Epoxy resin composition capable of being rapidly cured at medium and low temperatures, epoxy resin-based composite material and preparation method thereof

An epoxy resin and rapid curing technology, applied in the field of epoxy resin-based composite materials and their preparation, and epoxy resin compositions, can solve the problem of low glass transition temperature of epoxy resin matrix materials and production efficiency of epoxy resin composite materials Low, product mechanical properties decline and other issues, to achieve the best mechanical properties of the product, stable mechanical properties of the product, and increase the effect of resin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

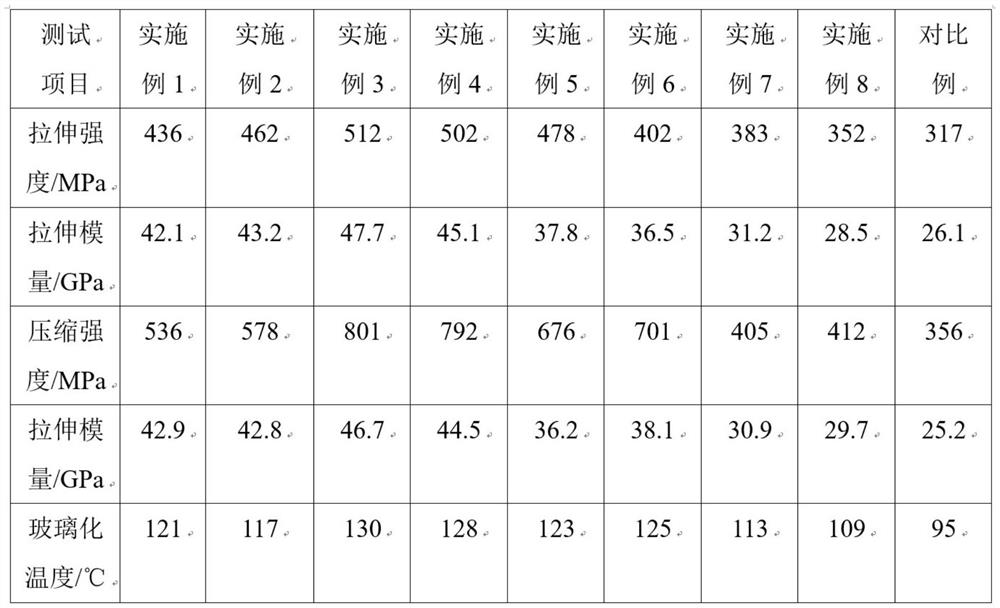

Examples

Embodiment 1

[0040] The epoxy resin composition of middle and low temperature rapid curing described in the present embodiment comprises the following components:

[0041]100 parts of epoxy resin, 1 part of imidazole accelerator 2-ethyl-4-methylimidazole, 10 parts of filler, 90 parts of anhydride curing agent methyl hexahydrophthalic anhydride, 10 parts of toughening agent o-phthalic anhydride Dioctyl dicarboxylate, 2 parts release agent calcium stearate. Wherein, the filler includes kaolin, asbestos powder, silica gel powder, and diphenylisodecyl phosphate in a mass ratio of 1:4:3:5.5.

[0042] The preparation method of the epoxy resin composition of medium and low temperature fast curing of the present embodiment specifically comprises the following steps:

[0043] S1. According to the selected mass fraction, add the filler, the toughening agent and the release agent to the epoxy resin, stir at a speed of 500-800r / min for 20-30min, and then increase the speed To 1000-1500r / min, stirrin...

Embodiment 2

[0049] The epoxy resin composition of middle and low temperature rapid curing described in the present embodiment comprises the following components:

[0050] 100 parts of epoxy resin, 1.5 parts of imidazole accelerator 2,4-dimethylimidazole, 10 parts of filler, 90 parts of anhydride curing agent methyl tetrahydrophthalic anhydride, 10 parts of toughening agent methyl tetrahydro Phthalic Anhydride, 2 parts Release Agent Magnesium Stearate. Wherein, the filler includes kaolin, asbestos powder, silica gel powder, and diphenylisodecyl phosphate with a mass ratio of 1:4.5:3.5:6.5.

[0051] The preparation method of the epoxy resin composition of medium and low temperature fast curing of the present embodiment specifically comprises the following steps:

[0052] S1. According to the selected mass fraction, add the filler, the toughening agent and the release agent to the epoxy resin, stir at a speed of 500-800r / min for 20-30min, and then increase the speed To 1000-1500r / min, stir...

Embodiment 3

[0058] The epoxy resin composition of middle and low temperature rapid curing described in the present embodiment comprises the following components:

[0059] 100 parts of epoxy resin, 2 parts of imidazole accelerator 2-methylimidazole, 10 parts of filler, 90 parts of anhydride curing agent 2-methylimidazole, 10 parts of toughening agent triphenyl phosphate, 2 parts of mold release agent Zinc fatty acid. Wherein, the filler includes calcined kaolin, asbestos powder, silica gel powder, and diphenylisodecyl phosphate with a mass ratio of 1:5:3.5:6.

[0060] The preparation method of the epoxy resin composition of medium and low temperature fast curing of the present embodiment specifically comprises the following steps:

[0061] S1. According to the selected mass fraction, add the filler, the toughening agent and the release agent to the epoxy resin, stir at a speed of 500-800r / min for 20-30min, and then increase the speed To 1000-1500r / min, stirring for 10-20min;

[0062] S2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com