Total amplitude supporting high-frequency linear vibrating screen

A linear vibrating sieve, full-amplitude technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the difficulty in realizing the synchronous vibration state of multiple vibrating beams, the inability to realize linear vibration trajectory screening, and the development limitation in the screening field and other problems, to achieve the effect of reducing impact, high utilization rate of screen mesh, and high performance of anti-vibration index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

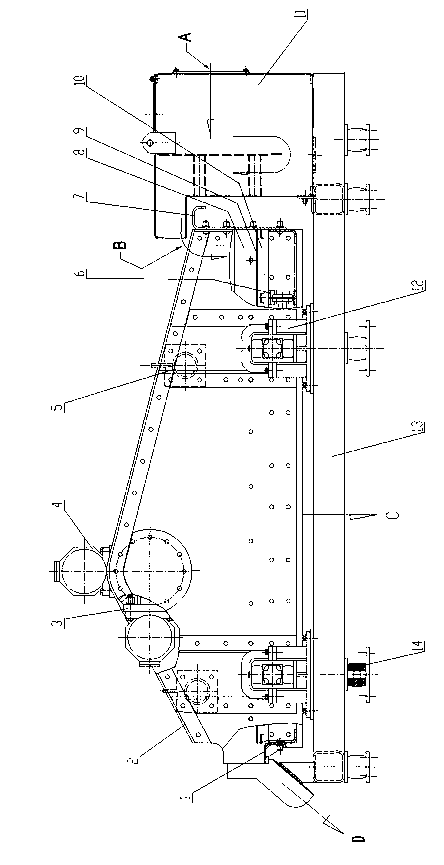

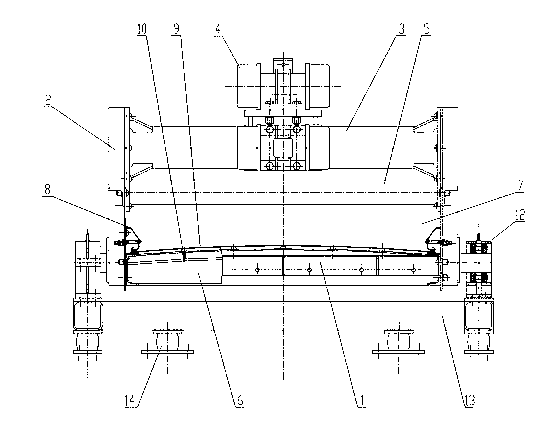

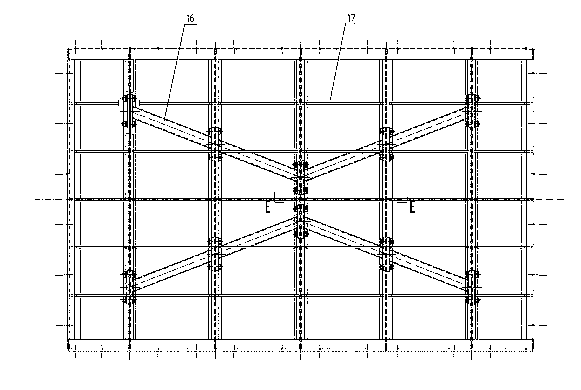

[0011] An embodiment of the present invention will be described below in conjunction with the accompanying drawings. It is mainly composed of screen frame, screen surface, vibrator and vibration damping support device. The screen frame is composed of two side plates 2, discharge port 1, screen bracket 6, rear baffle plate 7, vibrating beam 3 and beam 5, which are riveted together by ring groove rivets. The three-section screen 9 is horizontally arc-shaped and tensioned and installed on the screen bracket 6, and is tensioned into a drum shape by the tension plates 8 on both sides. The three-section screen is arranged to facilitate the replacement of a damaged certain section of the screen. The vibrating beam 3 is installed on the side plate 2 of the screen box above the screen surface, that is, the outlet side of the screen box passes obliquely above the 45° line of the center of gravity of the screen box. Two vibrating motors 4 are installed on the horizontal and vertical vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com