Hot-melt controllable carbon fiber thermoplastic pre-impregnated fabric structure and preparation method thereof

A technology of carbon fiber fabric and fabric structure, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of high equipment requirements, high energy consumption of hot melt impregnation process, and difficulty in solvent discharge. Achieve flexible adjustment and solve the effect of uneven hot melt impregnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The second aspect of the present invention provides a method for preparing the above-mentioned heat-melt controllable carbon fiber thermoplastic prepreg fabric structure, including the following steps:

[0029] preparing a thermoplastic resin base film layer;

[0030] Spraying and processing a layer of thermoplastic resin particle layer on the inner surface of the thermoplastic resin base film layer;

[0031] The sizing agent is removed from the carbon fiber fabric, and the surface-treated carbon fiber fabric is pressed and hot-melted and laminated on the thermoplastic resin particle layer to obtain the finished product.

[0032] In some embodiments, the surface treatment method of the carbon fiber fabric is electrochemical oxidation or liquid phase oxidation.

[0033] In some embodiments, the temperature of pressurized hot melting is 10-30° C. higher than the melting point of the resin, and the pressure is 2-10 MPa.

Embodiment 1

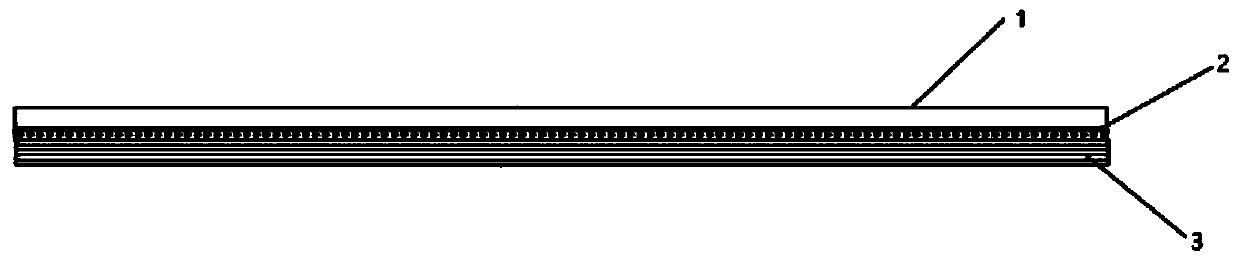

[0035] Such as figure 1 As shown, the heat-melt controllable carbon fiber thermoplastic prepreg fabric structure is a layered structure, followed by a thermoplastic resin base film layer 1, a thermoplastic resin particle layer 2, and a laminated multi-dimensional carbon fiber fabric layer 3.

[0036] First, a 0.1 mm thick polyolefin thermoplastic film-like resin is used as the thermoplastic resin base film layer 1, and a layer of 2 μm particles with a thickness of 0.05 mm is processed by physical spraying on the inner surface of the thermoplastic resin base film layer 1 in contact with the carbon fiber fabric. diameter polyolefin thermoplastic resin layer (thermoplastic resin particle layer 2), forming a heat-melt controllable thermoplastic resin base film. After that, T300 carbon fibers are used in a unidirectional arrangement to form a laminated multi-dimensional carbon fiber fabric layer 3 with a width of 1 m. After the fiber fabric is processed, the sizing agent is removed...

Embodiment 2

[0038] Such as figure 1 As shown, the heat-melt controllable carbon fiber thermoplastic prepreg fabric structure is a layered structure, followed by a thermoplastic resin base film layer 1, a thermoplastic resin particle layer 2, and a laminated multi-dimensional carbon fiber fabric layer 3.

[0039] First, a 0.3mm thick polyamide thermoplastic film-like resin is used as the thermoplastic resin base film layer 1, and a layer of 3 μm particle diameter with a thickness of 0.3 mm is processed by physical spraying on the inner surface of the thermoplastic resin base film layer 1 in contact with the carbon fiber fabric. The polyamide thermoplastic resin layer forms a heat-melt controllable thermoplastic resin base film. After that, T700 carbon fibers are used in a satin pattern to form a fabric layer with a width of 1.6m. After the fiber fabric is processed, the sizing agent is removed and the surface is activated. Finally, the continuous pressurized hot-melt method is used to sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com