Full automatic vibrating fine screen allowing water spraying

A fully automatic and fine screening technology, which is applied in the direction of screening, solid separation, grille, etc., can solve the problems of large water consumption of vibrating screens, blockage of screen materials, high production costs, etc., to achieve strong water saving capabilities and increase production The effect of high efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

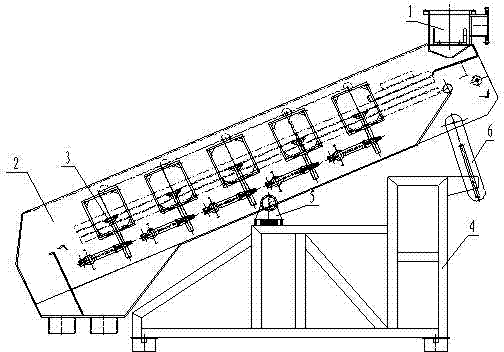

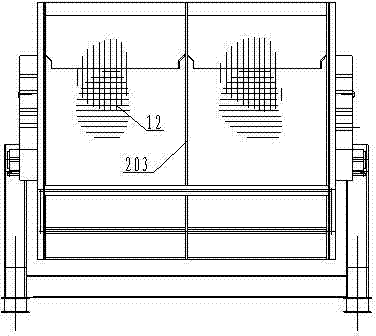

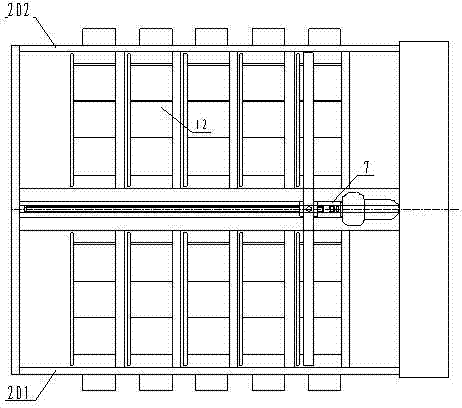

[0019] Such as Figure 1~5 A fully automatic water spray vibrating fine sieve shown, including support, Hopper , sieve body, screen mesh, water spray pipe and transmission device, described sieve body 2 is made up of left end plate 201, right end plate 202 and middle plate 203, the distance from middle plate to left end plate, right end plate same , the screen body is fixed on the bracket 4 through the support 5 and the pull arm 6, the upper hopper 1 is fixed on the screen body, the screen mesh 12 is fixed on the excitation system 3, and the excitation system 3 is installed on both sides of the screen body, each There are multiple excitation systems on each side, the excitation system is made of coils and suppressing irons, and the coils absorb and release the suppres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com