Full automatic vacuum impregnation device

A vacuum impregnation and fully automatic technology, which is applied in the fields of application, food processing, food science, etc., can solve the problems affecting the progress of product production, high labor intensity of workers, and long impregnation time, so as to speed up production, save labor costs, The effect of accelerating the impregnation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

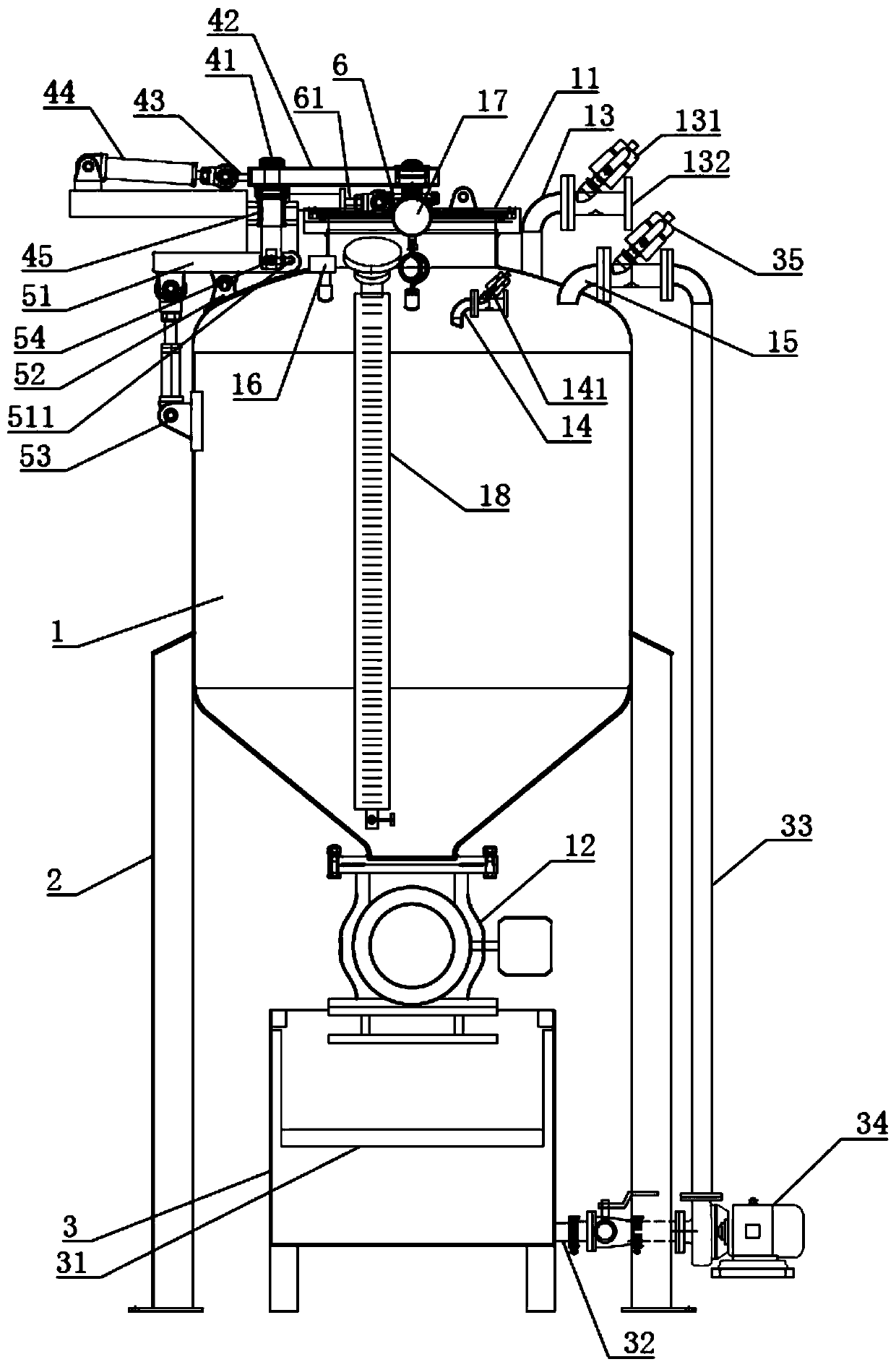

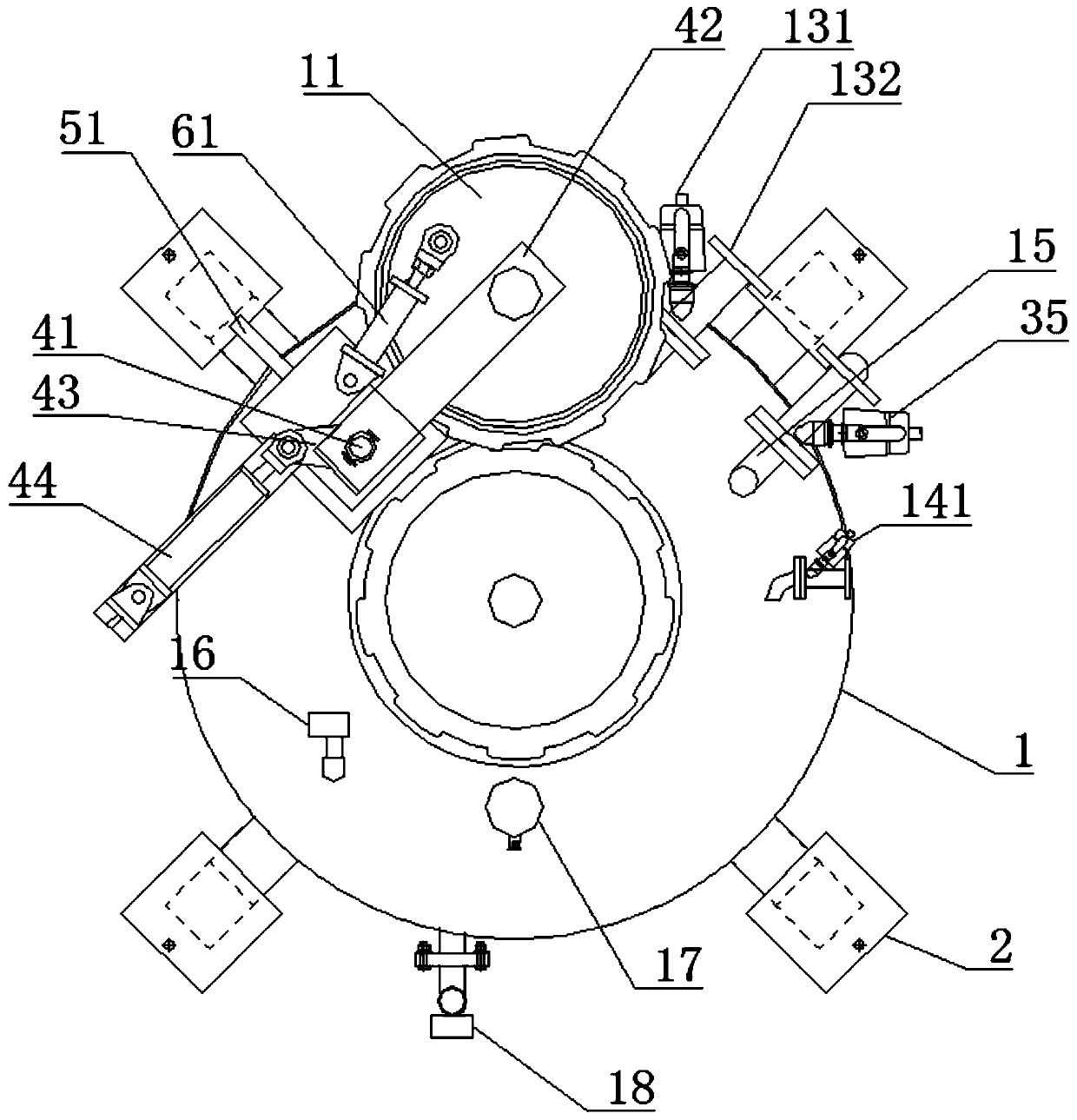

[0017] Such as figure 1 and figure 2 As shown, a fully automatic vacuum impregnation device includes a vacuum impregnation tank 1 and a support frame 2. The support frame 2 supports the tank body 1 at a certain height from the ground. There is a feeding door 11, the bottom of the tank body 1 is provided with a discharge port, and a material outlet valve 12 is installed at the discharge port, and the top of the tank body is also provided with a vacuum nozzle 13, an atmospheric communication pipe 14 and an impregnating liquid inlet 15. The vacuum nozzle 13 is connected to the vacuum pump through the vacuum valve 131 and the pipeline 132, the atmosphere communication pipe 14 is provided with the atmosphere communication valve 141, and a negative pressure sensor 16, a liquid level sensor 18 and a negative pressure gauge 17 are also installed in the tank body 1. The negative pressure sensor 16 and the negative pressure gauge 17 are in the same space at the pressure taking positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com