Splint using thermoplastic resin fabric and manufacturing method thereof

A technology of thermoplastic resin and manufacturing method, which is applied in medical science, finger bandages, absorbent pads, etc., can solve the problems of not conforming to the patient's physical condition, high price, etc., and achieve the effect of improving adhesion, easy production, and effective production of splints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The description of the specific structures and functions in the embodiments of the present invention is only for illustrating the embodiments based on the concept of the present invention, and the embodiments based on the concept of the present invention can be implemented in various forms. In addition, it should not be understood as being limited to the embodiments described in this specification, but should be understood as including all modifications, equivalents, and substitutions within the spirit and technical scope of the present invention.

[0029] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

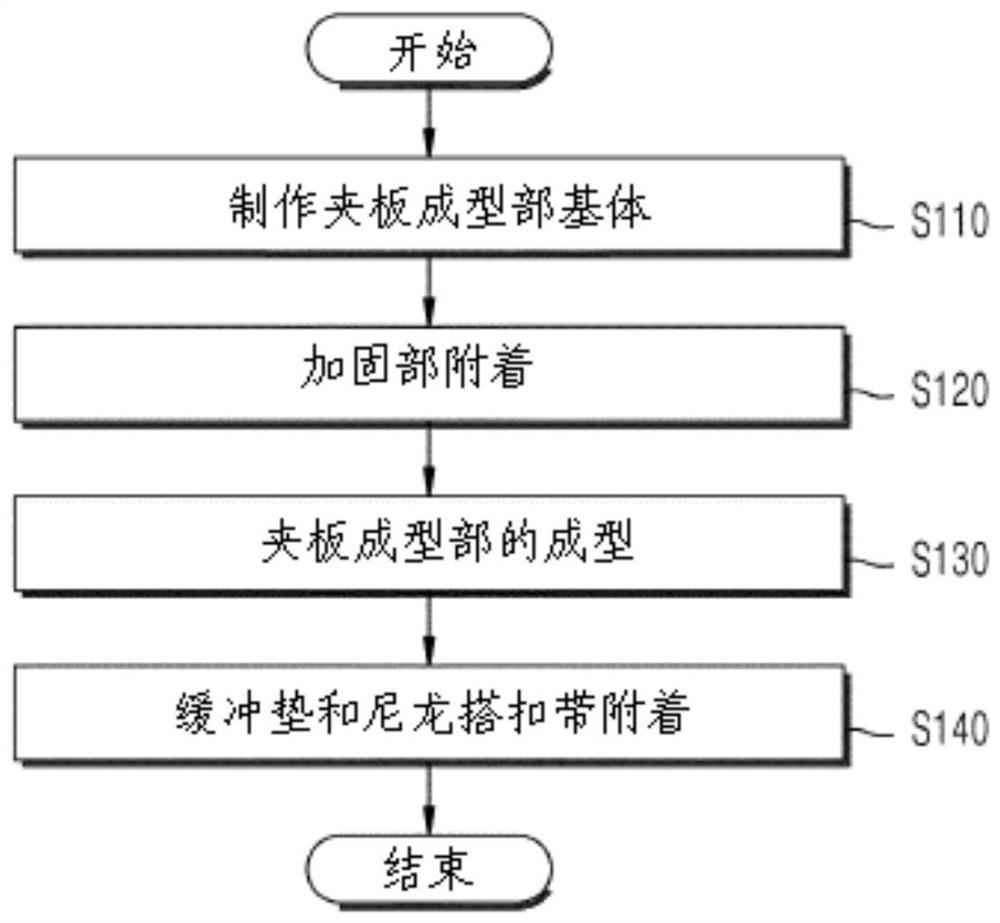

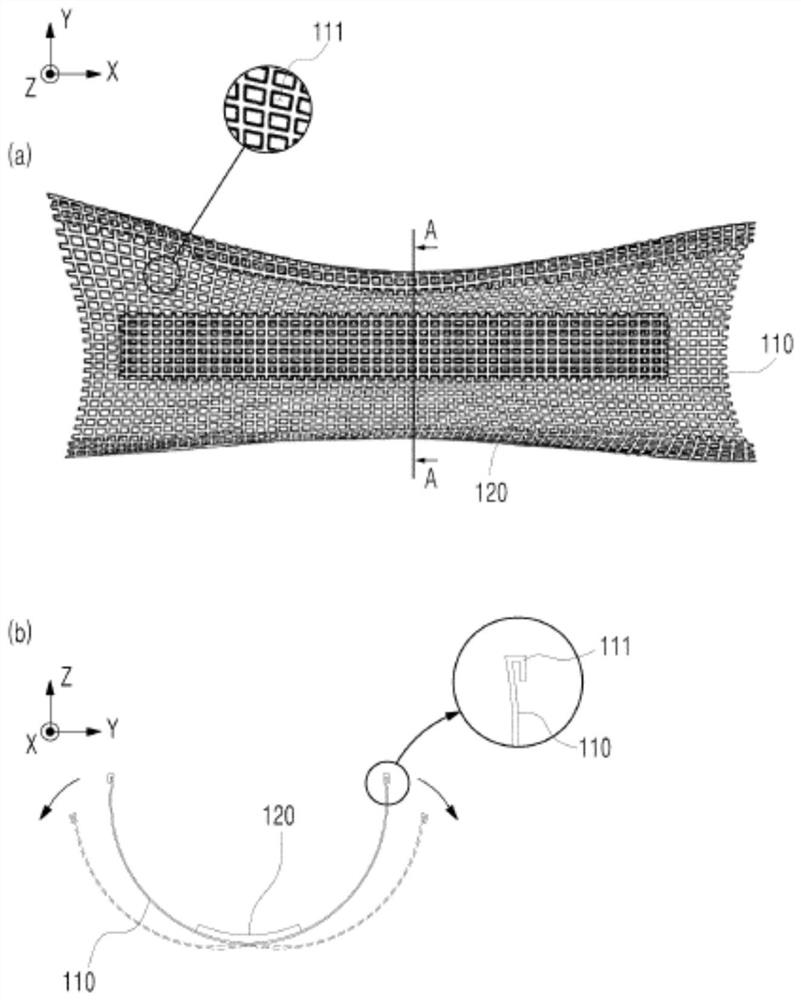

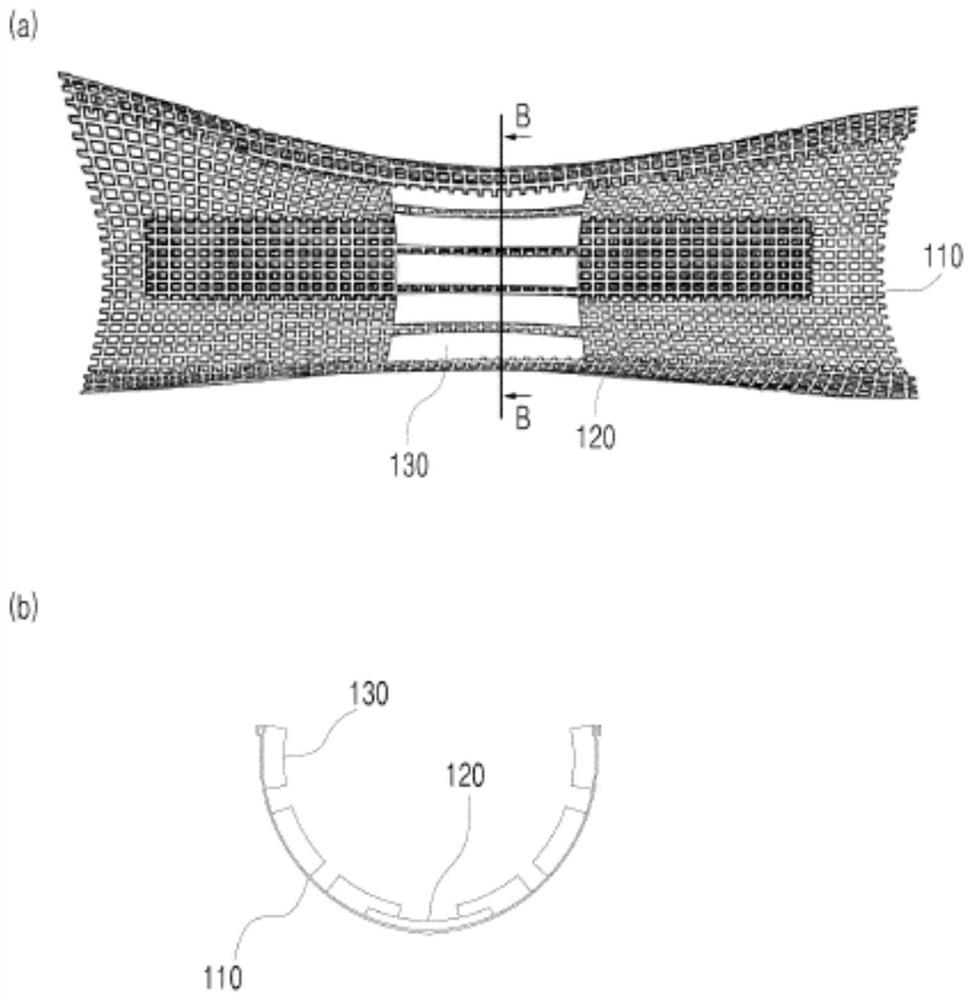

[0030] The splint using the thermoplastic resin fabric of the present invention is manufactured by softening the thermoplastic resin fabric used for the splint in an activated atmosphere (condition), molding it into the shape of the affected part, and then hardening it. At this time, the splint utilizin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com