Patents

Literature

40results about How to "Achieve elastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic training system based on CT (Computed Tomography) image simulation and positioning

ActiveCN103295455AReduce computational complexityThe pose matrix is accurateEducational modelsHuman bodyThree dimensional ct

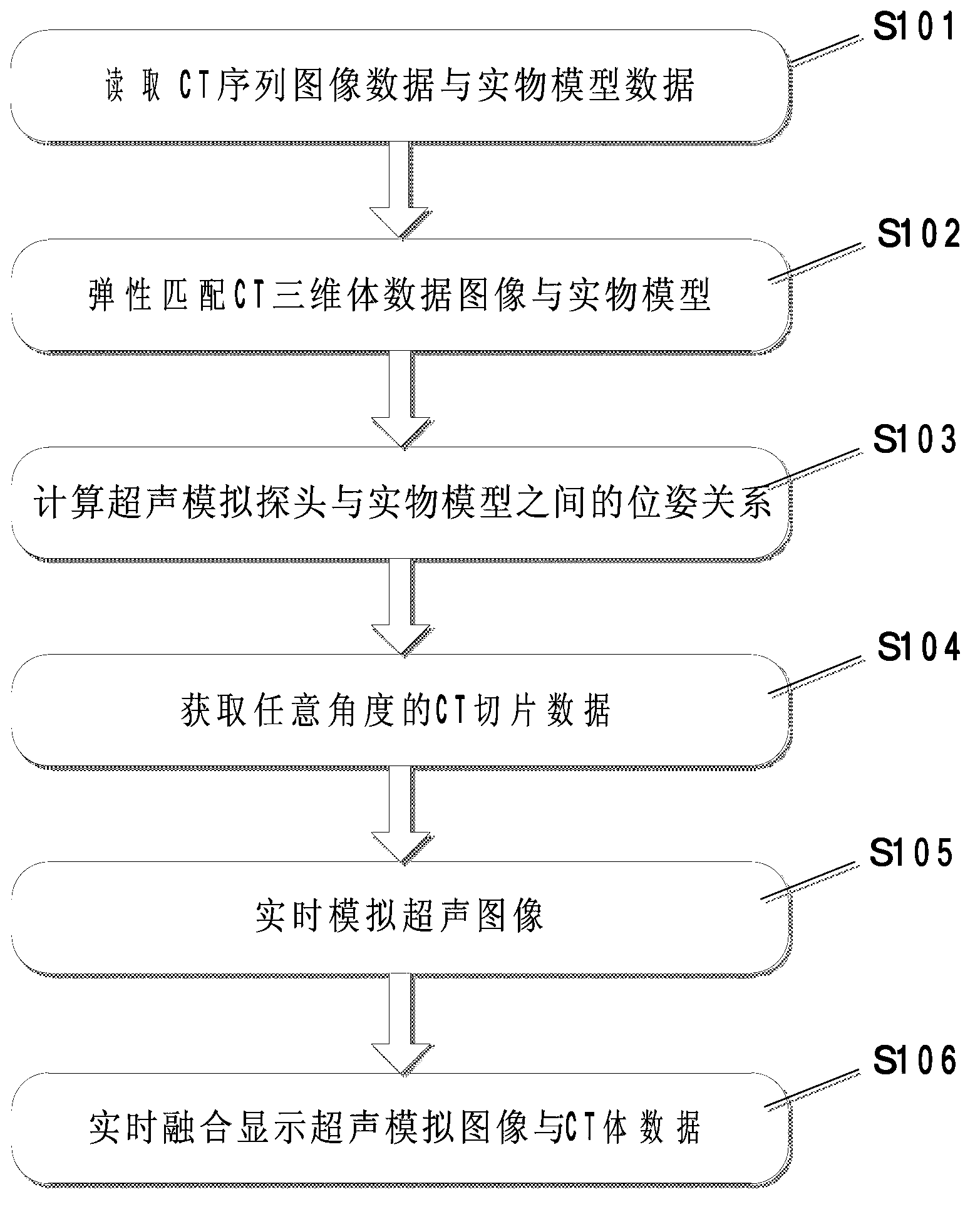

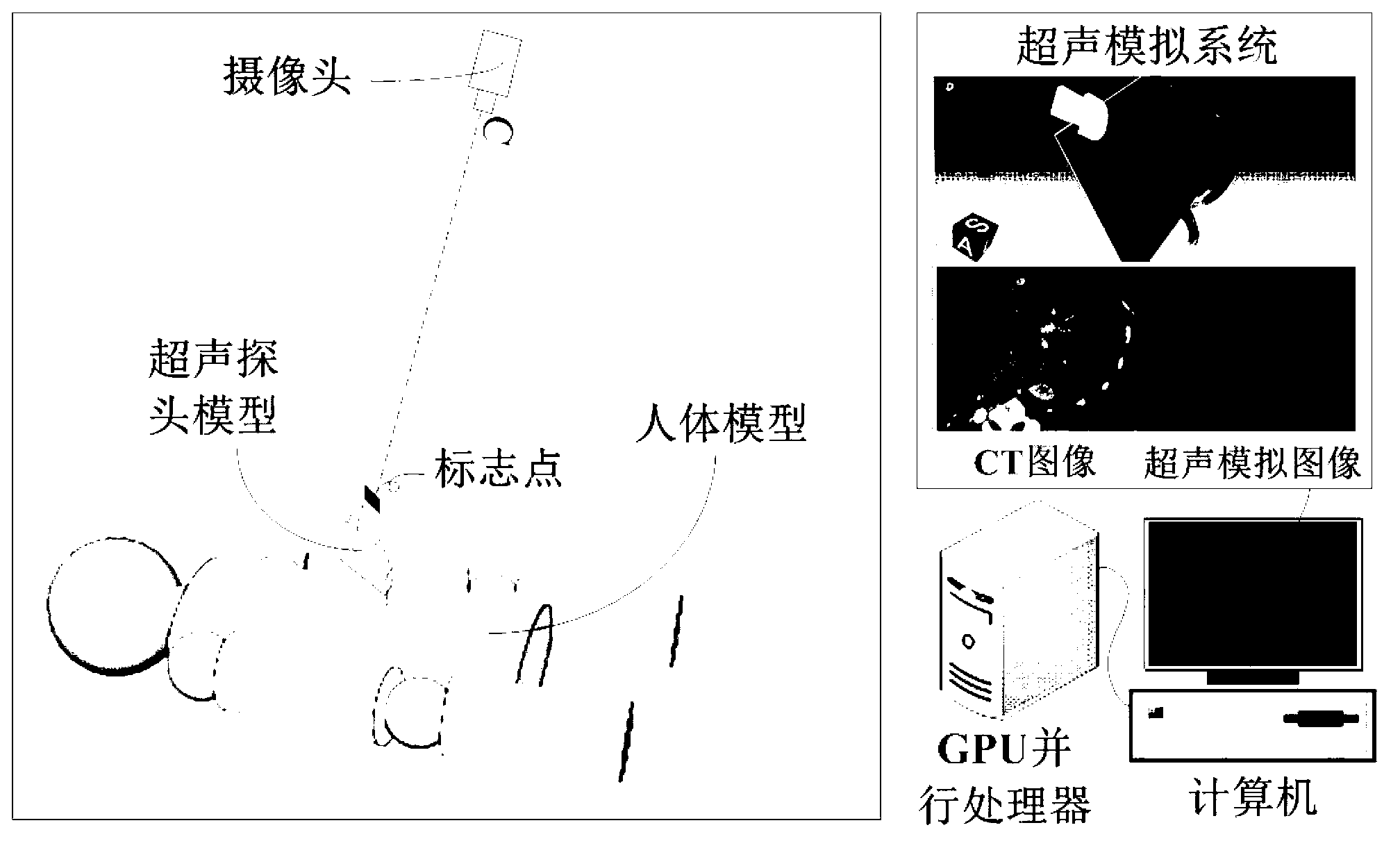

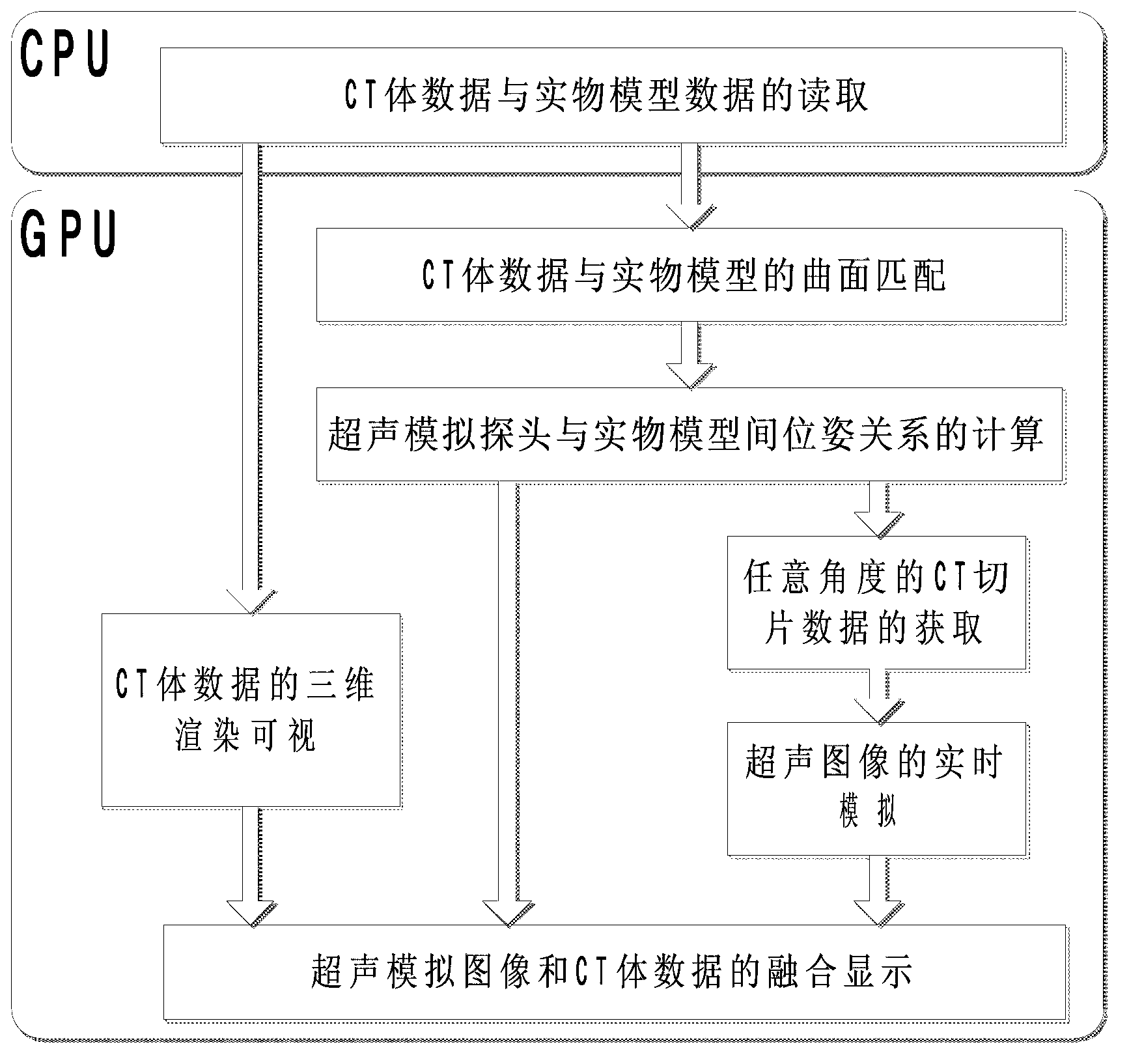

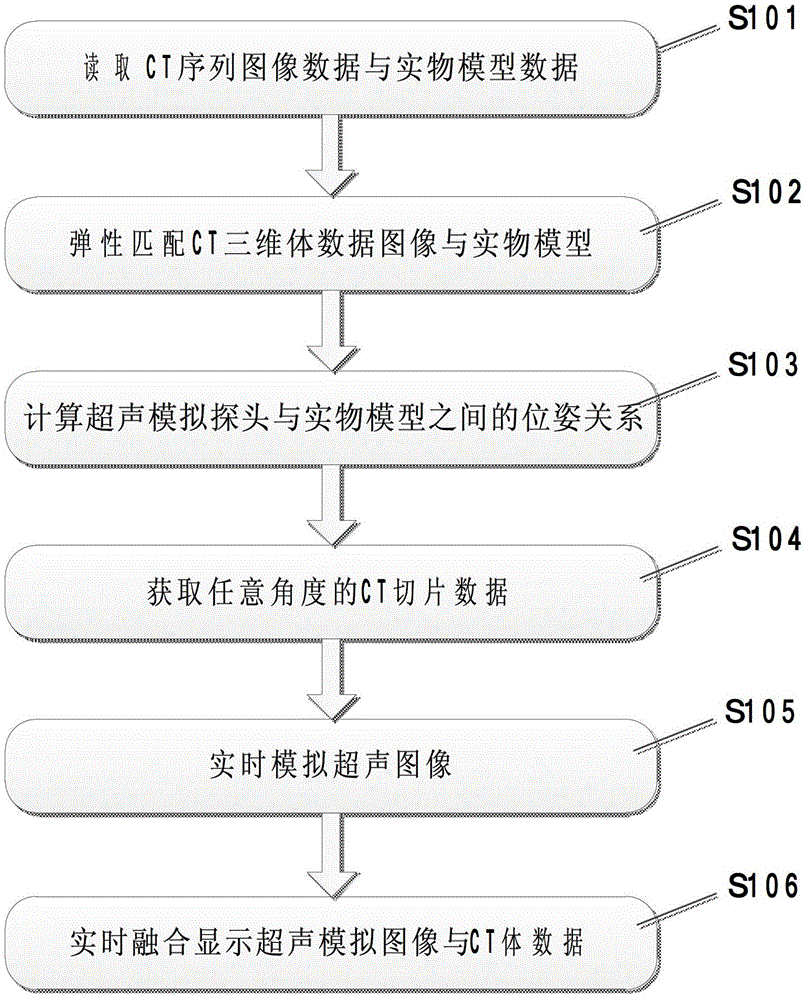

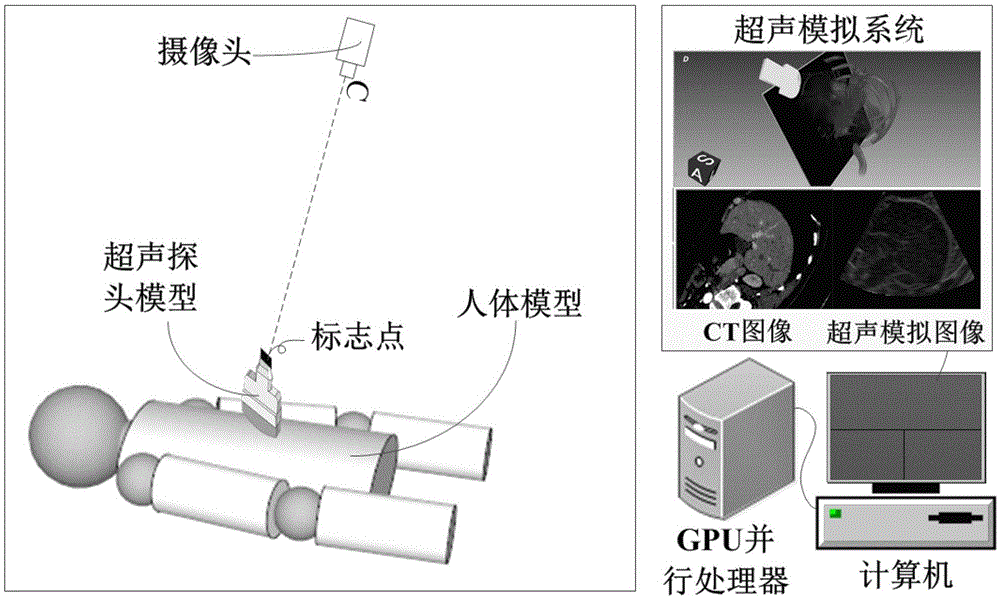

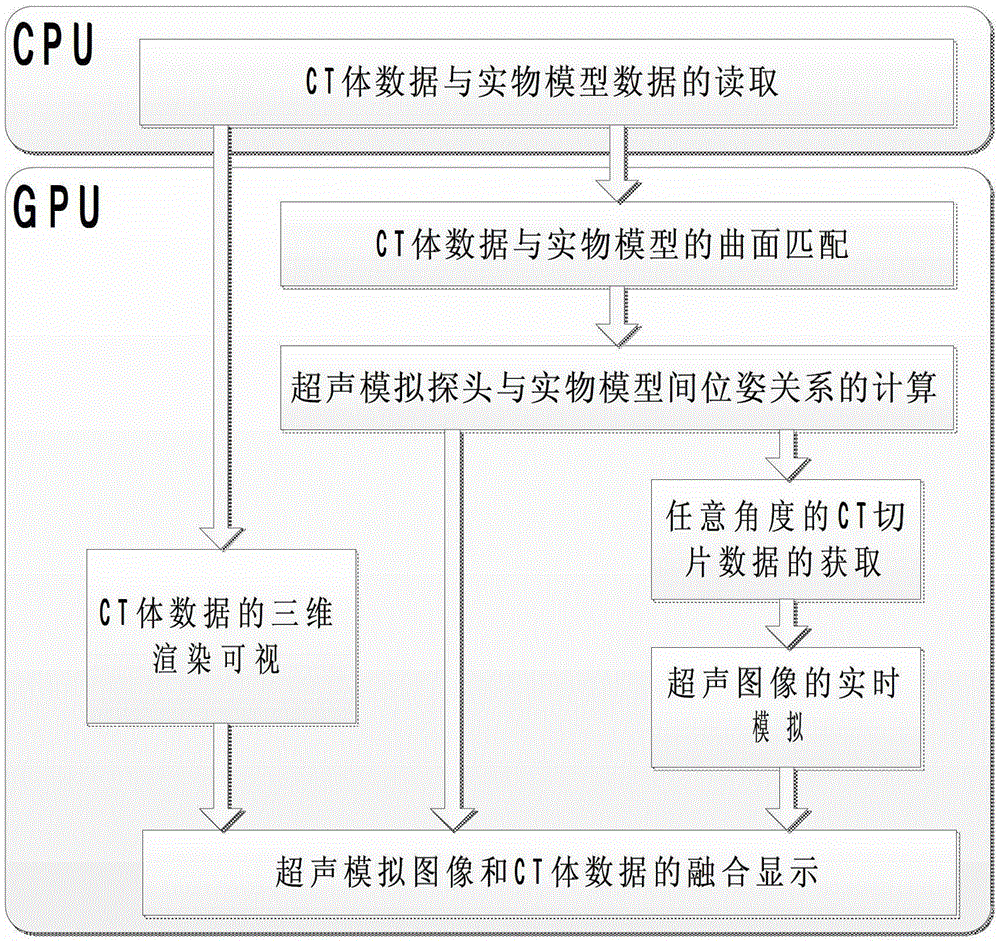

The invention provides an ultrasonic training system based on CT (Computed Tomography) image simulation and positioning. Ultrasound image simulation and CT volumetric data rendering are accelerated to be achieved through a GPU (Graphics Processing Unit) and the real-time performance of the system is improved. A curved surface matching module is used for performing surface matching on read human body CT volumetric data and physical model data with a physical model as the standard and achieving elastic transformation of a curved surface based on an interpolation method of thin plate splines; an ultrasonic simulation probe position tracking module is used for performing real-time calculation on ultrasonic simulation probe positions relative to the physical model by a marking point tracking method and obtaining arbitrary angle CT slice images according to a position matrix; an image enhancement and ultrasonic image simulation generation module is used for improving the vessel contrast ratio in CT images by a multi-scale enhancement method and achieving the ultrasound image simulation based on the CT volumetric data; and an integration display module is used for accelerating to achieve rendering display of the CT volumetric data based on CUDA (Compute Unified Device Architecture) and integrating and displaying ultrasound simulation images and three-dimensional CT images according to the obtained position matrix.

Owner:ARIEMEDI MEDICAL SCI BEIJING CO LTD

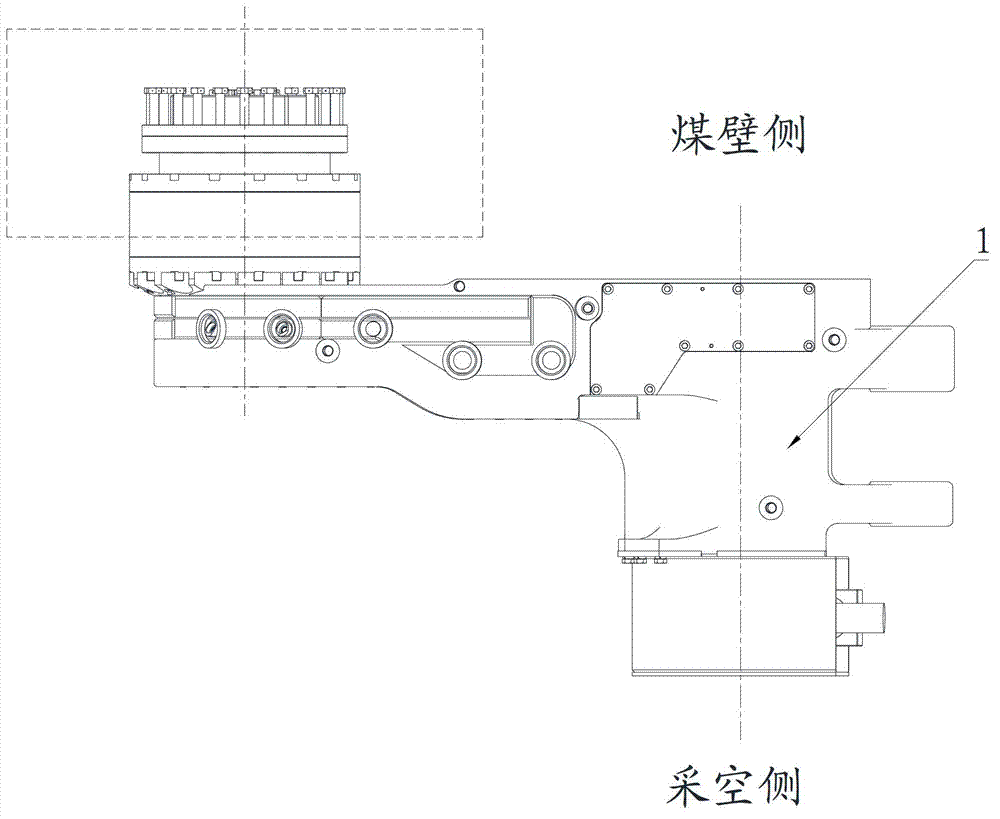

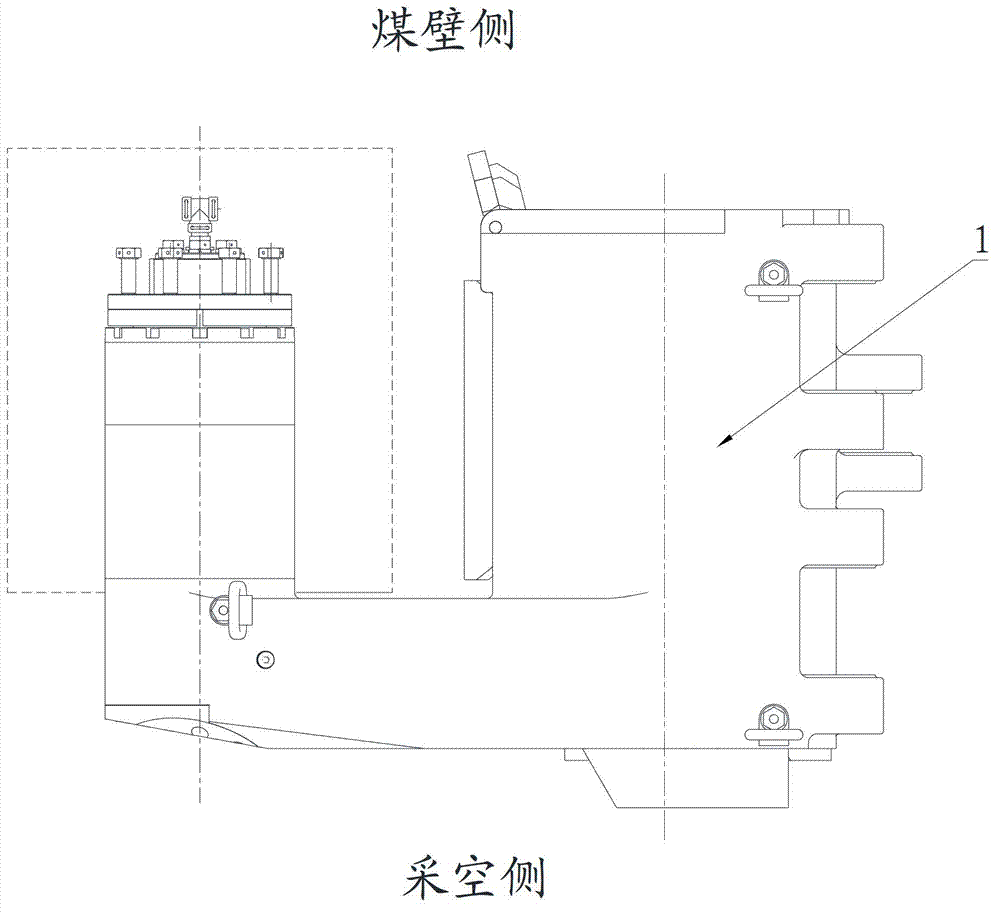

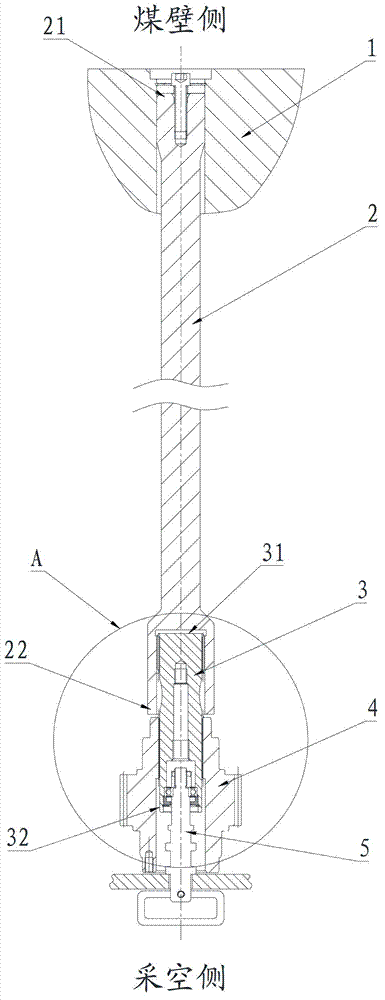

Torque clutch and coal cutter

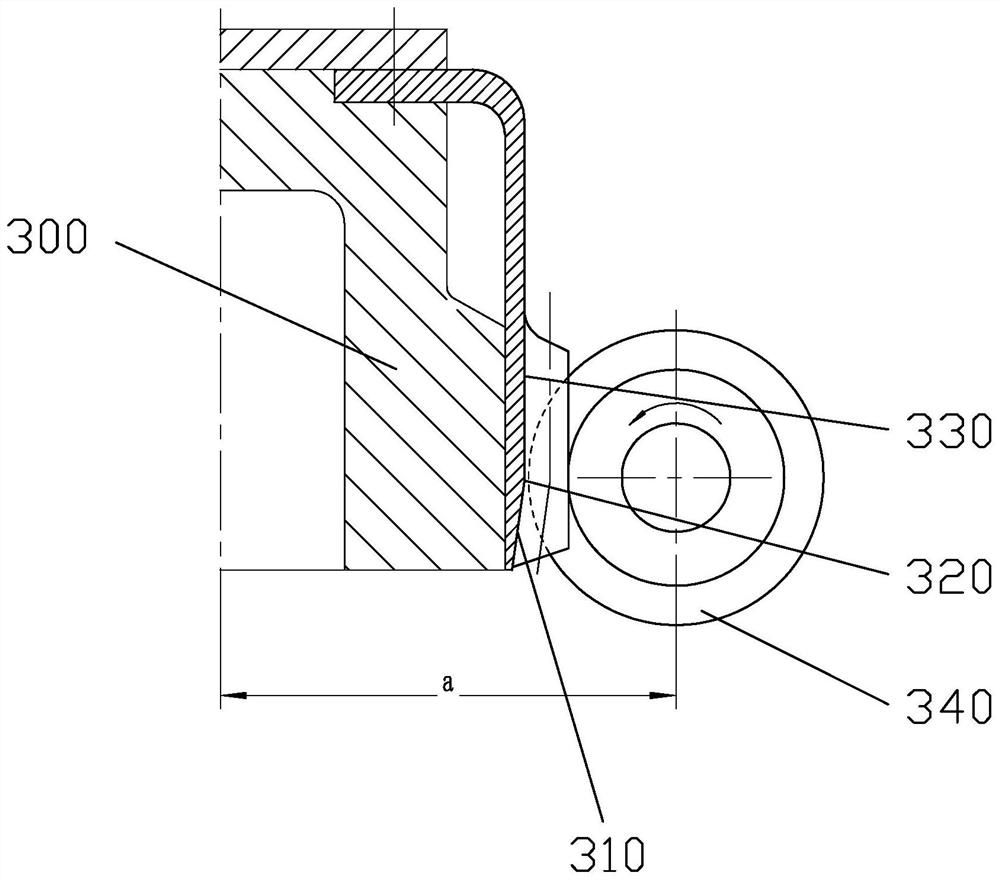

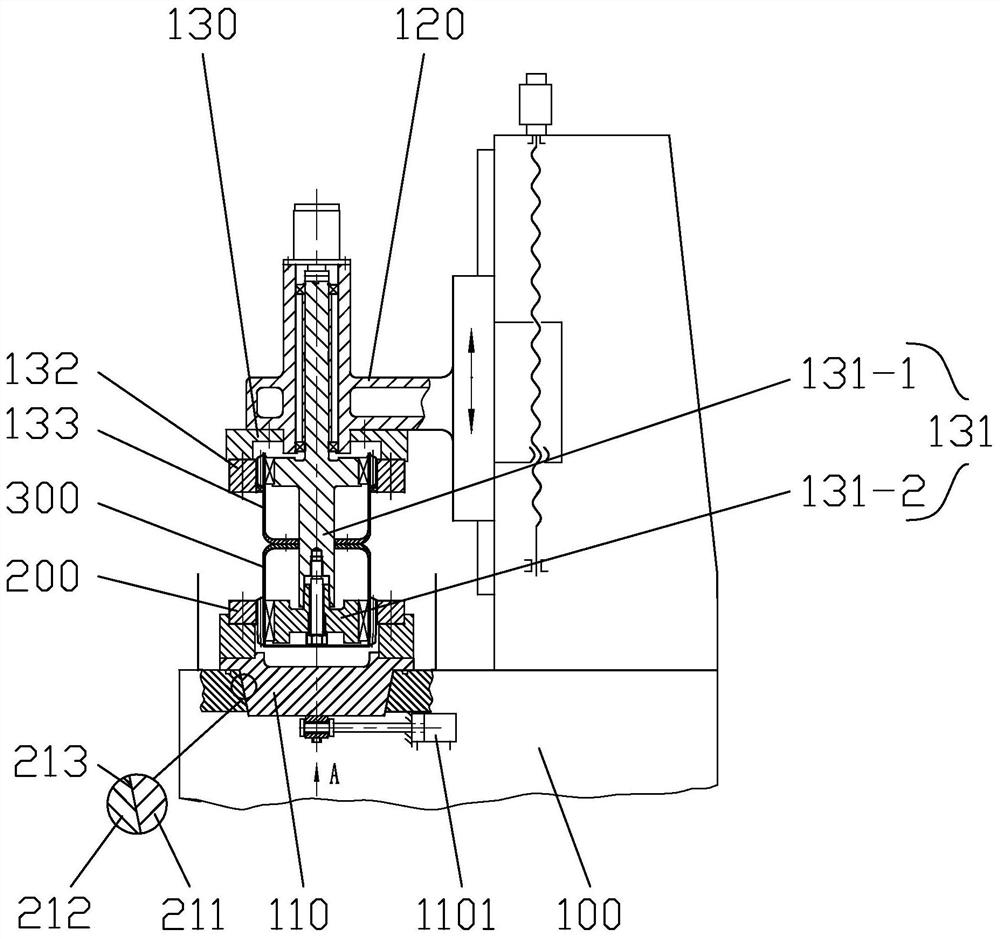

ActiveCN102788104AAchieve elastic deformationRealize the function of elastic cushioningAutomatic clutchesControl theoryMotor shaft

The invention provides a torque clutch and a coal cutter. One end of the torque clutch is installed in a hollow shaft motor while the other of the torque clutch is connected with a transmission gear. The torque clutch comprises a motor shaft and a torque shaft. Both ends of the motor shaft and the torque shaft are respectively a first end and a second end. The first end of the motor shaft is installed in the hollow shaft motor and the second end of the motor shaft is coaxially connected with the first end of the torque shaft. The second end of the torque shaft is coaxially connected with the transmission gear. A pull rod extending out of the end part of the transmission gear is connected at the second end of the torque shaft. According to the torque clutch provided by the invention, aiming at a cutting part in C-shaped layout, the torque shaft clutch can be operated on a worked-out side, and as the motor shaft is longer, elastic deformation can be realized to realize the function of elastic buffer. As the torque shaft is provided with a groove structure or an arc-shaped gap, the function of overload protection can be realized.

Owner:SANY HEAVY EQUIP

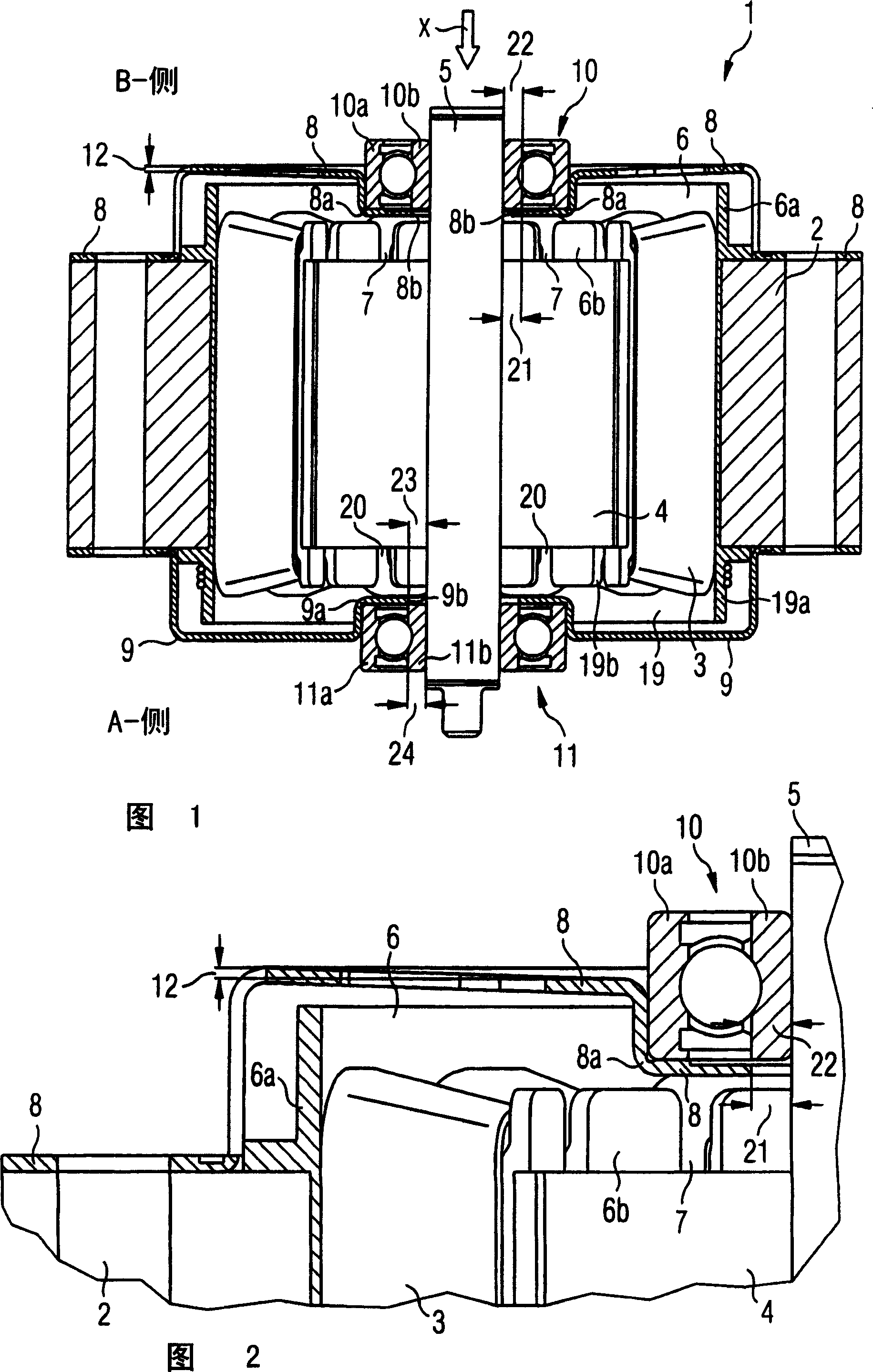

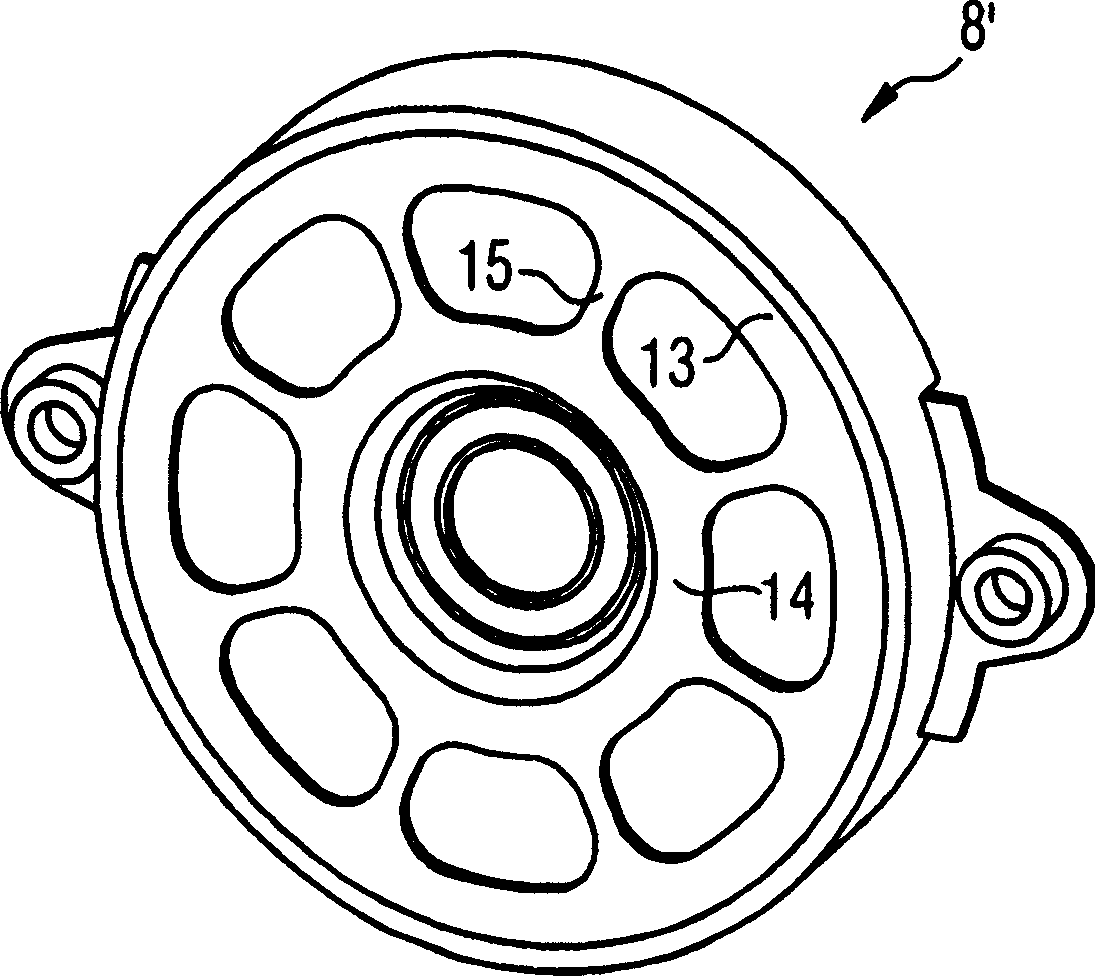

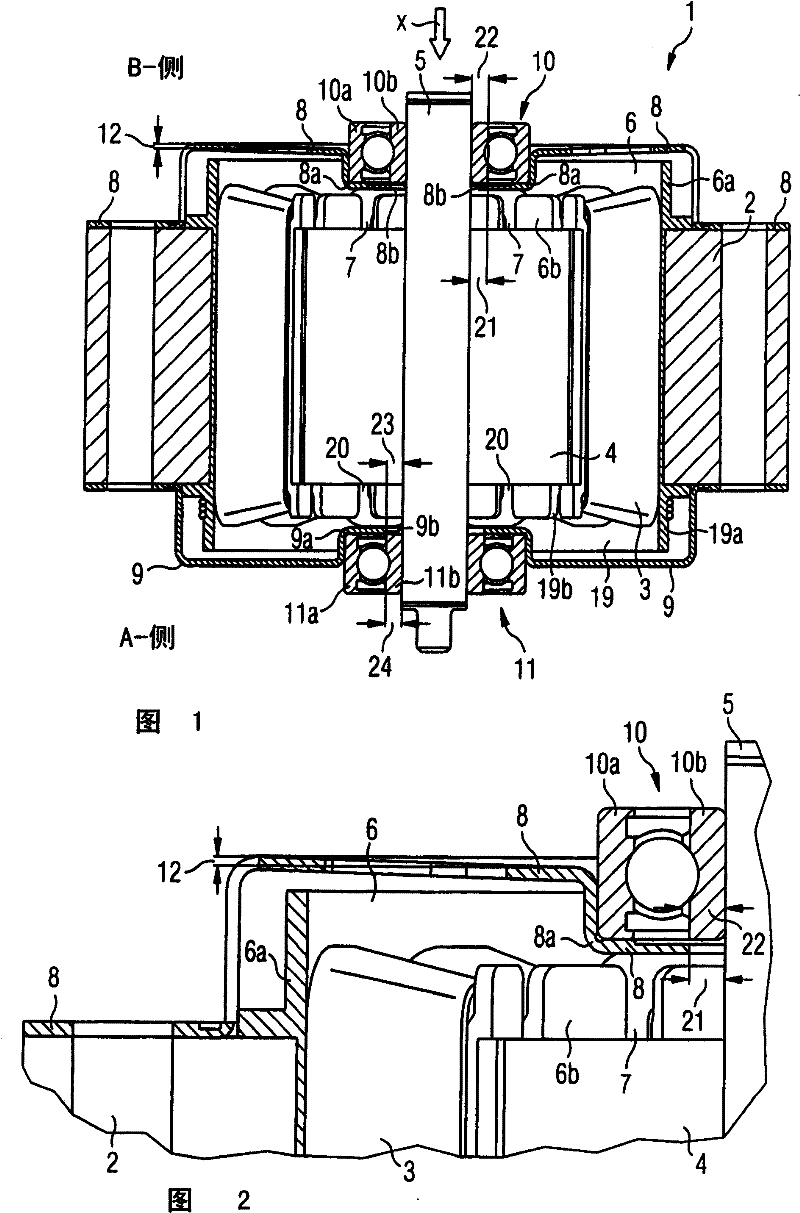

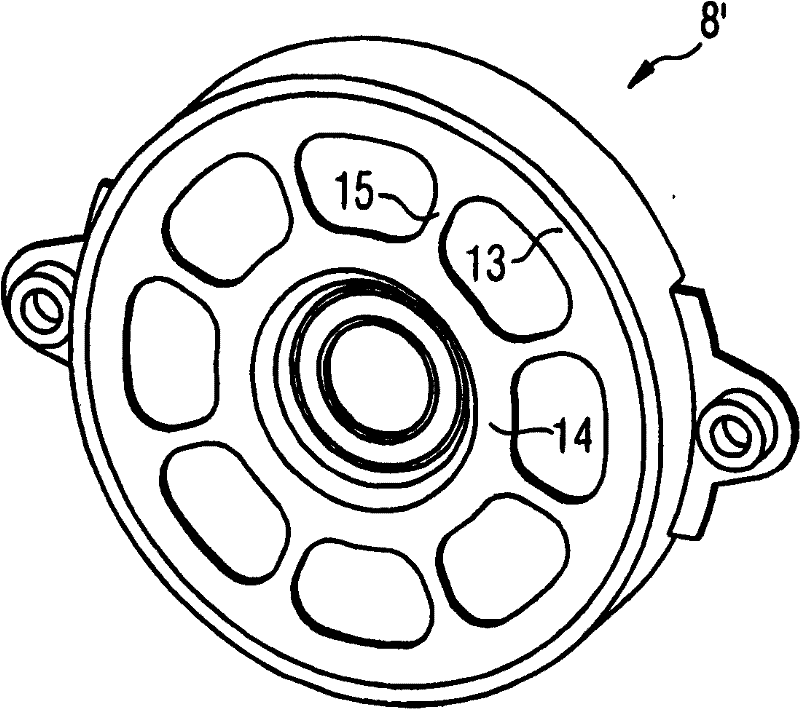

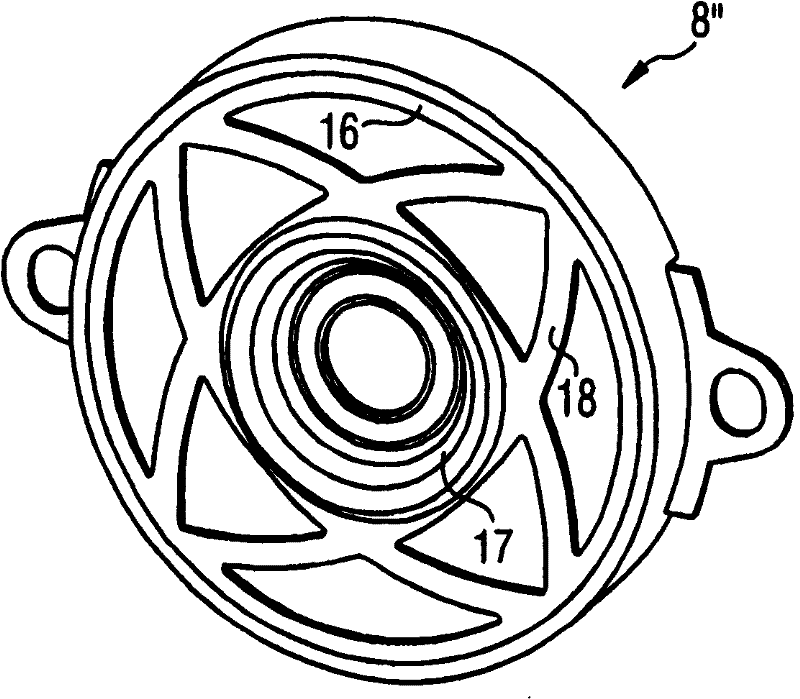

Electrical machine with preloaded ball race and method for manufacturing the same

An electrical machine with a ball race preloaded by elastic deformation of a bearing end plate as well as a method for manufacturing the same comprises a stator and a rotor with rotor shaft. The rotor shaft is supported via the ball race in the bearing end plates. At least one bearing end plate is embodied so that it can be elastically deformed in an axial direction and the preloading of the ball race is created by a preloading of the bearing end plate in the axial direction.

Owner:CONTINENTAL TEVES AG & CO OHG +1

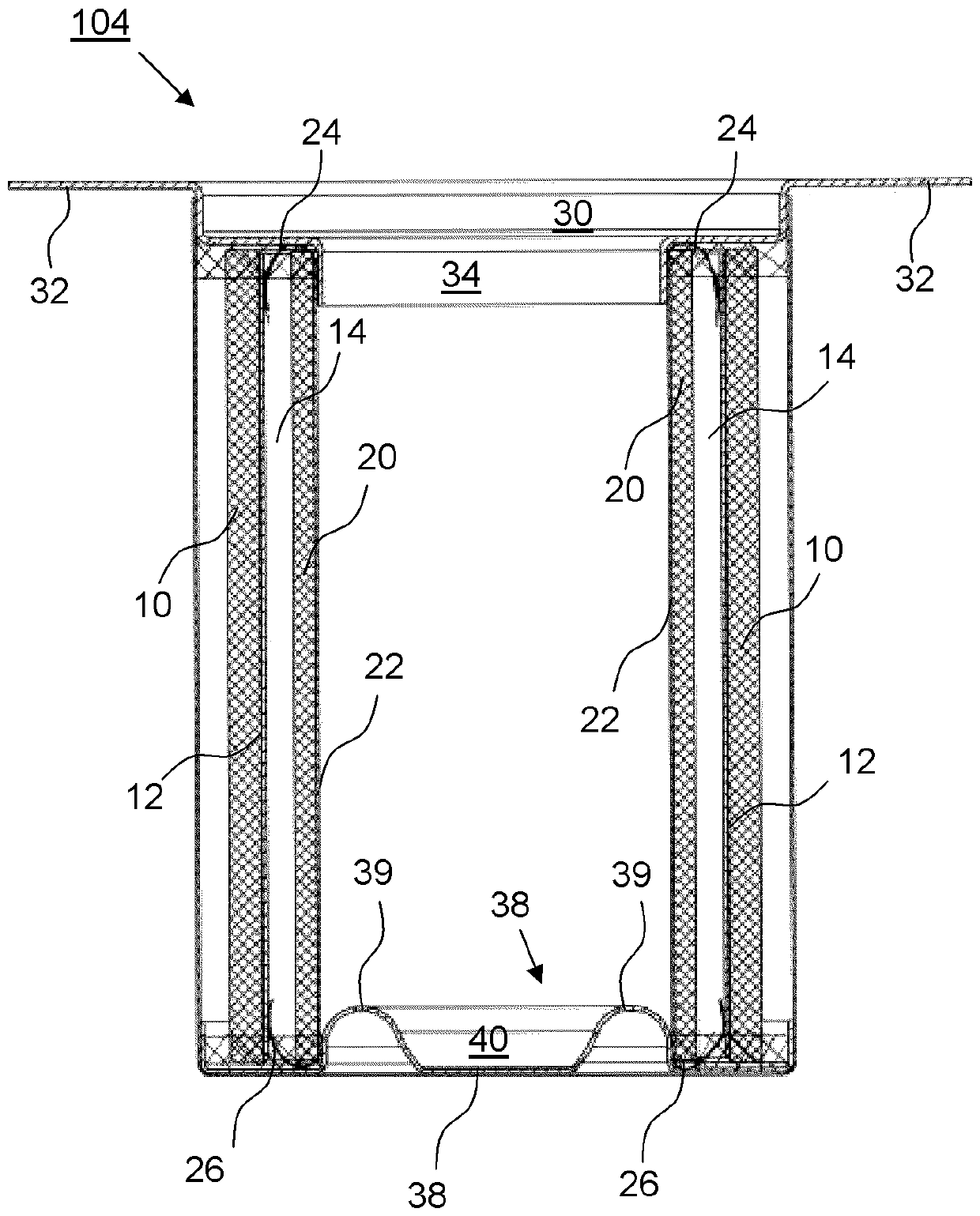

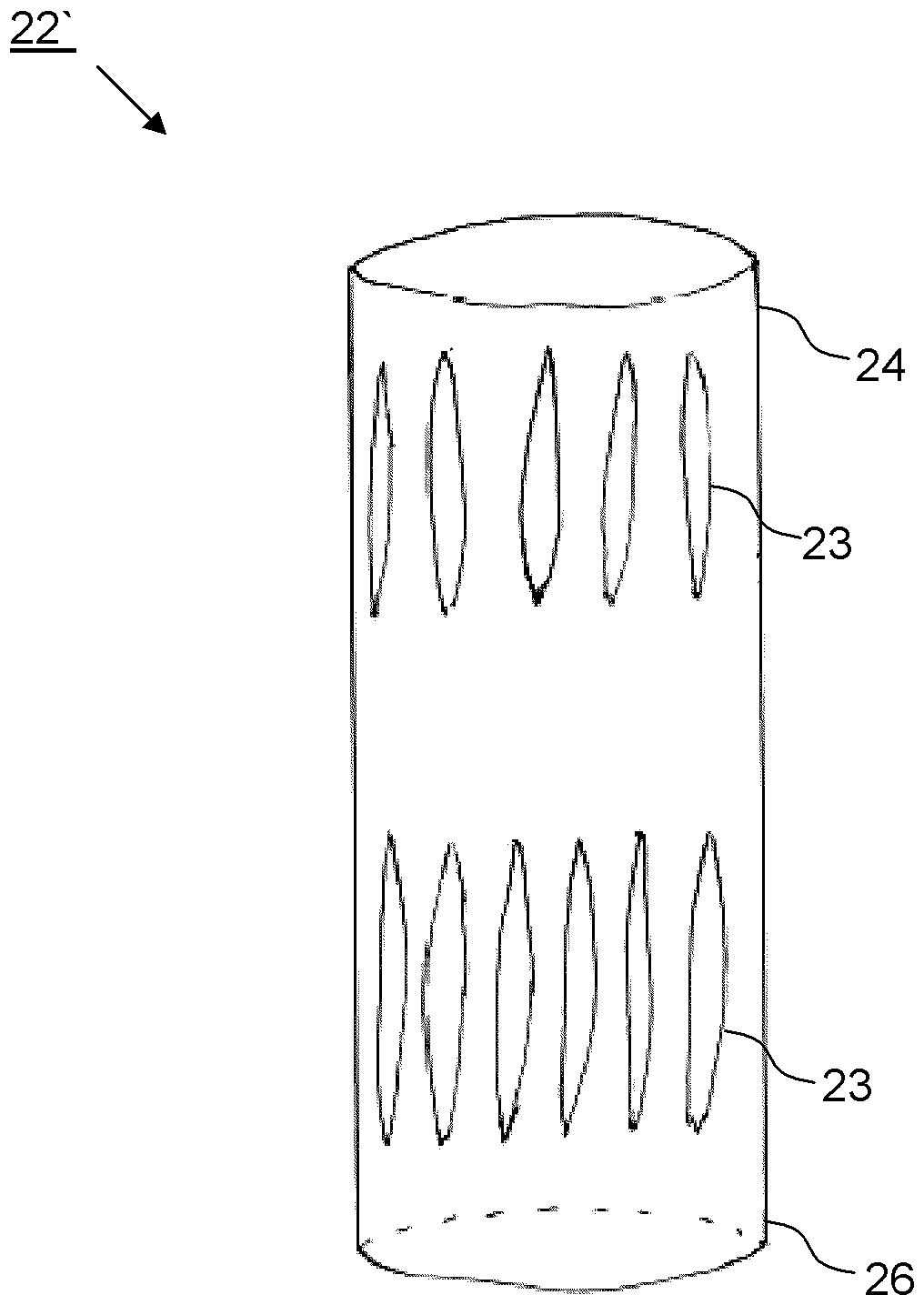

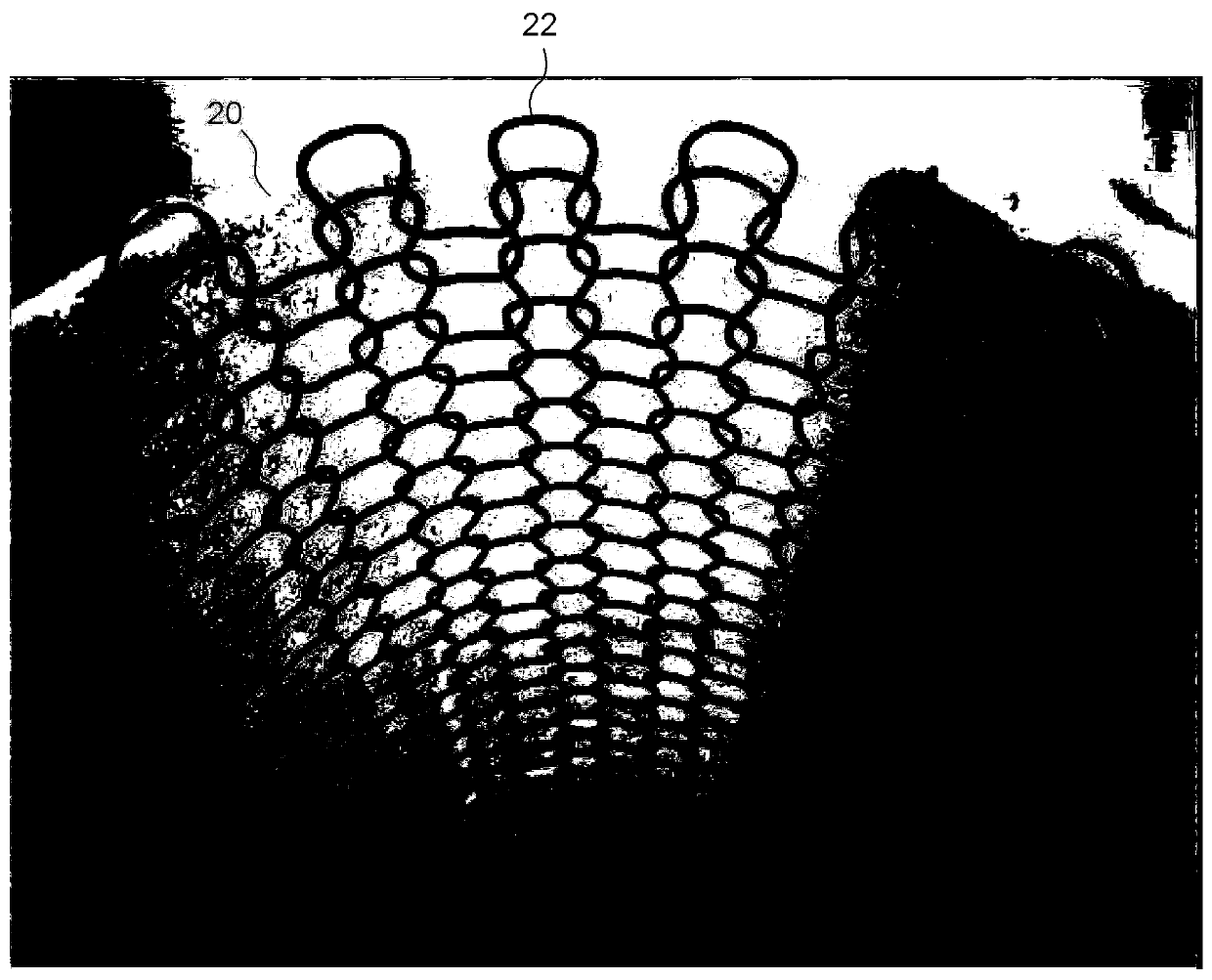

Filter Insert as well as Fluid Filter

ActiveCN109663398APrevent static electricityAchieve elastic deformationDispersed particle filtrationTransportation and packagingEngineeringMechanical engineering

Owner:MANN HUMMEL GMBH

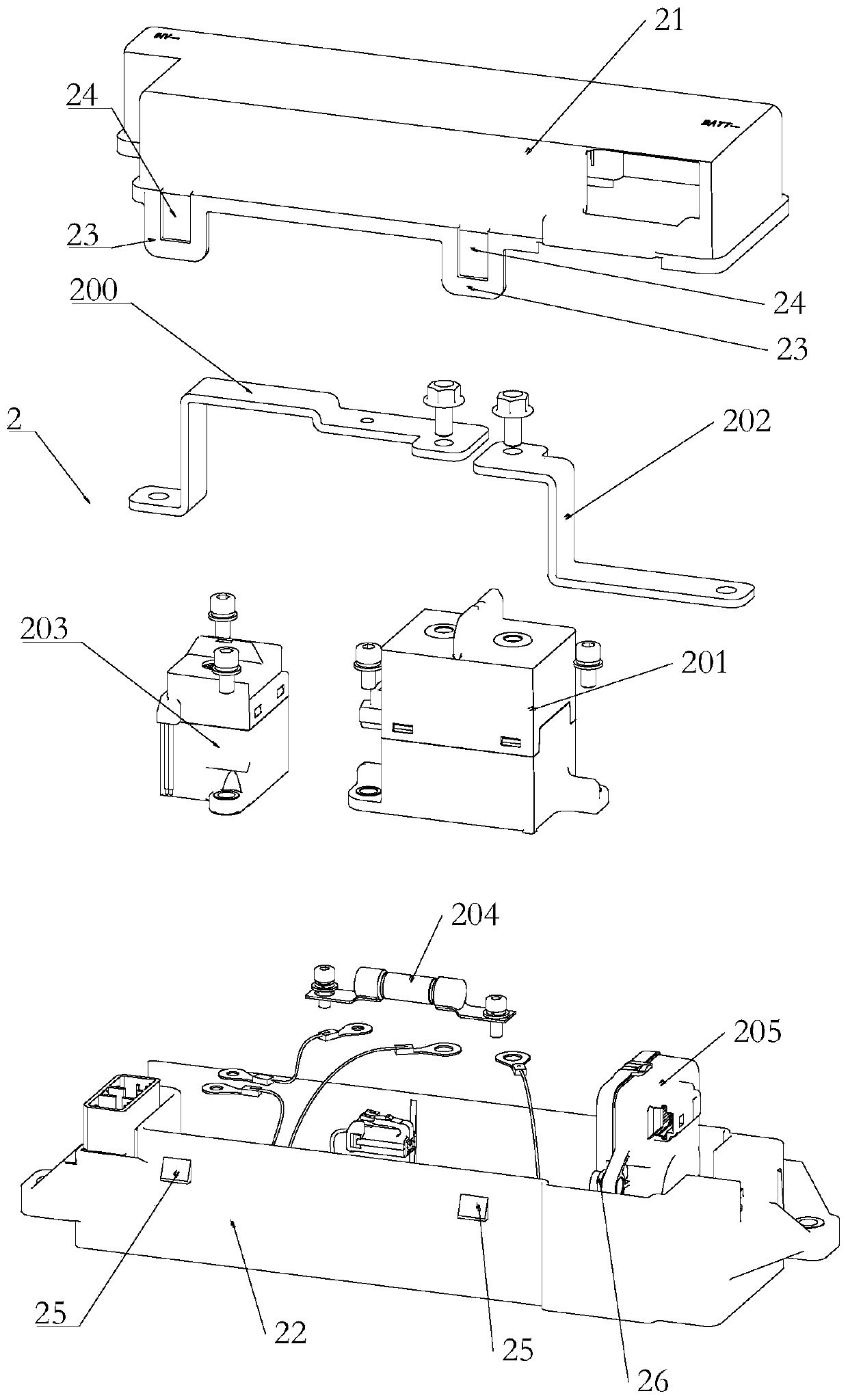

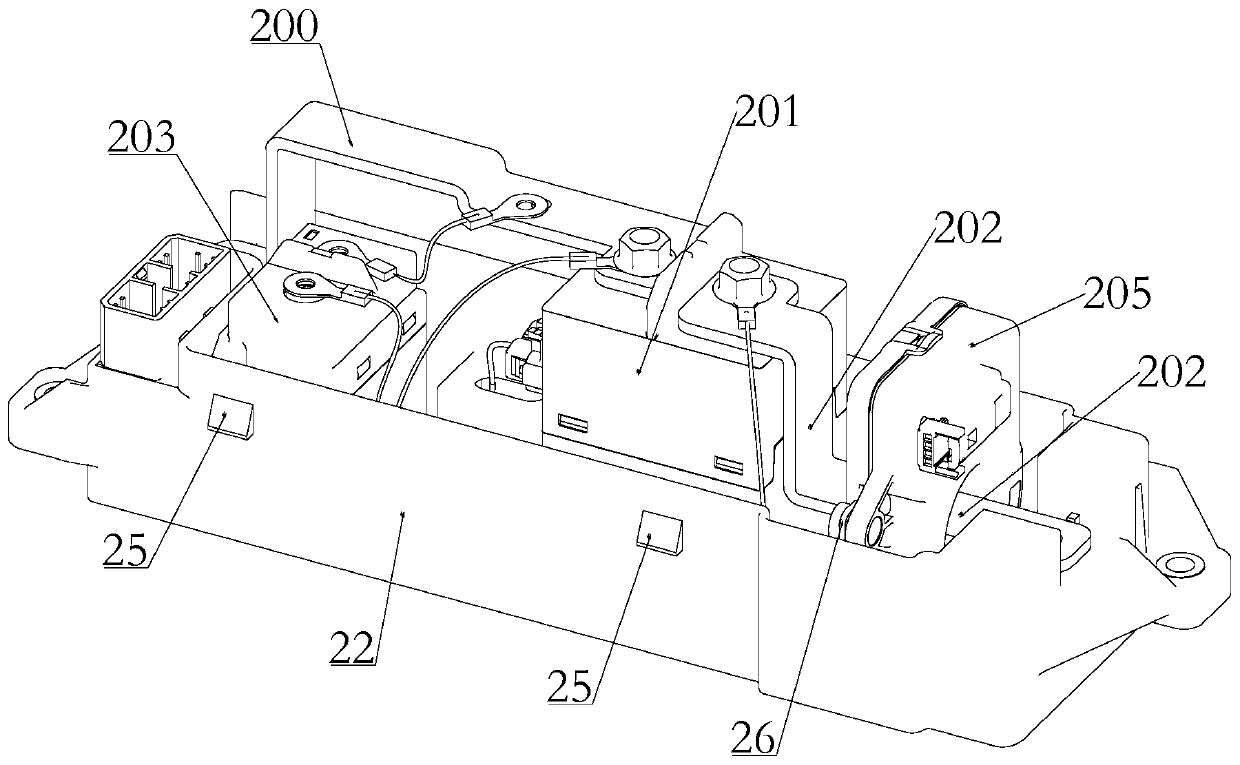

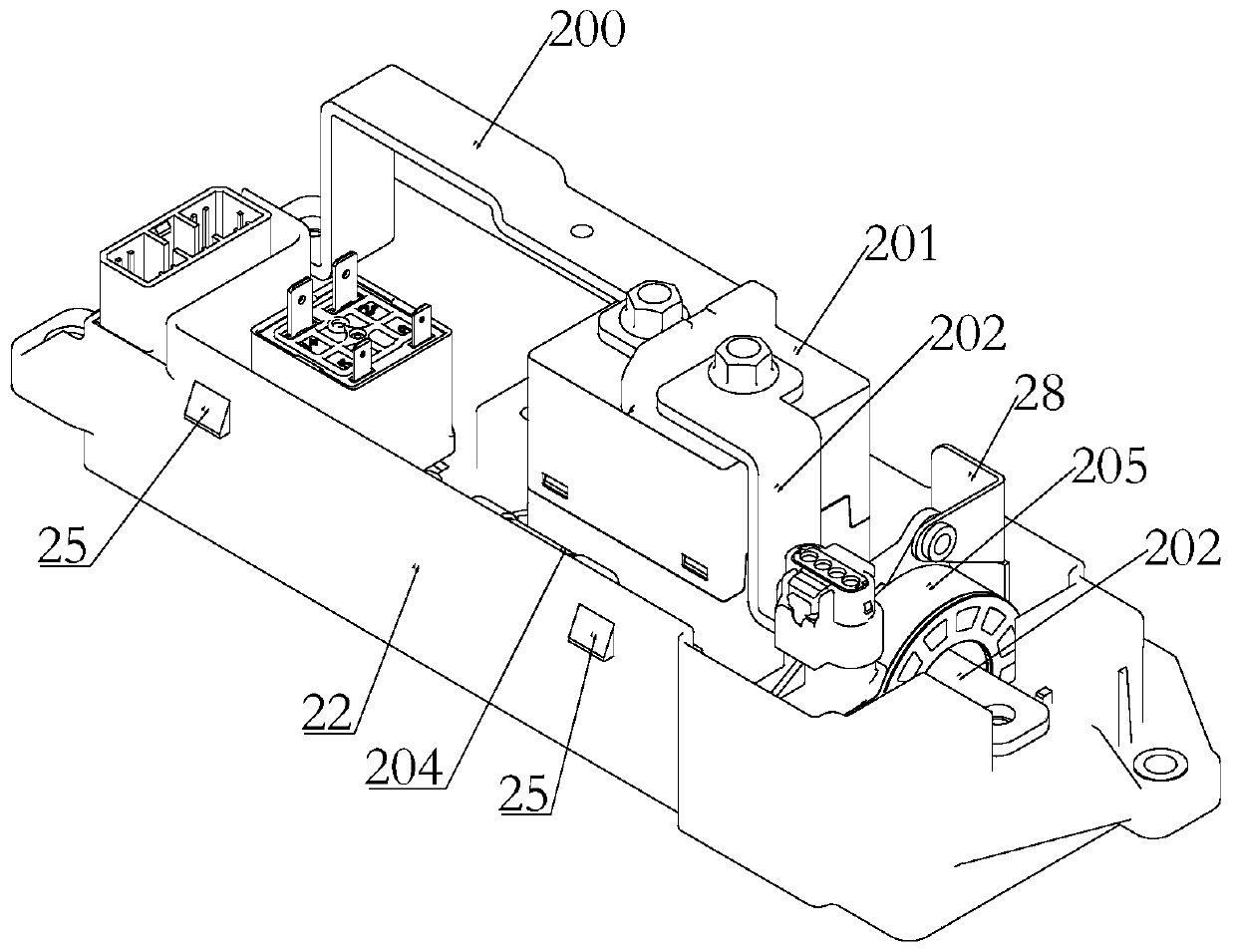

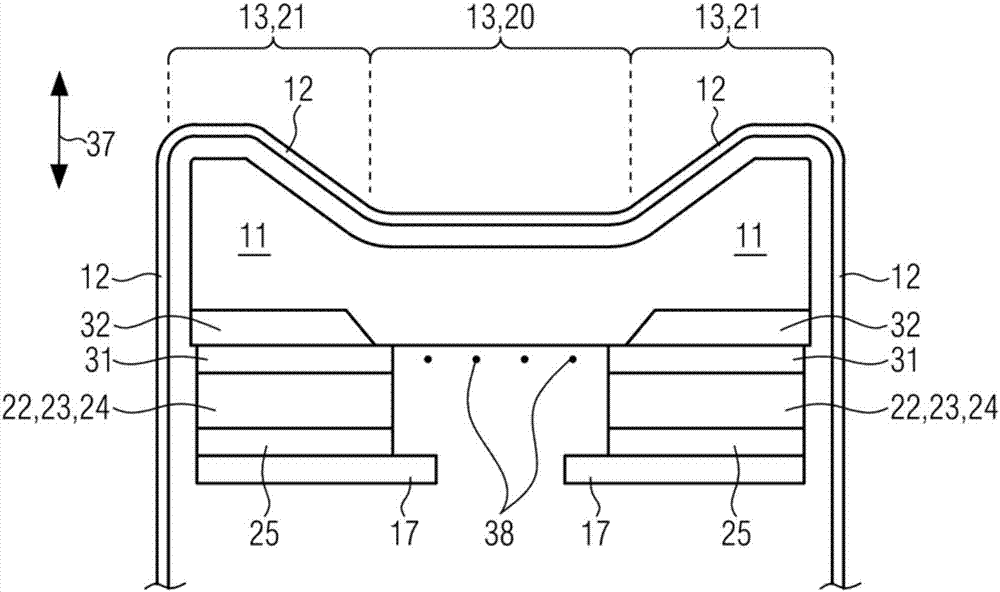

Universal economic compatibility BDU and battery pack

PendingCN110277525AReduce connectionsReduce weightCells structural combinationCell component detailsEngineeringBattery pack

The invention relates to a universal economic compatibility BDU and a battery pack. The BDU comprises a positive electrode BDU and a negative electrode BDU which are designed in a split manner. The positive electrode BDU comprises a positive electrode upper shell and a positive electrode lower shell, wherein the positive electrode upper shell is detachably connected with the positive electrode lower shell through a buckle. The negative electrode BDU comprises a negative electrode upper shell and a negative electrode lower shell, wherein the negative electrode upper shell is detachably connected with the negative electrode lower shell through a buckle. According to the BDU, the positive electrode and the negative electrode are integrated in different shells in a split mode, and the upper shell and the lower shell of the positive electrode BDU and the lower shell of the negative electrode BDU are respectively of a buckle design, thereby reducing the bolt connection, and effectively reducing the weight and cost of a system effectively. Moreover, due to the fact that an installation space in the battery pack is limited, the positive electrode BDU and the negative electrode BDU are designed in the split mode, so the limited space in the battery pack can be effectively utilized, the structure is compact, and the space is saved.

Owner:江苏和中普方新能源科技有限公司

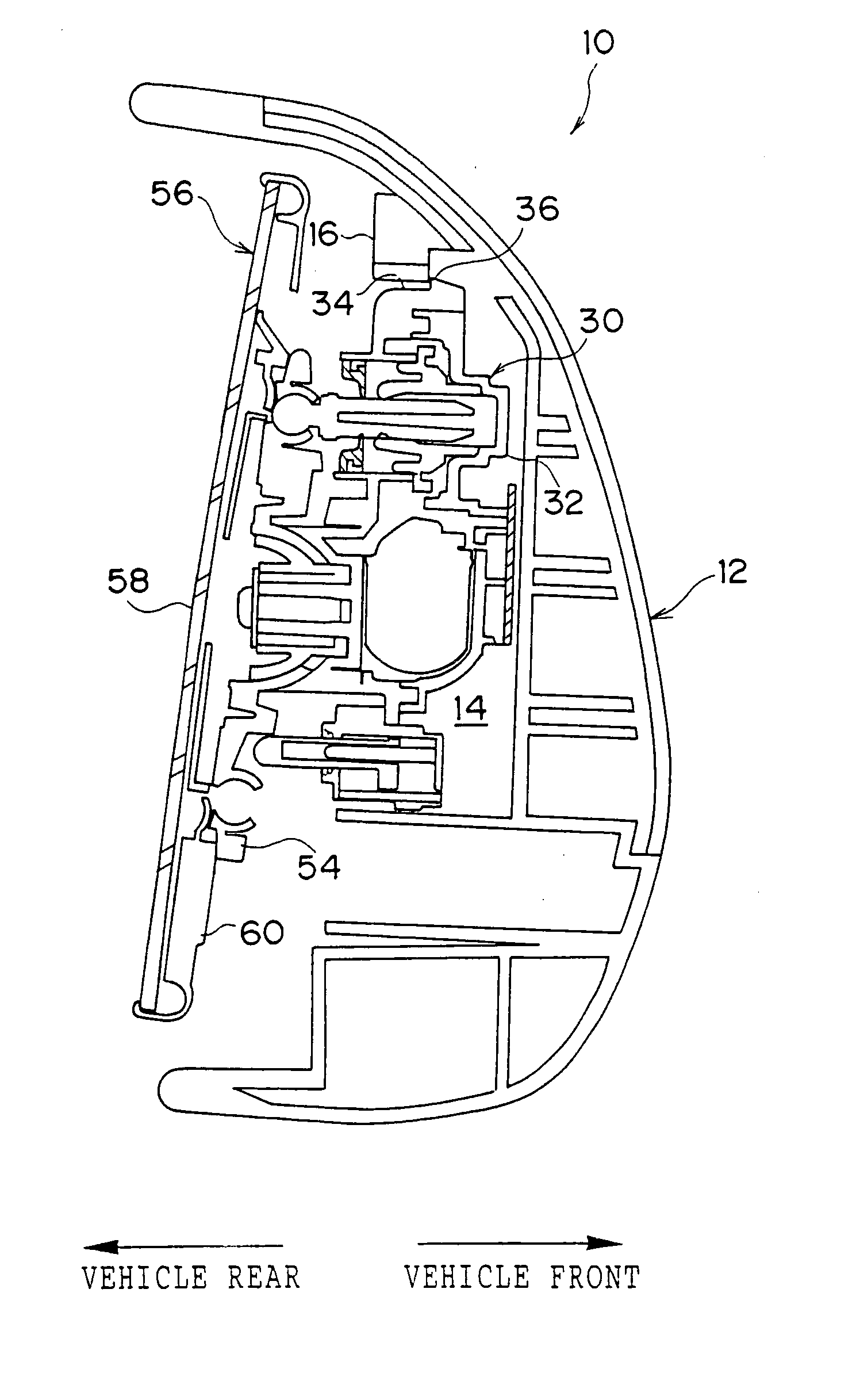

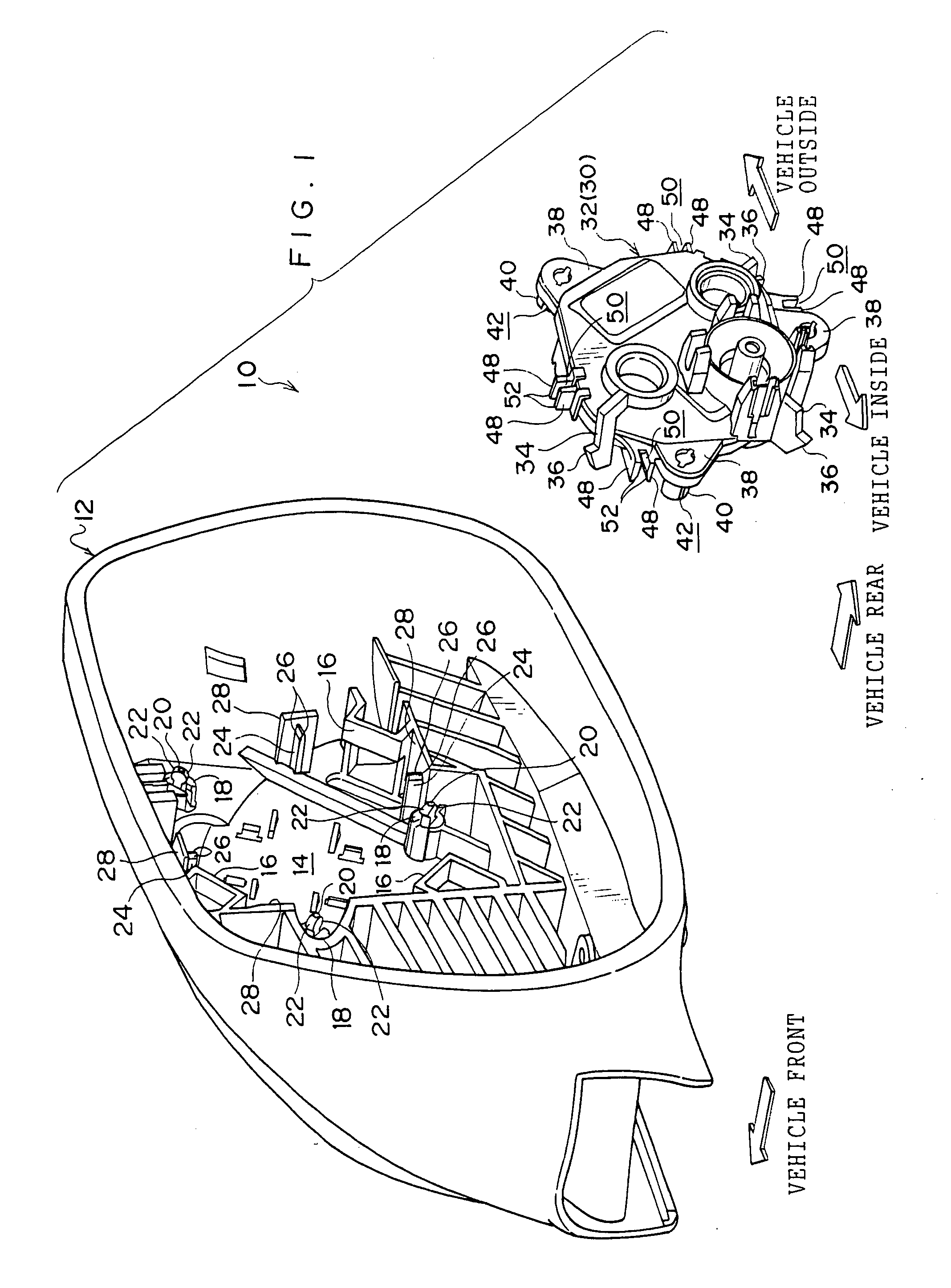

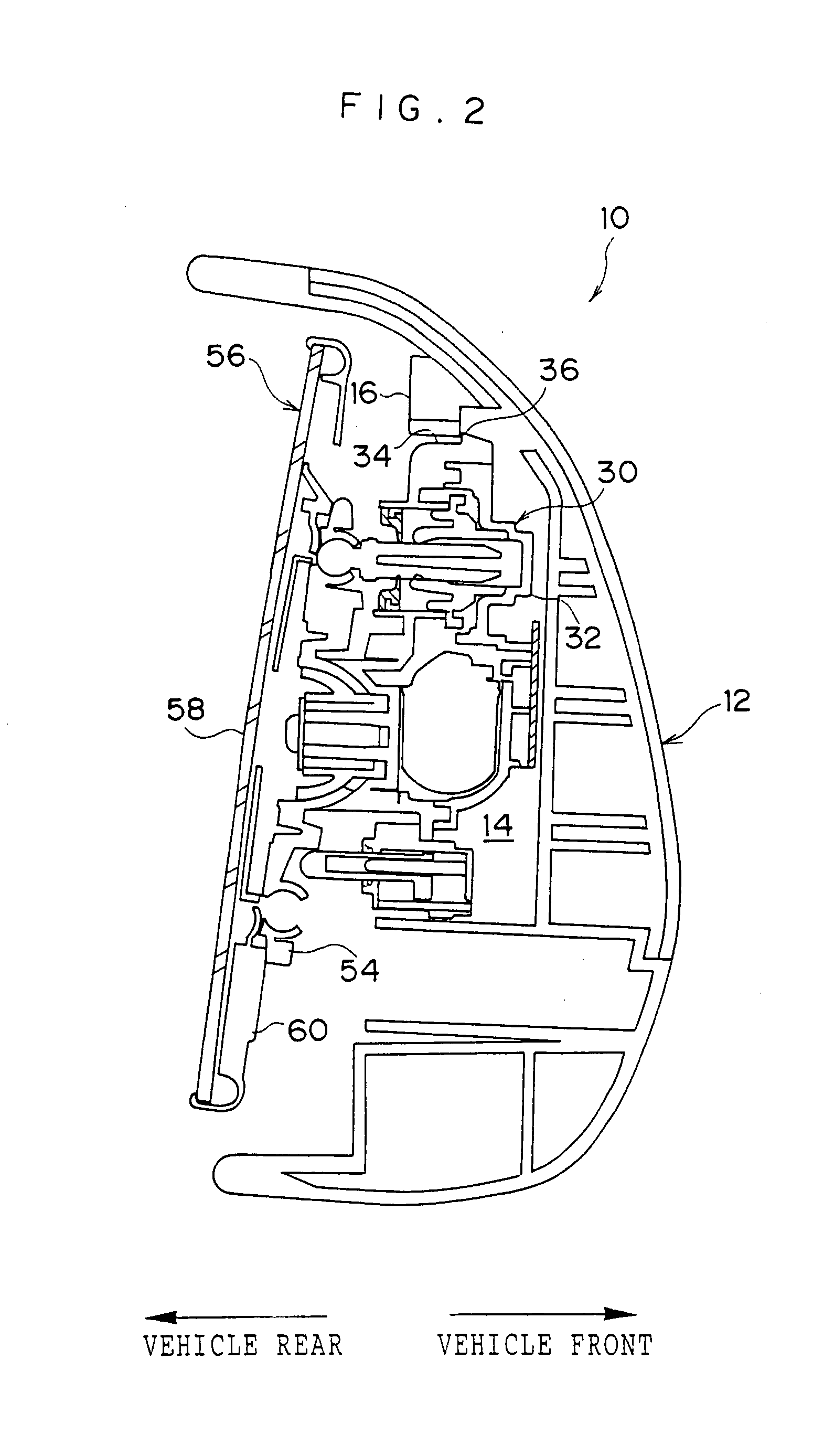

Mirror device for a vehicle

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

Double-elasticity high-temperature-resistant high-pressure-resistant bidirectional sealing double-eccentric hard sealing butterfly valve

PendingCN111594621AExtended service lifeGuaranteed that the valve seat can be deformedLift valveEngineeringButterfly valve

The invention discloses a double-elasticity high-temperature-resistant high-pressure-resistant bidirectional sealing double-eccentric hard sealing butterfly valve, and relates to the field of valve. The butterfly valve comprises a valve body, a valve rod and a butterfly plate, wherein the valve rod penetrates through the butterfly plate and is rotationally arranged on the valve body; a positioningstep, a valve seat, a check ring and a fixing ring are sequentially arranged on the inner wall of the valve body; an elastic sealing groove is formed in the side, close to the check ring, of the valve seat; an adjusting gap X is formed between the valve seat and the check ring; a butterfly plate matched with the valve seat is fixed to the valve rod; a pressing plate ring is arranged at the end, deviating from the valve rod, of the butterfly plate; a butterfly plate sealing ring is embedded between the butterfly plate and the pressing plate ring; the butterfly plate sealing ring comprises a clamping part and a bowl-shaped elastic sealing component arranged on the outer ring of the clamping part; the clamping part is arranged between the butterfly plate and the pressing plate ring; the outer side face of the bowl-shaped elastic sealing component is an outer cone sealing face; a limiting boss is arranged on the side, close to the butterfly plate sealing ring, of the butterfly plate; andan adjusting gap Y is formed between the limiting boss and the end of the bowl-shaped elastic sealing component. The butterfly valve has the advantages of being capable of achieving bidirectional sealing and long in service life.

Owner:HENAN YUDA VALVE MFG

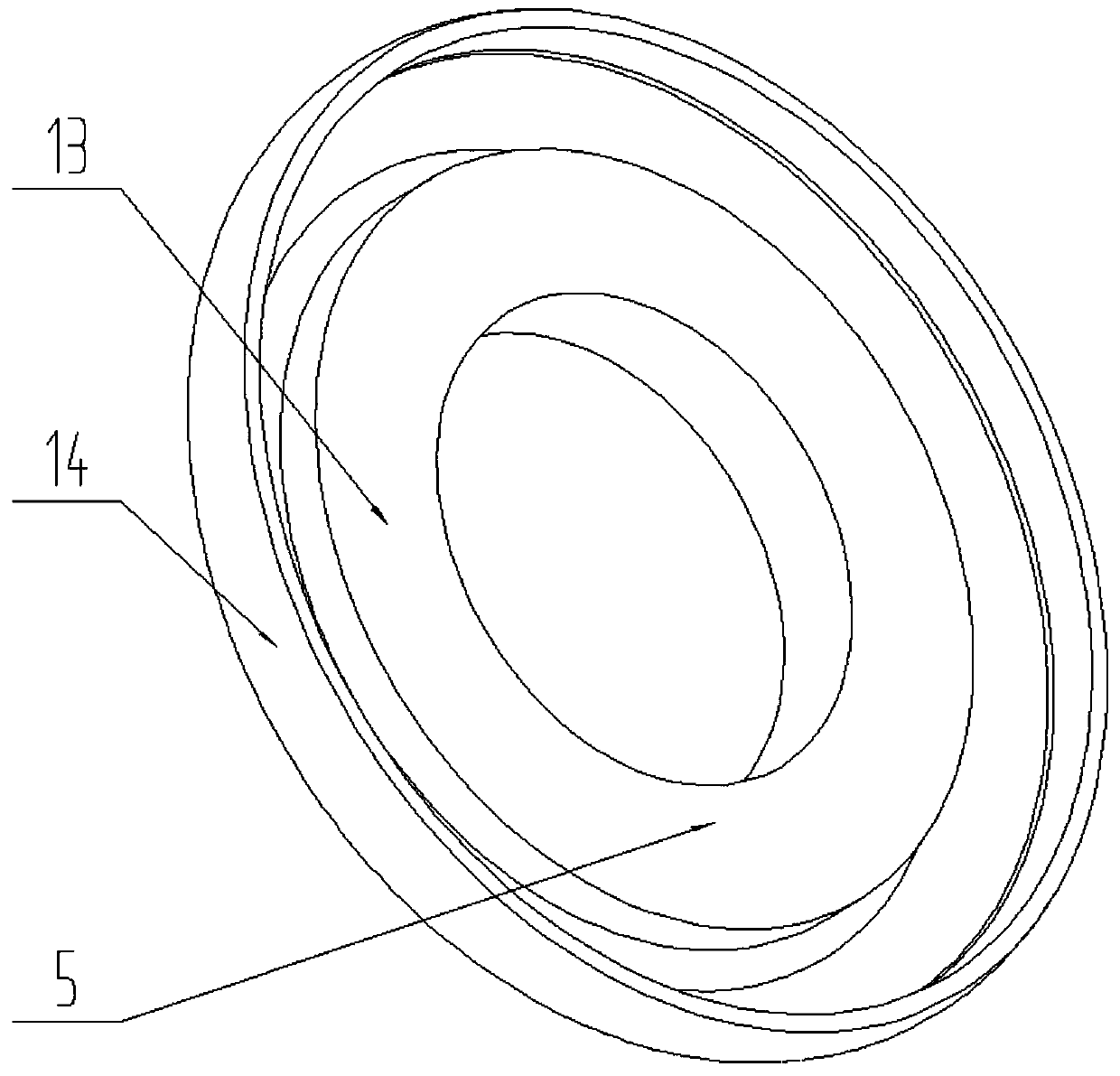

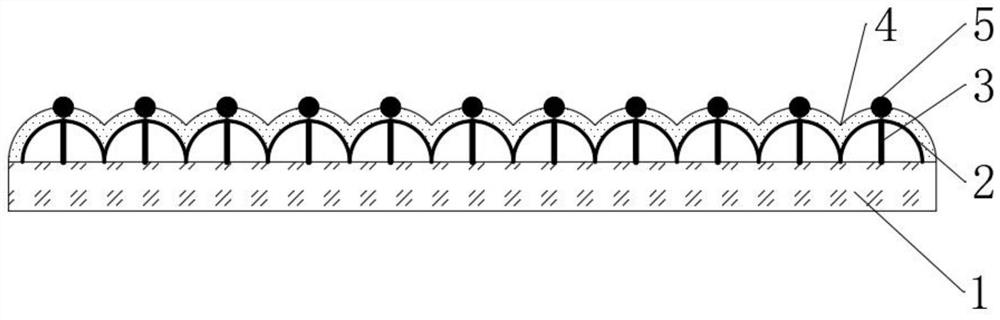

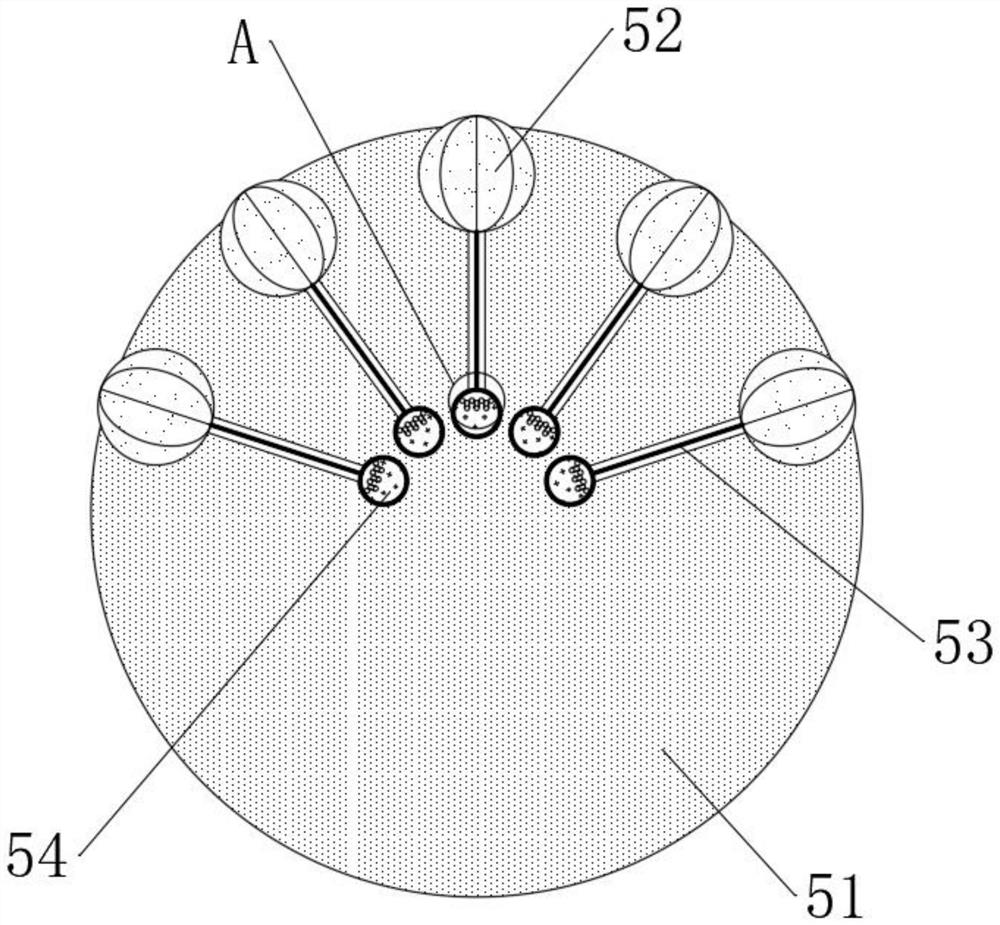

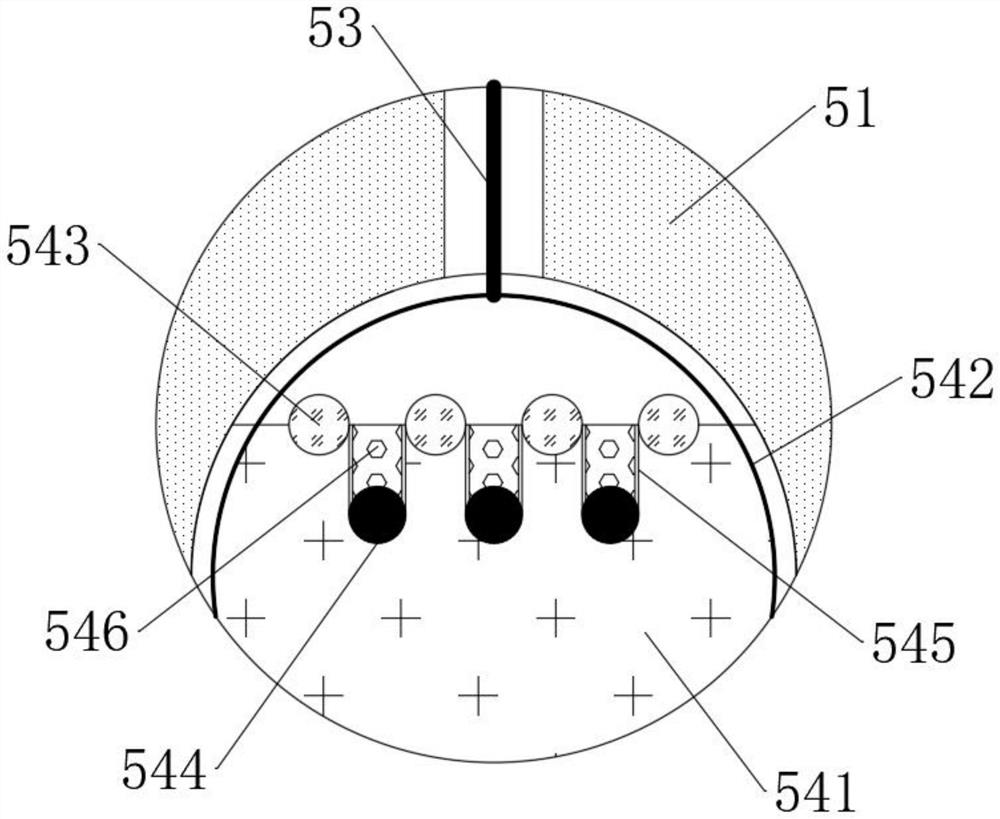

High-wear-resistance PVC air bubble film for transportation

ActiveCN112277413AImprove wear resistanceImprove wear lifeFlexible coversWrappersThermal dilatationMetal membrane

The invention discloses a high-wear-resistance PVC air bubble film for transportation, belongs to the technical field of air bubble films, and aims at improving the strength and wear resistance of theair bubble film by covering the surface of the air bubble film with a metal film layer, embedding single-point wear-resistant beads on the metal film layer in a multi-point manner, and reducing friction in a manner from surface contact to single-point contact. Heat of different degrees can be generated by sensing the friction degree, then the lubricating action in the single-point wear-resistantbeads is triggered by utilizing the heat, and pre-stored magnetic lubricating fluid is released in a thermal expansion extrusion mode, so that the wear condition of the surface of the single-point wear-resistant beads is effectively improved, the single-point wear-resistant beads can be protected, and meanwhile, friction damage can be effectively counteracted, and after the friction phenomenon disappears, the magnetic lubricating fluid is recycled by controlling the magnetic field, so that the consumption loss of the magnetic lubricating fluid in the outside is reduced, subsequent lubricatinguse is reserved, the wear-resisting life of the single-point wear-resistant balls is prolonged, and the wear-resisting performance of the bubble film is remarkably improved.

Owner:JIANGSU HIMEI NEW MATERIAL CO LTD

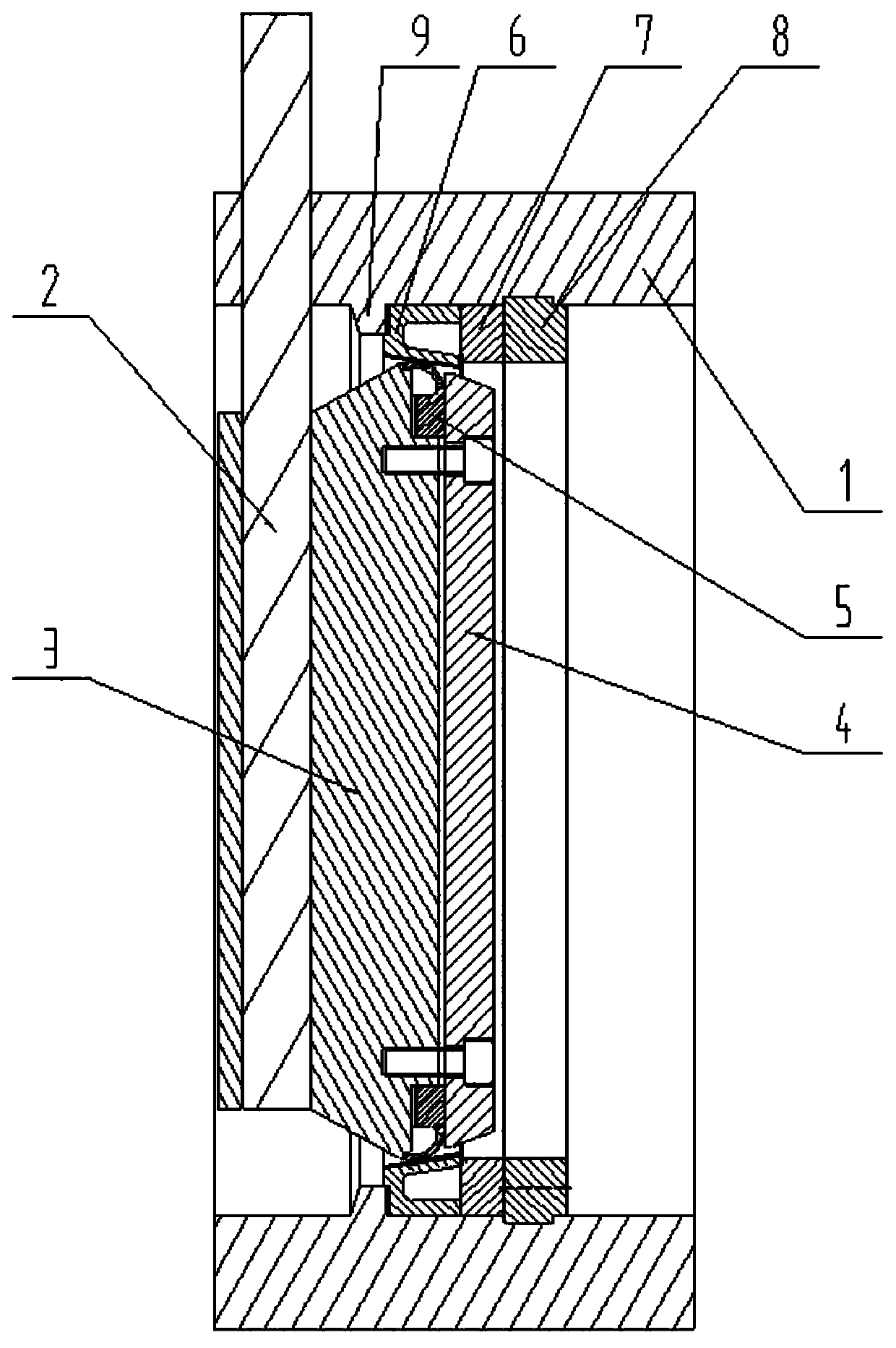

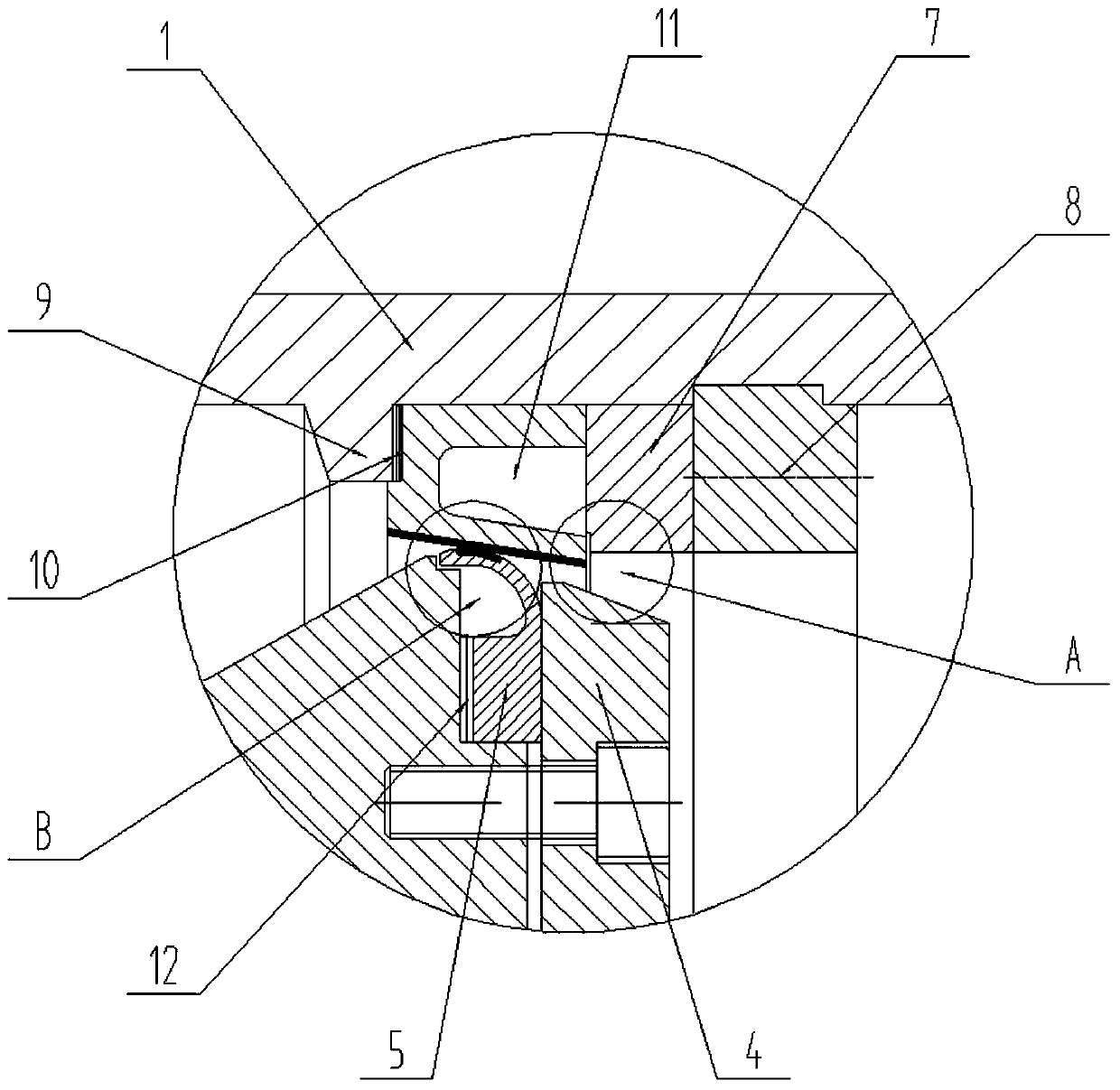

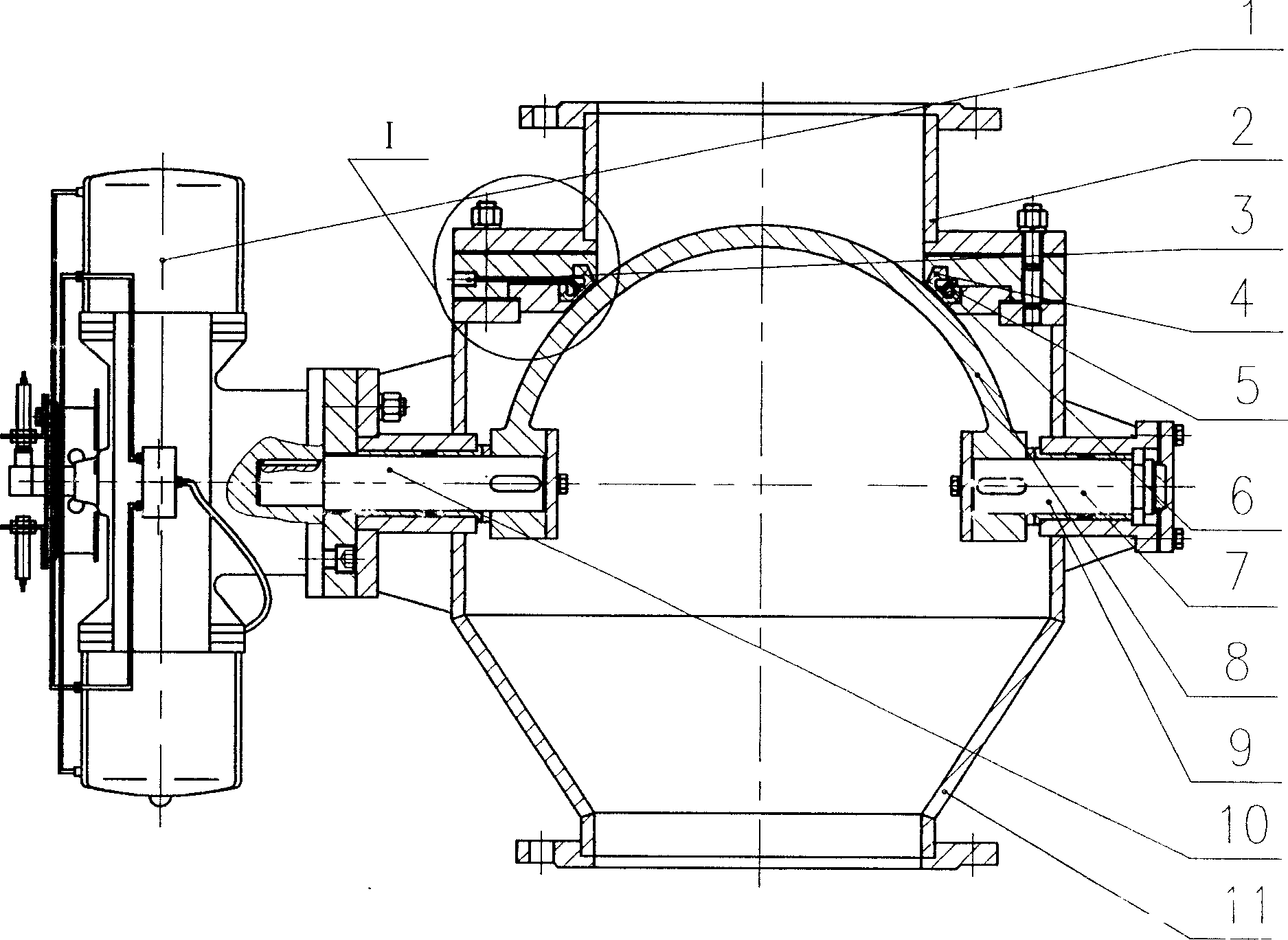

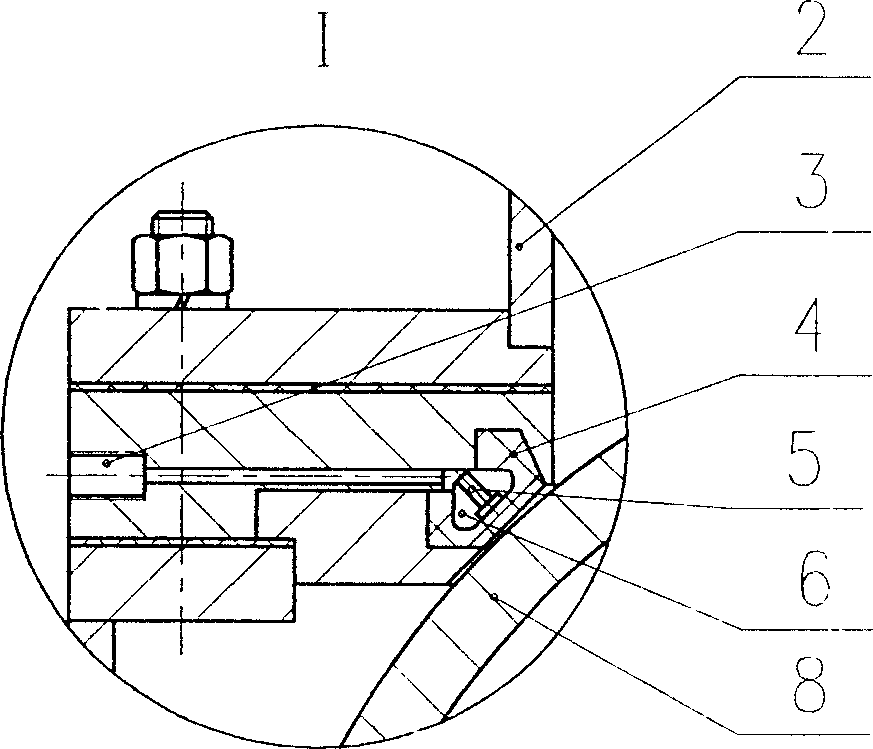

Air bag valve

A gasbag valve comprises a valve body, a valve cover, upper and lower valve shafts, a drive device, a spool, an end cap and a seal ring. The valve body is connected with the valve cover via bolts. The spool is supported in the valve body by the upper and lower valve shafts. In the valve body is mounted the seal ring, in which is inlaid a metal lining ring with several radial through-holes. An air inlet is set on the valve body. Outside the air inlet there is compression air and the inside of the air inlet is in communication with the metal lining ring. The seal ring is made of acrylonitrile rubber or silicon rubber.

Owner:JIANGSU SHENTONG VALVE

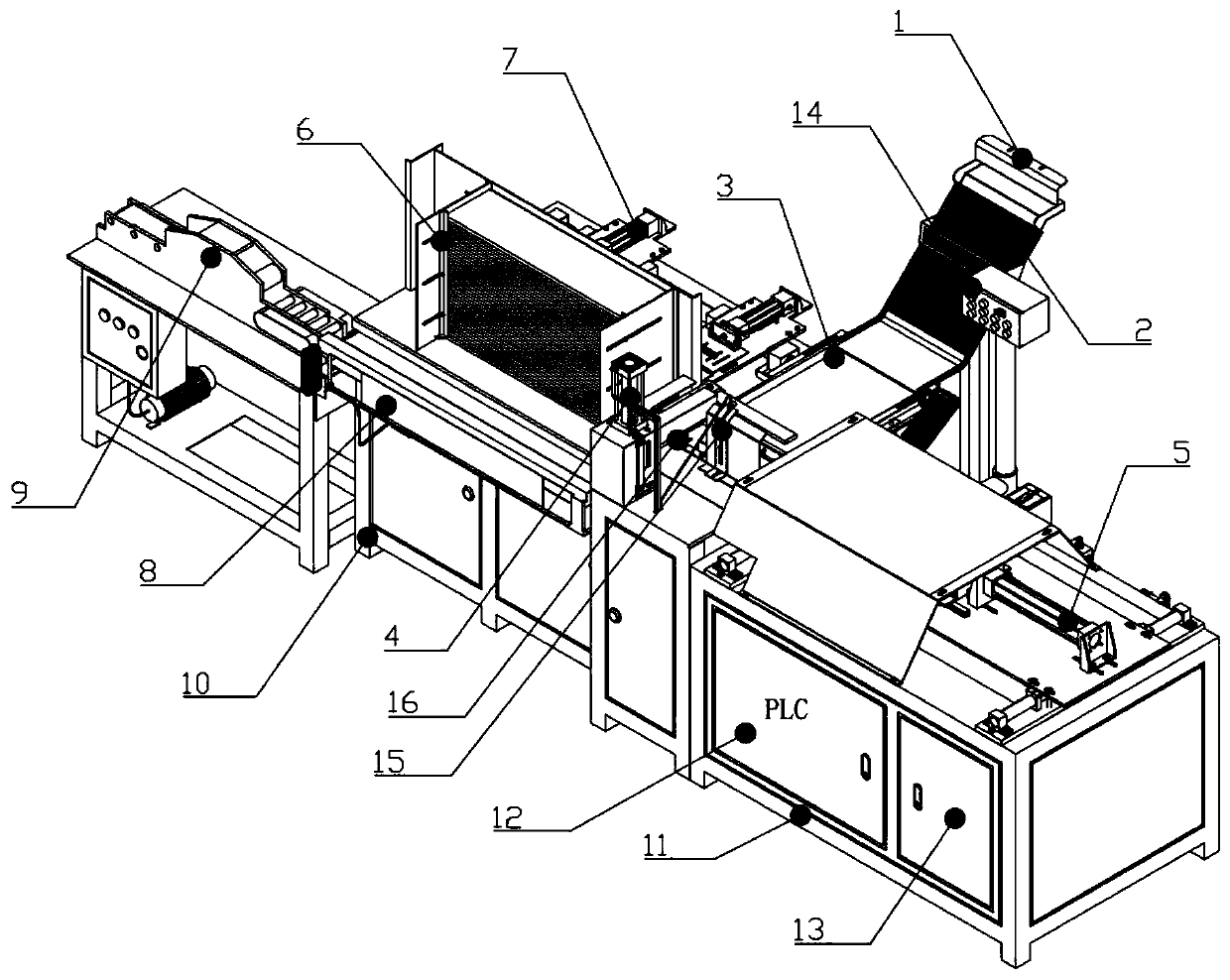

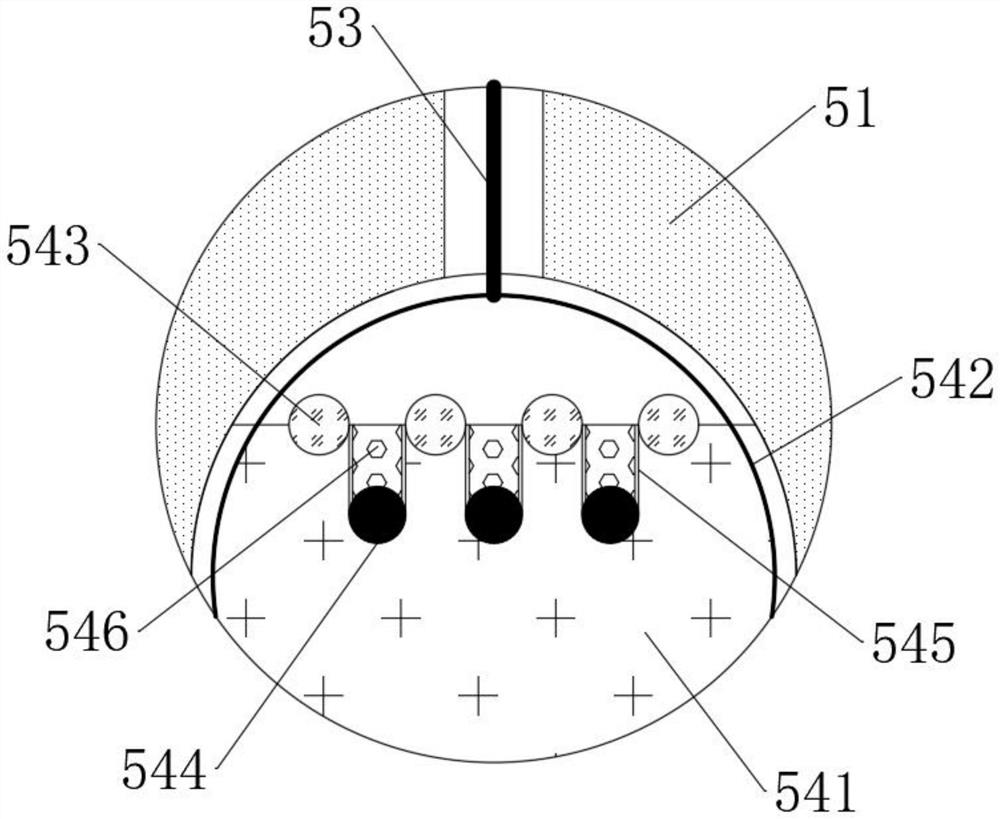

Automobile intercooler flat pipe inner fin inserting and flat pipe leveling integrated equipment

PendingCN110434246AImprove the efficiency of automatic transfer into flat tube leveling and correctionSave work spaceHeat exchange apparatusMarine engineeringIntercooler

The invention relates to automobile intercooler flat pipe inner fin inserting and flat pipe leveling integrated equipment. The automobile intercooler flat pipe inner fin inserting and flat pipe leveling integrated equipment comprises a rack, a fin transmission module which is arranged at the middle part of the rack, a fin prepressing unit and a fin compression unit which are arranged at the lowerpart of the fin transmission module, a flat pipe storage unit which is arranged on one side of the fin transmission module, a flat pipe inner fin propelling unit which is arranged on the other side ofthe fin transmission module, and a flat pipe push-out unit which is arranged at the bottom of the flat pipe storage unit, and is used for horizontally pushing out a flat pipe after being inserted. The automobile intercooler flat pipe inner fin inserting and flat pipe leveling integrated equipment further comprises a flat pipe correcting and rolling unit which is arranged on one side of the flat pipe push-out unit and is used for leveling and correcting the flat pipe, and a flat pipe conveying unit. Compared with the prior art, flat pipe fin inserting and correcting and rolling integrated andautomatic work is achieved, the working efficiency is improved, the working space is saved, the labor cost is reduced, simultaneously, the equipment can insert flat pipe fins in different sizes and can correct and level the flat pipe after the fins are inserted, and the application range is wide.

Owner:SHANGHAI DELANG AUTO RADIATOR MFG

Harmonic reducer tooth surface machining method and device

The invention discloses a harmonic reducer tooth surface machining method. A rigid wheel is machined through a conjugate tooth profile electric spark generating method. The machined rigid wheel is connected with a positive electrode of an electric spark power supply; and a flexible gear is connected with a negative electrode of the electric spark power supply, a flexible bearing and a wave generator are arranged in the flexible gear, the transmission ratio among the flexible gear, the rigid gear and the wave generator is controlled through a transmission chain or a harmonic reducer of a machining device, and the tooth portion of the flexible gear comprises a conical tooth section, a finish machining section and a running-in section. The conjugate tooth profile electric spark generating method is adopted for machining, the transmission ratio among the flexible gear, the rigid gear and the wave generator is consistent with the design of a harmonic reducer, the obtained tooth profile of the rigid gear is a no-load conjugate tooth profile conforming to the effect of no theoretical error, and the conjugate tooth profile under the load condition is obtained through loading running-in.

Owner:查世梁

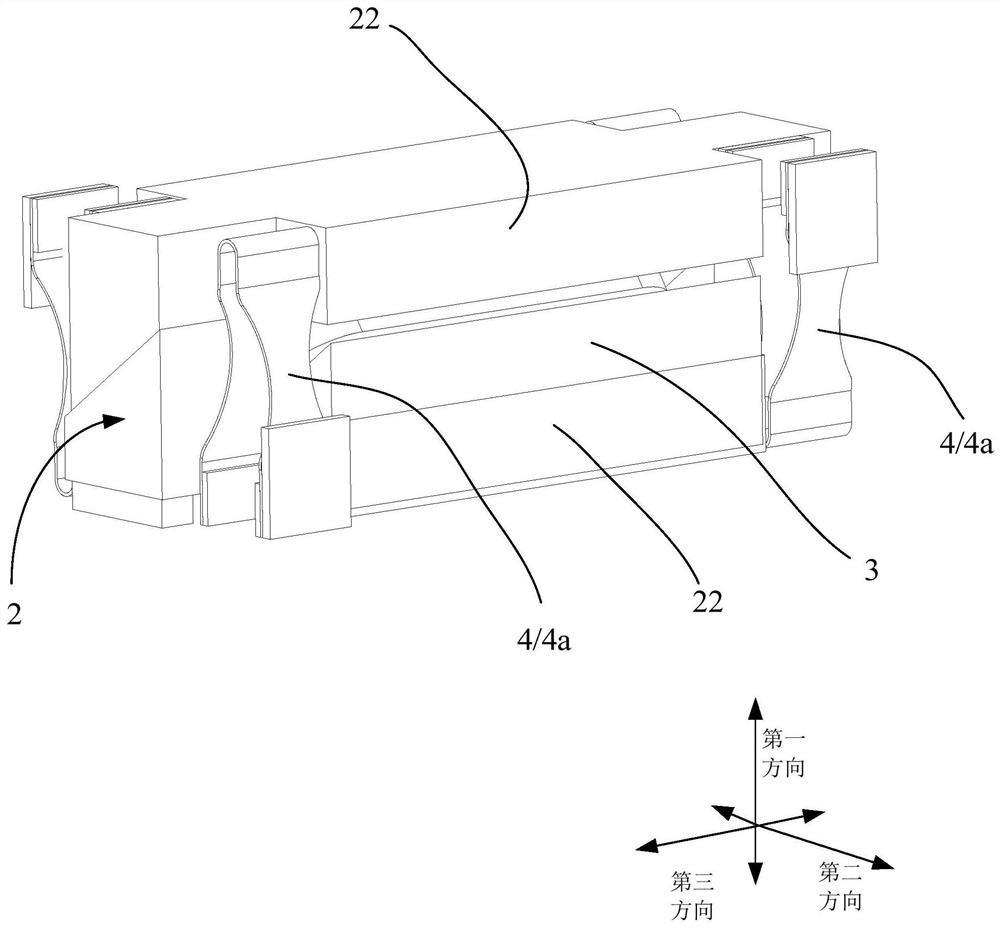

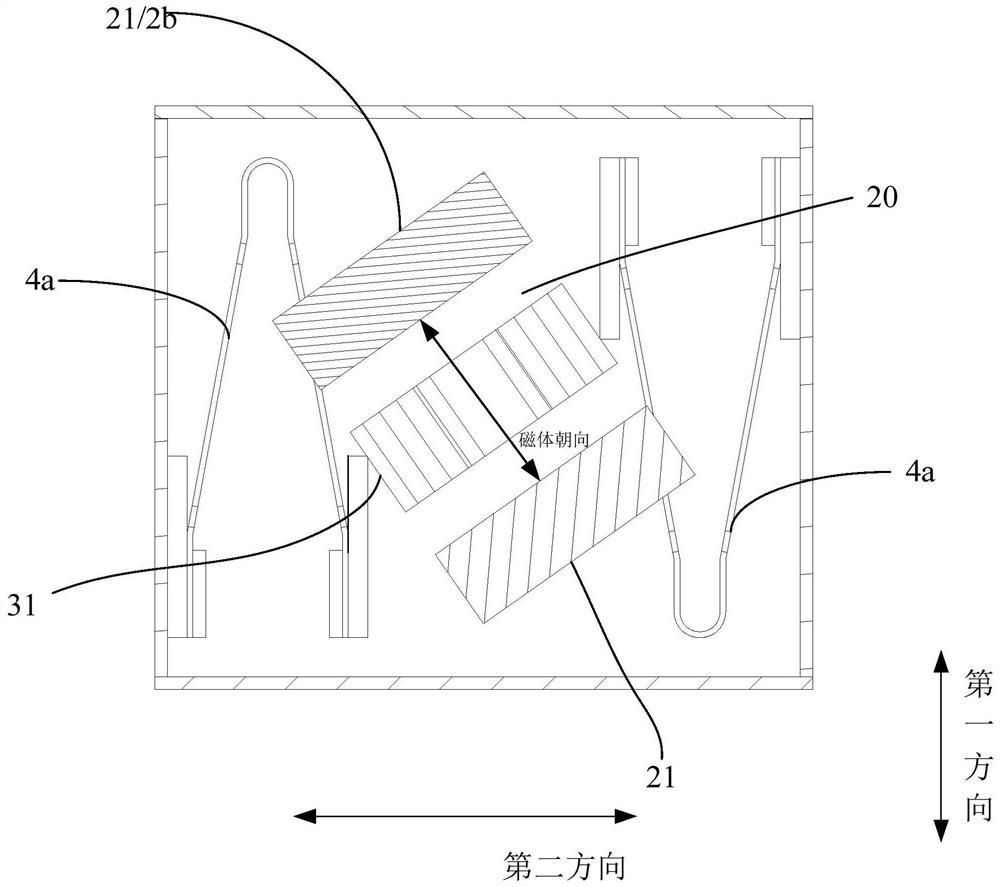

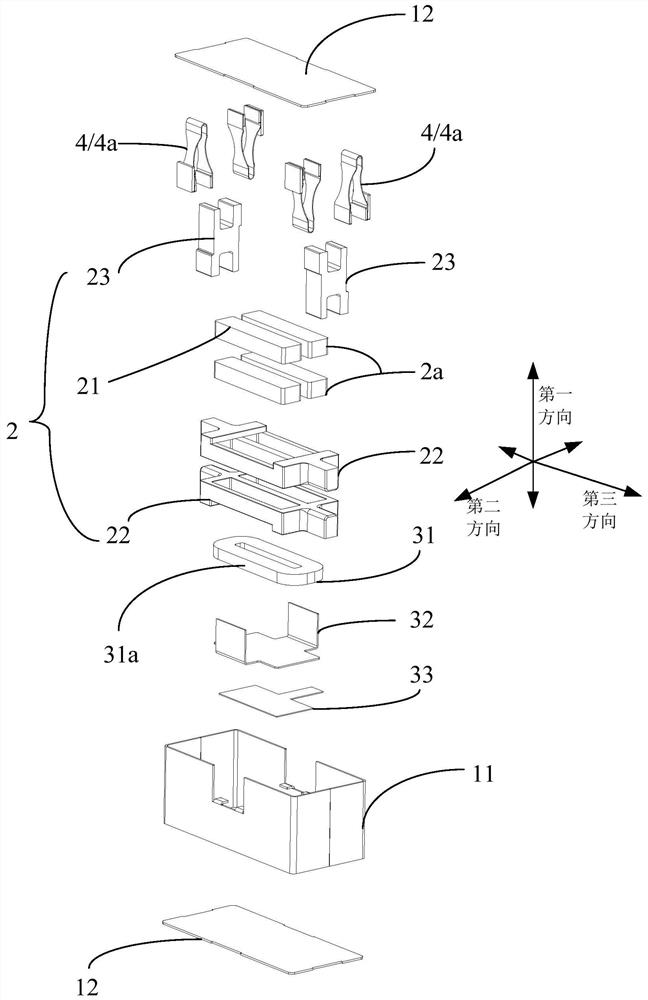

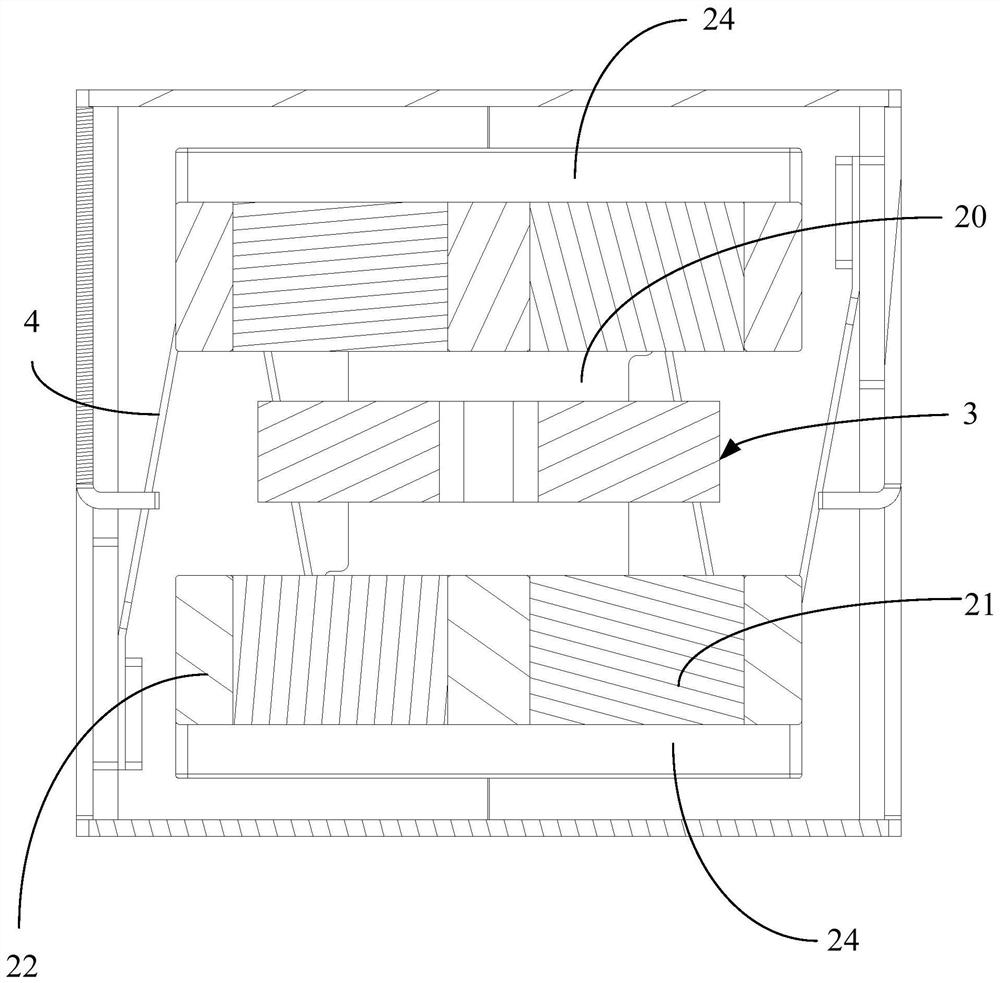

Vibration device and electronic apparatus

The invention discloses a vibration device and electronic equipment. The vibration device comprises a shell, a magnetic circuit assembly, a coil assembly and an elastic supporting piece, wherein at least part of a magnet of the magnetic circuit assembly or the coil assembly is arranged to be a vibration piece, the elastic supporting piece is connected with the shell and the vibrating piece, the magnet of the magnetic circuit assembly is inclined relative to a first direction so as to enable the direction of a magnetic field formed in the magnetic gap to be arranged in a mode of forming an inclined included angle with the first direction; a wire section, which extends in a third direction, of the coil is arranged in the magnetic gap, so that when the coil is electrified with alternating current, the vibrator vibrates in the first direction and the second direction; and the elastic supporting piece comprises an elastic piece, the width direction of the elastic piece is arranged in the third direction, the elastic piece extends in the second direction and is bent in the first direction, and the crease of the elastic piece is parallel to the third direction so as to enable the elasticpiece to deform in the first direction and the second direction easily.

Owner:GOERTEK INC

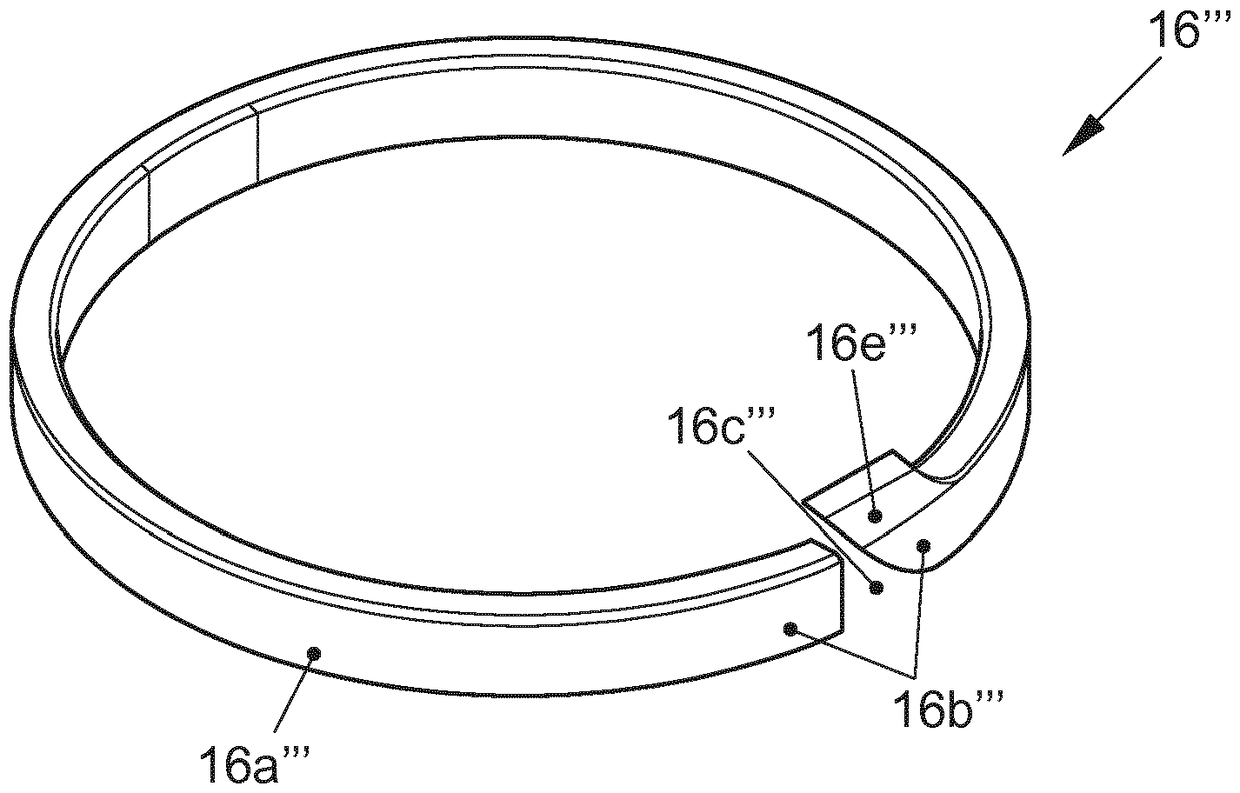

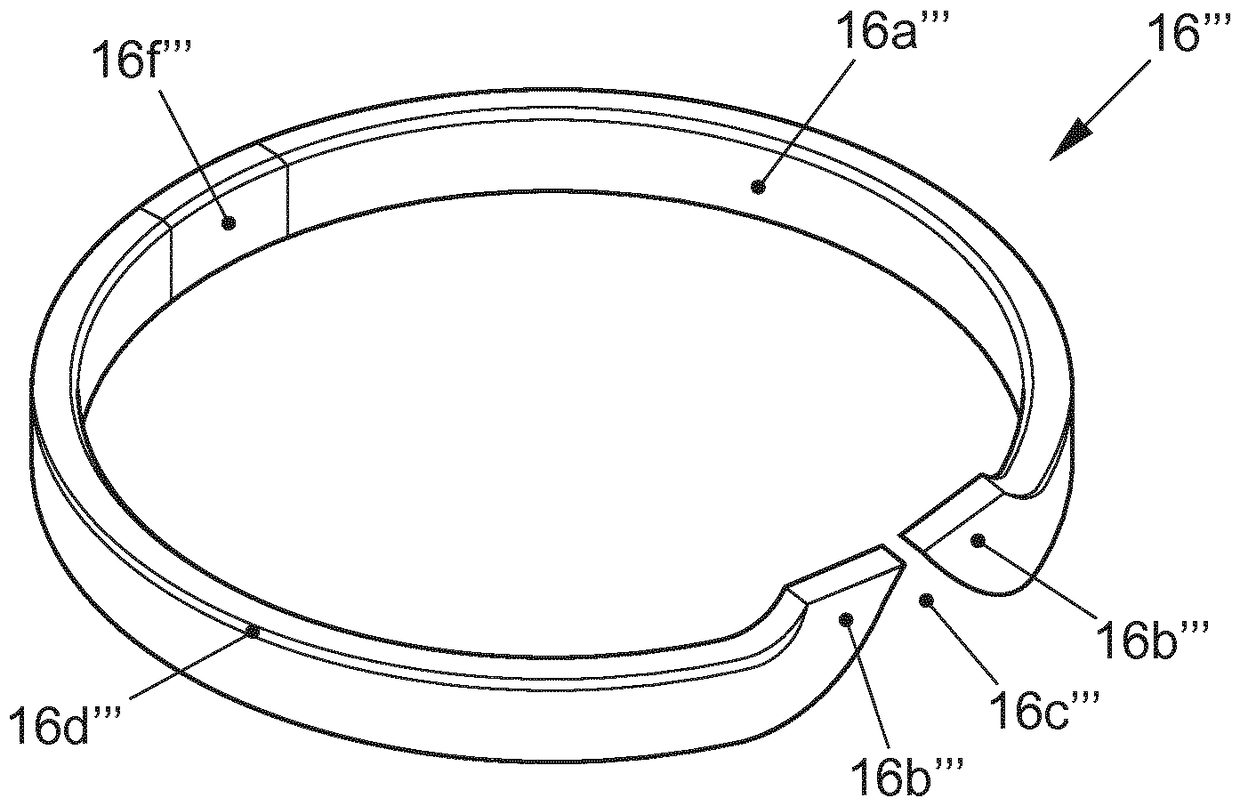

Vibration damper having a hydraulic traction stop

ActiveCN108291602AAccelerate openAccelerated closureSpringsResilient suspensionsControl theoryPiston rod

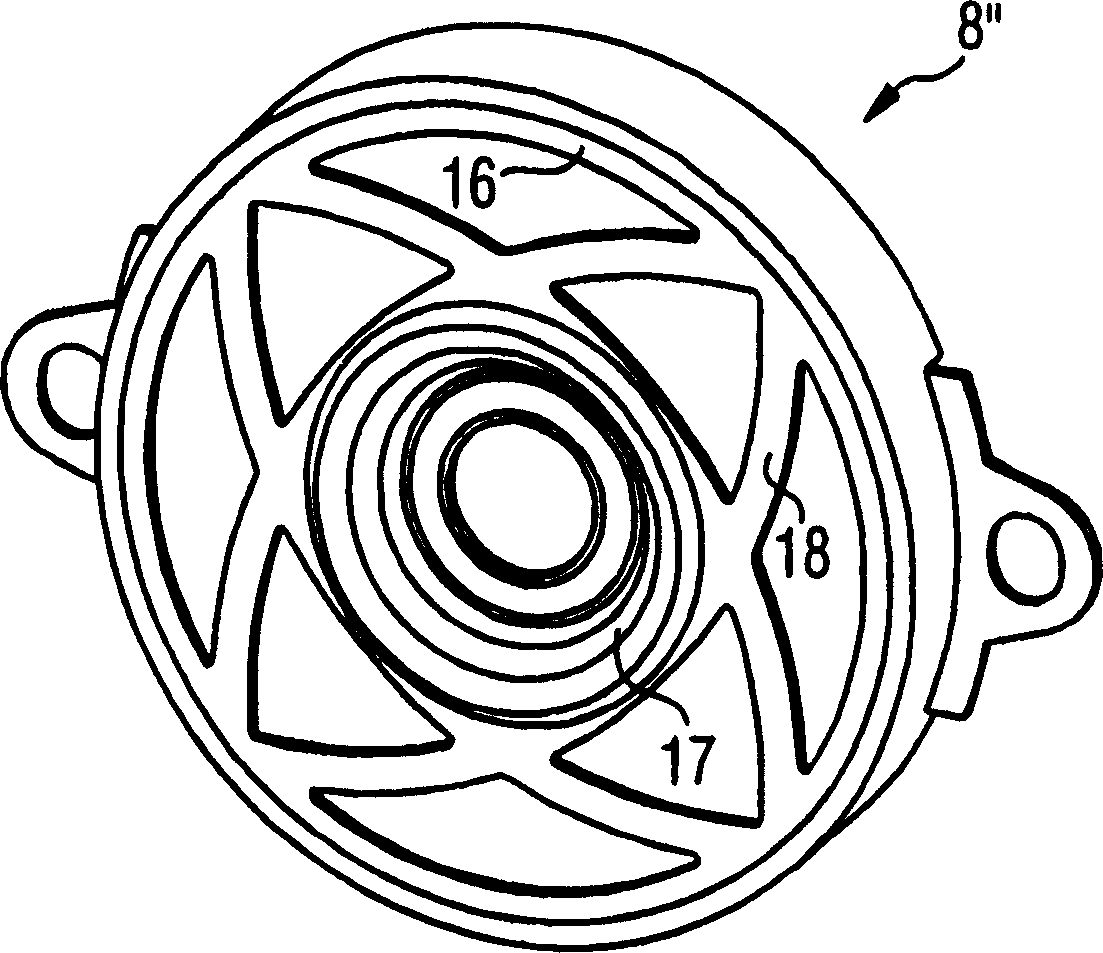

The invention relates to a vibration damper having a hydraulic traction stop for a motor vehicle wheel suspension, comprising a reservoir tube (2"), a piston rod (3") and a hydraulic damping device (10") having a damping piston (11") fastened on the piston rod (3), which provides a hydraulic force directed against the tractive motion of the piston rod (3") in an end region of a piston rod extraction path before reaching the maximum piston rod extraction path. The damping piston (11") has a circumferential groove (12") in which a slotted sealing ring (16") is received, which hydraulically sealsin the groove (12") in said end region of the piston rod extraction path upon movement of the piston rod (3") in the traction direction and, upon movement of the piston rod (3") in the pressure direction at least locally rises from a flank (14") of the groove (12") on the pressure direction side, which delimits the groove (12") on the side in the pressure direction and in the traction direction,in order to provide a defined permeability for a hydraulic damping medium between the groove (12") and the sealing ring (16").

Owner:VOLKSWAGEN AG

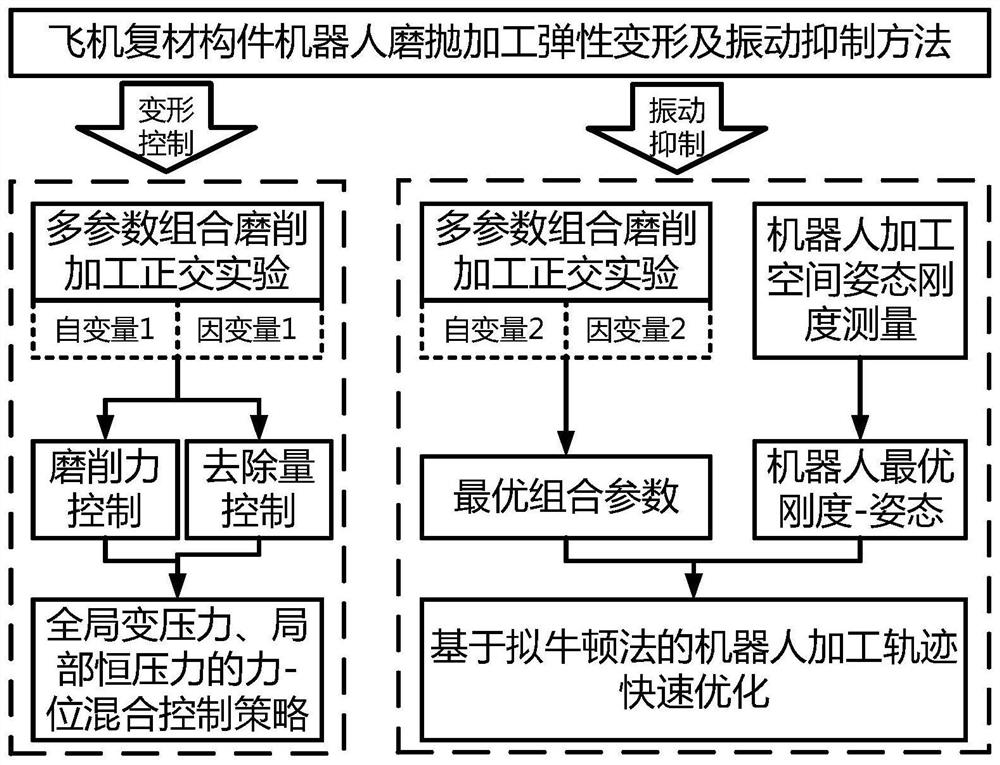

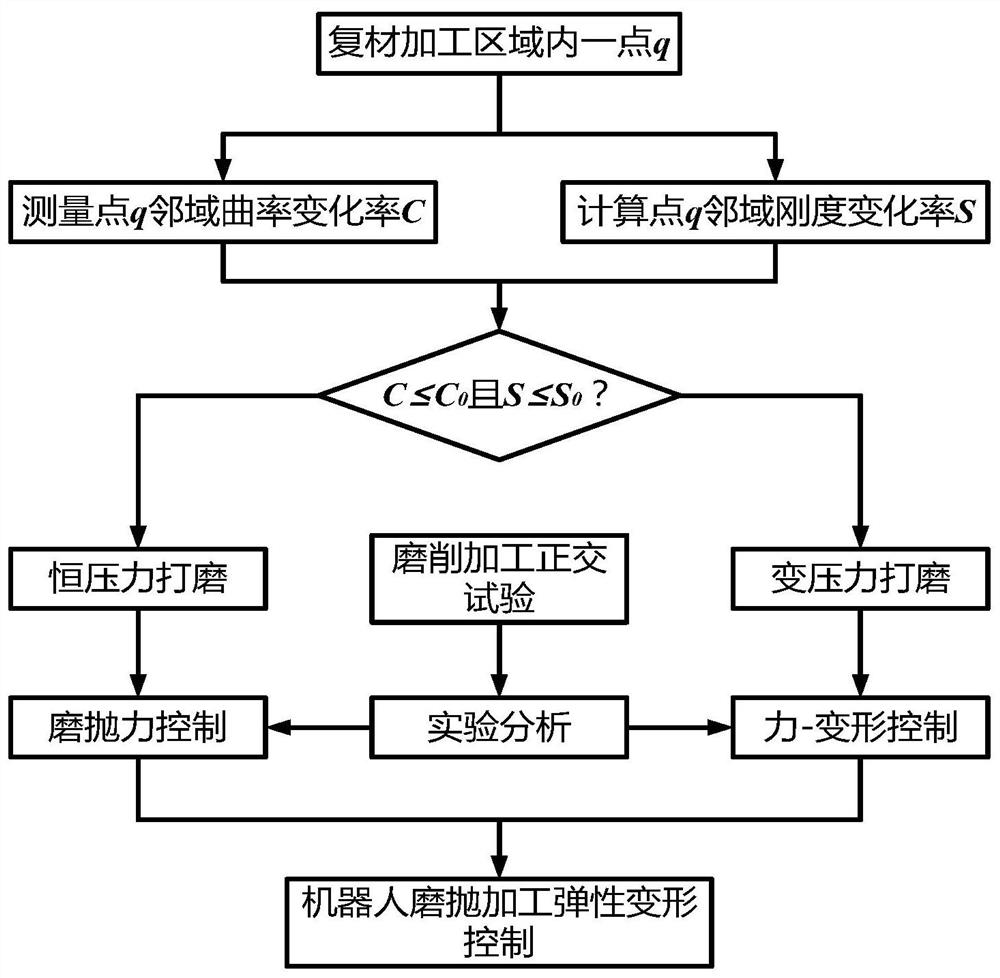

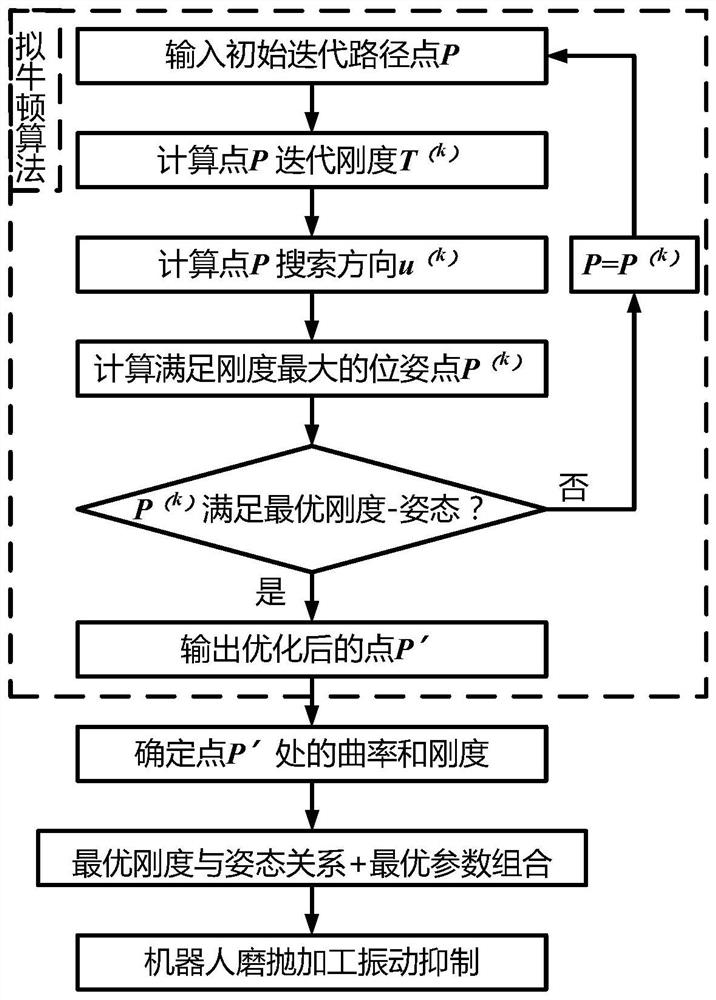

Elastic deformation and vibration inhibition method for grinding and polishing machining of airplane composite material component by robot

ActiveCN111673611AReduce vibrationMeet sizeProgramme controlProgramme-controlled manipulatorMachining vibrationsMaterial removal

The invention belongs to the field of grinding and polishing machining of a composite material component by a robot, and particularly discloses an elastic deformation and vibration inhibition method for grinding and polishing machining of the airplane composite material component by the robot. The method comprises the following steps that a first independent variable group and a first dependent variable group are designed; a multi-parameter combined grinding machining orthogonal test is carried out on the first independent variable group and the first dependent variable group to obtain a nonlinear relationship between the grinding force and the material removal amount; a force-position hybrid control strategy of global variable pressure and local constant pressure is adopted to control elastic deformation in the grinding machining process by the robot; and an optimal rigidity and posture relation in the machining space of the robot is constructed, a machining track of the robot is optimized according to optimal combination and grinding and polishing machining process parameters after elastic deformation control to determine grinding and polishing machining process parameters of a machining area. According to the elastic deformation and vibration inhibition method for grinding and polishing machining of the airplane composite material component by the robot, effective control ofthe elastic deformation and vibration suppression in the grinding and polishing machining process of the airplane composite material component by the robot can be achieved, grinding and polishing machining vibration lines are eliminated, and the machined surface quality is guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH +1

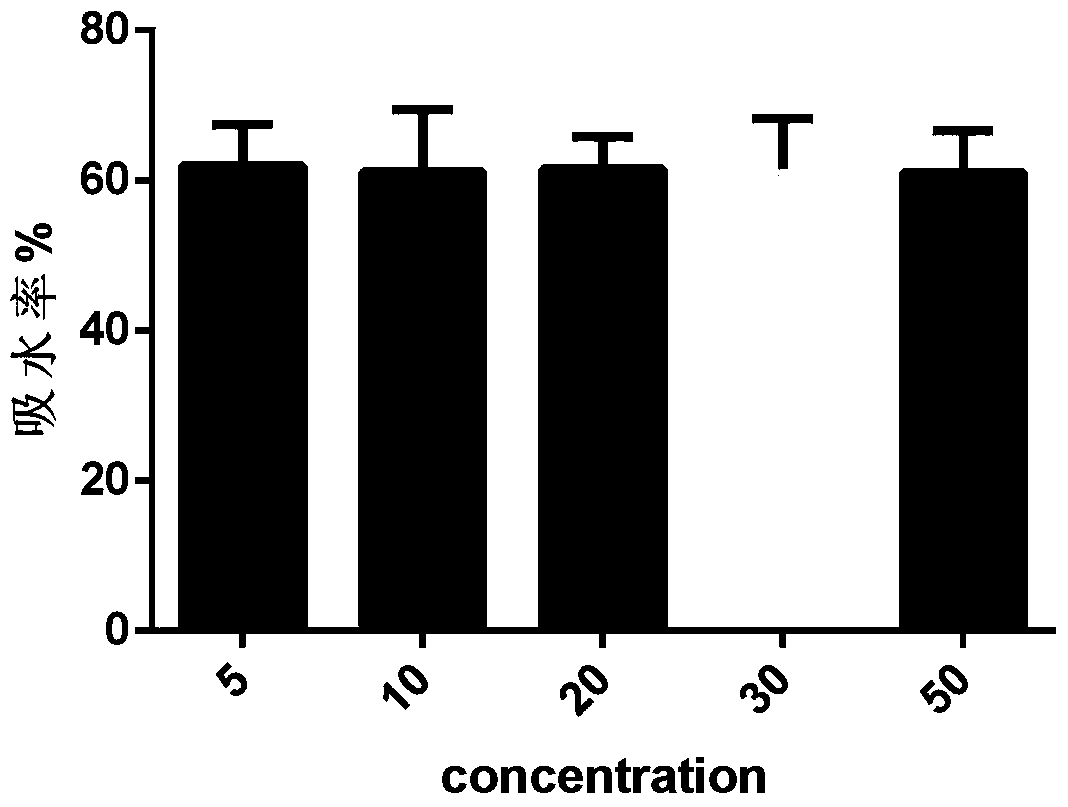

Anti-bacterial and anti-inflammatory natural biological material and application thereof

The invention provides a biological material which is prepared from small intestinal submucosa (SIS) and is characterized by containing nano silver, the material is of a porous structure, pores are mutually through, and the original form can be restored if the volume compression is more than 85%. The biological material provided by the invention has anti-inflammatory and anti-bacterial functions and is free of cytotoxicity and good in biocompatibility.

Owner:CHONGQING ACAD OF ANIMAL SCI

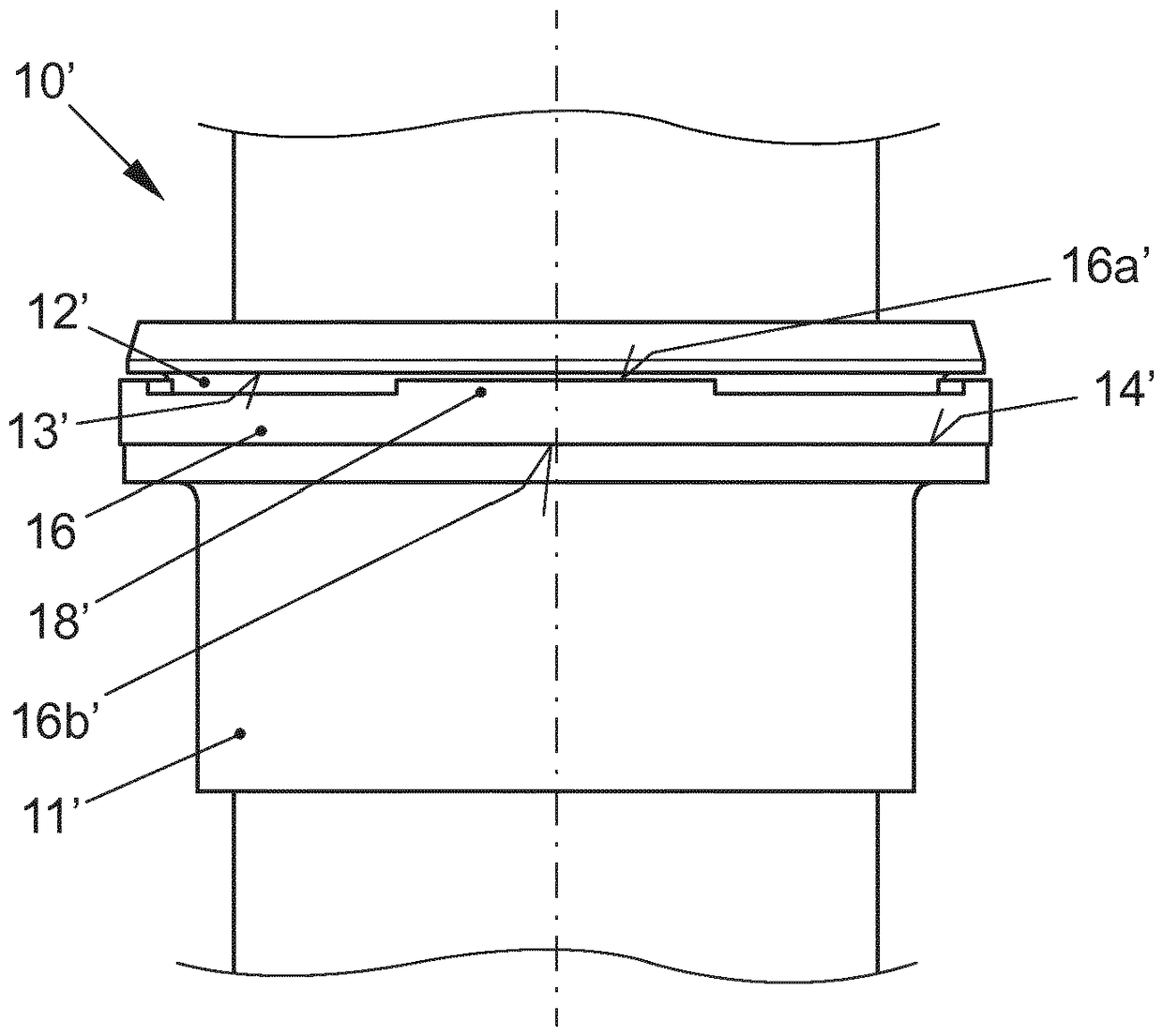

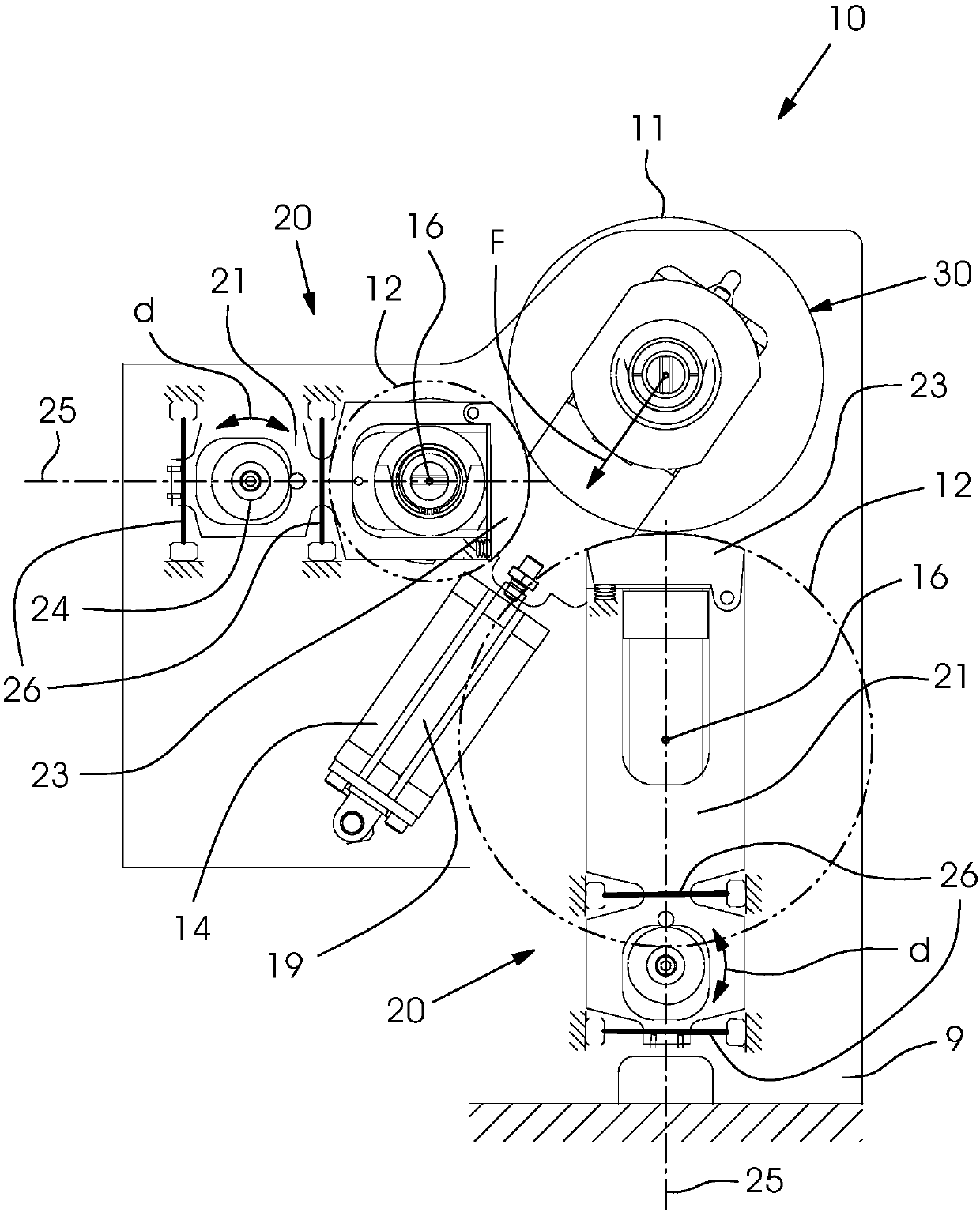

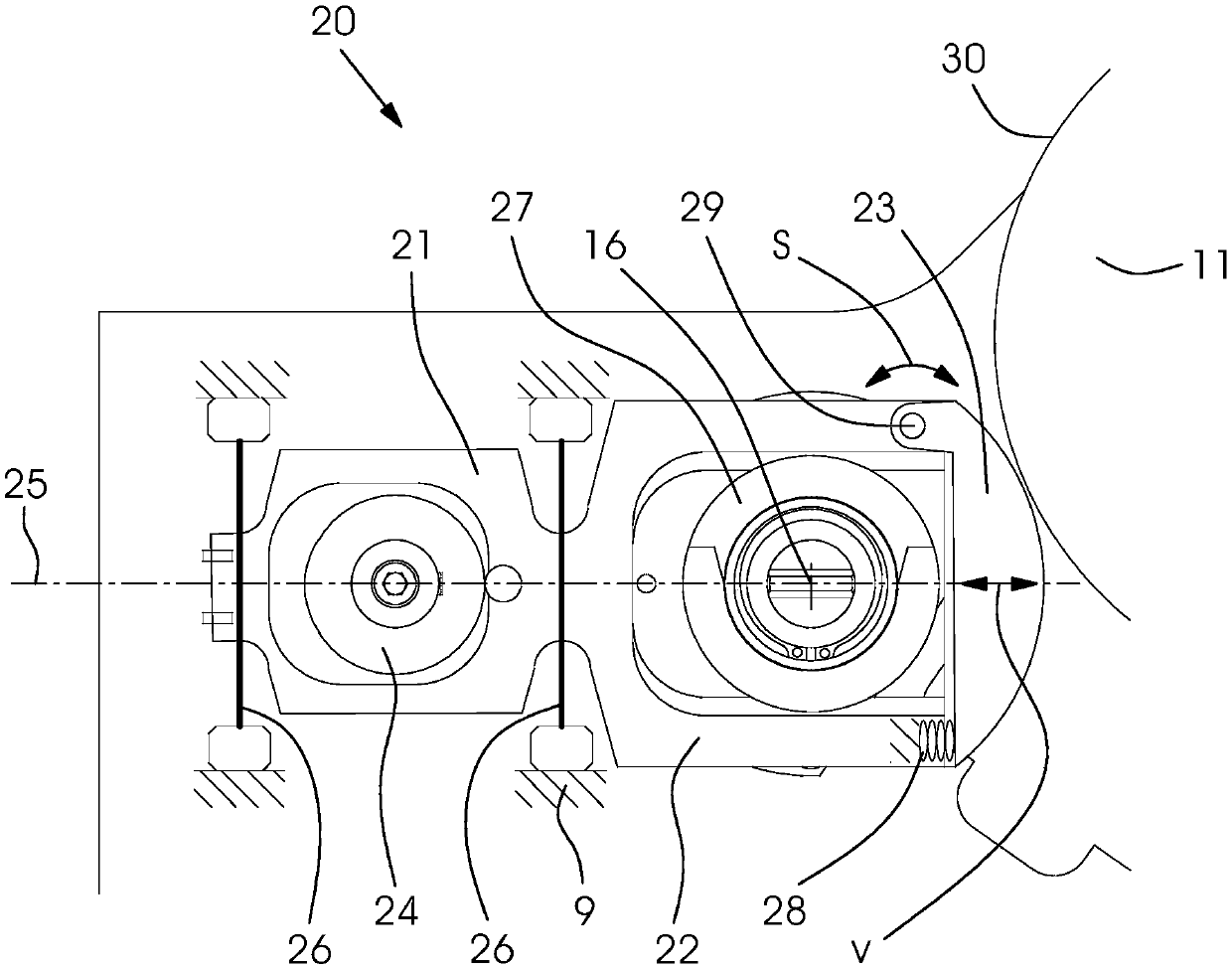

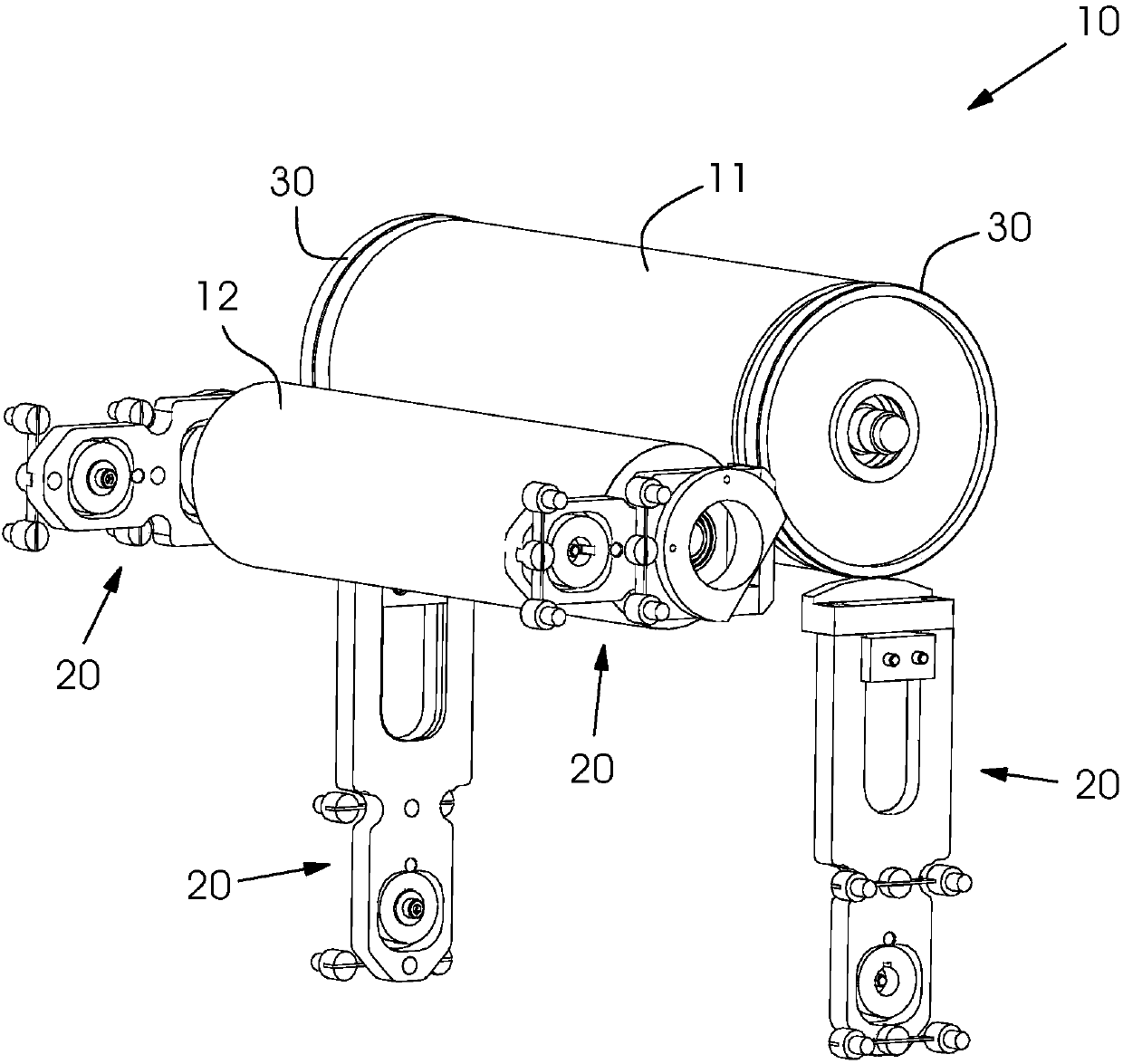

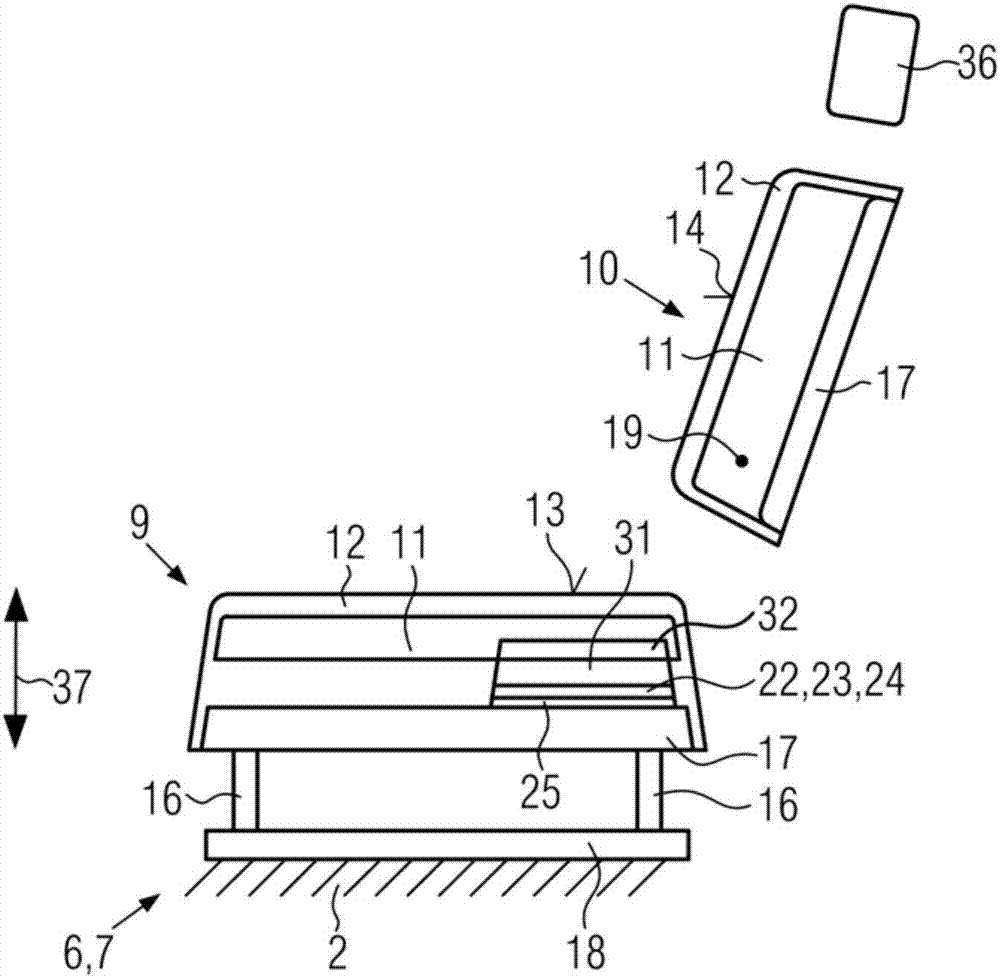

Processing unit and label printing machine having the processing unit

The invention relates to a processing unit (10), for the rotational processing of a web-shaped or sheet-shaped substrate (1000), including a machine frame, at least a first processing cylinder (11) movably mounted in the machine frame (9), a second processing cylinder (12) stationarily mounted in the machine frame (9), and a pair of support members (20, 30) associated with each respective processing cylinder (11, 12, 13). A respective support member (20) of the second processing cylinder (12) has a solid joint (21), a manipulator (24) and an annular segment (23) attached to the solid joint andcontacting one support member (30) of the first processing cylinder (11). A solid joint (21) is linearly displaceable (v) by the manipulator (24) and an annular segment (23) is linearly displaceabletherewith. A gap dimension between the processing cylinders (11, 12, 13) of the processing unit (10) can therefore be adjusted in a simple, accurate manner with precise repeatability.

Owner:GALLUS DRUCKMASCHINEN GMBH

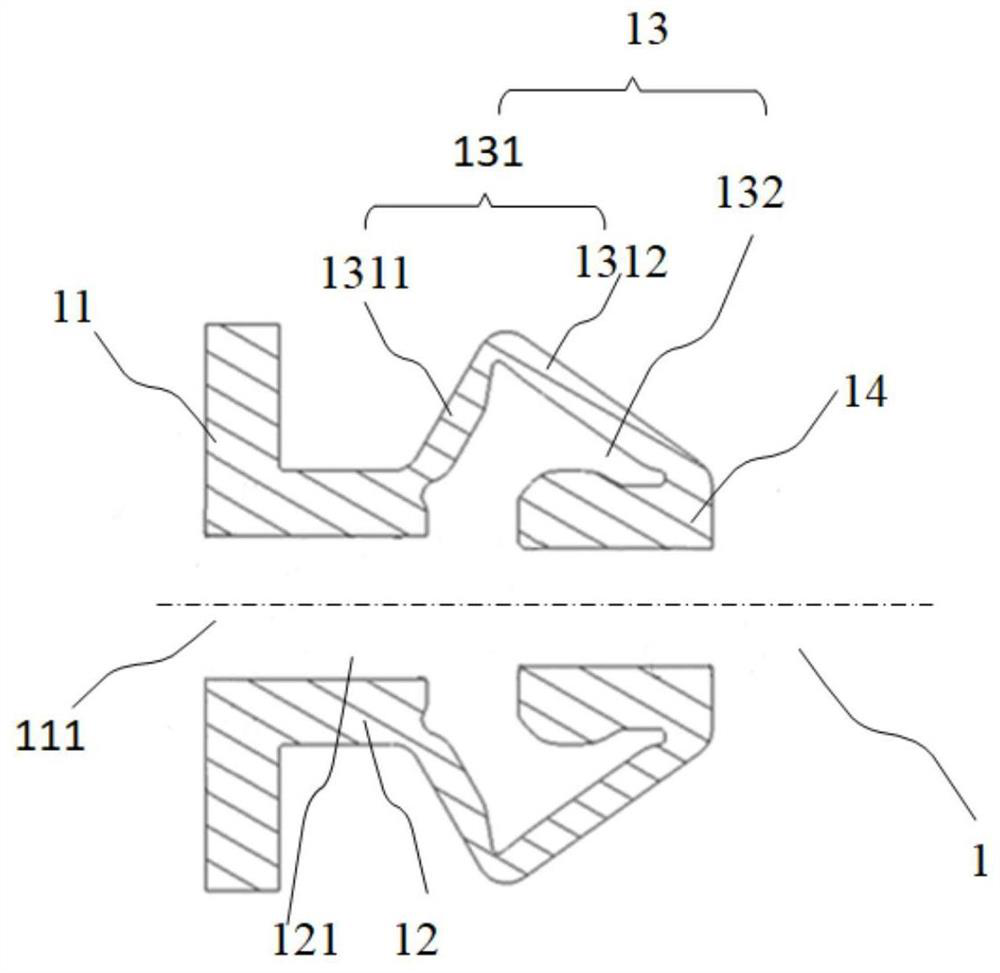

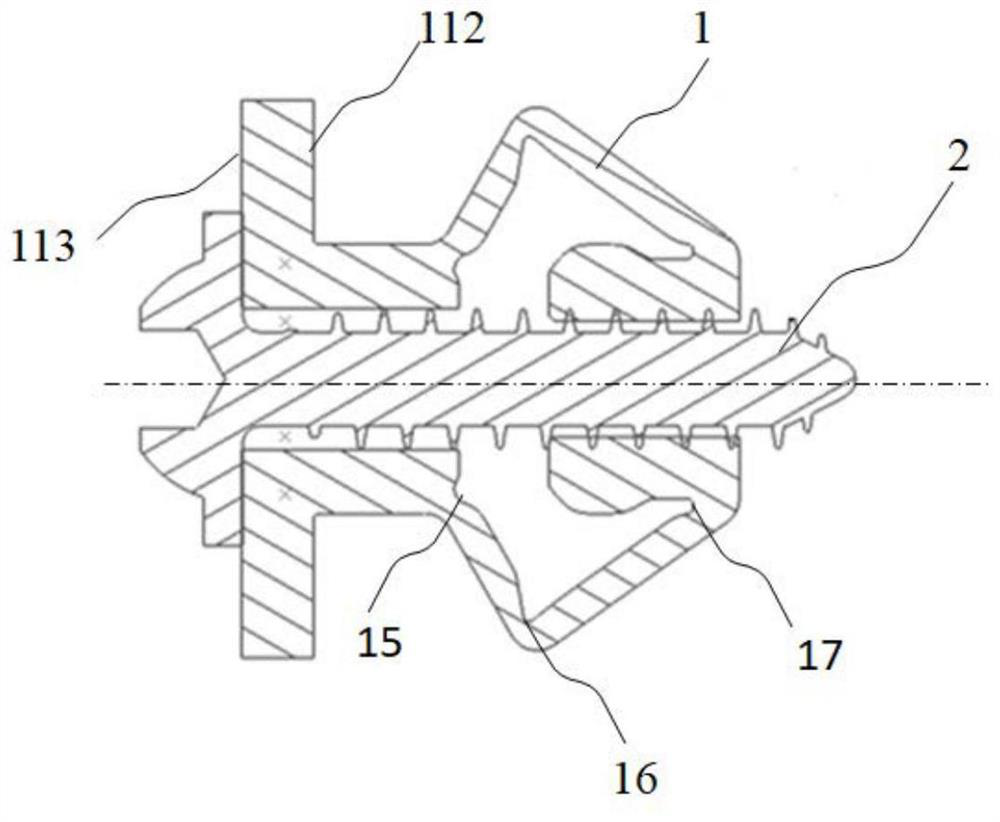

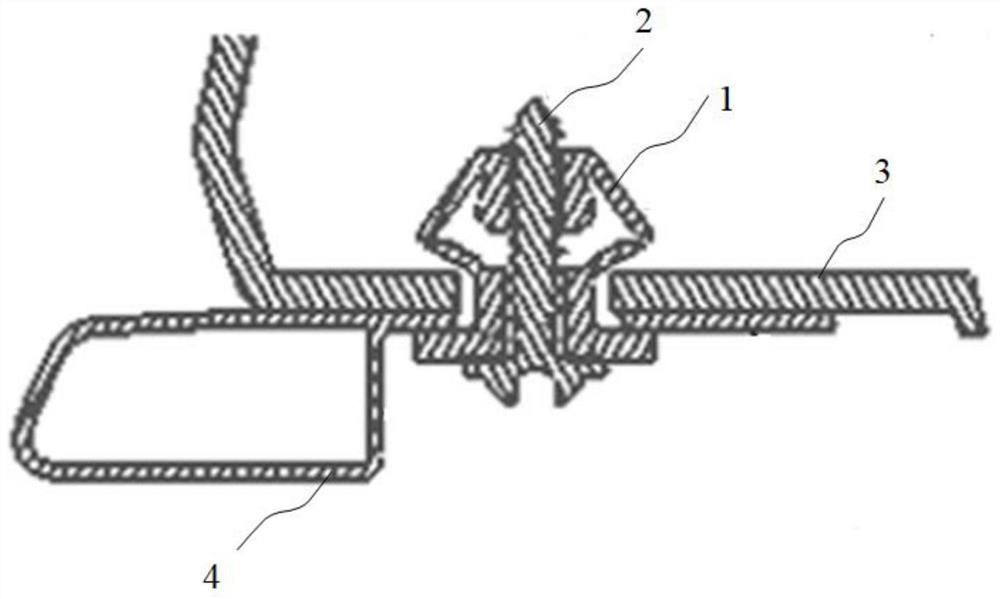

Rivet nut

The invention provides a rivet nut, and particularly relates to the technical field of riveting fasteners. The rivet nut comprises a stop portion, a tubular portion, an elastic deformation portion and a threaded connecting body, wherein the stop portion is connected with one end of the tubular portion and stops at one side of a rivet nut mounting hole; the elastic deformation portion is connected with the other end of the tubular portion and is provided with a deformation body and a containing cavity; the deformation body penetrates through the rivet nut mounting hole after being axially stretched and deformed, and stops at the other side of the rivet nut after being axially compressed and deformed; and the threaded connecting body is arranged in the containing cavity and is connected with the end, facing away from the tubular portion, of the elastic deformation portion. According to the rivet nut, a rivet tool does not need to be independently arranged, and deformation of the elastic deformation portion can be realized by means of a screw; and the deformation of the elastic deformation portion of the rivet nut is elastic deformation, so that the rivet nut is convenient to disassemble or replace.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

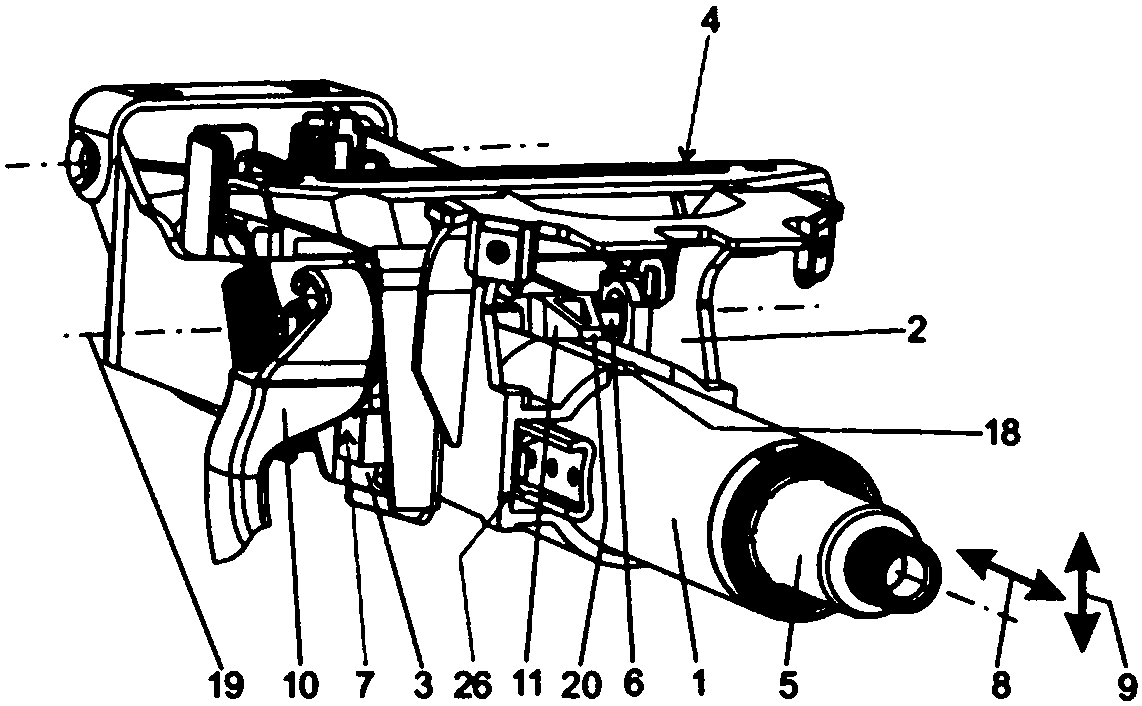

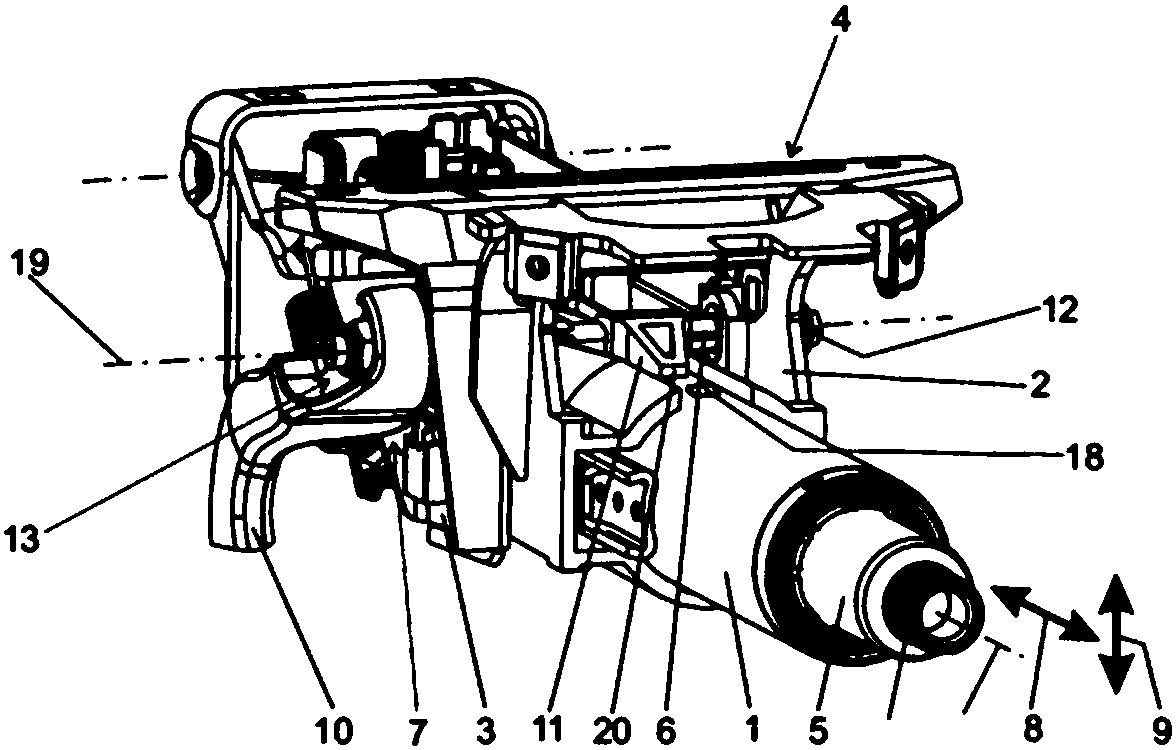

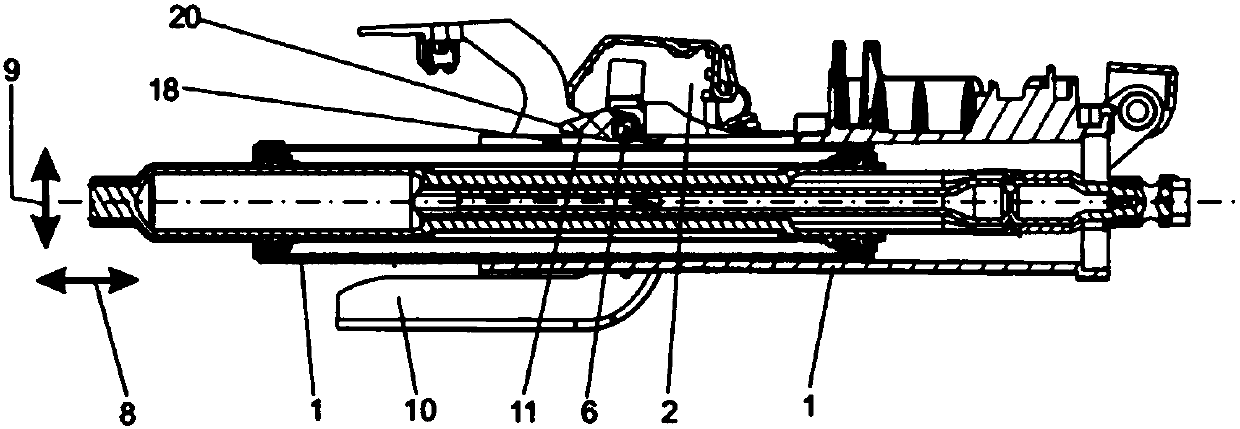

Clamping device of an adjustable steering column for motor vehicles

The invention relates to a clamping device of an adjustable steering column for motor vehicles, wherein a carrier (4) fixedly connected to the vehicle chassis is connected to two clamping jaws (2, 3)surrounding the steering column, between which clamping jaws a longitudinally and / or vertically adjustable jacket tube (1) of the steering column, which jacket tube rotatably supports a steering shaft(5), can be fixedly clamped, having a clamping bolt (6), which connects the two clamping jaws (2, 3) and which interacts with an application device (7), which is arranged on at least one of the two clamping jaws (2, 3), in such a way that, in the event of rotation of the clamping bolt (6) about the bolt axis (19) in the closing direction (14), the application device (7) clamps the jacket tube (1)between the two clamping jaws (2, 3) and, in the event of rotation in the opening direction (15), the application device releases the clamping jaws (2, 3) such that the jacket tube (1) can be adjusted. Said clamping device is improved with a view to a simple and especially economical design in that a damping body (11, 24) is arranged on the clamping bolt (6) and is frictionally or elastically connected to the clamping bolt (6) and that the damping body (11, 24) has a stop tongue (16), which radially protrudes from the clamping bolt (6) and, in the event of rotation of the clamping bolt (6) inthe opening direction (15), comes into contact with the jacket tube (1) or another part of the steering column and prevents rotation of the damping body (11, 24) such that the rotation of the clamping bolt (6) in the opening direction (15) occurs against the frictional force or elastic force and is damped.

Owner:THYSSENKRUPP PRESTA AG +1

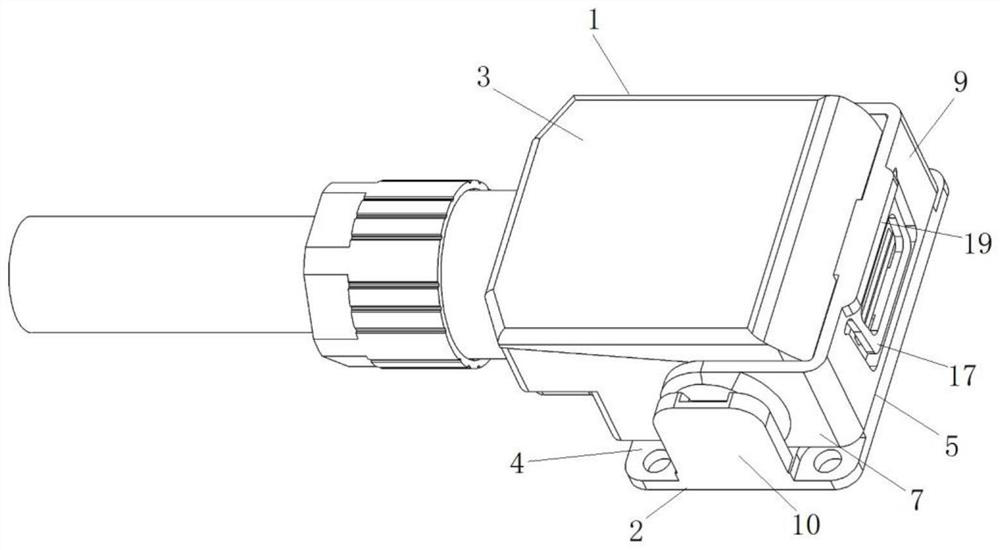

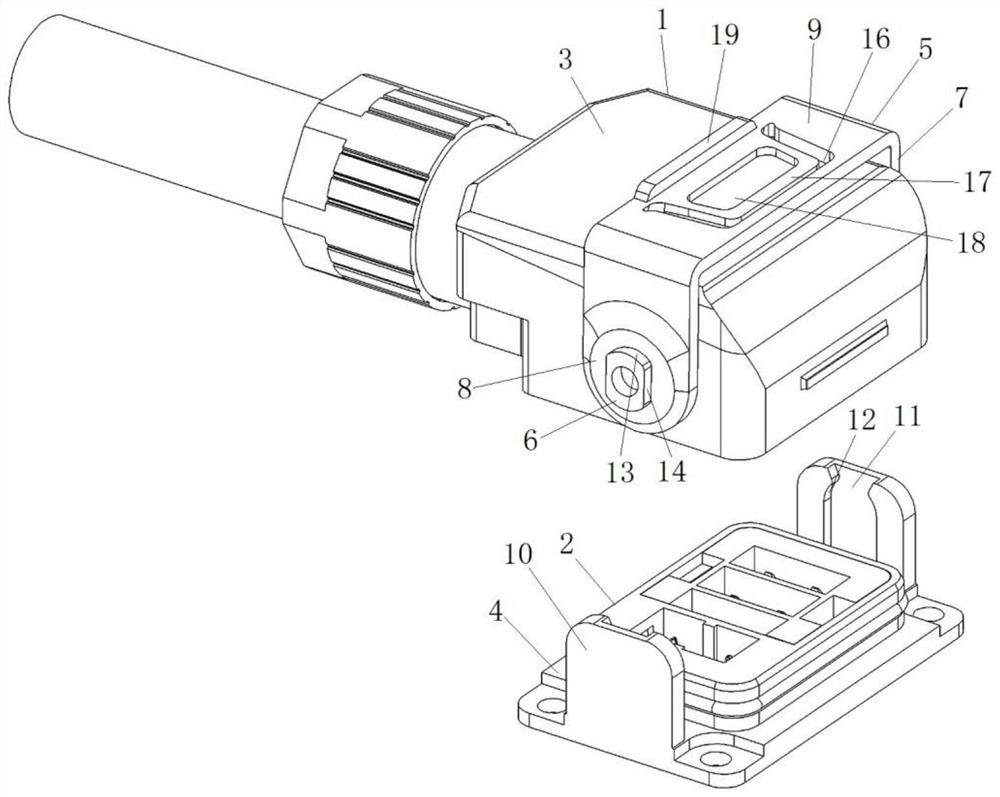

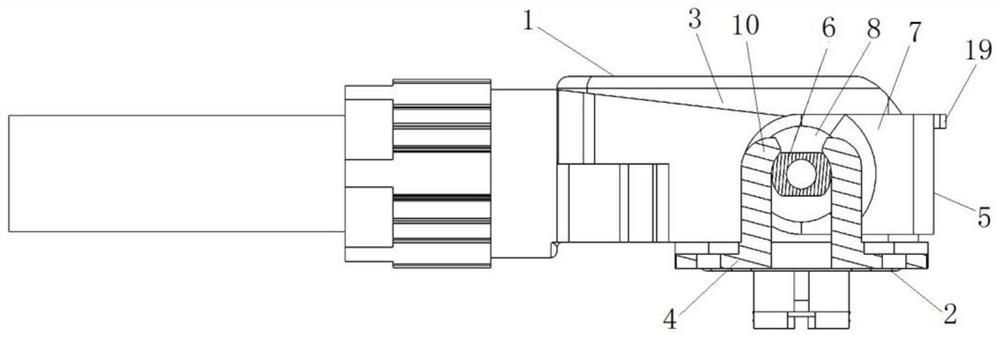

Connector assembly and plug and socket locking connection structure

PendingCN114447702ASmall footprintSmall sizeCoupling device detailsTwo-part coupling devicesComputer hardwareCam

The invention relates to a connector assembly and a plug and socket locking connection structure. The connector assembly comprises a plug, a socket and a locking connection structure for locking the plug and the socket, the locking connection structure comprises a locking wrench, the locking wrench has a locking position and an unlocking position in the rotating process, a locking cam is arranged at the position of the rotating axis of the locking wrench, the locking connection structure further comprises a locking arm, a locking groove is formed in the locking arm, and the locking arm is connected with the locking cam. The locking groove is a closing groove; when the locking wrench is located at the unlocking position, the locking cam can enter the locking groove from the notch, and when the locking wrench is located at the locking position, the locking cam cannot be separated from the locking groove in the insertion direction, and locking of the plug and the socket is achieved. As the locking cam is arranged at the position of the rotating axis of the locking wrench, the size of the locking wrench in the inserting direction when the locking wrench is located at the locking position can be effectively reduced, the space occupied by the connector assembly in the inserting direction is reduced, and the requirement for installation miniaturization of the servo motor can be met.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

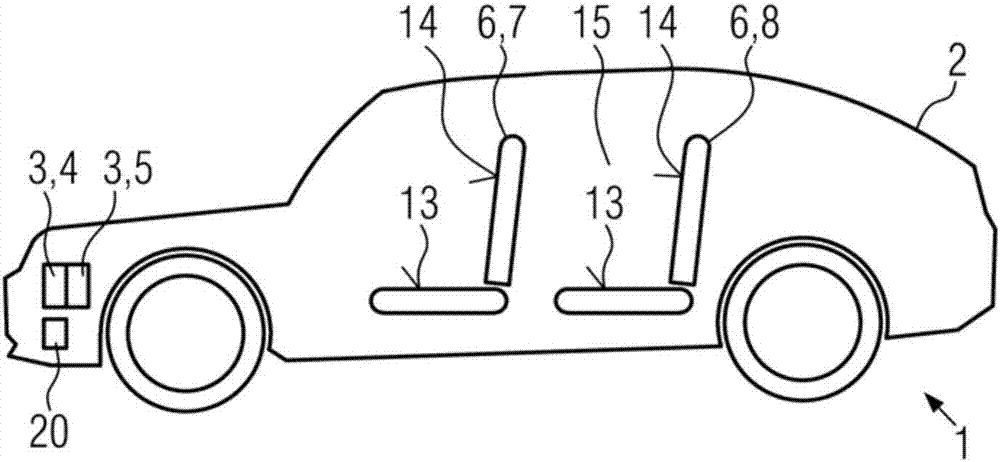

A seat for a motor vehicle

InactiveCN107117083ACheap manufacturingEasy stop connectionThigh restsSeat framesEngineeringMechanical engineering

Owner:GM GLOBAL TECH OPERATIONS LLC

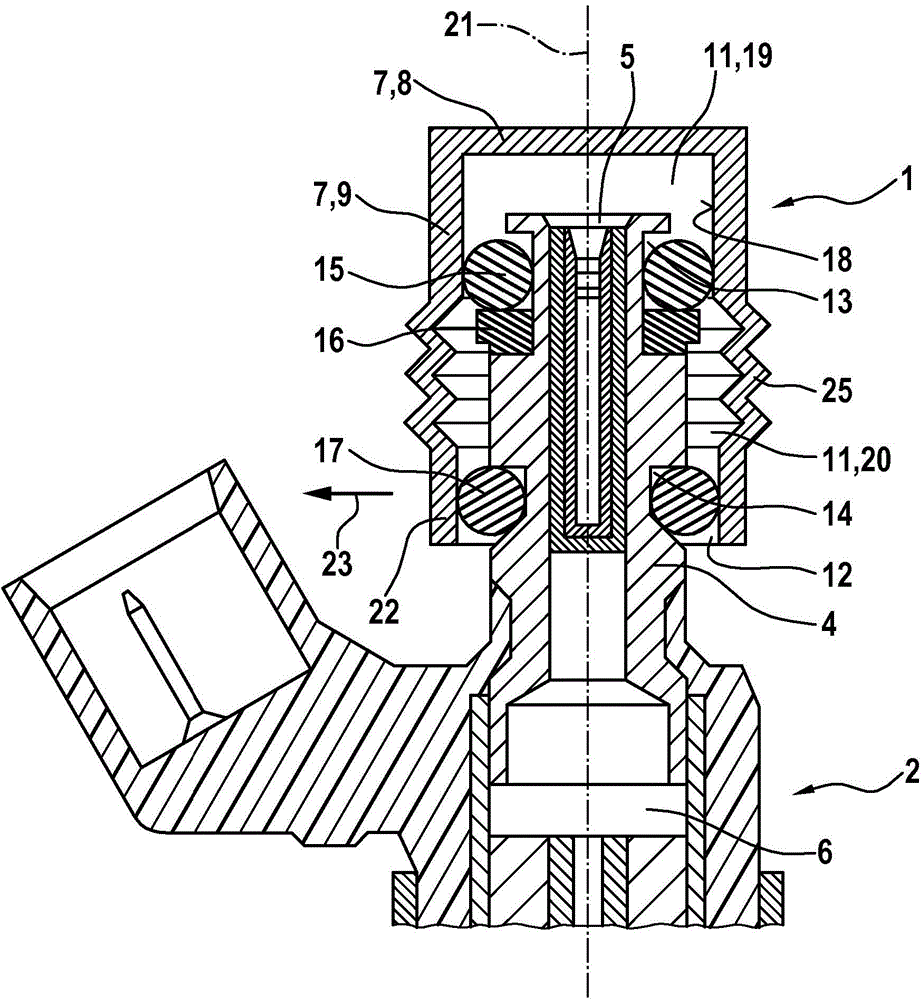

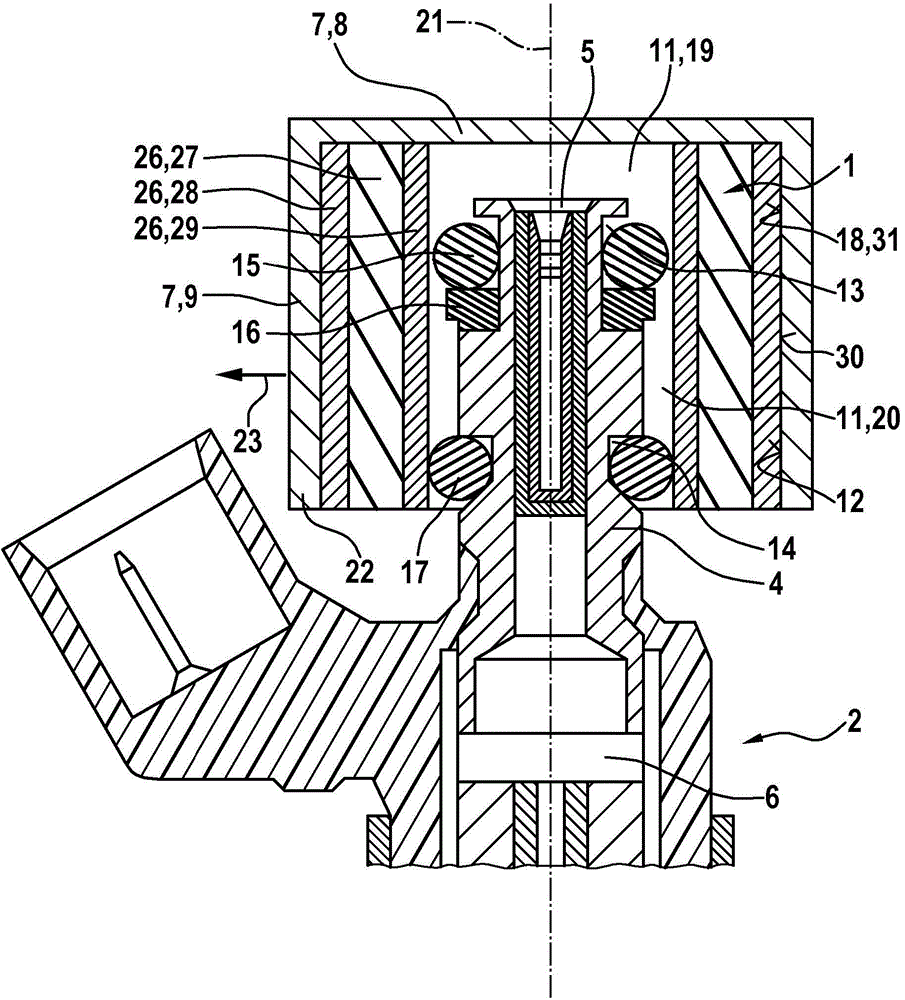

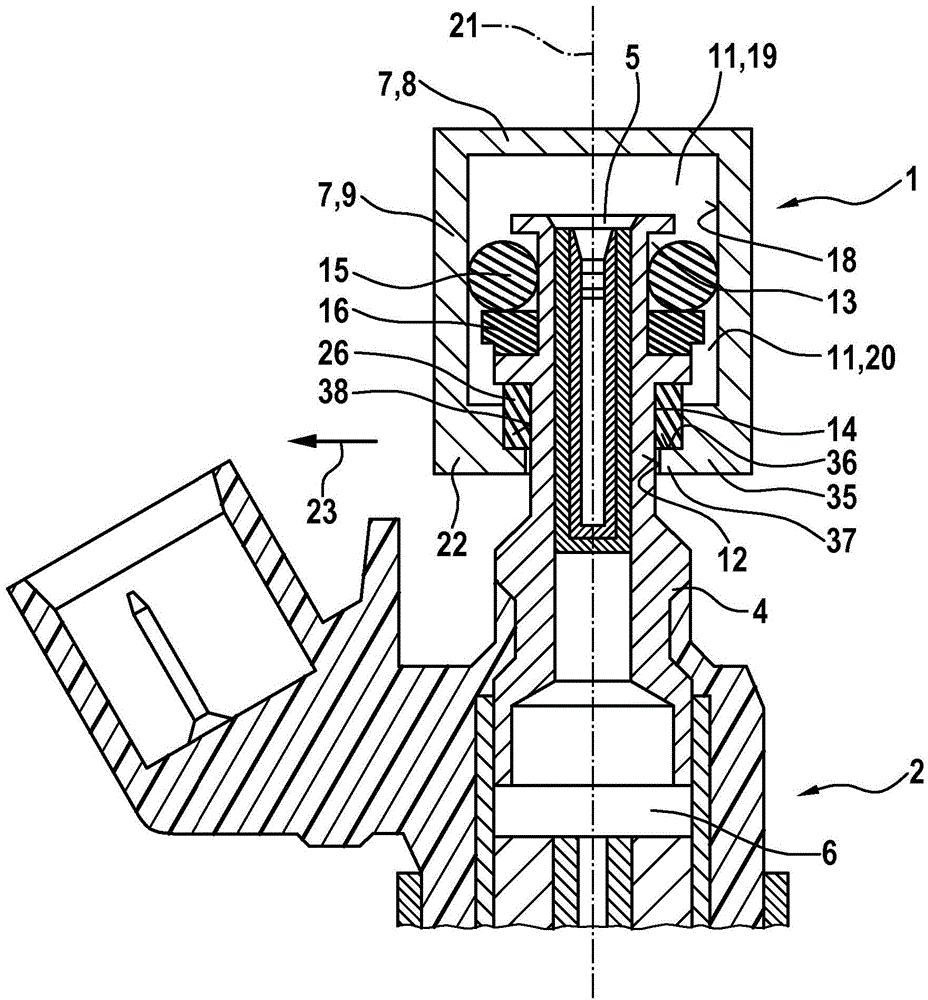

Fuel injection system comprising a fuel-guiding component, a fuel injection valve and a connecting element

InactiveCN104919172AReliable receptionUniform loadNoise reducing fuel injectionLow pressure fuel injectionFuel injectionNozzle

Owner:ROBERT BOSCH GMBH

Electrical machine with preloaded ball race and method for manufacturing the same

ActiveCN1866685BCause preloadExtended service lifeShaftsBall bearingsEngineeringMechanical engineering

An electrical machine with a ball race preloaded by elastic deformation of a bearing end plate as well as a method for manufacturing the same comprises a stator and a rotor with rotor shaft. The rotor shaft is supported via the ball race in the bearing end plates. At least one bearing end plate is embodied so that it can be elastically deformed in an axial direction and the preloading of the ballrace is created by a preloading of the bearing end plate in the axial direction.

Owner:CONTINENTAL TEVES AG & CO OHG +1

Vibration devices and electronic equipment

ActiveCN111641315BAchieve elastic deformationDynamo-electric machinesElectronic equipmentWire segment

Owner:GOERTEK INC

A gel biomaterial with shape memory function and preparation method thereof

InactiveCN105126171BImprove adhesionPromote growthProsthesisCell-Extracellular MatrixAdditive ingredient

Owner:ARMY MEDICAL UNIV

Housing for an electrical appliance

ActiveCN109845058AEasy to assembleImprove the protection levelSubstation/switching arrangement detailsCasings/cabinets/drawers detailsElectrical devicesMechanical engineering

The invention relates to a housing (1) for an electrical appliance, comprising: a housing base (10), which has a connecting portion (4) for connecting the housing (1) to a machine, a technical apparatus or a building wall, and at least one fastening element (2), which is provided on an outer face of the connecting portion (4), wherein the fastening element (2) is designed such that said fasteningelement can be interlockingly and / or frictionally connected to a corresponding retaining element of the machine, the technical apparatus or the building wall, and wherein: the housing (1) can be closed by means of a housing cover; the connecting portion (4) is designed to be resiliently deformable and has, on an inner face, an unlocking element (3) which can be actuated by a user, is operatively connected to the fastening element (2) and is designed such that the unlocking element can only be actuated from the inside when the housing (1) is open, in order to release the interlocking and / or frictional connection of the fastening element (2) to the retaining element of the machine, the technical apparatus, or the building wall.

Owner:PILZ (COMPANY)

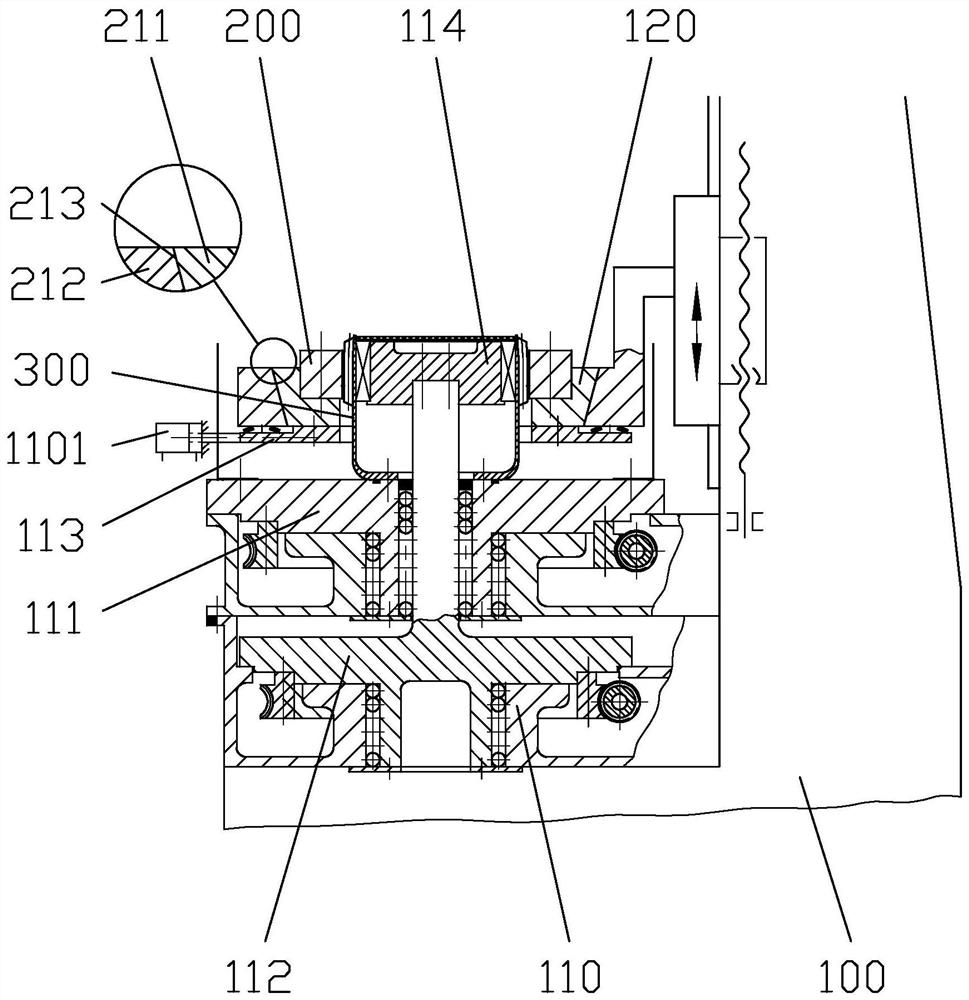

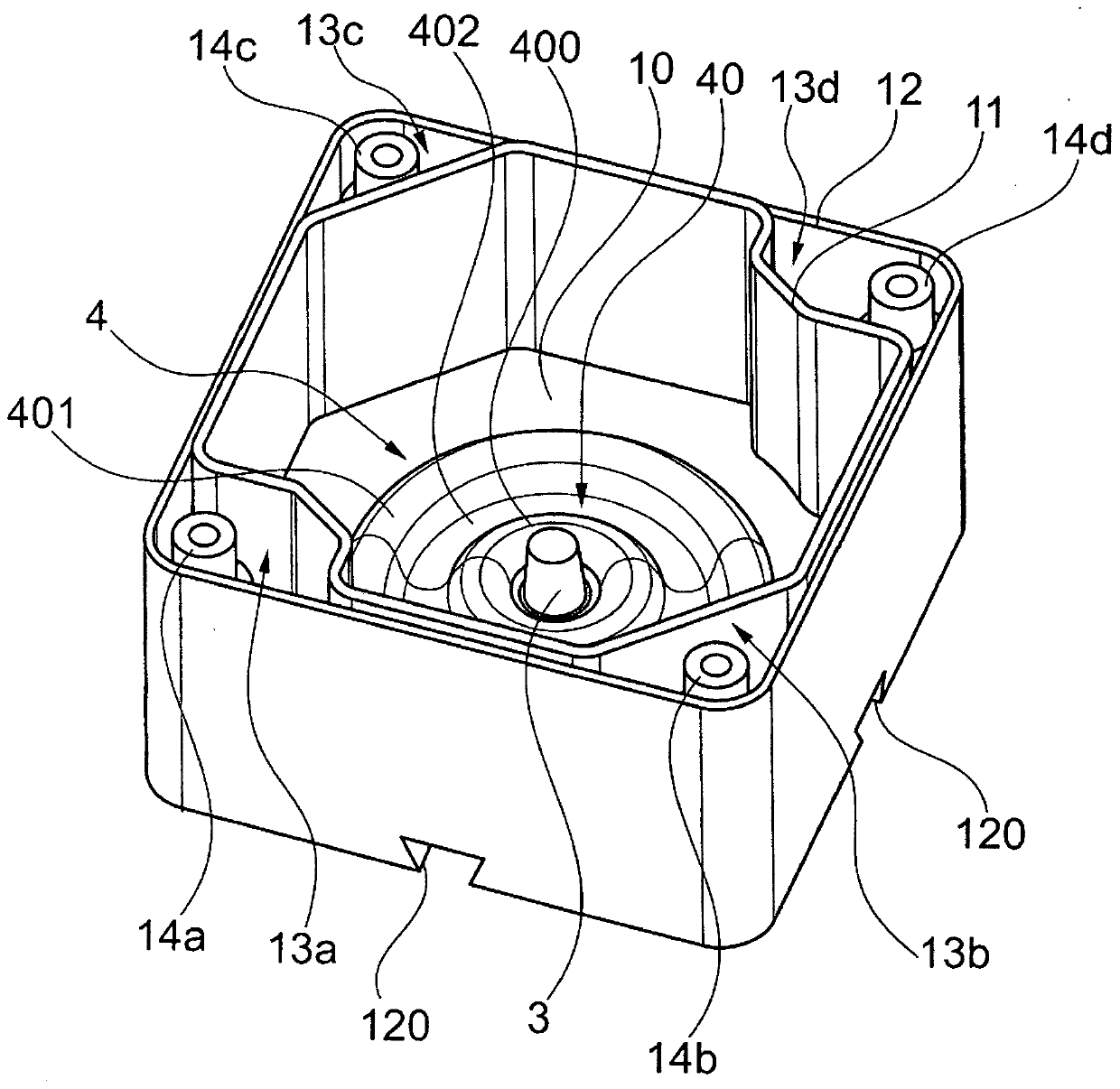

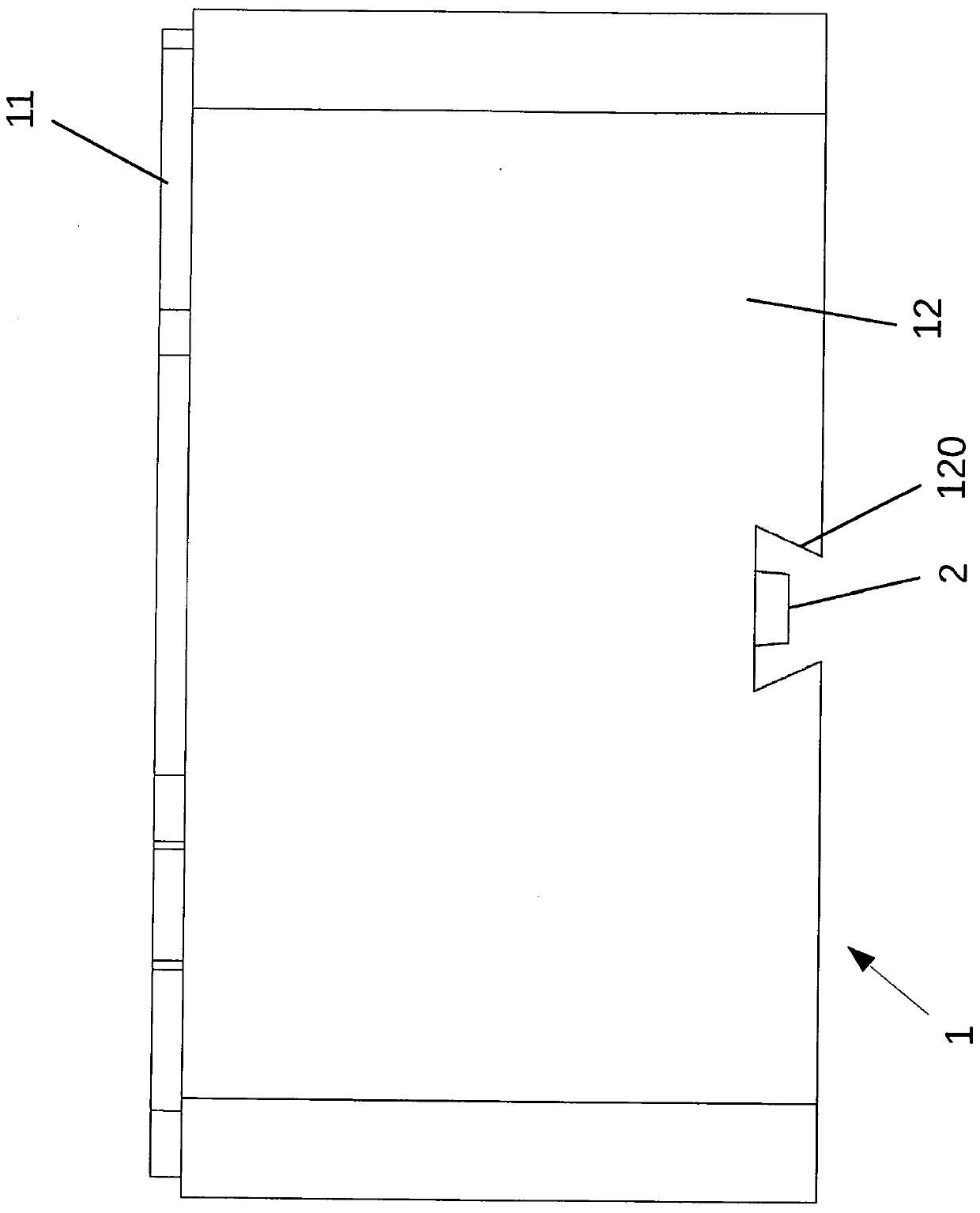

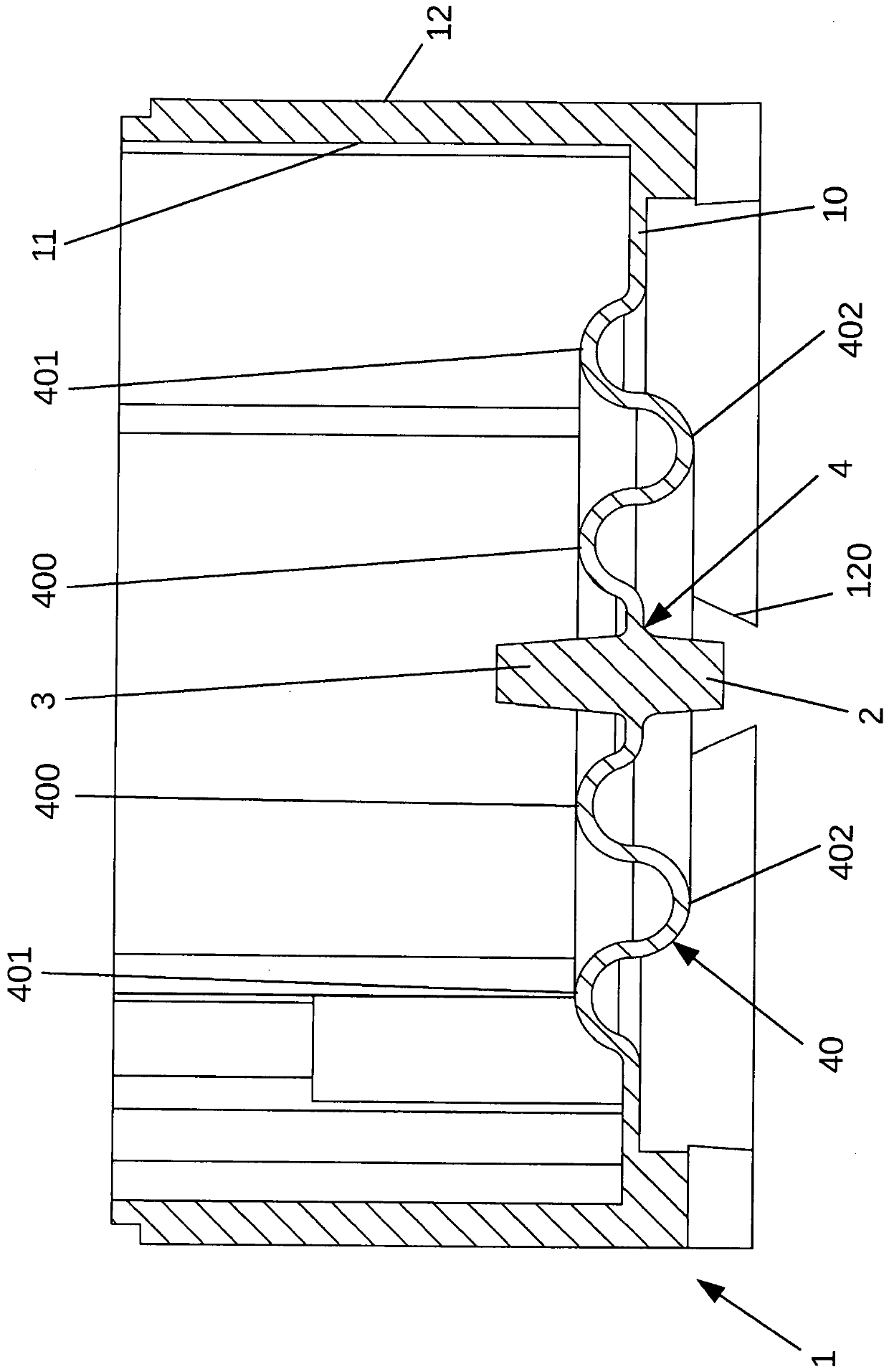

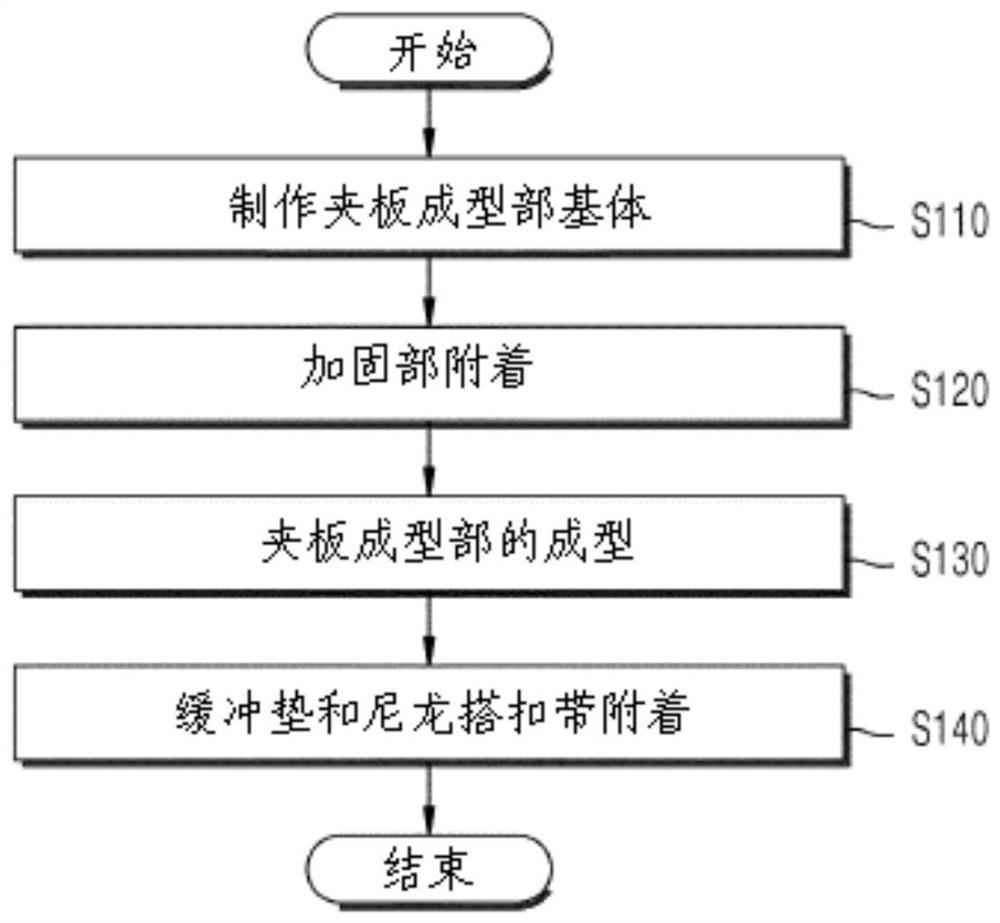

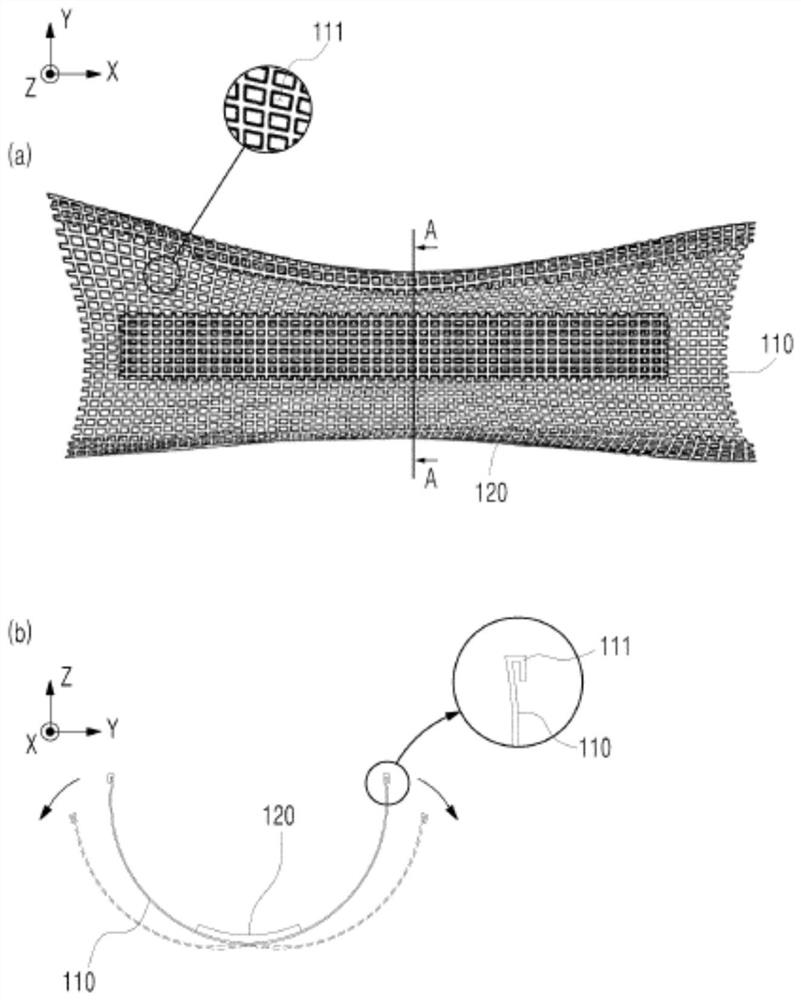

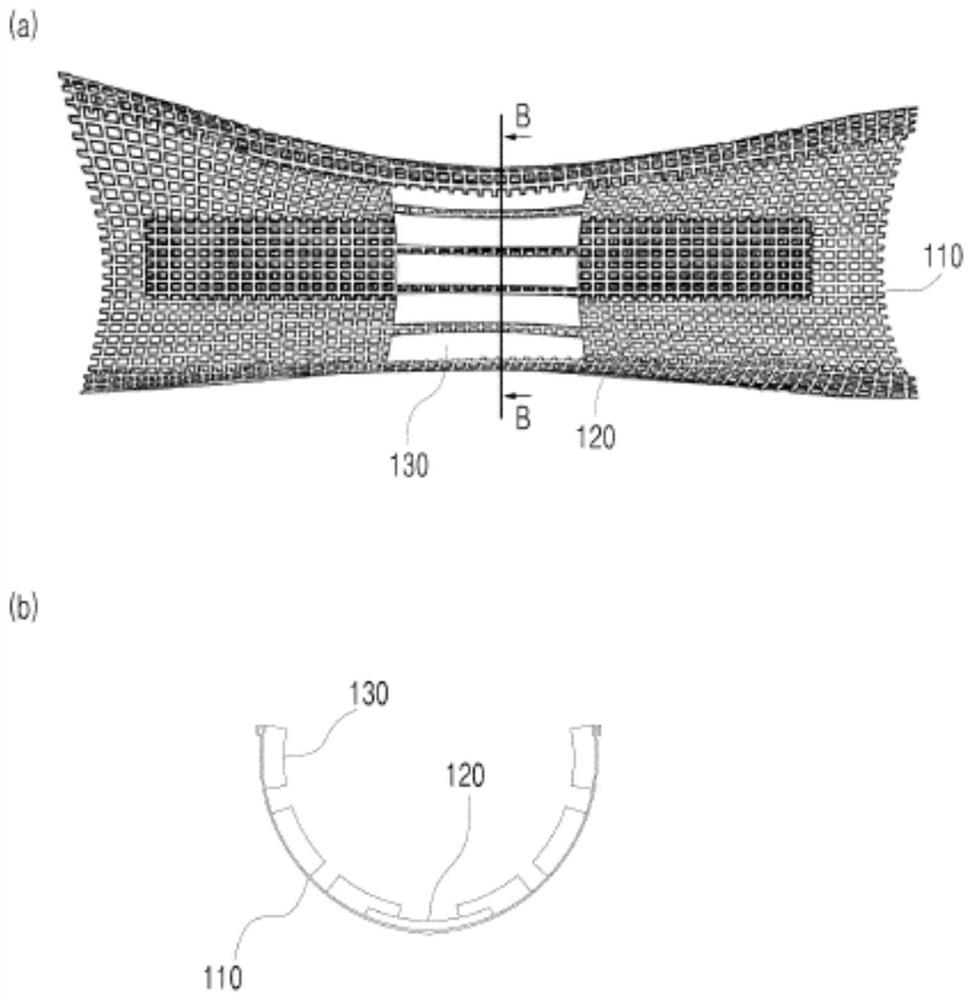

Splint using thermoplastic resin fabric and manufacturing method thereof

ActiveCN107530180BAchieve fixationFit closelyFinger bandagesAbsorbent padsOrthopedics surgeryPolymer science

The present invention relates to a splint using a thermoplastic resin fabric and, more particularly, to a splint which can be used for orthopedic surgery utilizing a thermoplastic resin fabric which can be reversibly transformed, and a manufacturing method therefor. The splint according to the present invention comprises: a splint formed body (110) made of a single layered thermoplastic resin fabric which has a net shape with a plurality of ventilation windows repeatedly formed therein and is formed in the shape of an affected part; a reinforcing body (120) made of a multilayered thermoplastic resin fabric of the same material as the splint formed body (110) and attached in multiple layers in the longitudinal direction of the splint formed body (110); a plurality of cushion pads (130) attached to an inner surface of the splint formed body (110); and a high elastic Velcro tape (140) having a loop surface tape (142) attached to the splint formed body (110) and provided with a plurality of hooking rings on one surface thereof.

Owner:EM TECHNOLOGY CO LTD

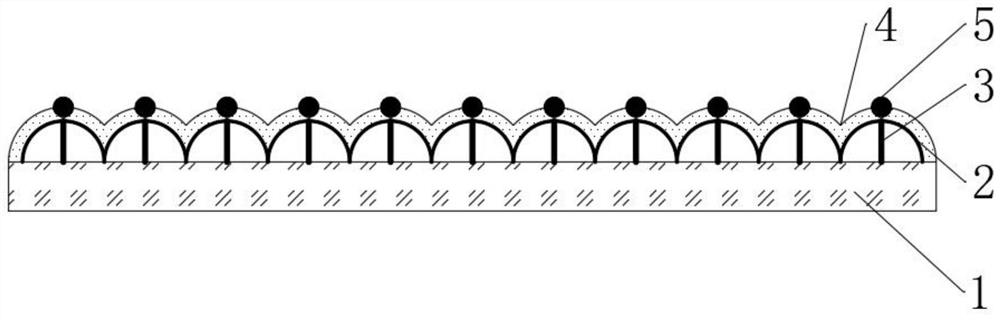

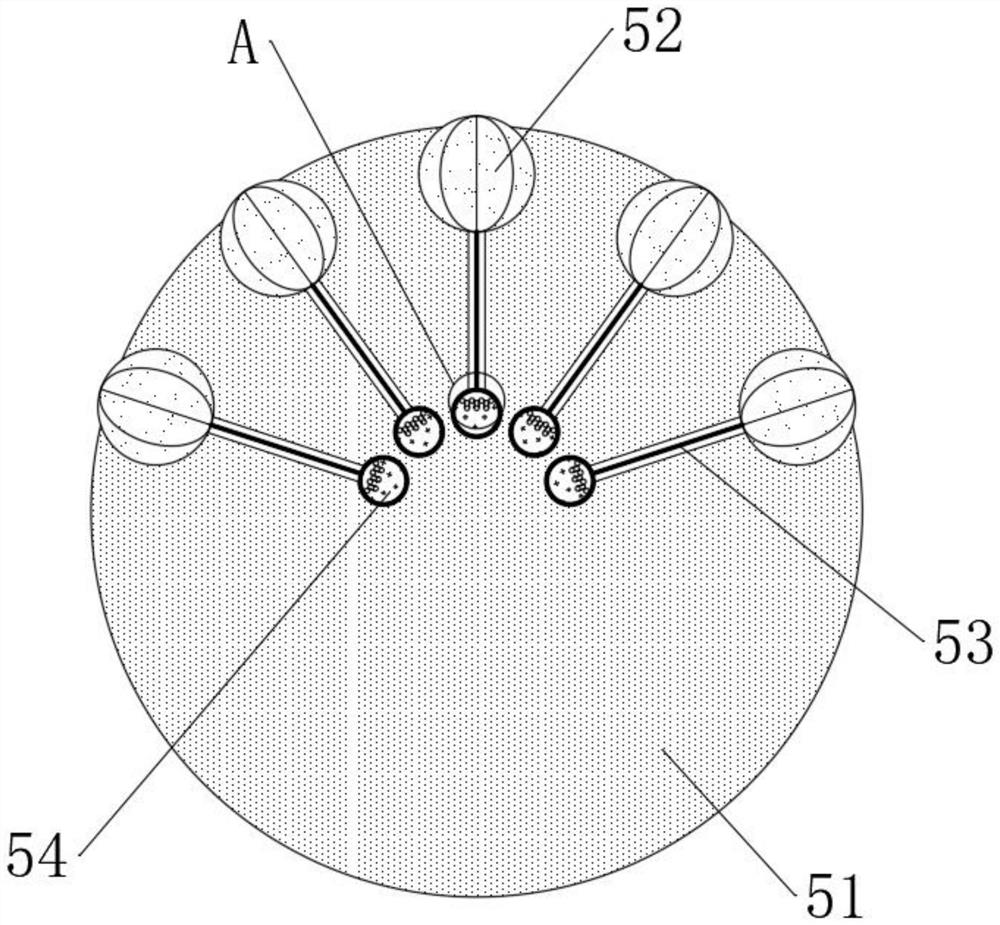

A high wear-resistant pvc bubble film for transportation

ActiveCN112277413BImprove wear resistanceImprove wear lifeFlexible coversWrappersThermal dilatationMetal membrane

The invention discloses a highly wear-resistant PVC air bubble film for transportation, which belongs to the technical field of air bubble film. The invention can improve its strength and wear resistance by covering the surface of the air bubble film with a metal film layer. The upper multi-point is inlaid with single-point wear-resistant beads, using the method of surface contact to single-point contact to reduce friction, and can sense the degree of friction to produce different degrees of heat, and then use the heat to trigger the lubrication action in the single-point wear-resistant beads , the pre-stored magnetic lubricating fluid is released through thermal expansion and extrusion, thereby effectively improving the wear on the surface of the single-point wear-resistant bead. It can not only protect the single-point wear-resistant bead, but also effectively offset the friction damage. After the phenomenon disappears, the magnetic lubricating fluid is recovered by controlling the magnetic field to reduce its consumption loss in the outside world and leave it for subsequent lubrication, thereby prolonging the wear-resistant life of the single-point wear-resistant beads and significantly improving the wear-resistant performance of the bubble film .

Owner:JIANGSU HIMEI NEW MATERIAL CO LTD

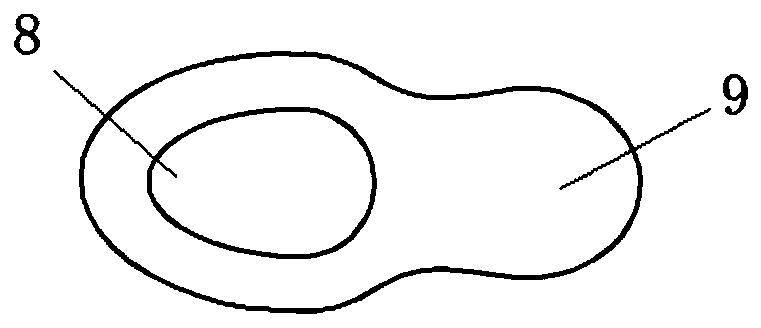

Damping wheel attaching device

InactiveCN106314017AGood buffer performanceBroad application prospectsHigh resiliency wheelsSteel platesWheel and axle

The invention discloses a damping wheel attaching device. An axle hole is formed in the center of a hub. A damping spring is arranged in a rim. One end of the damping spring is fixed to a hub. The other end of the damping spring is fixed to the rim through fixing devices. Elliptical damping rings are arranged on the same horizontal line with the endpoint of the spring fixed to the rim as the axis endpoint. The two elliptical damping rings are arranged perpendicularly. The inner walls of damping ring bodies are provided with a plurality of grooves used for resolving external force. The cross section of each groove is in an isosceles trapezoid shape. An inner-concave outer-convex steel plate is arranged between every two adjacent fixing devices. The fixing devices are grooves of which the interiors are rhombic. The strength of a tire is improved maximally while certain damping performance is kept, and thus the tire is not subjected to deformation after long-term pressing. The performance is stable, and the environment adaptive capacity is high. After the damping rings are subjected to the action of external force, groove deformation is more regular, and the reliability of anti-falling during installation of the damping rings is improved.

Owner:青岛时空机械科技有限公司

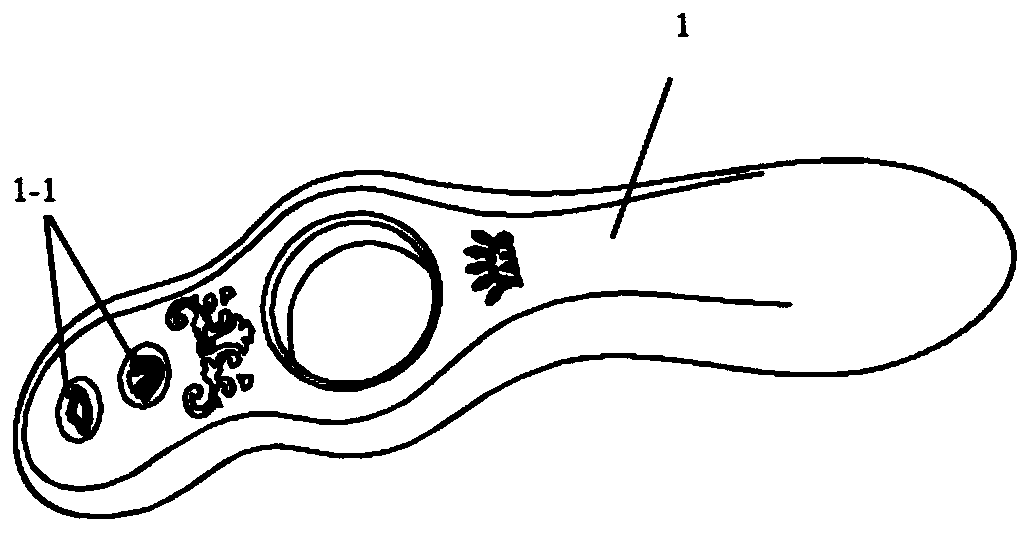

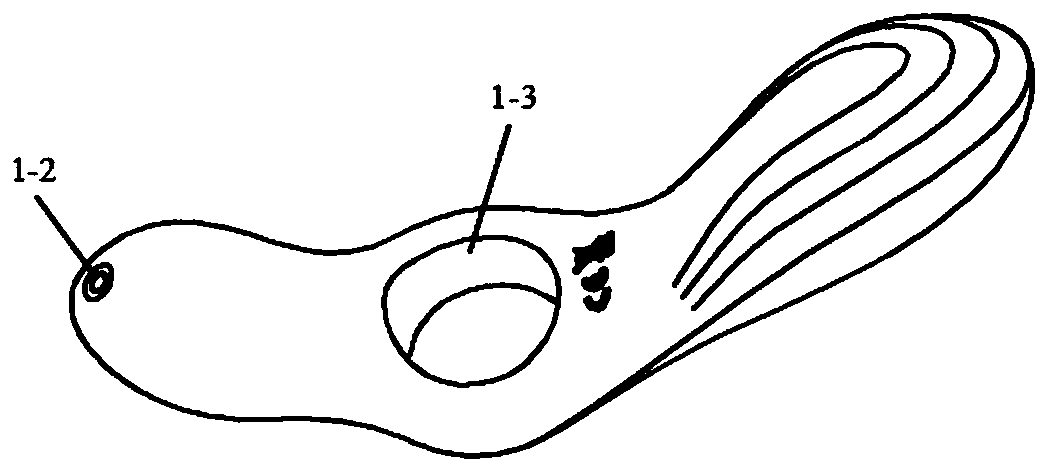

Massager with flexible frame

PendingCN111529354ARealize the massage functionGood flexibilityVibration massageElectric motor speed/torque regulationSilicone coatingSilica gel

Owner:LEAI HEALTH TECH SUZHOU CO LTD

Ultrasound Training System Based on CT Image Simulation and Positioning

ActiveCN103295455BReduce computational complexityThe pose matrix is accurateEducational modelsThree dimensional ctSonification

The invention relates to an ultrasound training system based on CT (computed tomography) image simulation and positioning, the real-time performance of which is improved through GPU (graphics processing unit) acceleration-based realization of ultrasound image simulation and CT volume data rendering. In the system, a curved surface matching module is used for performing surface matching between read human body CT volume data and physical model data with a physical model serving as the standard, and for realizing elastic transformation of a curved surface by means of an interpolation method based on a thin plate spline; an ultrasound simulation probe pose tracking module is used for computing the pose of an ultrasound simulation probe with respect to the physical model in real time by means of a mark point tracking method, and for acquiring CT image slices at any angle according to a pose matrix; an image enhancement and ultrasound image simulation generating module is used for improving the vessel contrast of a CT image by means of a multiscale enhancement method, and for simulating the ultrasound image based on the CT volume data; and a fusion display module is used for rendering and displaying the CT volume data based on the acceleration of CUDA (compute unified device architecture), and for fusing and displaying an ultrasound simulation image and a three-dimensional CT image according to the acquired pose matrix.

Owner:ARIEMEDI MEDICAL SCI BEIJING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com