Shell distribution catalyst, preparation method thereof and Fischer-Tropsch synthesis method thereof

A Fischer-Tropsch synthesis and catalyst technology, which can be used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of less intensity and simple and easy-to-control operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

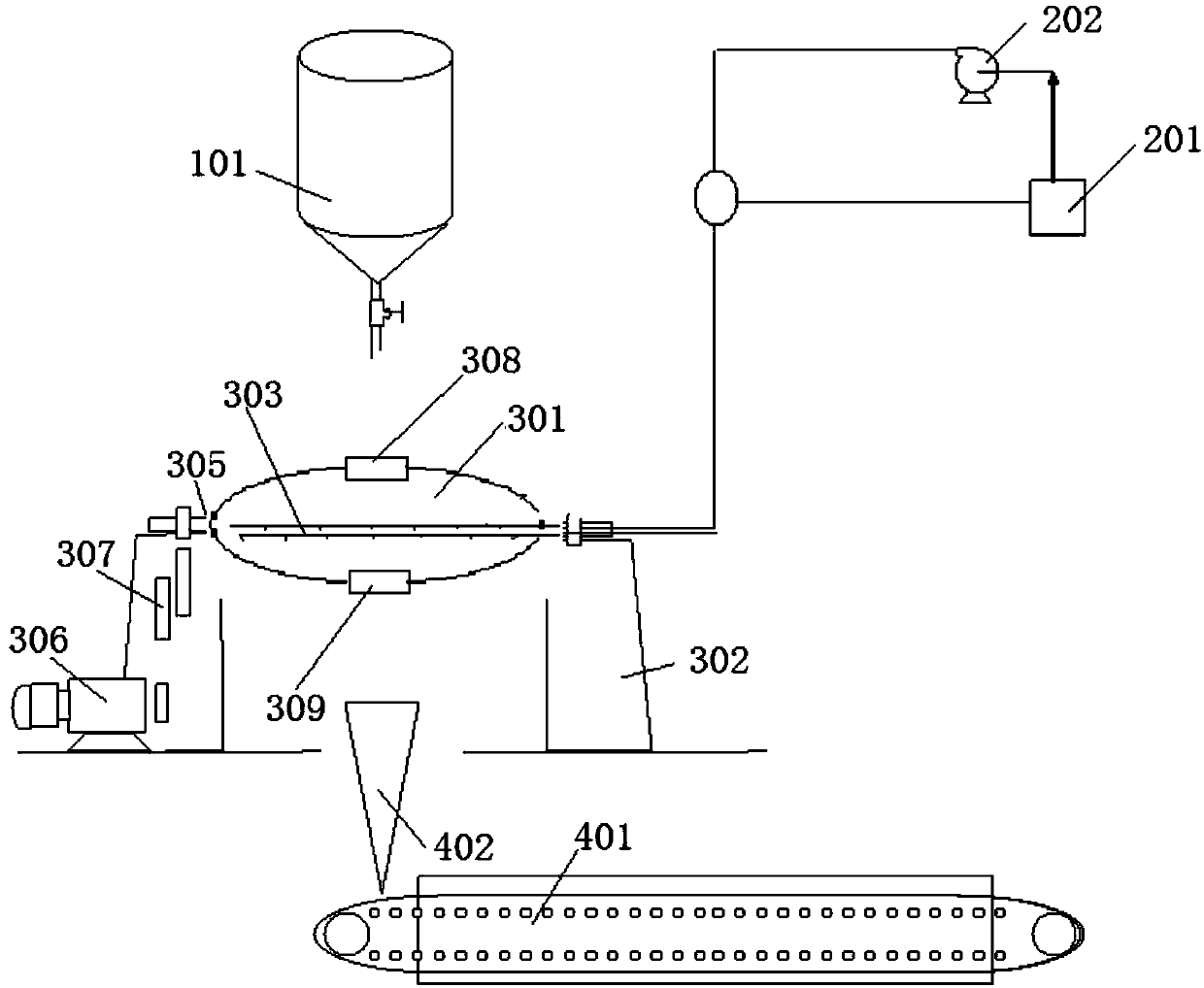

[0032] According to a first aspect of the present invention, the present invention provides a method for preparing a shell-distributed catalyst, the method comprising:

[0033] The porous carrier is placed in the hollow drum body, the solution containing the catalytically active component is sprayed on the surface of the porous carrier, the total spraying amount of the solution is less than the total pore volume of the porous carrier, and the drum body has The opening and closing inlet for receiving the porous carrier and the opening and closing outlet for outputting the porous carrier, the ratio of the axial length of the drum body to the maximum radial length is 3-9, the rotor The drum body is arranged horizontally, the porous carrier loaded with solution leaves the drum body through the outlet, and then replenishes the porous carrier into the drum body through the feed port, and the porous carrier leaving the drum body is dried and can be Selected roasting.

[0034] In the...

Embodiment approach

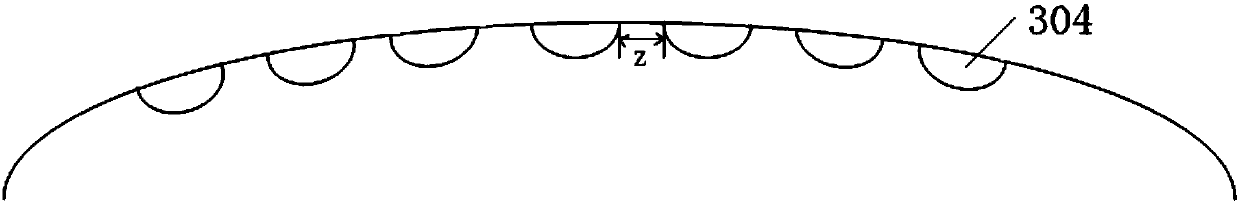

[0046] According to a preferred embodiment of the present invention, the sheet-shaped protrusions are arranged along the axial direction of the drum body. More preferably, the lifting plate includes multiple rows of sheet-like protrusions arranged in parallel, wherein the distance between two adjacent rows is adjustable, so that the turning frequency of the material to be impregnated can be changed, thereby changing the impregnation effect.

[0047] Specifically, the smaller the distance between two adjacent rows of sheet-shaped protrusions is, the higher the frequency of flipping is. As a preferred manner, the distance between two adjacent rows of sheet-shaped protrusions is z (z is the linear distance between the right end point of the left sheet-shaped protrusion and the left end point of the right sheet-shaped protrusion), and Satisfied as 0<z<R, preferably 0<z<0.25R, more preferably 0.1R<z<0.25R, where R is the radius of the drum body 301 (the largest inner radius in the ...

Embodiment 1

[0101] 1. If figure 1 As shown, 200kg of butterfly-shaped γ-alumina particles extruded by a 1.6mm orifice (the particle length is 2-8 mm, and its water absorption rate is measured to be 0.8 ml / g) is used as a catalyst carrier and put into a porous carrier storage tank 101 middle.

[0102] 2. Dissolving cobalt nitrate in water to prepare an impregnating solution (calculated as CoO, the concentration of cobalt nitrate is 330 g / L) and placing it in the solution storage tank 201 containing catalytically active components.

[0103] 3. The porous carrier is sent into the drum body 301, the drum body 301 (the axial length of the drum body 301 is 3.5 meters, the maximum radial inner diameter (diameter) is 1 meter, and the minimum radial inner diameter (diameter) is 0.3 The inner wall of the drum body 301 is provided with a lifting plate 304, the axial section of the lifting plate 304 is arc-shaped, x=2.2y, z is 0.2R, and the drum body 301 is horizontally arranged, wherein, x is a lif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com