A kind of solid capacitor impregnation method

A capacitor, solid-state technology, applied in the field of solid-state capacitor impregnation, can solve the problems of long impregnation time, insufficient impregnation, and incomplete impregnation in the center of the element.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for impregnating solid capacitors, comprising the steps of:

[0029] 1. Before the solid capacitor is impregnated, the preparation work is as follows:

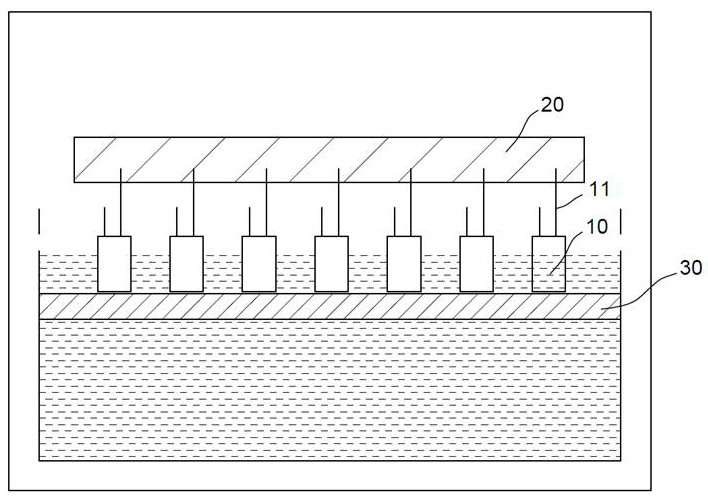

[0030] The guide pin 11 of the capacitor faces upward, and the anode guide pin 11 is spot-welded on the carrier strip 20. The consistency of the welding height must be ensured to fix multiple elements 10 on the same plane to facilitate the impregnation operation. The carrier bar 20 can be an iron bar.

[0031] Second, impregnation:

[0032] Perform the first cycle of impregnation:

[0033] (1) The tray 30 rises to suspend the elements 10, dry vacuuming to make the vacuum degree negative pressure, and the dry vacuuming time is 5-10s;

[0034] (2) Lower the tray 30 to lower the element 10 and immerse it in the impregnating solution. The impregnation depth of the element 10 is 1 / 2~2 / 3 of the height of the core package of the element 10; continue vacuuming so that the vacuum degree P1 is -30Kpa, and the holding ...

Embodiment 2

[0053] Different from Embodiment 1, in this embodiment:

[0054] During the first cycle of impregnation, the vacuum degree P1 is -40Kpa when the element is impregnated;

[0055] During the second cycle of impregnation, the vacuum degree P2 is -60Kpa when the element is impregnated;

[0056] When the third cycle of impregnation is carried out, the vacuum degree P3 is -80Kpa when the element is impregnated;

[0057] When vacuuming after impregnation, the vacuum degree P4 is -100Kpa.

Embodiment 3

[0059] Different from Embodiment 1, in this embodiment, the impregnation only includes two cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com