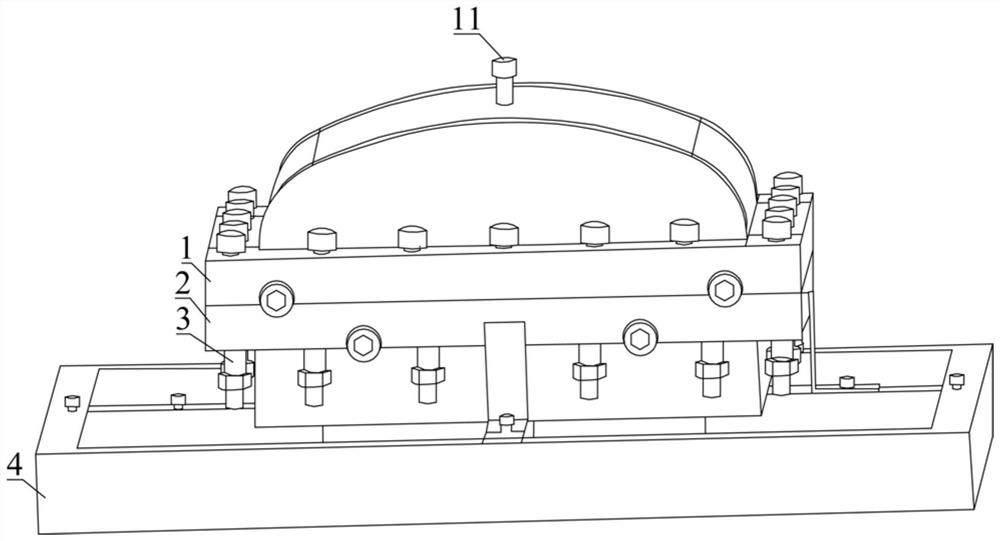

A Composite Dipping Tool and Its Application

A technology of dipping tooling and dipping parts, applied in the direction of coating, can solve the problems of low utilization rate of dipping liquid, low production efficiency, large size, etc., and achieve the effect of ensuring composite dipping effect, easy assembly and positioning, and reasonable structure setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

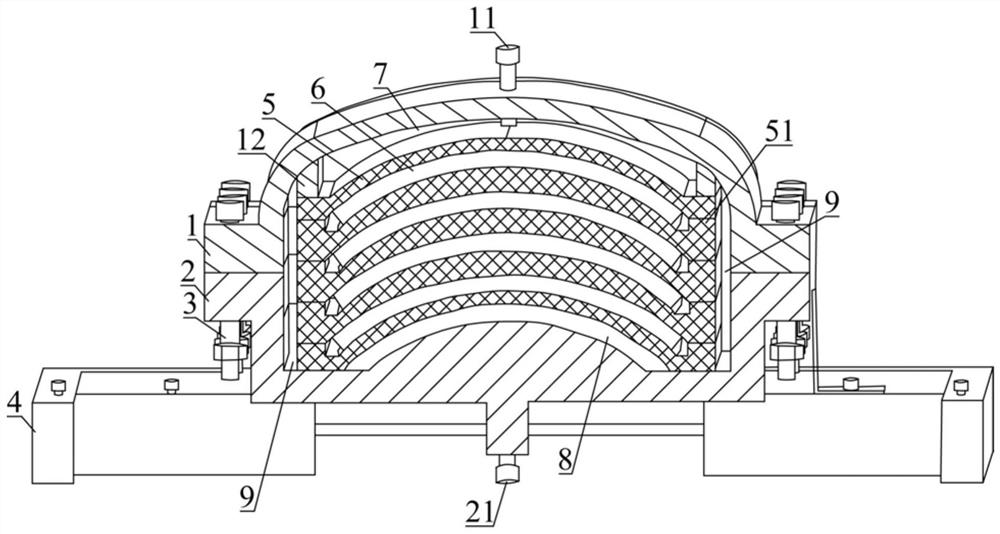

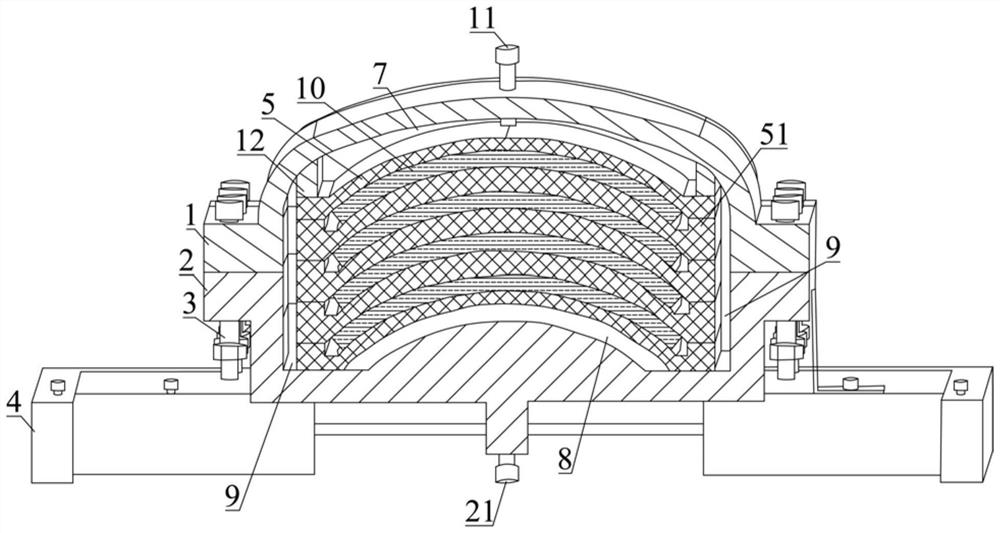

Embodiment 1

[0042] use as image 3 The composite dipping tool shown in the figure forms a curved special-shaped product (the length of the special-shaped product is 500 mm, and the width is 400 mm), and the number of the pallets is five. Using the composite dipping tool in this embodiment, each can can simultaneously form four pieces Special-shaped products; the impregnated parts to be composited used in forming special-shaped products in this embodiment are fabric prefabricated bodies; in this embodiment, the amount of impregnating liquid raw materials is 300kg / piece, and the impregnating liquid raw materials can save 62.5%. In this embodiment, impregnating The liquid pretreatment time is 5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com