Fuel injection system comprising a fuel-guiding component, a fuel injection valve and a connecting element

A fuel injection system and fuel injection valve technology, applied to fuel injection devices with noise reduction measures, low-pressure fuel injection, low-pressure fuel injection, etc., can solve problems such as noise, achieve noise reduction, improve connections, and realize assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

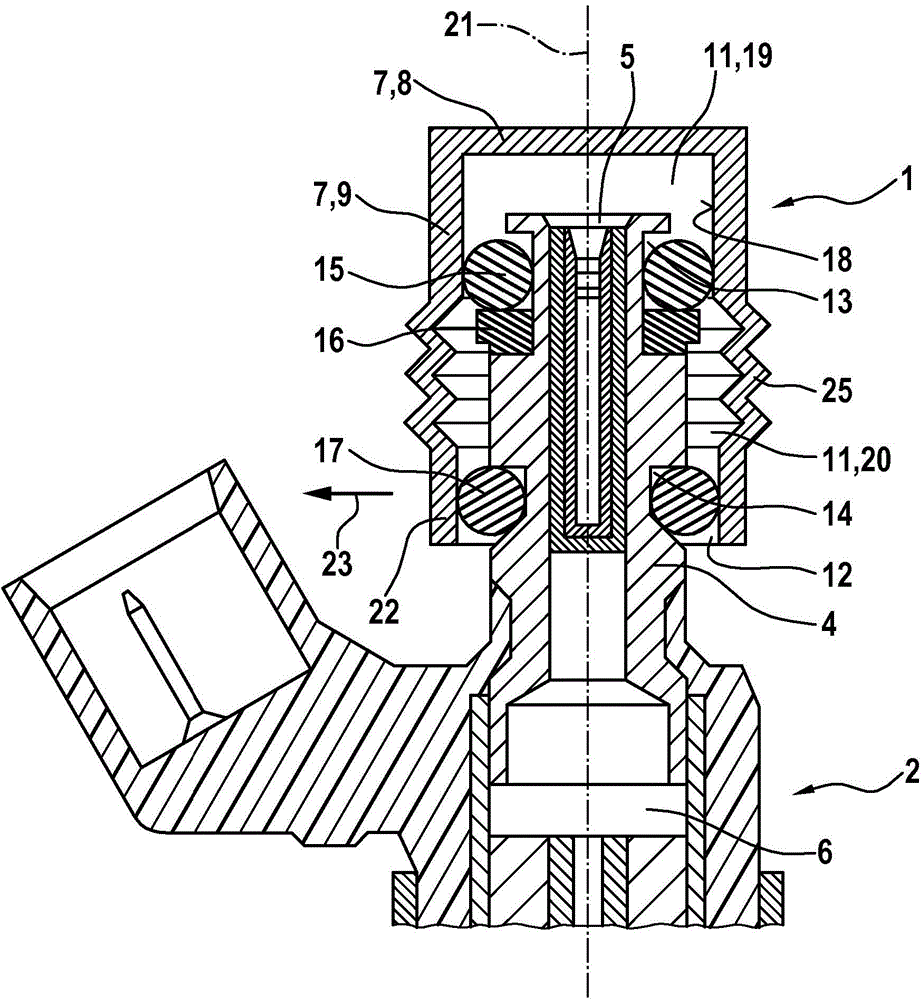

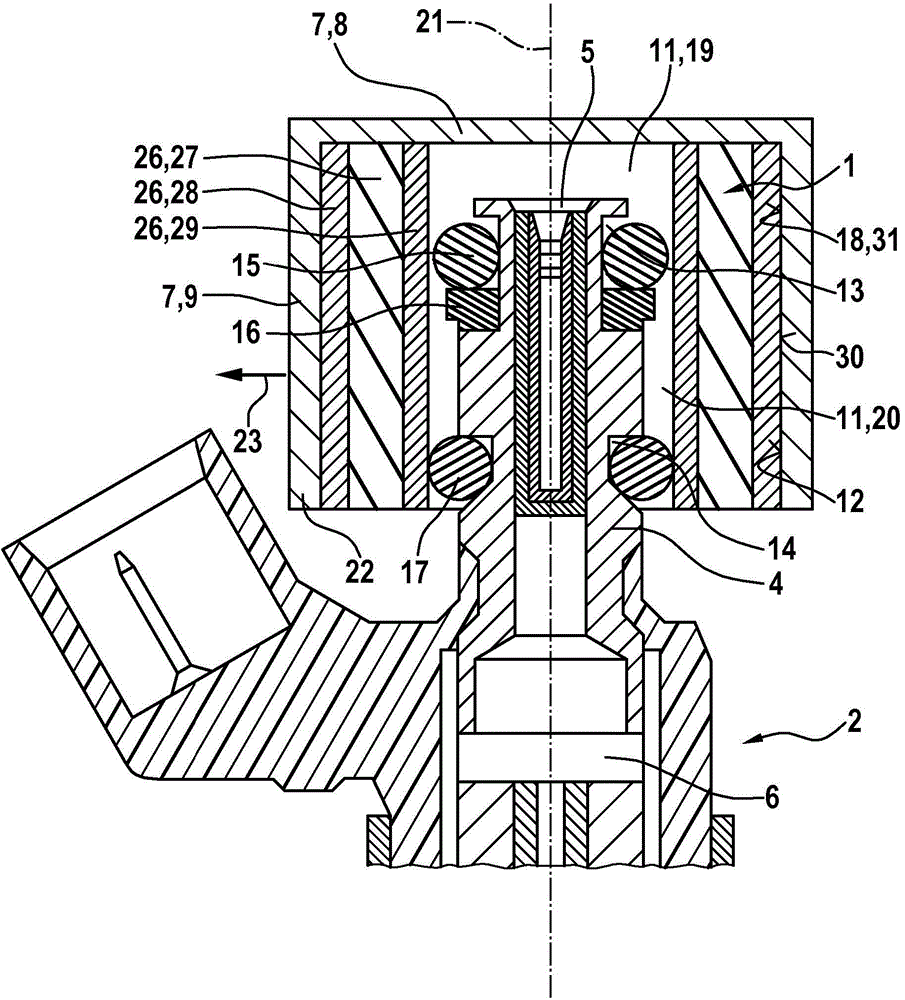

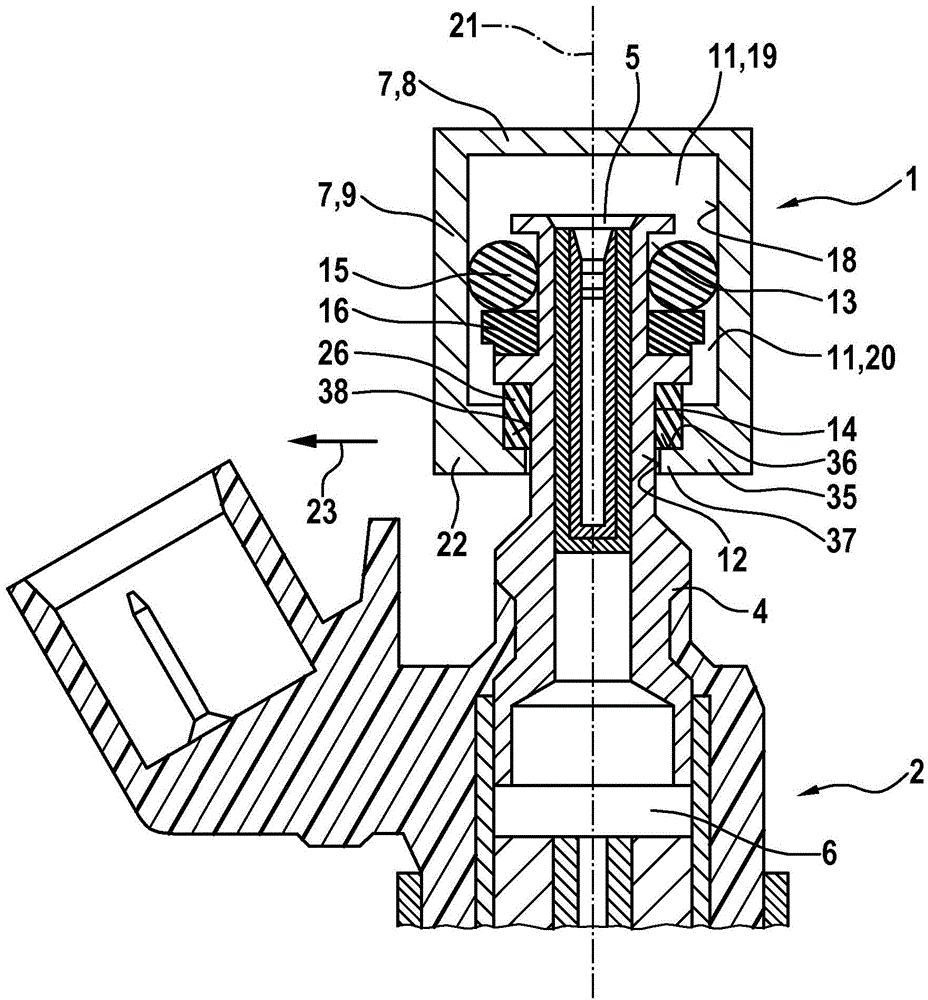

[0026] figure 1 A fuel injection system 3 ( Figure 5 ) connecting element 1 and fuel injection valve 2. The fuel injection system 3 can be used in particular for high-pressure injection in internal combustion engines. The fuel injection system 3 can be used in particular in hybrid compression external ignition internal combustion engines. The connecting element 1 is particularly suitable for such a fuel injection system 3 .

[0027] The fuel injection valve 2 of the fuel injection system 3 has a fuel connection 4 . At the inflow-side end 5 of the fuel connection 4 , fuel is guided into the fuel chamber 6 of the fuel injector 2 during operation.

[0028] The connecting element 1 has a base body 7 with an upper part 8 and a tubular part 9 . Appropriate inlet boreholes 10 are configured in the upper part 8 ( Figure 5 ) in order to guide the fuel into the receiving chamber 11 of the base body 7 of the connecting element 1 .

[0029] In the assembled state, the fuel connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com