Resin impregnation and curing device

A curing device and resin impregnation technology, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as affecting insulation life and resin insulation testing, unstable resin impregnation curing effect, inconsistent time and speed, etc. The effect of saving manpower and material resources, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

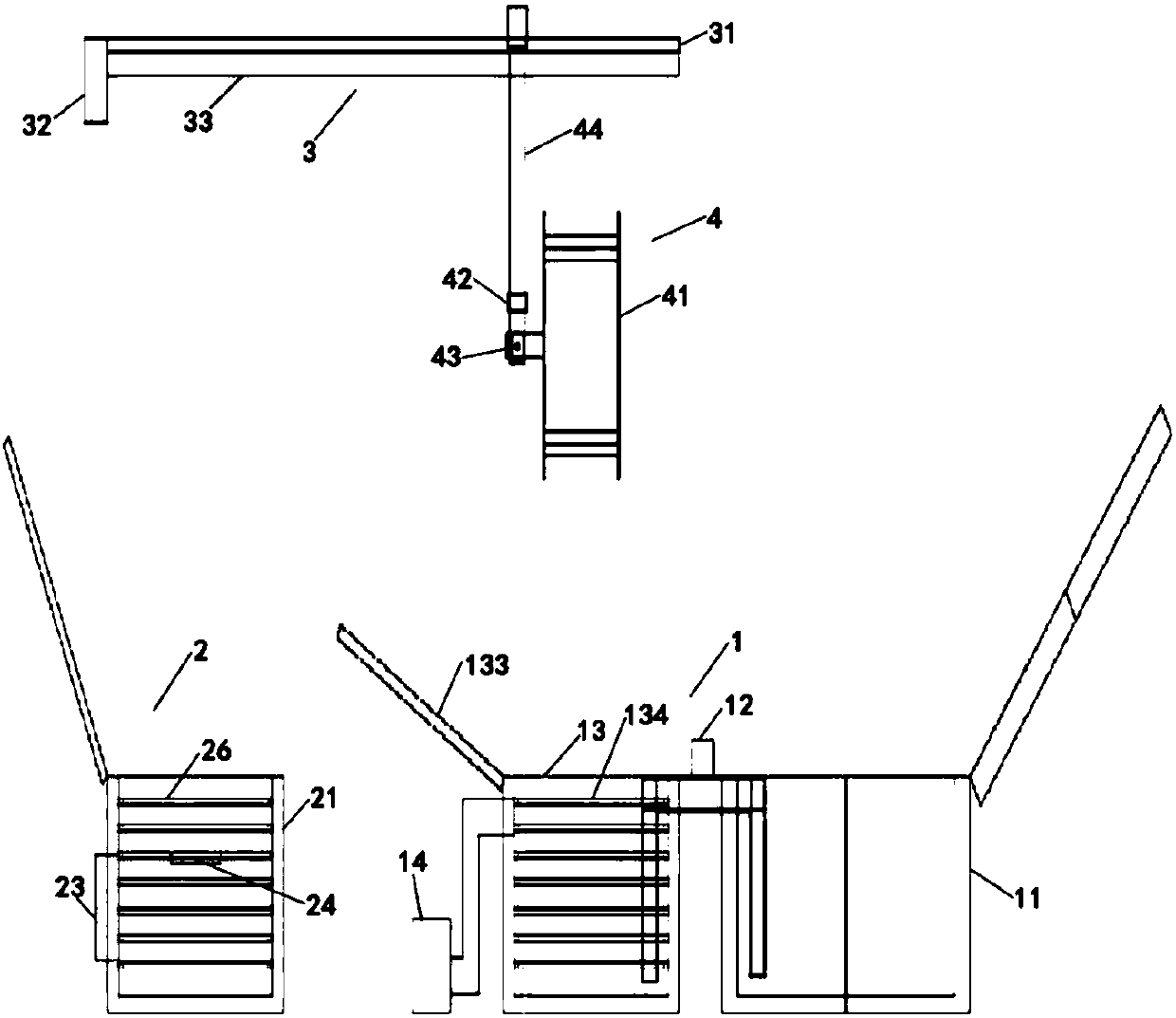

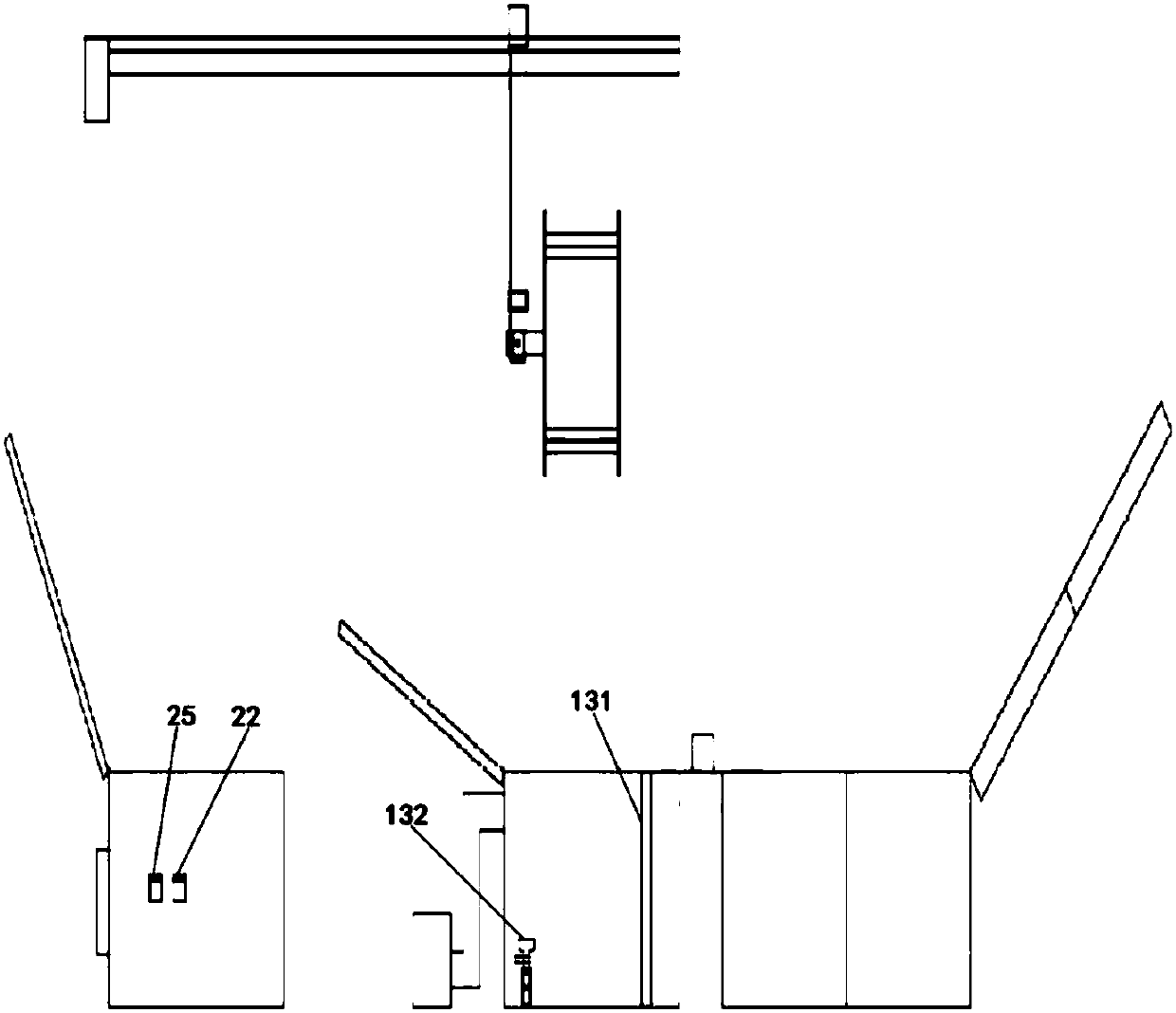

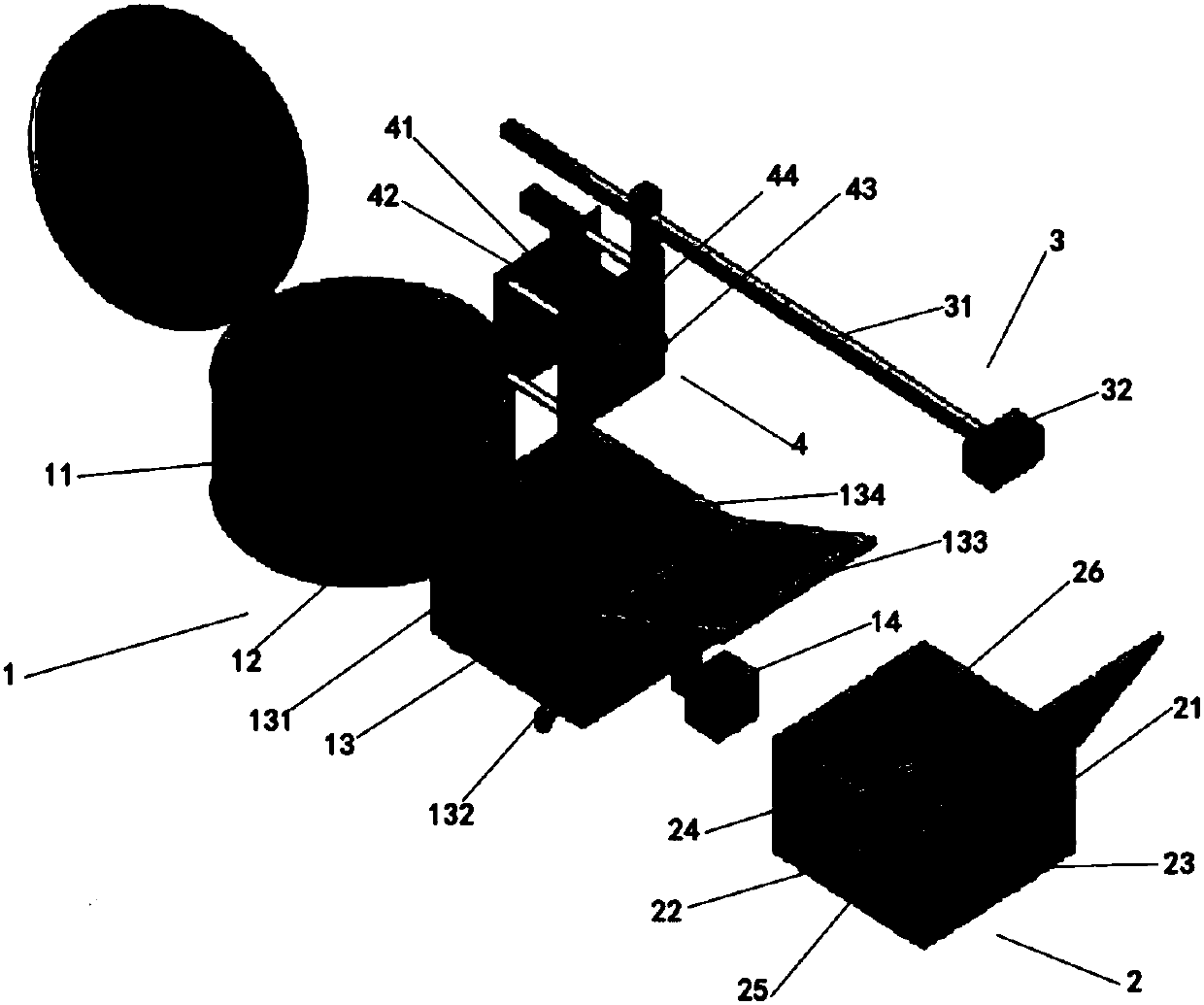

[0038] an application such as figure 1 and figure 2 The shown resin impregnation curing device impregnates the helical coil with the polyesterimide solvent-free impregnating varnish and cures it as follows: first, the helical coil for testing is fixed by the clamping device 41 in the fixing device 4 . The resin is transported from the storage tank 11 to the dipping tank 13 through the delivery device 12, and the liquid level gauge 131 provided outside the dipping tank 13 controls the amount of resin in the dipping tank 13, so that the entire test spiral coil can be immersed in the resin; start the transmission Device 3, the conveying device 3 transports the helical coil for the test into the dipping tank 13, and immerses the helical coil for the test in the resin at a speed of 0.5mm / s; turns on the heating system 134, and makes the temperature in the dipping tank 13 reach 25°C, Immersion for 60S; lift the fixture out of the dipping tank 13 at a speed of 0.5mm / s, and let it d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com