylinder. According to the invention, the rotating cylinder capable of executing the dipping step in the preparation method is aslant arranged, so that the catalyst carrier is dipped by the active solution and simultaneously moves from the charging end to the discharging end, continuous preparation of the catalyst can be realized, and because that the material turning piece is arranged on the sidewall of the rotating cylinder, when the rotating cylinder is rotated, the catalyst carrier is capable of being turned over by the material turning piece, the catalyst carrier and the active solution are effectively contacted, and the dipping effect of the catalyst carrier is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

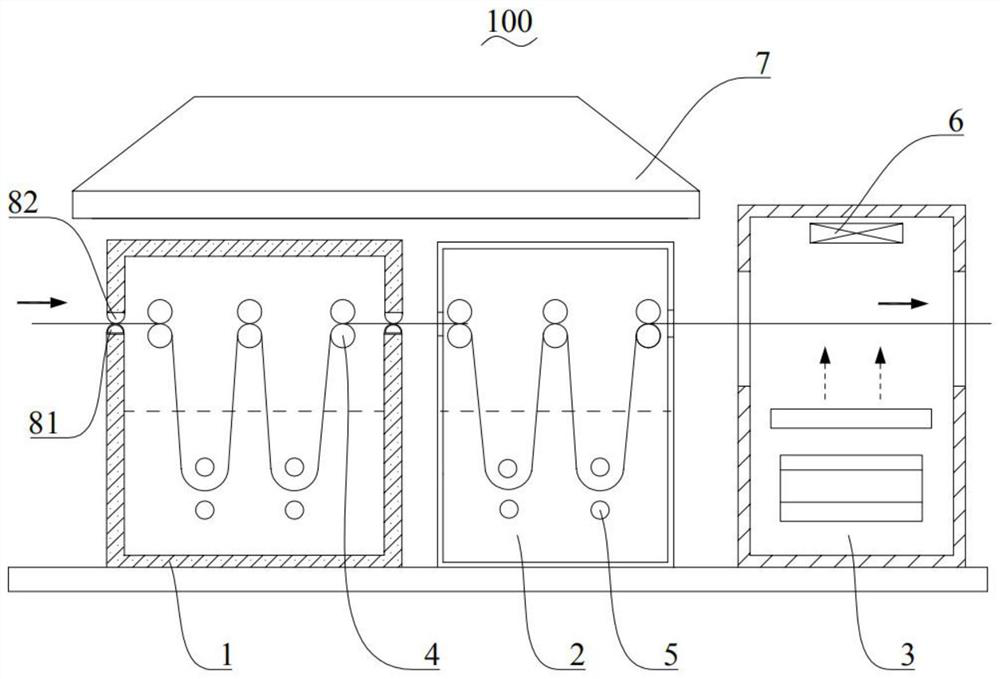

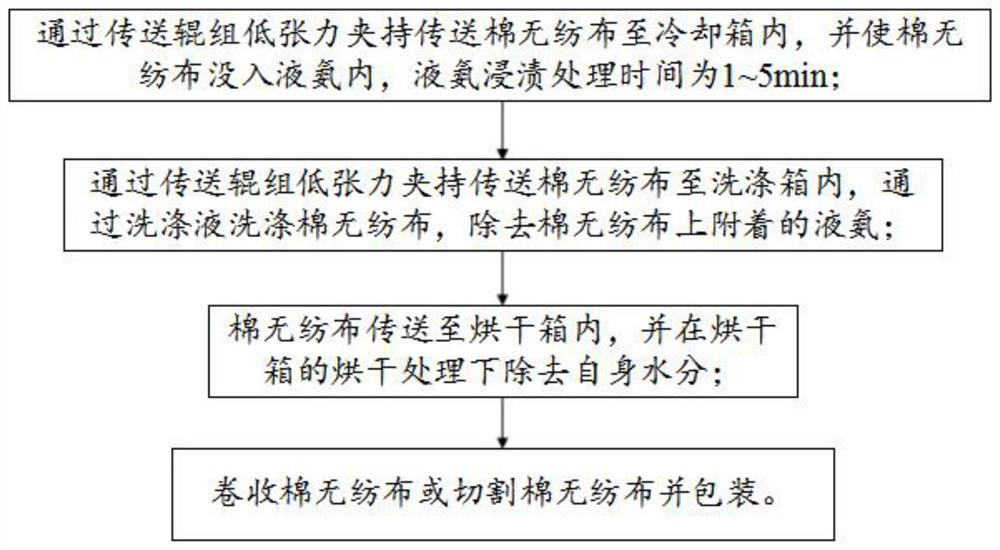

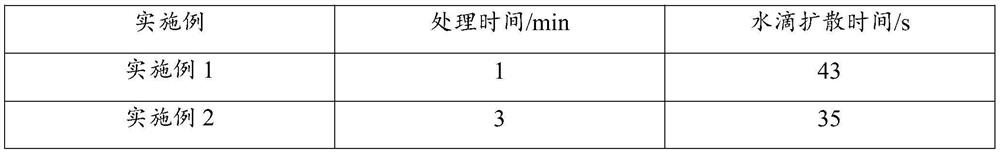

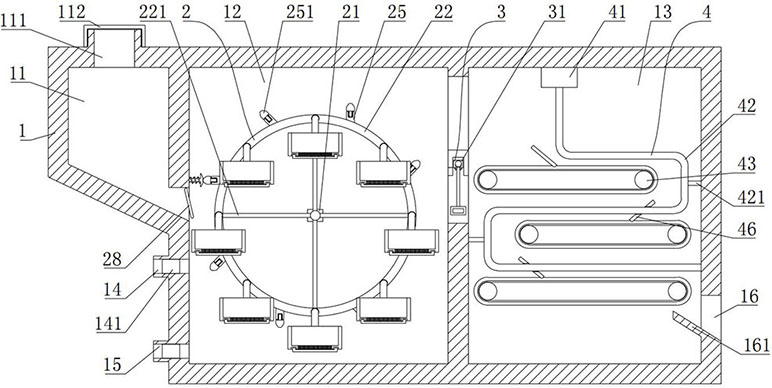

Continuous liquid ammonia finishing and processing device and method for improving hydrophilicity of cotton non-woven fabric

ActiveCN113605011AImprove hydrophilicityImprove the finishTextile treatment containersTextile treatment machine arrangementsProcess engineeringNonwoven fabric

The invention provides a continuous liquid ammonia finishing and processing device and method for improving the hydrophilicity of a cotton non-woven fabric. The finishing and processing device comprises a cooling box, a washing box, a drying box, a plurality of conveying roller sets, a driving assembly and a control assembly which are sequentially arranged in the conveying direction so as to realize continuous processing of the cotton non-woven fabric. The cooling box is provided with an air bag type sealing device and used for containing liquid ammonia and dipping the cotton non-woven fabric; the washing box contains washing liquid and is used for removing the liquid ammonia on the cotton non-woven fabric; the drying box is used for drying the cotton non-woven fabric; and the control assembly can independently control the rotating speed of the driving assembly, so that the cotton non-woven fabric between every two adjacent conveying roller sets can naturally droop, loose low-tension processing is achieved, and the structure and performance of the cotton non-woven fabric are prevented from being damaged. The cotton non-woven fabric is subjected to liquid ammonia dipping and slack treatment, so that the hydrophilicity and smoothness of the cotton non-woven fabric are improved, and the cotton non-woven fabric is soft and full in hand feeling and rich in elasticity; and liquid ammonia treatment is adopted, and no chemical reagent is introduced, so that the advantages of environmental protection and low energy consumption are achieved.

Owner:WUHAN TEXTILE UNIV

Stable and reliable anti-oxidation impregnation device for graphite electrode

ActiveCN113953139AEasy to handleReduce wasteLiquid surface applicatorsCoatingsGraphite electrodeStructural engineering

The invention provides a stable and reliable anti-oxidation impregnation device for a graphite electrode. The device comprises a lower shell and an upper shell, wherein the lower shell and the upper shell are vertically opposite, a rotating mechanism is arranged between the lower shell and the upper shell, the rotating mechanism can drive the lower shell and the upper shell to be staggered, impregnation liquid is placed in the lower shell, a first electric telescopic rod is arranged in the lower shell, a horizontal supporting plate is mounted at a movable end of the first electric telescopic rod, a containing device is arranged on the supporting plate, and a graphite electrode can be placed in the containing device. The device is characterized in that a pressurizing device is arranged in the upper shell and can pressurize the impregnation liquid, a rotating device is arranged in the containing device and can drive the graphite electrode to rotate, and self-rotation of the graphite electrode can enable impregnation to be fully conducted and the impregnation liquid to be recycled.

Owner:HUNAN INSTITUTE OF ENGINEERING +1

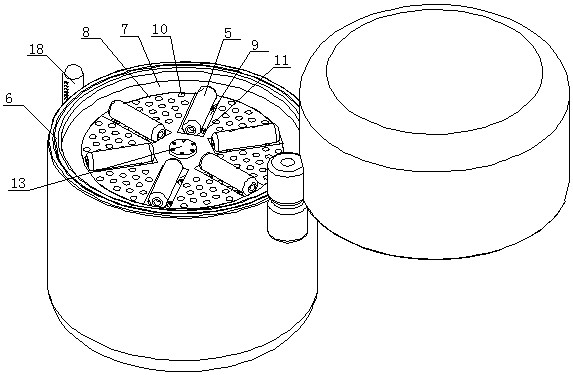

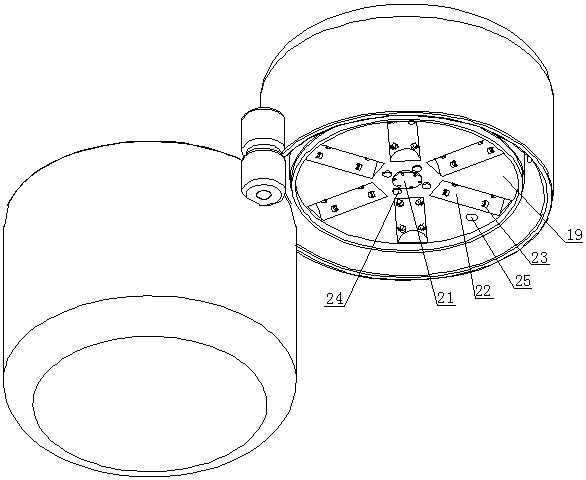

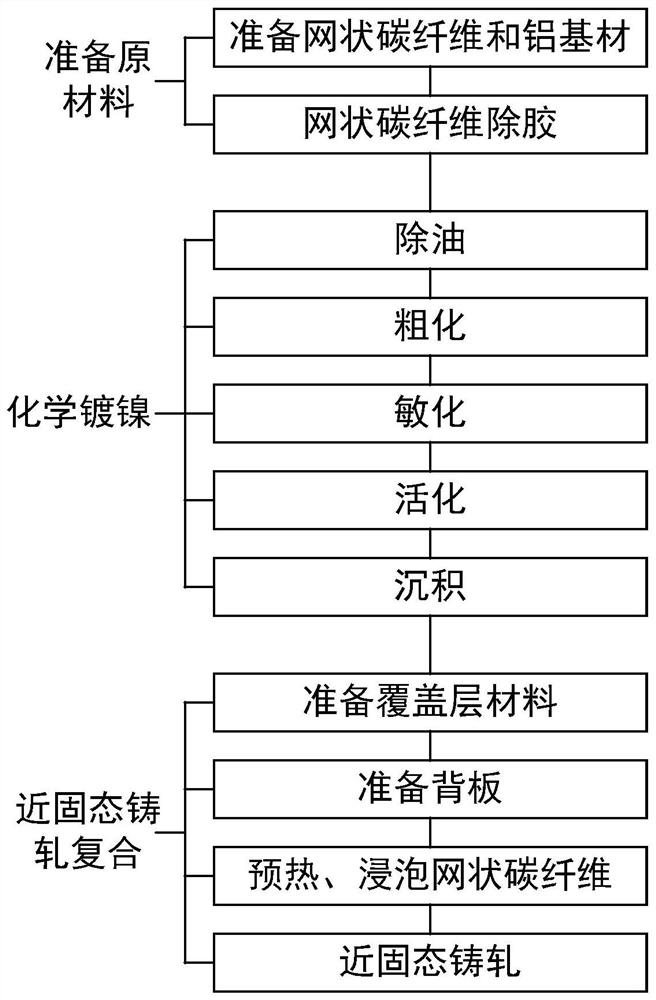

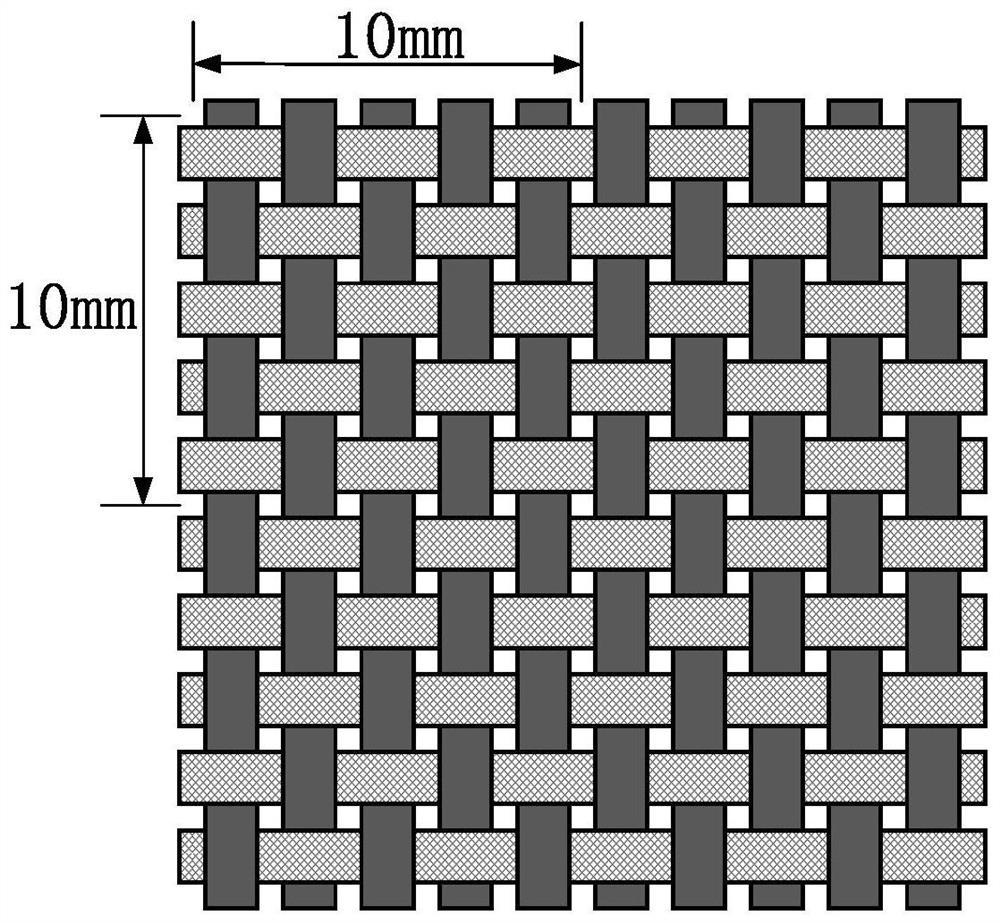

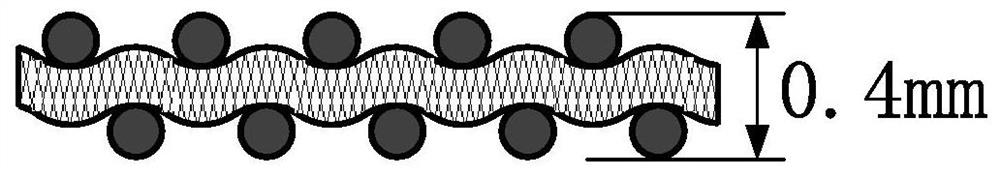

Preparation method and cast rolling method of reticular carbon fiber aluminum-based composite material

ActiveCN113897562AGood stabilityGood deep plating abilityLiquid/solution decomposition chemical coatingCleaning using liquidsCarbon fibersFiber bundle

The invention discloses a preparation method of a reticular carbon fiber aluminum-based composite material. The preparation method comprises the following steps of preparing reticular carbon fibers and an aluminum base material, and staggering carbon fiber bundles by a cross plain weaving method to form the reticular carbon fibers; degumming the reticular carbon fibers, carrying out chemical nickel plating on the reticular carbon fibers by using an ultrasonic cleaning machine, specifically, deoiling, coarsening, sensitizing, activating and depositing; and carrying out near-solid-state cast-rolling compounding by adopting cast-rolling equipment. According to the preparation method, the carbon fiber pretreatment process comprising the three steps of surface activation, chemical nickel plating and constant-temperature heating is designed according to the specific distribution mode of the cross plain net-shaped carbon fibers, and excellent preconditions are provided for preparation of the net-shaped carbon fiber reinforced aluminum-based composite material; in the near-solid-state casting-rolling compounding process, the near-solid-state covering layer in the solidification stage can fully infiltrate the carbon fiber under the condition of ensuring the complete structure and stable distribution of the carbon fiber by virtue of proper self flowability and reasonable external pressure; and the prepared cross plain reticular carbon fiber reinforced aluminum-based composite board can realize multi-angle reinforcement in a two-dimensional space.

Owner:SHANDONG UNIV

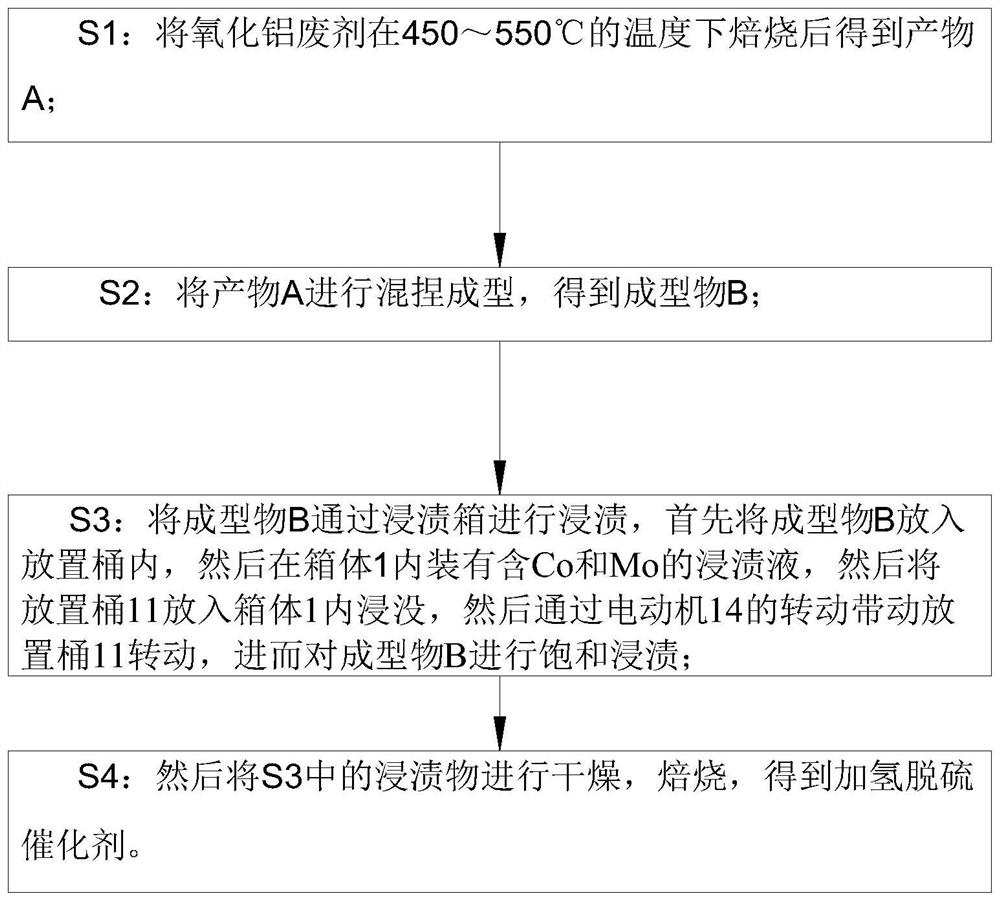

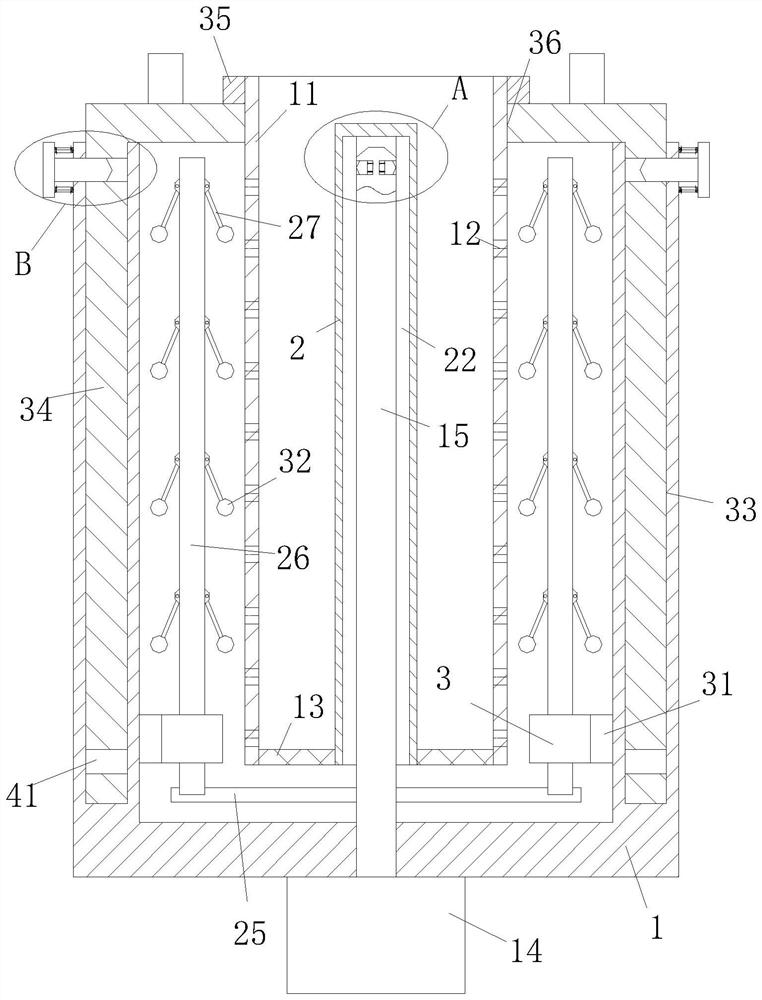

Hydrodesulfurization catalyst and preparation method thereof

PendingCN114505078AImprove impregnation efficiencyGuaranteed impregnation effectGas treatmentDispersed particle separationComposite materialOxide

The invention belongs to the technical field of catalyst materials, and particularly relates to a hydrodesulfurization catalyst and a preparation method thereof.The preparation method includes the steps that S1, an aluminum oxide waste agent is roasted at the temperature of 450-550 DEG C, and then a product A is obtained; s2, the product A is subjected to mixing, kneading and forming, and a formed matter B is obtained; s3, impregnating the molded substance B through an impregnating box, firstly putting the molded substance B into a placement barrel, then filling a box body with an impregnating solution containing Co and Mo, then putting the placement barrel into the box body to be immersed, then driving the placement barrel to rotate through the rotation of a motor, and further performing saturated impregnation on the molded substance B; and S4, drying and roasting the impregnated material in S3 to obtain the hydrodesulfurization catalyst. The invention discloses a material dipping box, and aims to solve the problems that when materials are dipped, the materials are generally directly put into the box body, so that the dipped materials are inconvenient to take out, and dipping liquid is attached to the outer sides of the materials after the dipped materials are taken out, so that the dipping liquid is wasted.

Owner:马超

Composite material and metal part dovetail groove integrated forming connection structure and method

The invention provides a composite material and a metal component dovetail groove integrated forming connection structure and method, the structure includes: a metal component, provided with a dovetail groove; the composite material component includes: a composite material main body and a composite material connection part, the composite material connection part includes a composite material The molding structure is set in the dovetail groove, and the outer surface is attached to the inner surface of the dovetail groove, and the composite material molding structure is integrally formed with the composite material main body; the composite material prefabricated block is used to fix the reinforcing material of the composite material molding structure in the dovetail groove The position in the center is filled inside the composite material forming structure, and the outer surface of the composite material prefabricated block is bonded to the inner surface of the composite material forming structure. In this structure and method, before the composite material is formed, the reinforcing material and the dovetail groove are effectively combined, and then the integrated molding is carried out, so that the connection structure has both the strength and the sealing function of the connection between the composite material and the metal, and the composite material and the metal part are avoided. There are many disadvantages of mechanical connection and adhesive connection.

Owner:北京玻钢院复合材料有限公司

A kind of capacitor production equipment and process

ActiveCN111599611BAvoid it happening againGuaranteed impregnation effectWinding capacitor machinesDrying/impregnating machinesProcess engineeringVacuum pump

The invention discloses a capacitor production equipment and process, which is applied in the field of capacitor production, and solves the problem that the air in the impregnating agent delivery pipeline is not removed when the capacitor is impregnated, and the dye solution produces air bubbles during the impregnating agent transportation process. A technical problem that affects the quality of produced capacitors. The main point of the technical solution is a capacitor production equipment, including a vacuum tank. Buffer tube, there is a pipeline valve at the connection between the buffer tube and the vacuum tank, and the outer wall of the upper end of the buffer tube is connected with a vent pipe, and the upper end of the vent pipe is provided with a vent port, and the diameter of the cross section of the vent pipe increases first and then becomes smaller from bottom to top , the air release pipe is provided with a floating block, the outer wall of the floating block is attached to the inner wall of the lower end of the air release pipe; the technical effect is to ensure the vacuum state in the capacitor and ensure the quality of the produced capacitor.

Owner:NINGBO BAOCHENG ELECTRIC CO LTD

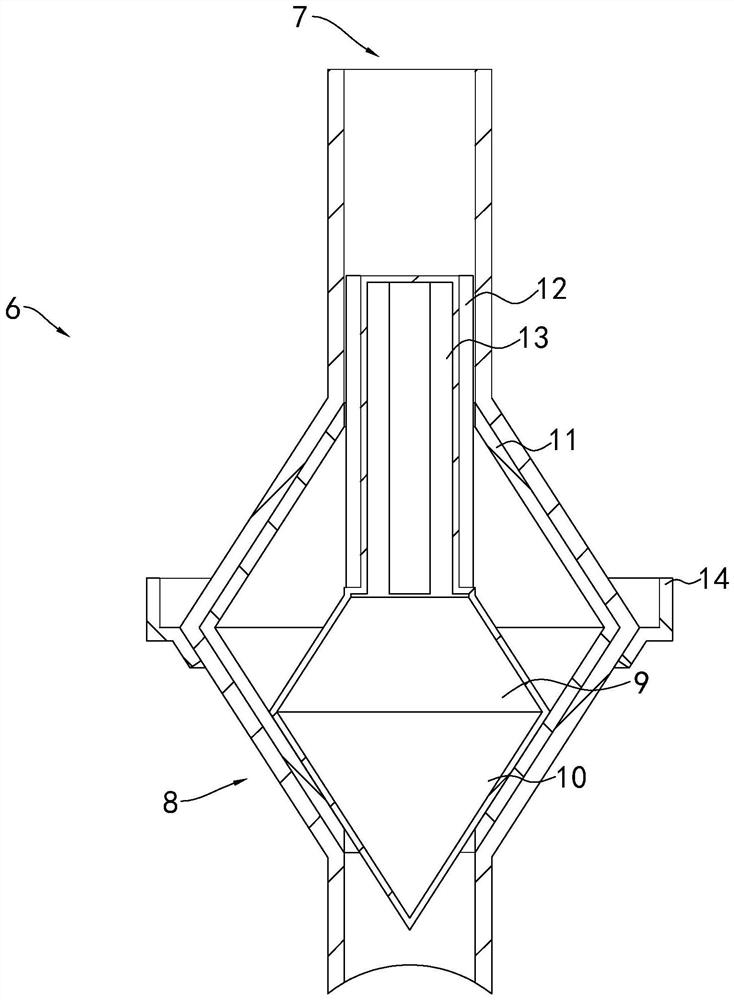

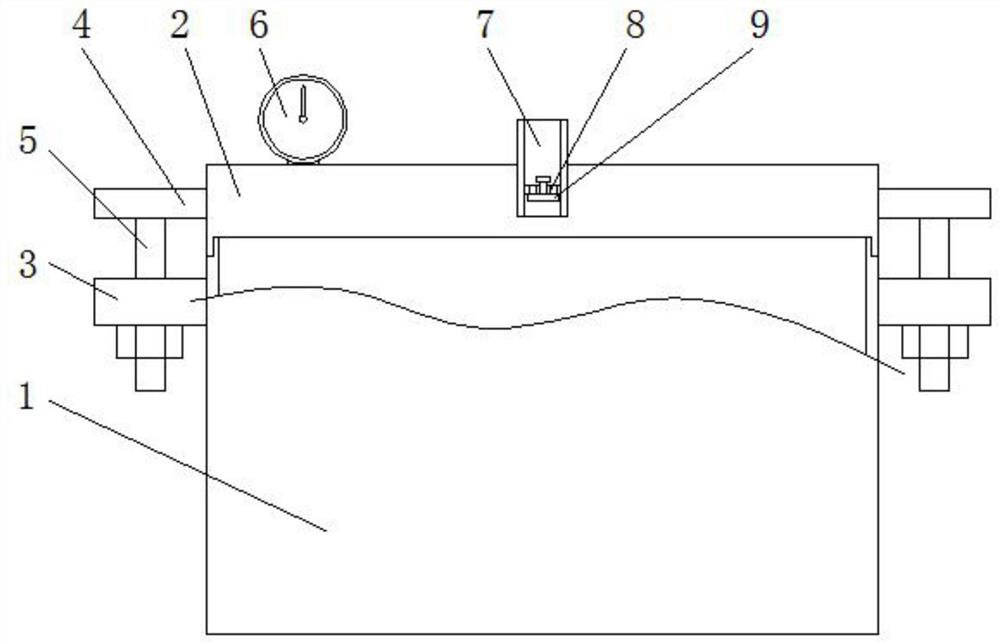

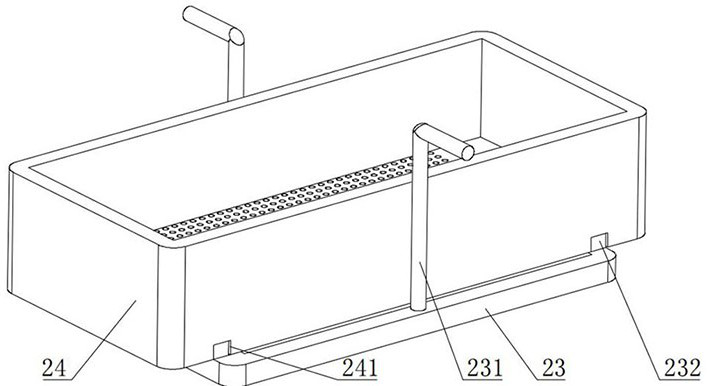

Straddle plate type peanut impregnator

PendingCN113100419AGuaranteed impregnation effectIncreased dipping speedFood shapingEngineeringStructural engineering

The invention relates to the technical field of peanut impregnation, in particular to a straddle plate type peanut impregnator, and solves the defects that peanut impregnation needs to consume a lot of time and peanuts cannot be in full contact with an impregnation solution. The straddle plate type peanut impregnator comprises an outer box body, a box cover is clamped at the top of the outer box body, insertion plates are welded on two sides of the outer box body, and connecting plates are welded on two sides of the box cover. The insertion plates are welded to the bottom of the connecting plates, a pressure gauge is installed on the upper surface of the box cover, an air nozzle is welded on the upper surface of the box cover, a partition plate is welded to the inner side of the air nozzle, a plug is clamped in the middle of the partition plate, a three-section rail is fixed to the inner side of the outer box body through screws, one side of the three-section rail is connected with the inner box body through screws, and the outer side of the inner box body is connected with a supporting plate through a rotating shaft; springs are welded to one sides of the supporting plates, bottom plates are welded to the interiors of the two sides of the inner box body, and storage baskets are clamped to the tops of the bottom plates, peanuts are fixed in a layered mode and soaked, the peanuts make complete contact with the soaking solution, and the peanut soaking effect is guaranteed.

Owner:青岛宝芝泉精密机械制造有限公司

A kind of rapid preparation device of catalyst

ActiveCN114345419BRealize automatic impregnationGuaranteed impregnation effectCatalyst activation/preparationPtru catalystEngineering

The present invention is applicable to the technical field of catalyst preparation, and provides a rapid catalyst preparation device, comprising: a housing, in which a storage chamber, an impregnation chamber and a drying chamber are sequentially arranged from left to right, and the storage chamber communicates with the impregnation chamber There is a rotatable baffle at the center; the dipping assembly includes a runner and a dipping frame, and a number of bearing seats are movably connected to the runner, and a dipping frame is set up on the bearing seat; the dumping assembly includes a rotating shaft and a gripper, and the rotating shaft is set on the dipping frame. Between the chamber and the drying chamber, the two ends of the rotating shaft are movably connected to the connecting rod, and the connecting rod is connected to the jaws. The side wall of the housing is provided with a guide block that cooperates with the connecting rod. The guide block is chamfered near the bottom side of the impregnation chamber; the drying assembly, It includes a conveyer belt and a hot air blower, the conveyer belt is arranged horizontally in the drying room, the hot blower is connected with an air duct, and the air duct is located above the conveyer belt. Thereby, the invention can automatically complete the impregnation and drying process, save manpower and improve efficiency, and is also applicable to the production of various catalysts, and the device occupies a small area and has low manufacturing cost.

Owner:WEIFANG UNIVERSITY

A Composite Dipping Tool and Its Application

The invention relates to a composite impregnating tool and application thereof. The composite impregnating tool comprises a tank body and a plurality of support plates with hole arrays, wherein holesin the hole arrays are through holes; the tank body comprises an upper tank body and a lower tank body; a tank cavity is formed between the upper tank body and the lower tank body; a liquid inlet is formed in the top of the upper tank body; a liquid outlet is formed in the bottom of the lower tank body; both the liquid inlet and the liquid outlet communicate with the tank cavity; the support plates are stacked in the tank cavity in a height direction of the tank body; and a cavity for accommodating a part to be subjected to composite impregnating is formed between every two adjacent support plates. The composite impregnating tool disclosed by the invention can simultaneously form two or more products, increases a utilization rate of an impregnating solution, greatly reduces the cost, and improves product production efficiency.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A kind of manufacturing method of solid capacitor

ActiveCN109192510BAffect the formation effectReduce the chance of sheddingElectrolytic capacitor manufactureElectrical resistance and conductanceConductive polymer

The invention discloses a manufacturing method of a solid state capacitor, which comprises the following steps in sequence: S1, winding a core bag; Numbering each core pack; 2, detect whether that core bag is short circuit one by one, and immerse the tested qualified core bag into a chemical forming liquid for chemical for repairing treatment. The positive electrode guide pin and the negative electrode guide pin of the core package are electrically connected with the positive electrode and the negative electrode of the power supply respectively in the forming and repairing process. The residual current of the core pack is detected one by one after the forming and repairing treatment. 3, dry that core pack; S4, immersing the core pack in the monomer solution for immersion treatment; 5, aftthat immersion treatment is finished, dry the core pack; S6, injecting a quantitative oxidant into the core pack; 7, heat to carry out polymerization reaction to generate conductive polymer in that core pack; S8. Assembled sealing; S9. Ageing. The invention adopts one-to-one charging to the core pack in the chemical forming process, avoids the defective products affecting the forming effect of other adjacent core packs, reduces the ESR series equivalent resistance, and improves the consistency of the products.

Owner:ZHAOQING BERYL ELECTRONICS TECH

A kind of fast impregnation equipment of Chinese medicine decoction pieces and automatic impregnation method of Chinese medicine decoction pieces

ActiveCN109157415BShorten the soaking timePrevent corruptionPharmaceutical product form changeMedicinal herbsPhysical chemistry

A Chinese medicine in that form of decoction slice is prepared from 11 Chinese-medicinal material through immersing them in decoction slices, immersing them in water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them withwater, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them with water, mixing them, mixing them with water, mixing them, mixingthem with water, mixing them, mixing, mixing, mixing, mixing, mixing, mixing and mixing. The invention can solve the problem that when the prior Chinese medicinal decoction pieces are impregnated, Toolong impregnation time, It usually takes a long time to get there, and soaked for a long time, Chinese herbal slices are prone to decay, Traditional Chinese medicine slices usually float above the water surface when impregnated, impregnation is not complete, traditional Chinese medicine slices usually accumulate together when impregnated, affecting the impregnation effect, complicated operation,slow impregnation, low efficiency and other difficult problems, can realize the function of automatic and high-efficient impregnation of traditional Chinese medicine slices, and has the advantages ofsimple operation, rapid impregnation, high efficiency and so on.

Owner:安徽冯了性中药材饮片有限公司

Forming method of thermoplastic composite material with integrated sandwich structure

InactiveCN113001820ASolve the problem of difficult impregnationGuaranteed impregnation effectCoatingsYarnPolymer science

The invention discloses a forming method of thermoplastic composite material with an integrated sandwich structure. The forming method comprises the following steps of (1) compounding continuous reinforced fiber tows and thermoplastic resin tows to form composite yarns with "skin-core structures"; (2) weaving the prepared composite yarns into a three-dimensional fabric preform with an integrated hollow structure through a special weaving machine; (3) heating the three-dimensional fabric preform to melt the thermoplastic resin tows and infiltrate the reinforced fiber tows; and (4) cooling and shaping to prepare the composite material with the integrated sandwich structure. The forming method provided by the invention solves the problems that the thermoplastic special engineering plastic is high in viscosity and the three-dimensional fabric reinforcement is difficult to impregnate, and the forming process is low in equipment requirement, simple in process and low in production cost.

Owner:南京特塑复合材料有限公司

Cooling and filtering device for carbon material dipping production

PendingCN112413980AAvoid cloggingEnsure safetyLighting and heating apparatusCooling fluid circulationProcess engineeringEnvironmental geology

The invention discloses a cooling and filtering device for impregnation production of a carbon material. A water inlet mechanism is used for adding cooling water into a shell; impurities in the watercan be filtered by a filter; a floating ball in a liquid level floating switch rises along with the increase of the cooling water until the floating ball is in contact with a magnetic reed mechanism;the floating ball can continue to push the magnetic reed mechanism to ascend along with increase of the water level, so that a baffle is driven to ascend; a water outlet pipeline is opened to drain the cooling water; and meanwhile, a jacking component can continue to ascend until the water outlet pipeline is completely opened; at the moment, the magnetic reed mechanism makes contact with a magnetblock; a circuit is switched on to operate, and then a collecting mechanism is driven to slide on a top cover to collect high-viscosity impurity clusters generated in the shell; and therefore, a wateroutlet pipe is prevented from being blocked, and the dipping effect is guaranteed.

Owner:浙江瑞能炭材料科技有限公司

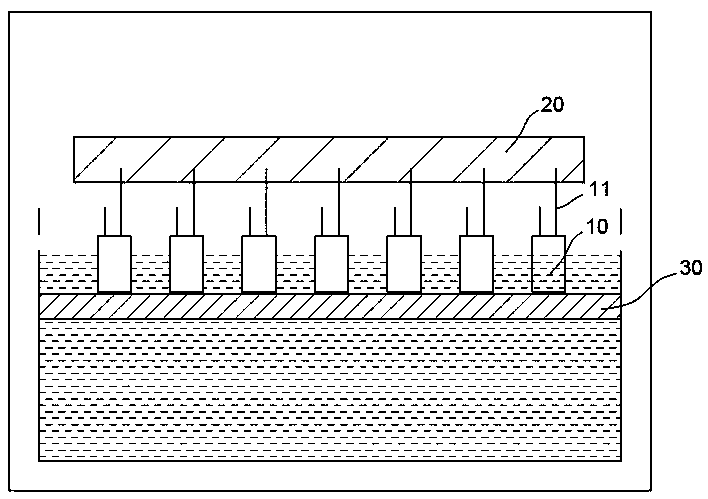

Hot-melt controllable carbon fiber thermoplastic pre-impregnated fabric structure and preparation method thereof

PendingCN111284103ASolve the uneven effect of hot melt impregnationFlexible adjustmentSynthetic resin layered productsPolymer chemistryFabric structure

The invention discloses a hot-melt controllable carbon fiber thermoplastic pre-impregnated fabric structure and a preparation method thereof; the hot-melt controllable carbon fiber thermoplastic pre-impregnated fabric structure is a layered structure, and sequentially comprises a thermoplastic resin substrate adhesive film layer, a thermoplastic resin particle layer and a laminated multi-dimensional carbon fiber fabric layer; the thickness of the thermoplastic resin particle layer is 0.05-1 mm, and the particle size of resin particles is 1-10 [mu]m. The laminated multi-dimensional carbon fiberfabric layer is formed by laminating a plurality of layers of planar fabrics. The structure of the pre-impregnated fabric can ensure the production efficiency, can control the hot melting impregnation speed and the impregnation effect, and can avoid adverse effects of a solvent on the structural compactness of the pre-impregnated fabric.

Owner:山东宽原新材料科技有限公司

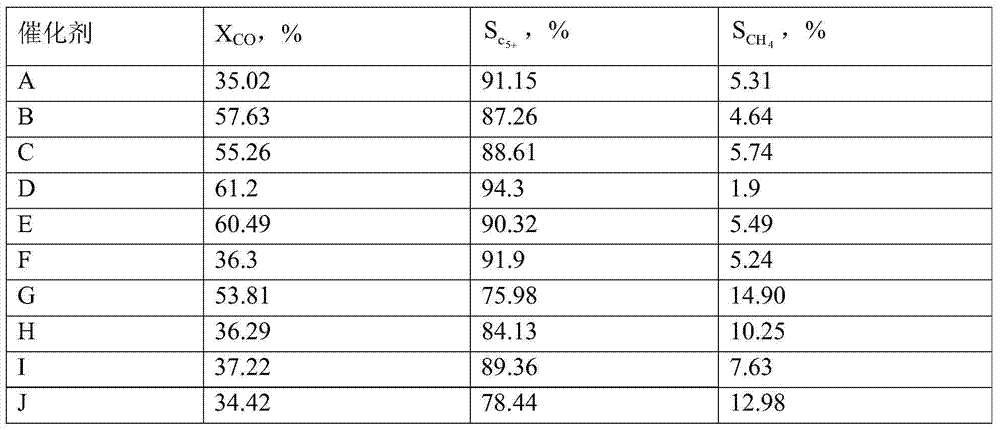

A shell-distributed Fischer-Tropsch synthesis catalyst and preparation method thereof

ActiveCN104759296BRealize continuous preparationImprove production efficiencyCatalyst activation/preparationLiquid hydrocarbon mixture productionBULK ACTIVE INGREDIENTActive ingredient

The invention discloses a shell-distributed Fischer-Tropsch synthesis catalyst and a preparation method thereof. The method comprises contacting an active component solution with a catalyst carrier, followed by drying and optional roasting, and the contacting is carried out in a catalyst preparation system The preparation system includes an inclined drum, a carrier storage device for storing the catalyst carrier, and a solution storage device for storing the active components. The side wall of the drum is provided with a turning member, the carrier storage device and the solution storage device. respectively communicated with the drum, the method includes spraying the active component solution from the solution storage device into the drum in an atomized form, turning over the catalyst carrier that enters the drum from the carrier storage device when the drum rotates, and the active component solution The injection amount satisfies V L / V C = 0.01 to 0.99. The Fischer-Tropsch synthesis activity and C of the catalyst prepared by the preparation method of the present invention 5+ Higher selectivity for hydrocarbons and lower selectivity for methane.

Owner:CHINA PETROLEUM & CHEM CORP +1

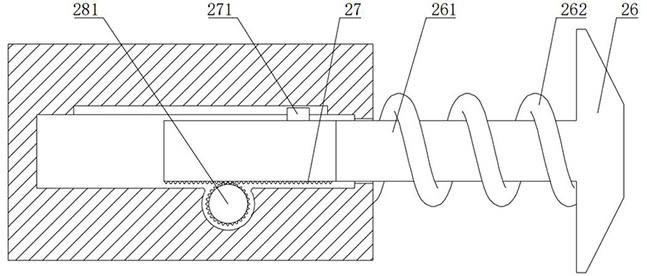

Lowering device of impregnation tank workpiece basket

The invention discloses a lowering device of an impregnation tank workpiece basket. The lowering device comprises a guide sleeve, a sliding rod, an air cylinder and a movable pin, wherein the air cylinder is connected with the movable pin, the air cylinder stenches to drive the movable pin to stretch, and the guide sleeve is internally provided with the sliding rod; one side of the guide sleeve, close to the movable pin, is provided with a hole, and one side of the sliding rod, close to the movable pin, is provided with a groove; the top end of the sliding rod is provided with a workpiece basket clamping groove with a Huff-structured clamping groove, and the Huff-structured clamping groove is arranged between two fixed clamping grooves; and the lower end of the guide sleeve is provided with a liquid outlet, the guide sleeve at the upper end of the liquid outlet is internally provided with a seal sleeve, and the guide sleeve is connected with the inner wall of an impregnation tank. The lowering device provided by the invention is automatic, does not need manual operation, is safe and convenient, reach the purpose that a workpiece is always in a vacuum state, guarantees the impregnation effect, and can remarkably improve the impregnation qualified rate as compared with the traditional process.

Owner:NANJING AIBUNA SEALING TECH CO LTD

Shell distribution catalyst, preparation method thereof and Fischer-Tropsch synthesis method thereof

ActiveCN108855057AImprove shelling rateHigh strengthCatalyst activation/preparationLiquid hydrocarbon mixture productionSynthesis methodsActive component

The invention relates to the field of catalyst preparation, and discloses a shell distribution catalyst, a preparation method thereof and a Fischer-Tropsch synthesis method thereof. The preparation method of the catalyst comprises the steps of placing a porous support in a hollow drum body, spraying a solution containing a catalytically active component onto the surface of the porous support. Thetotal spray amount of the solution is smaller than the total pore volume of the porous support. The drum body has a closable feeding port for receiving the porous support and a closable discharge portfor outputting the porous support. The ratio of the axial length to the maximum radial length of the drum body is 3-9. The drum body is horizontally disposed, and the porous support loaded with the solution leaves the drum body through the discharge port, then the porous support is added to the drum body through the feeding port, and the porous support left an intermediate containerthe drum bodyis dried and optionally calcined. The catalyst prepared by the method has a high shell layer ratio, high strength and a high molding rate, and is more favorable for detecting product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Impregnation device for heat-resistant creep-resistant polyethylene fiber preparation

PendingCN107723960AEfficient and uniform impregnationImprove mechanical propertiesTextile treatment machine arrangementsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberMaterials science

The invention discloses an impregnation device for heat-resistant creep-resistant polyethylene fiber preparation. By means of the device, in a preparation and processing process of polyethylene fibers, impregnation processing treatment can be conducted on the polyethylene fibers though an impregnation container; in an actual work process of the impregnation device for heat-resistant creep-resistant polyethylene fiber preparation, conveying treatment can be conducted on the polyethylene fibers through conveying rollers, and by means of an impregnation liquid inlet and an impregnation liquid outlet in the upper portion of the impregnation container, adjustment of the liquid level of impregnation liquid in the impregnation container can be achieved, so that it is ensured that the impregnationliquid is always maintained to be over the polyethylene fibers. By means of a stirring container in the impregnation container and an auxiliary stirring container in an impregnation liquid storage container, stirring treatment can be conducted on the impregnation liquid in the impregnation container and impregnation liquid which is exported into the impregnation liquid storage container simultaneously, so that the whole impregnation effect is guaranteed.

Owner:JIANGSU SHENTAI SCI & TECH DEV

A kind of preparation method of continuous fiber reinforced nylon 6 composite material

The invention discloses a preparation method of a continuous fiber reinforced nylon-6 composite material, which comprises the following steps: (1) separately storing caprolactam molten masses containing a catalyst and a catalyst promoter in a constant-temperature constant-speed liquid feeding tank; (2) placing a continuous fabric in a mold of an injection molding machine; (3) starting the injection molding machine and a constant-temperature liquid feeding device separately, adding the caprolactam molten masses containing the catalyst and the catalyst promoter into the feeding hole of the injection molding machine through the liquid feeding device at a same temperature and a same speed, mixing and injecting in the mold injection machine, and injecting the caprolactam molten masses containing the catalyst and the catalyst promoter into the mold paved with the continuous fabric; and (4) initiating caprolactam negative ring-opening polymerization in the mold. The preparation method disclosed by the invention can effectively prevent caprolactam from polymerization before entering the mold, so as to ensure good impregnation of fiber and caprolactam to obtain the continuous fiber reinforced nylon-6 composite material with more excellent mechanical properties.

Owner:江苏易元新材料科技有限公司

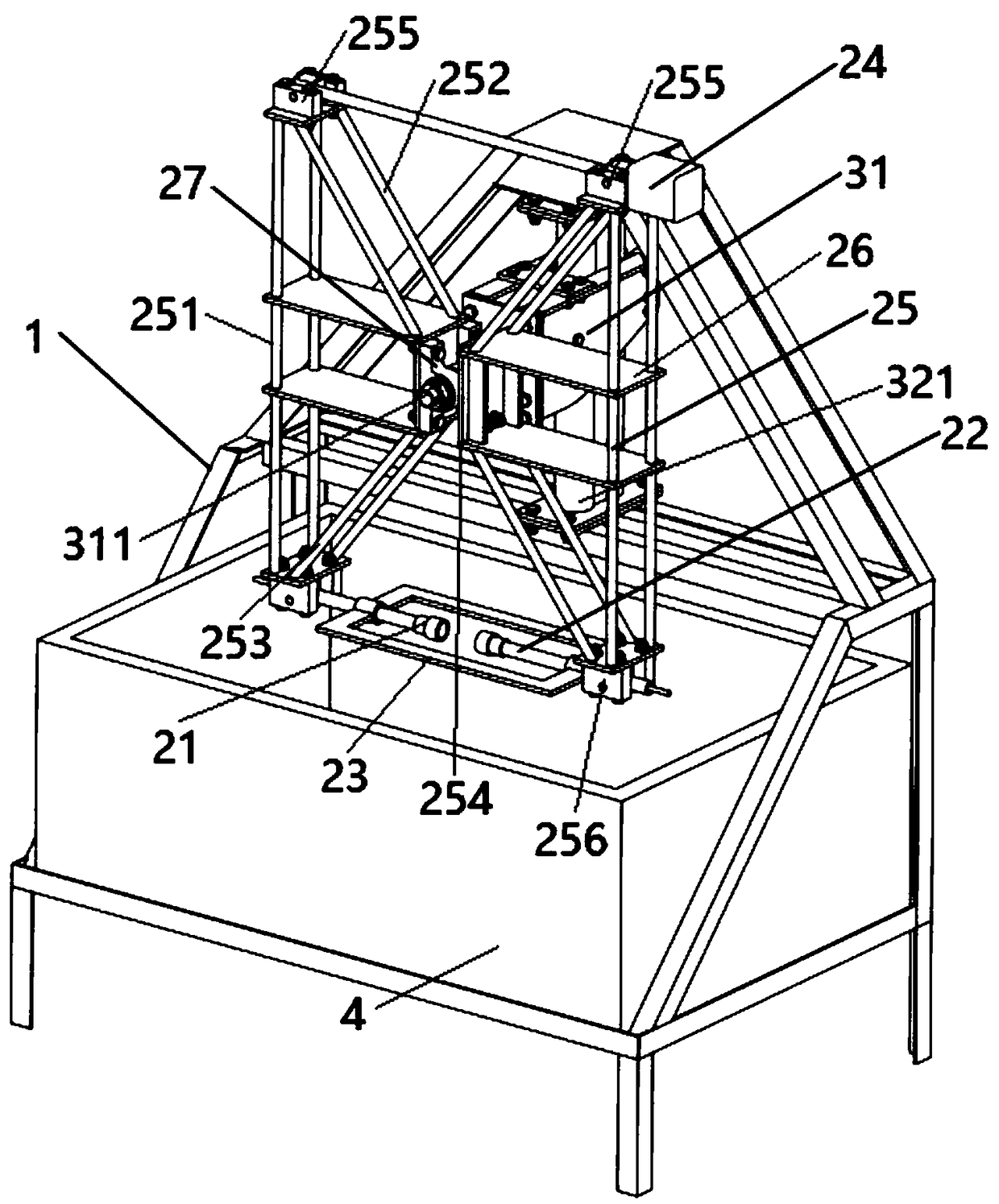

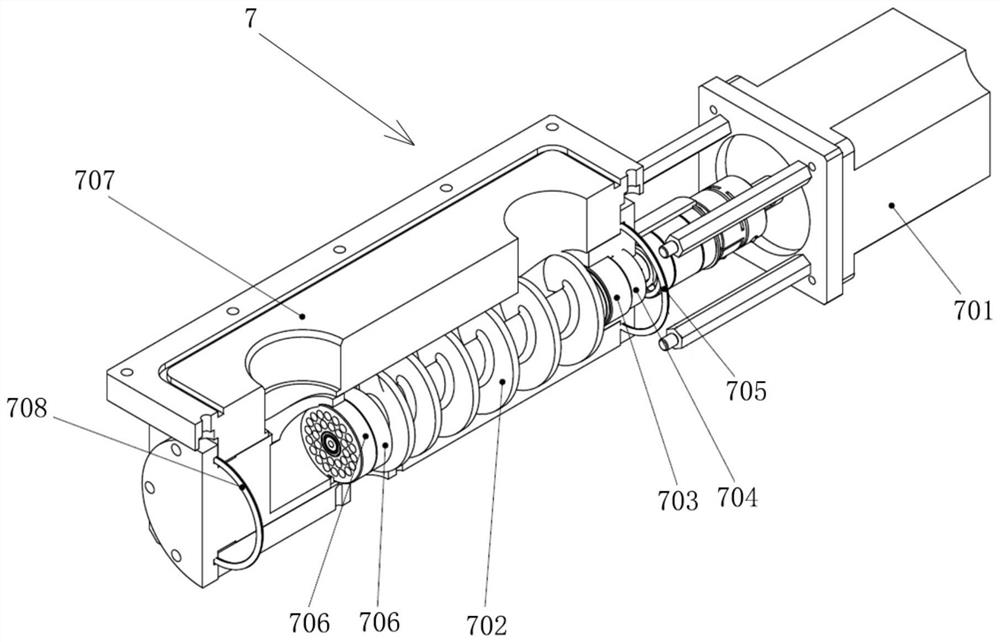

Rapid preparation device of catalyst

ActiveCN114345419ARealize automatic impregnationGuaranteed impregnation effectCatalyst activation/preparationPtru catalystStructural engineering

The invention is applicable to the technical field of catalyst preparation, and provides a rapid catalyst preparation device which comprises a shell, a material storage chamber, a dipping chamber and a drying chamber are sequentially arranged in the shell from left to right, and a rotatable baffle is arranged at the communicating position of the material storage chamber and the dipping chamber; the dipping assembly comprises a rotating wheel and a dipping frame, the rotating wheel is movably connected with a plurality of bearing seats, and the dipping frame is erected on the bearing seats; the dumping assembly comprises a rotating shaft and a clamping jaw, the rotating shaft is arranged between the dipping chamber and the drying chamber, two ends of the rotating shaft are movably connected with connecting rods, the connecting rods are connected with the clamping jaw, the side wall of the shell is provided with guide blocks matched with the connecting rods, and the bottom side edge, close to the dipping chamber, of the guide blocks is chamfered; the drying assembly comprises a conveying belt and an air heater, the conveying belt is horizontally arranged in the drying chamber, the air heater is connected with an air pipe, and the air pipe is located above the conveying belt. Therefore, the device can automatically complete the dipping and drying processes, saves manpower, improves the efficiency, can also be suitable for production of various catalysts, and is small in occupied area and low in manufacturing cost.

Owner:WEIFANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com