A kind of capacitor production equipment and process

A technology for producing equipment and capacitors, applied in the direction of capacitors, capacitor manufacturing, winding capacitor machines, etc., can solve problems such as affecting the quality of capacitors, producing bubbles in dye liquor, and no air removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

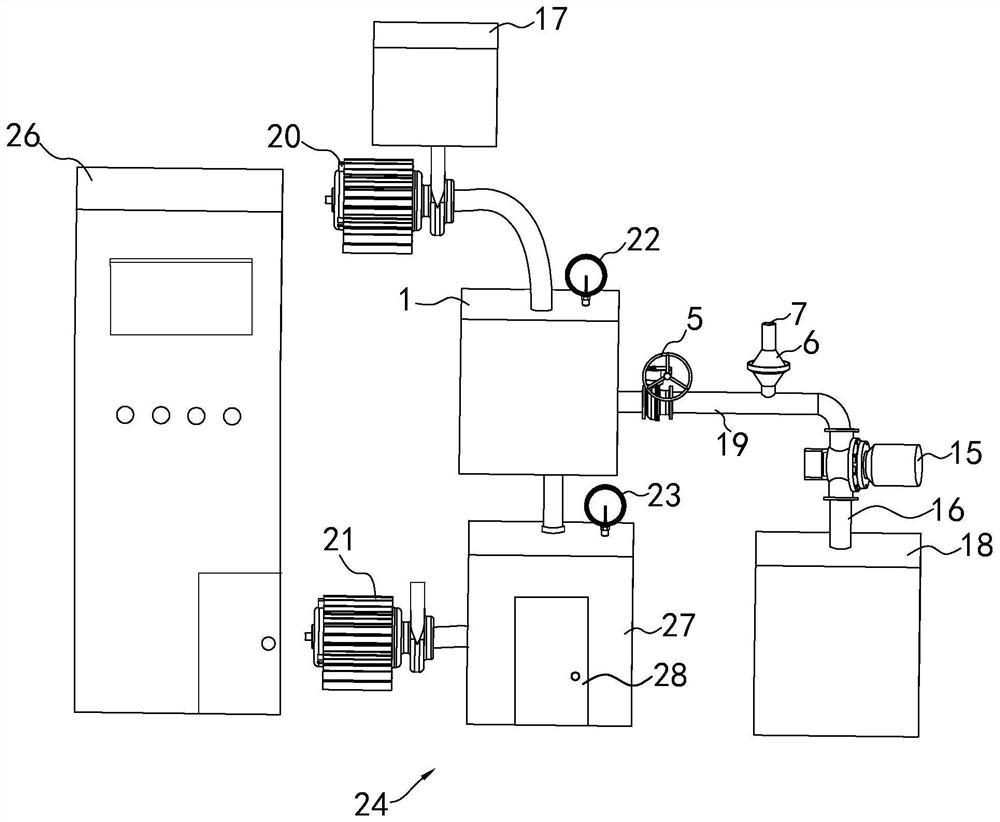

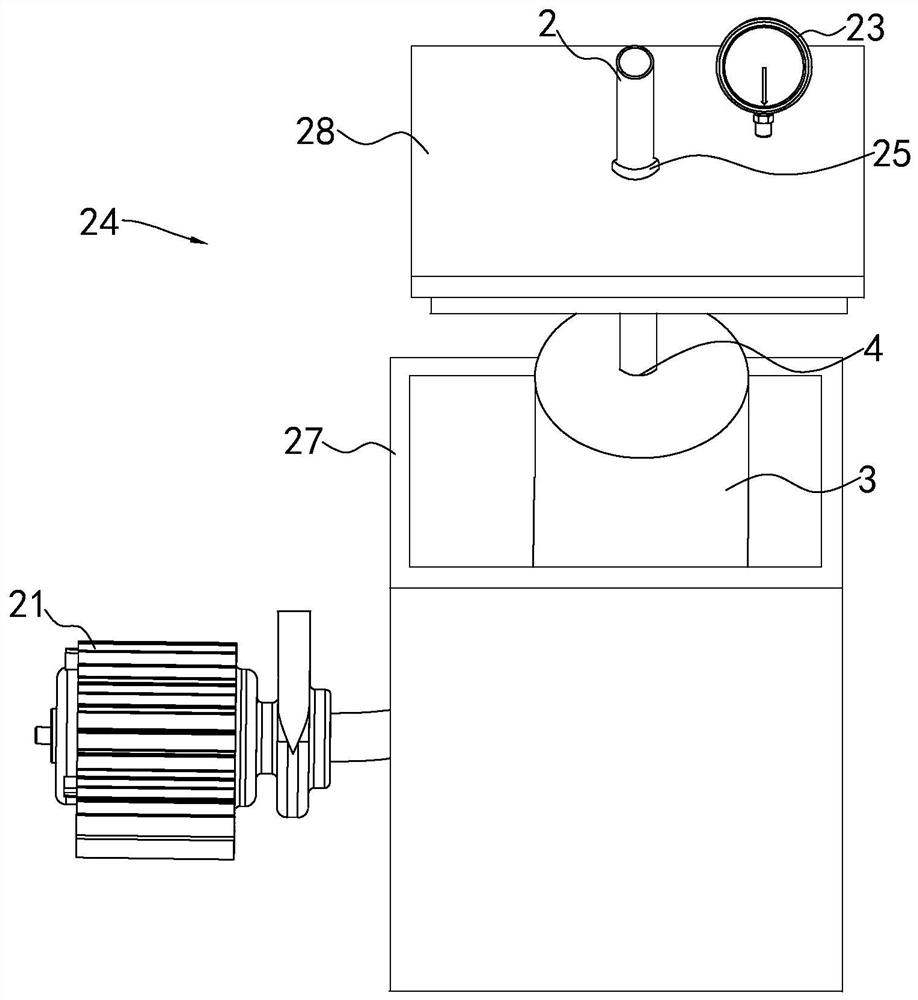

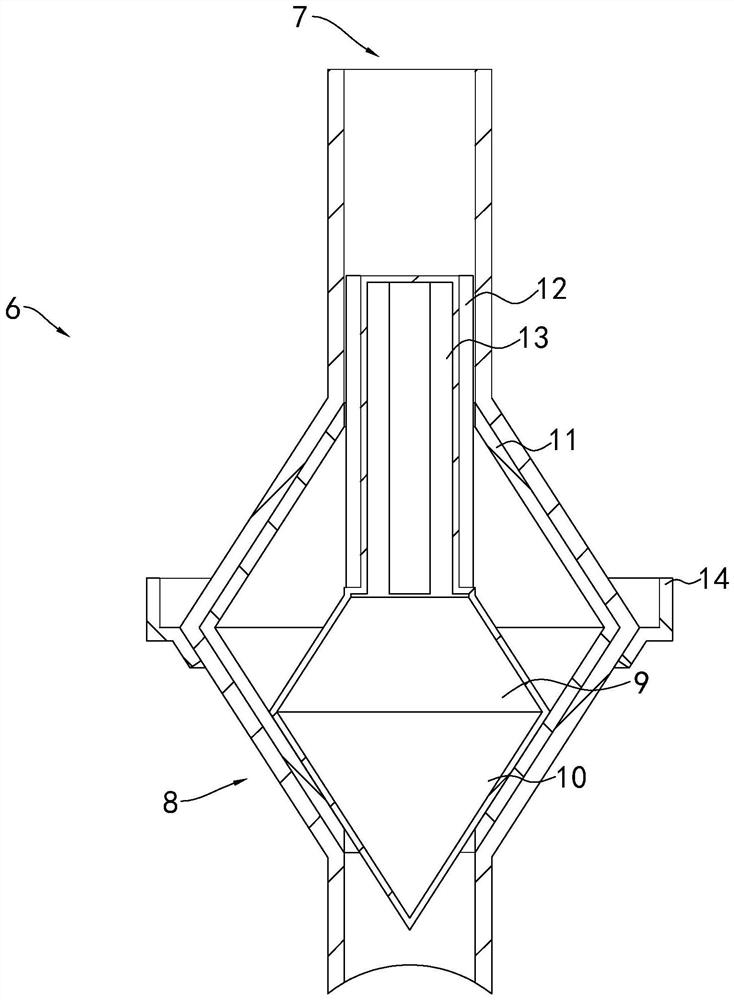

[0050] refer to figure 1 and figure 2 , is a capacitor production equipment disclosed in the present invention, comprising a vacuum tank 1, the upper end of the vacuum tank 1 is connected with a first vacuum pump 20, the lower end of the vacuum tank 1 is connected with an oil injection pipe 2, and the end of the oil injection pipe 2 is connected with a vacuum protection box 24 , the vacuum protection box 24 includes a box body 27 , the box body 27 is detachably connected with a placement door 28 , and the oil filling pipe 2 is inserted into the box body 27 through the upper end of the box body 27 . The oil filling pipe 2 and the box body 27 are detachably connected to facilitate the replacement of the vacuum protection box 24. A sealing ring 25 is provided at the connection between the box body 27 and the oil filling pipe 2. The sealing ring 25 seals the connection between the oil filling pipe 2 and the box body 27. The airtightness of the vacuum protection box 24 is ensured...

Embodiment 2

[0058] refer to figure 2 , a capacitor production process, which includes the following steps:

[0059] S1. Die cutting: the zinc-aluminum alloy is thinned and cut into metal sheets suitable for the production of capacitors 3;

[0060] S2, winding: the electrolytic paper is placed on the metal sheet after adsorbing the electrolyte, and the electrolytic paper and the metal sheet are wound layer by layer to form a cylinder;

[0061] S3. Gold spray: spray gold on both sides of the cylinder formed by winding the electrolytic paper and the metal sheet to facilitate welding;

[0062] S4. Welding: Weld the positive lead of the capacitor and the negative lead of the capacitor to the two sides of the electrolytic paper and the metal sheet respectively;

[0063] S5. Assembly: place the cylinder formed by the electrolytic paper and the metal sheet in the aluminum shell with the impregnation port 4;

[0064] S6, vacuum oil injection:

[0065] a. Heat the insulating oil to 70℃-80℃ for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com