Physicochemical sludge dewatering method

A sludge dewatering and sludge technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc. Application value, high clarity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

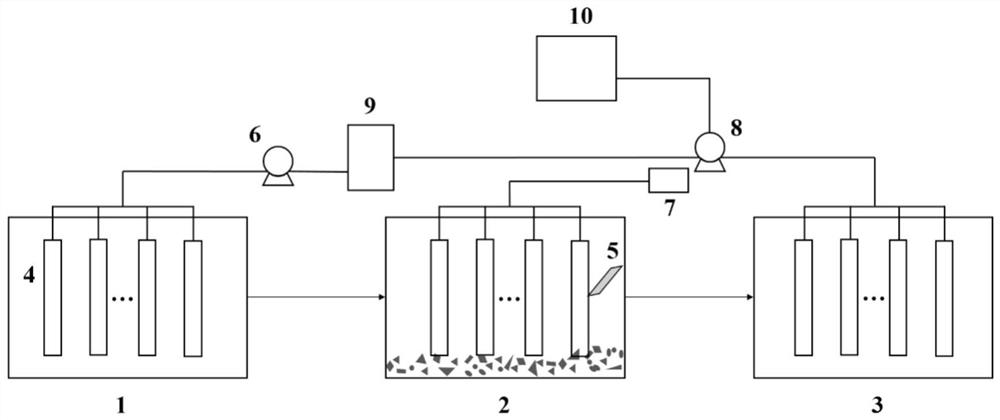

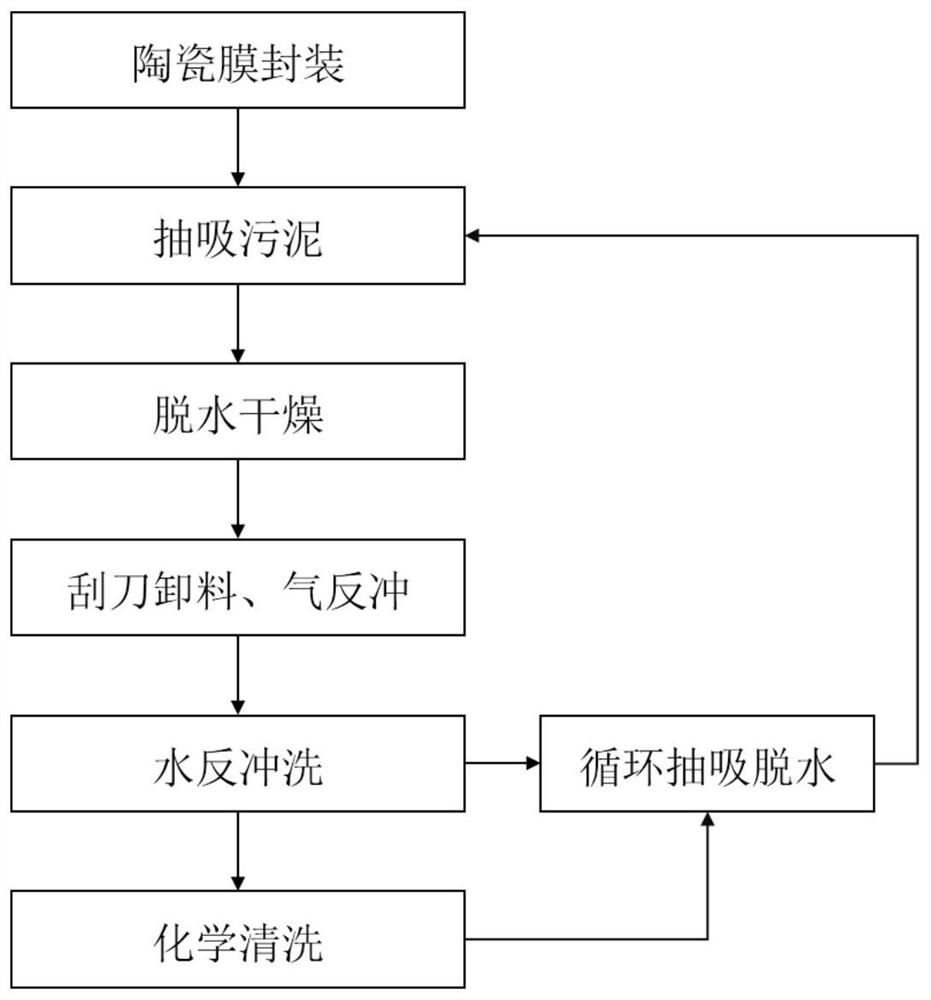

[0028] In this embodiment, the sludge dehydration process is as follows: figure 2 As shown, to treat the sludge feed liquid with a water content mass fraction of 98%, the selected flat ceramic membrane is an alumina ceramic microfiltration membrane, the average pore size of the membrane layer is 100nm, the thickness of the membrane layer is 20μm, and the thickness of the single ceramic plate is 5mm , its pure water permeability is 400L·m -2 h -1 · bar -1About, test its bending strength is about 40MPa. Among them, the membrane element is made of two flat ceramic membranes with a side length of 8cm, and is sealed with an acrylic plate support and epoxy resin glue. The membrane element contains a cavity and a water collection hole is left on one side , the ceramic membrane module 4 used for negative pressure suction can be designed to be composed of two membrane elements connected in parallel, the flat ceramic membrane module 4 in the sludge storage tank 1 is immersed in the ...

Embodiment 2

[0030] In this embodiment, the sludge dehydration process is as follows: figure 2 As shown, to treat sludge feed liquid with a water content mass fraction of 90%, the selected flat ceramic membrane is a zirconia ceramic microfiltration membrane, the average pore diameter of the membrane layer is 200nm, the thickness of the membrane layer is 40μm, and the thickness of a single ceramic plate is 6mm , its pure water permeability is 600L·m -2 h -1 · bar -1 About, test its bending strength is about 39MPa. Among them, the membrane element is made of two flat ceramic membranes with a side length of 8cm, which are sealed with the help of acrylic plate support and epoxy resin glue. hole. Such as figure 1 As shown, the ceramic membrane module 4 used for negative pressure suction can be designed to be composed of four membrane elements connected in parallel, and the flat ceramic membrane module 4 in the sludge storage tank 1 is immersed in the material liquid of physical and chemic...

Embodiment 3

[0032] In this embodiment, the sludge dehydration process is as follows: figure 2 As shown, to treat sludge feed liquid with a water content mass fraction of 88%, the selected flat ceramic membrane is a titanium oxide ceramic microfiltration membrane, the average pore size of the membrane layer is 300nm, the thickness of the membrane layer is 30μm, and the thickness of a single ceramic plate is 5.5 mm, pure water permeability is 900L m -2 h -1 · bar -1 About, test its bending strength is about 38MPa. Among them, the membrane element is made of two flat ceramic membranes with a side length of 9cm, which are sealed with the help of acrylic plate support and epoxy resin glue. The membrane element contains a cavity and a water collection hole is left on one side , the ceramic membrane module 4 used for negative pressure suction can be designed to be composed of two membrane elements connected in parallel, the flat ceramic membrane module 4 in the sludge storage tank 1 is immer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com