Harmonic reducer tooth surface machining method and device

A harmonic reducer and processing device technology, applied in the field of harmonic reducer, can solve the problems of machine tools relying on imports, small current, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

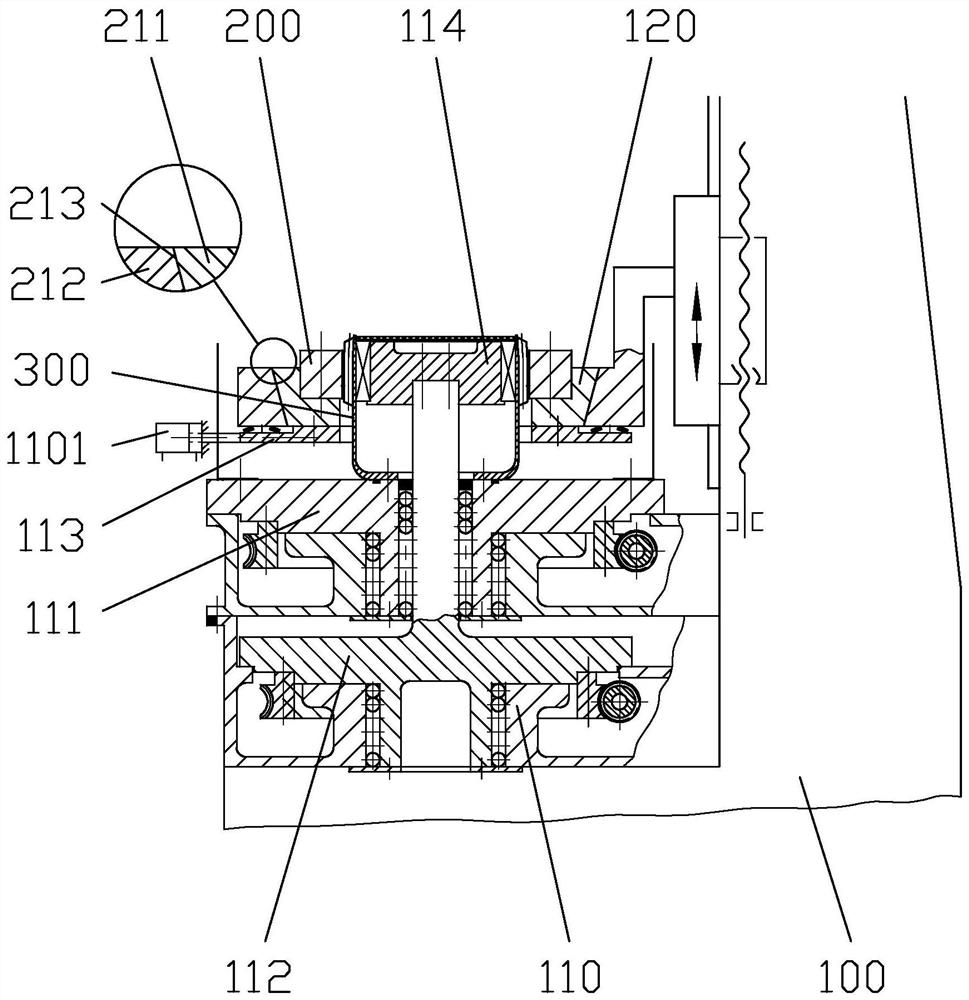

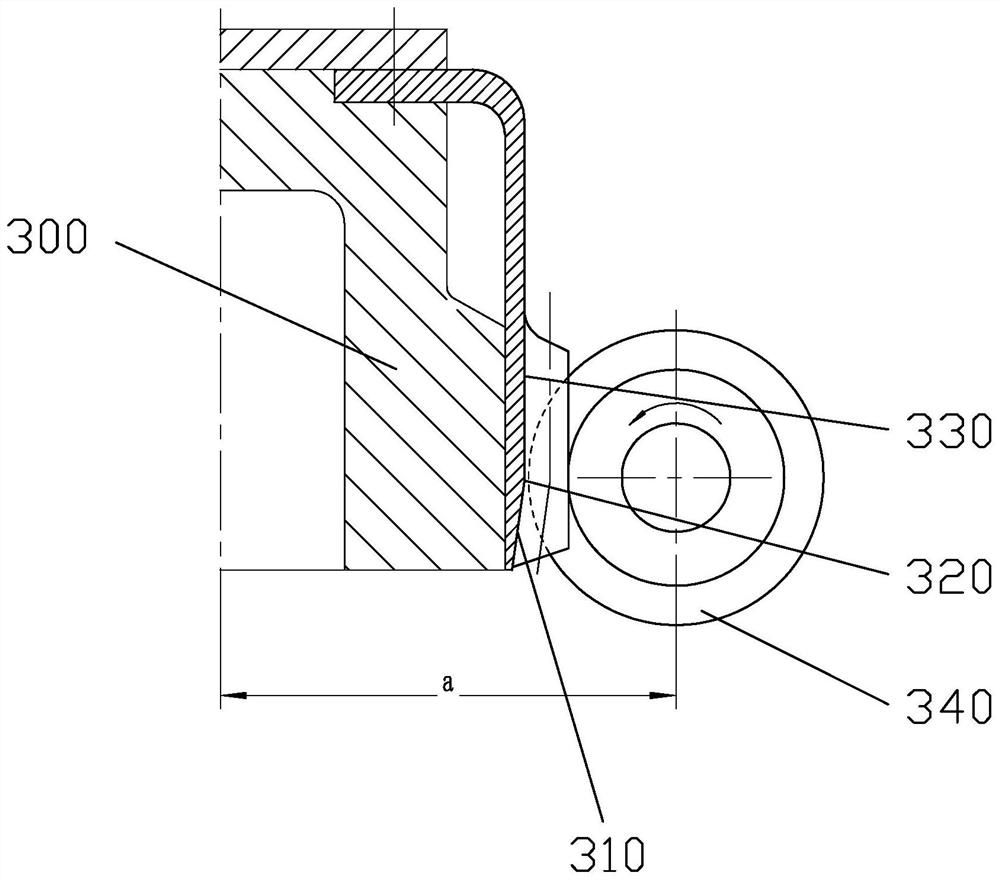

[0048] Embodiment 1, with reference to figure 1 , there are two closed-loop CNC turntables (turntable part 110) with a rotation accuracy of 1.0" on the bed and a rigid wheel fixture part (movable fixture part 120) that can move up and down, that is, the rigid wheel fixture 210 is located on the movable fixture part 120 , the movable fixture part 120 is used to fix the rigid wheel 200 to be processed, and the turntable part 110 includes a flexspline turntable 111 and a wave generator turntable 112. There is a flexible bearing and a wave generator 114, the rotation axes of the flexspline turntable and the wave generator turntable coincide, and the flexspline turntable 111 is provided with a flexspline clamp for fixing the flexspline 300, and the wave generator A wave generator fixture is provided on the turntable 112 . The rotation axes of the flexspline turntable 111 and the wave generator turntable 112 overlap, the flexspline fixture 113 is provided on the flexspline turntabl...

Embodiment 2

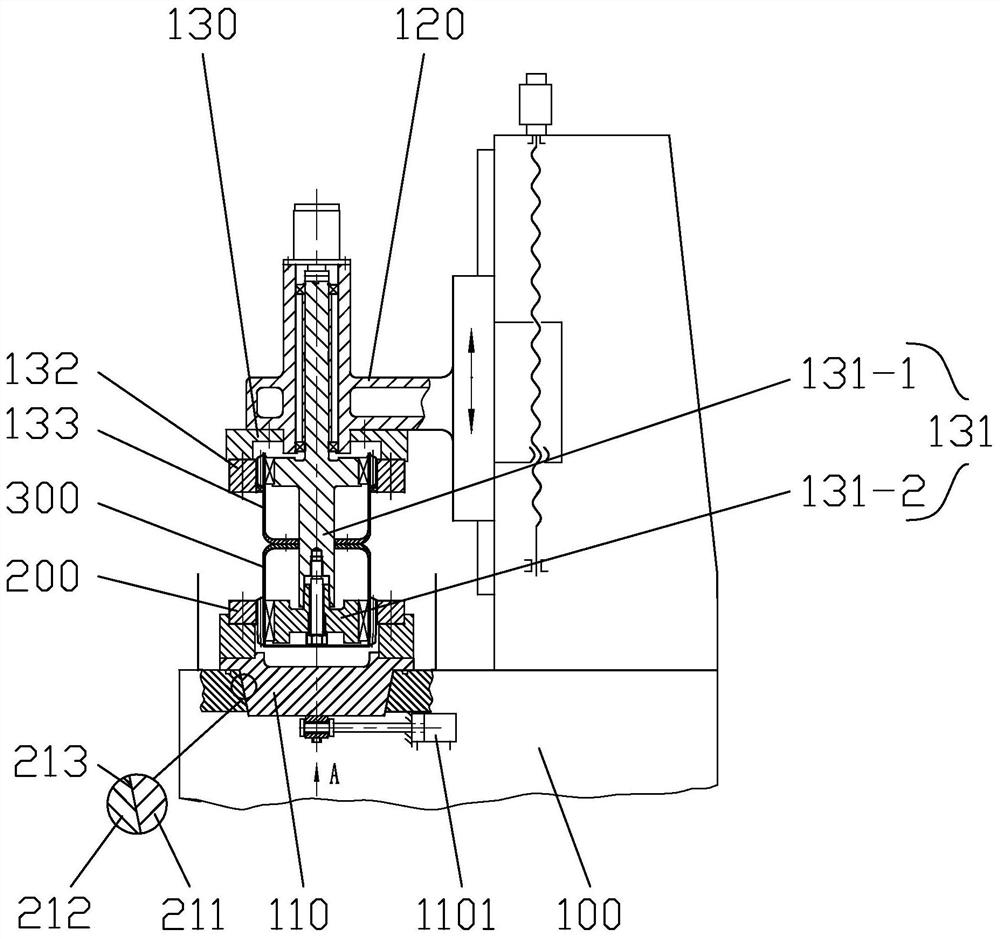

[0054] Embodiment 2, with reference to image 3 , the turntable part 110 is used to fix the steel wheel 200 to be processed, that is, the steel wheel fixture 210 is located on the turntable part 110, and the mother harmonic reducer 133 is arranged on the movable fixture arm, and the mother harmonic reducer 133 includes a mother harmonic reducer The wave generator 131, the rigid wheel 132 of the mother harmonic reducer, the flexible wheel 133 of the mother harmonic reducer, and the flexible wheel 300 as a tool is arranged on the flexible wheel 133 of the mother harmonic reducer. The flexspline 133 of the female harmonic reducer is provided with a female wave generator, a female flexible bearing and a flexspline 300 as a female cutter. The flexspline 300 as a tool is provided with a flexible bearing and a wave generator, wherein the wave generator 131 of the mother harmonic reducer simultaneously drives the flexspline 133 of the mother harmonic reducer and the tool flexspline 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com