Preparation method and cast rolling method of reticular carbon fiber aluminum-based composite material

A technology of aluminum matrix composite material and carbon fiber, which is applied in the direction of using liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., which can solve the problem of low degree of automation in the production of carbon fiber reinforced aluminum matrix composite materials and poor carbon fiber wettability , Low production efficiency and other issues, to achieve the effect of reducing energy consumption, high degree of mechanization, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

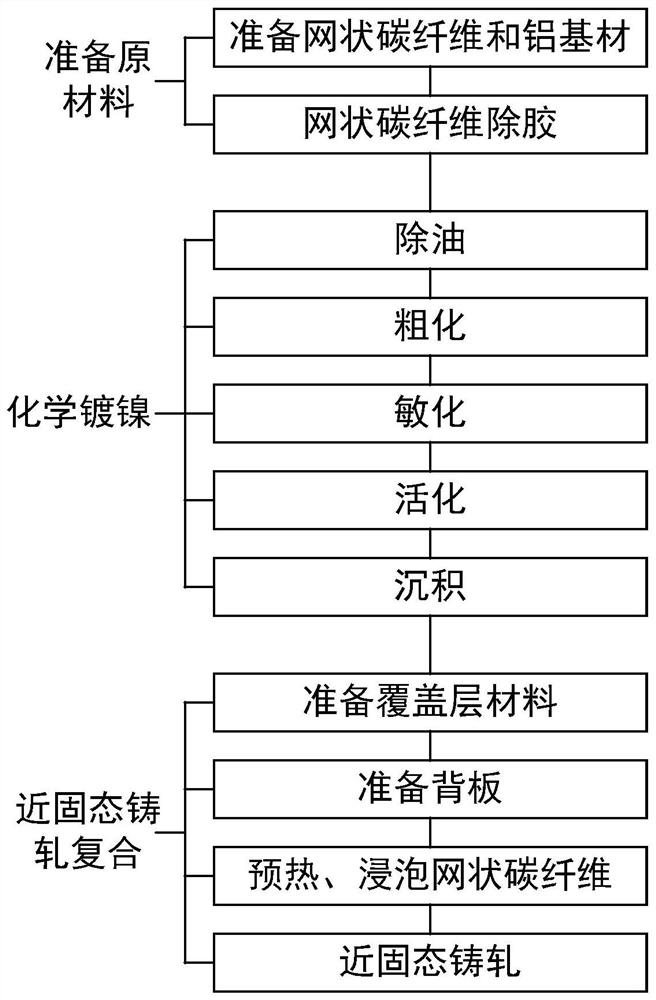

[0092] Refer to the attachment figure 1 The present invention relates to a method for preparing a mesh carbon fiber aluminum matrix composite, comprising the steps of:

[0093] Step 1, prepare mesh carbon fibers and aluminum substrates:

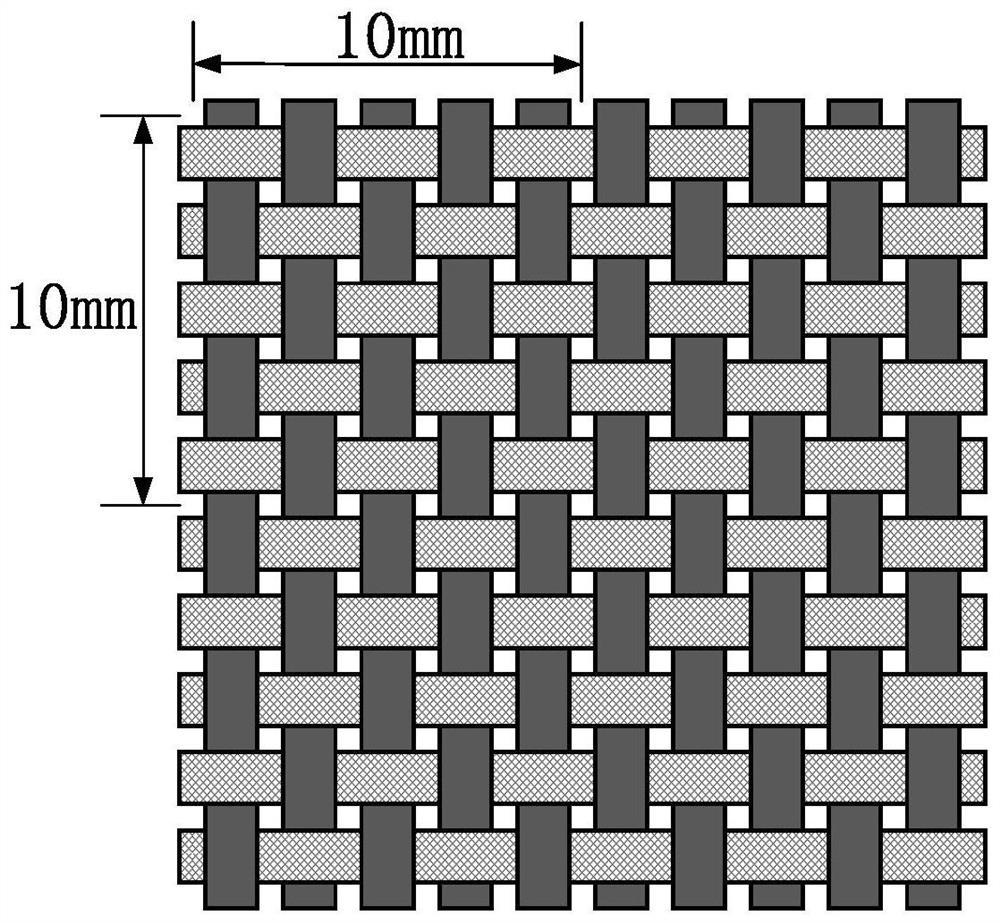

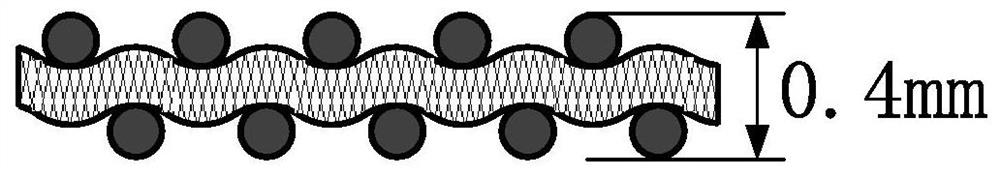

[0094] 1) Prepare polypropylene oxide carbon fibers to interleave with a cross-tilt method, so that the carrier is sequentially arranged in a vertical direction, so that the thickness of the mesh carbon fibers 31 is 0.4mm, and the inside, the latitude The direction of 5 bundles of fibers per 10mm per 10mm, each fiber contains 3000 fibers, see Figure 2-4 The cross-shaped carbon fiber of the present invention enhances the strength of the respective directional force, suitable for the reinforcement of sheet shape, tank-like shape material.

[0095] Among them, the carbon fiber physical properties are:

[0096] Fiber diameter: 7-8 μm;

[0097] Carbon content: 93-95%;

[0098] Line density: 198 ± 3 mg / m;

[0099] Volume density: 1.76-1.79g / cm 3 ; ...

Embodiment 1

[0140] Step 1, prepare mesh carbon fibers and aluminum substrates:

[0141] 1) preparing a polyacrylonitrile-based carbon fiber, a cross plain carbon fiber bundle method for interleaving, the warp beam and the beam weft fibers are arranged in the vertical direction are sequentially overlapped, so that the thickness of the carbon fiber web 31 is 0.4mm, the internal warp and weft the direction of each fiber bundle 5 10mm contain, per fiber bundle comprising 3000 fibers;

[0142] Wherein, the physical properties of the carbon fibers:

[0143] Fiber diameter: 7-8 μm;

[0144] Carbon content: 93-95%;

[0145] Line density: 198 ± 3 mg / m;

[0146] Bulk density: 1.76-1.79g / cm 3 ;

[0147] Tensile strength: 3.53 GPa;

[0148] Tensile modulus: 220GPa;

[0149] Fracture strain: 1.5%.

[0150] 2) Preparation of aluminum alloy 5083, wherein the chemical composition of the aluminum alloy is: Si: 0.38, Fe: 0.29, Cu: 0.33, Mn: 0.51, Mg: 4.42, Cr: 0.008, Zn: 0.01, Ti: 0.02, Al :margin.

[0151...

Embodiment 2

[0165] Step 1, prepare mesh carbon fibers and aluminum substrates:

[0166] 1) preparing a polyacrylonitrile-based carbon fiber, a cross plain carbon fiber bundle method for interleaving, the warp beam and the beam weft fibers are arranged in the vertical direction are sequentially overlapped, so that the thickness of the carbon fiber web 31 is 0.4mm, the internal warp and weft the direction of each fiber bundle 5 10mm contain, per fiber bundle comprising 3000 fibers;

[0167] Wherein, the physical properties of the carbon fibers:

[0168] Fiber diameter: 7-8 μm;

[0169] Carbon content: 93-95%;

[0170] Line density: 198 ± 3 mg / m;

[0171] Bulk density: 1.76-1.79g / cm 3 ;

[0172] Tensile strength: 3.53 GPa;

[0173] Tensile modulus: 220GPa;

[0174] Fracture strain: 1.5%.

[0175] 2) Preparation of aluminum alloy 5083, wherein the chemical composition of the aluminum alloy is: Si: 0.38, Fe: 0.29, Cu: 0.33, Mn: 0.51, Mg: 4.42, Cr: 0.008, Zn: 0.01, Ti: 0.02, Al :margin.

[0176...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com