Impregnation device for heat-resistant creep-resistant polyethylene fiber preparation

A technology of polyethylene fiber and impregnation device, which is applied in the processing of textile material equipment configuration, liquid/gas/vapor fiber/sliver/roving processing, textile and papermaking, etc., can solve problems such as insufficient treatment effect, and achieve high efficiency and uniformity. Effects of dipping treatment and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

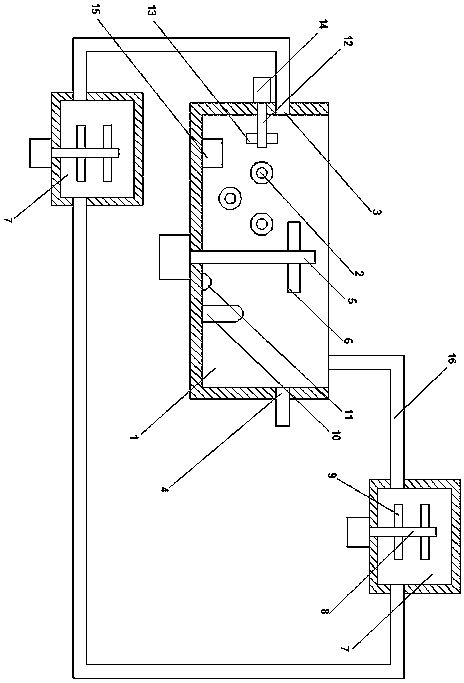

[0015] Such as figure 1 The shown impregnation device for the preparation of heat-resistant and creep-resistant polyethylene fibers includes an impregnation container 1, a transfer roller 2 for transferring polyethylene fibers is arranged inside the impregnation container 1, and an impregnation container 1 is arranged on the impregnation container 1. The liquid inlet 3 and the immersion liquid outlet 4, wherein the immersion liquid outlet 3 is arranged on the side end surface of the immersion container 1; the inside of the immersion container 1 is provided with a stirring device, which includes a stirring shaft 5 and a stirring blade 6; Two immersion liquid storage containers 7 are provided outside the immersion container, which are connected to each other, wherein any one of the immersion liquid storage containers 7 is connected with an overflow pipe 16 extending into the inside of the immersion container 1; There is an auxiliary stirring device, which includes an auxiliary st...

Embodiment 2

[0020] As an improvement of the present invention, the height position of the immersion liquid outlet 4 is higher than the height position of the transfer roller 2, and the height distance between them is at most 10 cm.

[0021] The remaining features and advantages of this embodiment are the same as those of the first embodiment.

Embodiment 3

[0023] As an improvement of the present invention, in the impregnation vessel 1, the stirring shaft 5 extends in the vertical direction, and two guide shafts 12 extending in the horizontal direction are provided on the side end surface of the impregnation vessel 1. A plurality of guide vanes 13 are arranged on one guide shaft 12; two guide shafts 12 are respectively arranged on both sides of the polyethylene transmission position; the guide shaft 12 passes through a guide motor arranged outside the immersion container 1 14 is driven; the bottom end of the immersion container 1 is provided with a hydraulic pump 15. By adopting the above technical solution, it can form a radial liquid flow on both sides of the polyethylene transmission position, so that the impregnation effect of the polyethylene fiber can be improved.

[0024] The remaining features and advantages of this embodiment are the same as those of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com