Preparation method for catalyst

A catalyst and catalyst carrier technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as inability to produce non-uniform catalysts, inability to achieve continuous production, and damage to catalyst carrier structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

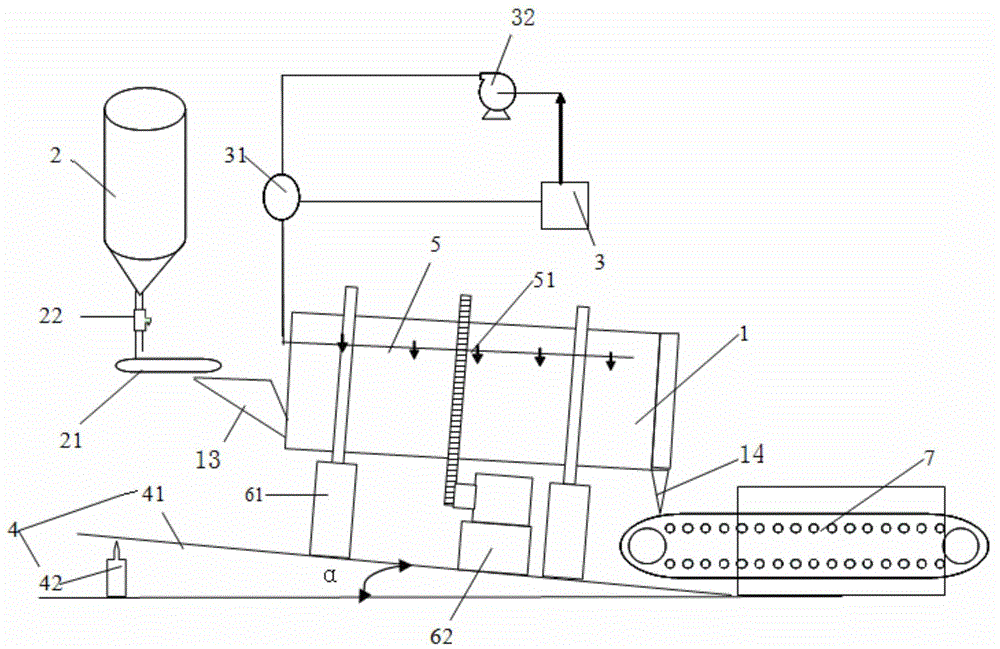

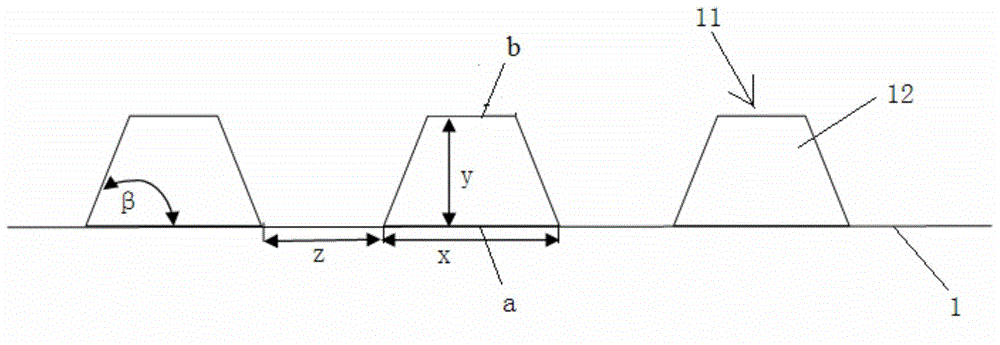

[0036] First, the present invention provides a catalyst preparation method, which is based on the impregnation method, that is, includes an impregnation step, and in the impregnation step, the purpose of impregnating the catalyst with an active component solution is achieved. The shape of the catalyst carrier has various shapes, such as circular, ellipsoid, Raschig ring and other structures. In addition, the active material in the active component solution mainly depends on the type of catalyst, such as various chemical elements such as alum and silver. In order to realize the purpose of the present invention, in the impregnation step of the preparation method provided by the invention, the catalyst carrier and the active component solution containing the active substance can be respectively input into the rotating drum 1 arranged at an inclination, and on the side of the rotating drum 1 The wall is provided with a turning member 11, wherein the active component solution is spr...

Embodiment 1

[0054]1. Put a strip-shaped alumina as a catalyst carrier and put it into the hopper-type carrier storage device 2, and enter the feed hopper 11 of the drum 1 through the second adjustment device 22 and the second conveyor belt 21 for transmission.

[0055] 2. The active component solution in the tank solution storage device 3 is transported through the pumping mechanism 32 first, and the active component in it is Ni+Mo, and then passes through the first regulating device 32 and enters the spray bar 5 and the atomizing nozzle 51 . The atomizing nozzle is a pressure nozzle, which can atomize the solution into droplets with a particle size of 20 microns to 120 microns, and spray them into the drum 1 at a volume flow rate of 0.3QM.

[0056] 3. Drive the rotating drum 1 by the rotating drive device 62, the rotating speed is 5 revolutions per minute, and the inner wall of the rotating drum 1 is provided with a material turning member 11, so that the catalyst carrier can be raised to...

Embodiment 2

[0060] 1. Put a strip-shaped alumina as a catalyst carrier and put it into the hopper-type carrier storage device 2, and enter the feed hopper 11 of the drum 1 through the second adjustment device 22 and the second conveyor belt 21 for transmission.

[0061] 2. The active component solution in the tank-type solution storage device 3 is first transported through the pumping mechanism 32 , and the active component therein is Co, then passes through the first regulating device 32 , and enters the spray bar 5 and the atomizing nozzle 51 . The atomizing nozzle is a pressure nozzle, which can atomize the solution into droplets with a particle size of 30 microns to 100 microns, and spray them into the drum 1 at a flow rate of 0.37 QM.

[0062] 3. Drive the rotating drum 1 by the rotating drive device 62, the rotating speed is 6 revolutions per minute, the inner wall of the rotating drum 1 is provided with a material turning member 11, so that the catalyst carrier can be raised to a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com