High-wear-resistance PVC air bubble film for transportation

A bubble film, high wear-resistant technology, used in transportation and packaging, containers to prevent mechanical damage, flexible coverings, etc. Achieve the effect of improving wear resistance, reducing friction and improving wear conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

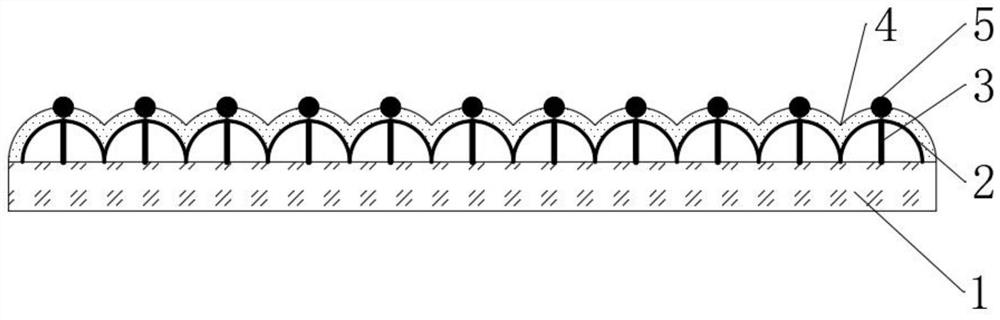

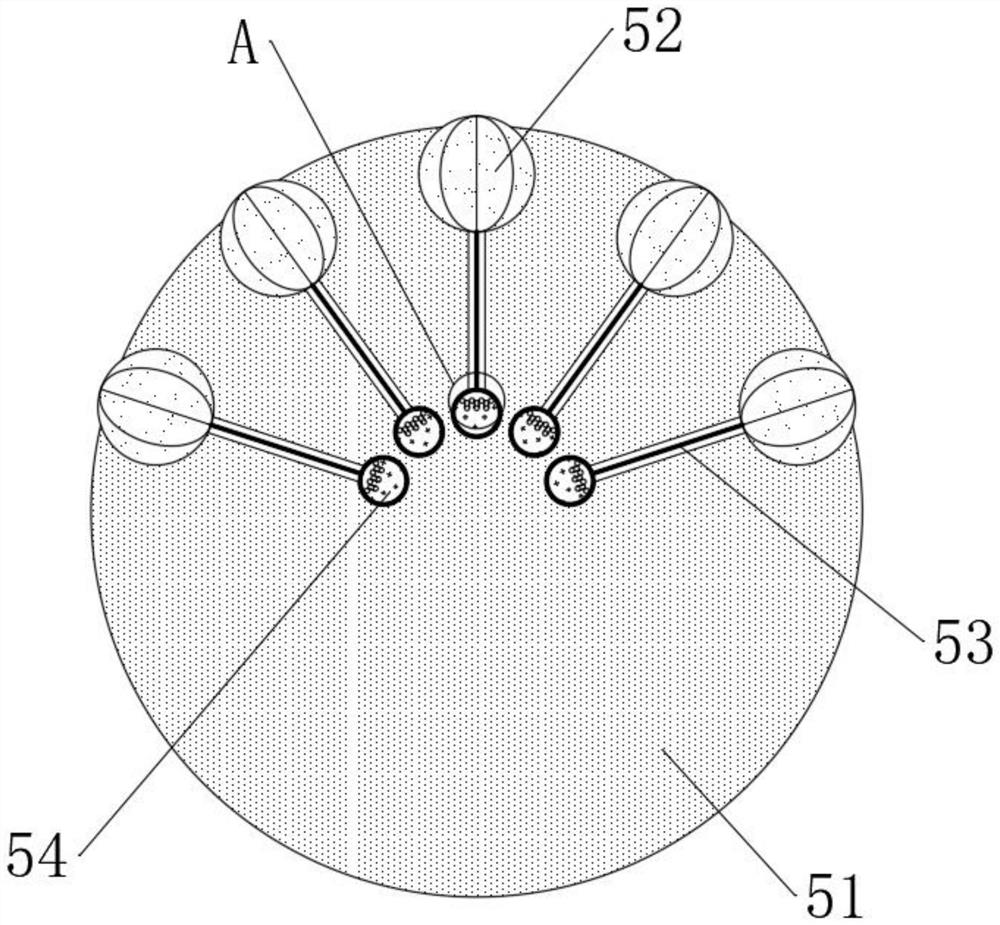

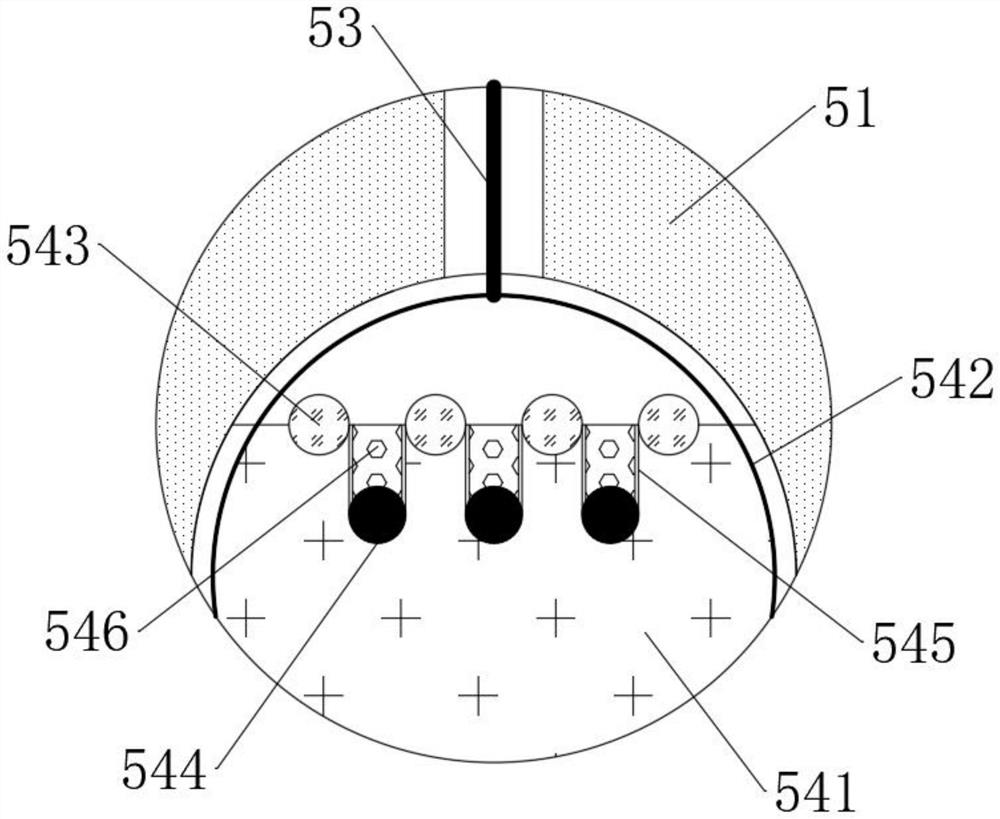

[0040] see Figure 1-2 , a highly wear-resistant PVC bubble film for transportation, comprising a bottom film 1, a PVC bubble film 2 is extruded on the outer surface of the bottom film 1, and the end of the PVC bubble film 2 away from the bottom film 1 is coated with a metal film by copolymerization The film layer 4 is inlaid with a plurality of uniformly distributed single-point wear-resistant beads 5 connected to the upper end of the metal film layer 4. The single-point wear-resistant beads 5 include an outer convex bead body 51, and the outer end of the outer convex bead body 51 is inlaid with a plurality of uniform wear-resistant beads. The distribution of sensing microspheres 52, the inner end of the outer convex bead body 51 is inlaid with a plurality of lubricating bags 54 corresponding to the sensing microspheres 52, and a plurality of lubricating bags 54 corresponding to the sensing microspheres 52 are provided in the outer convex bead body 51. In the migration groove...

Embodiment 2

[0052] see Figure 1-2 , a highly wear-resistant PVC bubble film for transportation, comprising a bottom film 1, a PVC bubble film 2 is extruded on the outer surface of the bottom film 1, and the end of the PVC bubble film 2 away from the bottom film 1 is coated with a metal film by copolymerization The film layer 4 is inlaid with a plurality of uniformly distributed single-point wear-resistant beads 5 connected to the upper end of the metal film layer 4. The single-point wear-resistant beads 5 include an outer convex bead body 51, and the outer end of the outer convex bead body 51 is inlaid with a plurality of uniform wear-resistant beads. The distribution of sensing microspheres 52, the inner end of the outer convex bead body 51 is inlaid with a plurality of lubricating bags 54 corresponding to the sensing microspheres 52, and a plurality of lubricating bags 54 corresponding to the sensing microspheres 52 are provided in the outer convex bead body 51. In the migration groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com