Vibration damper having a hydraulic traction stop

A shock absorber, hydraulic shock absorber technology, used in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as trouble, and achieve the effect of increasing cost and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

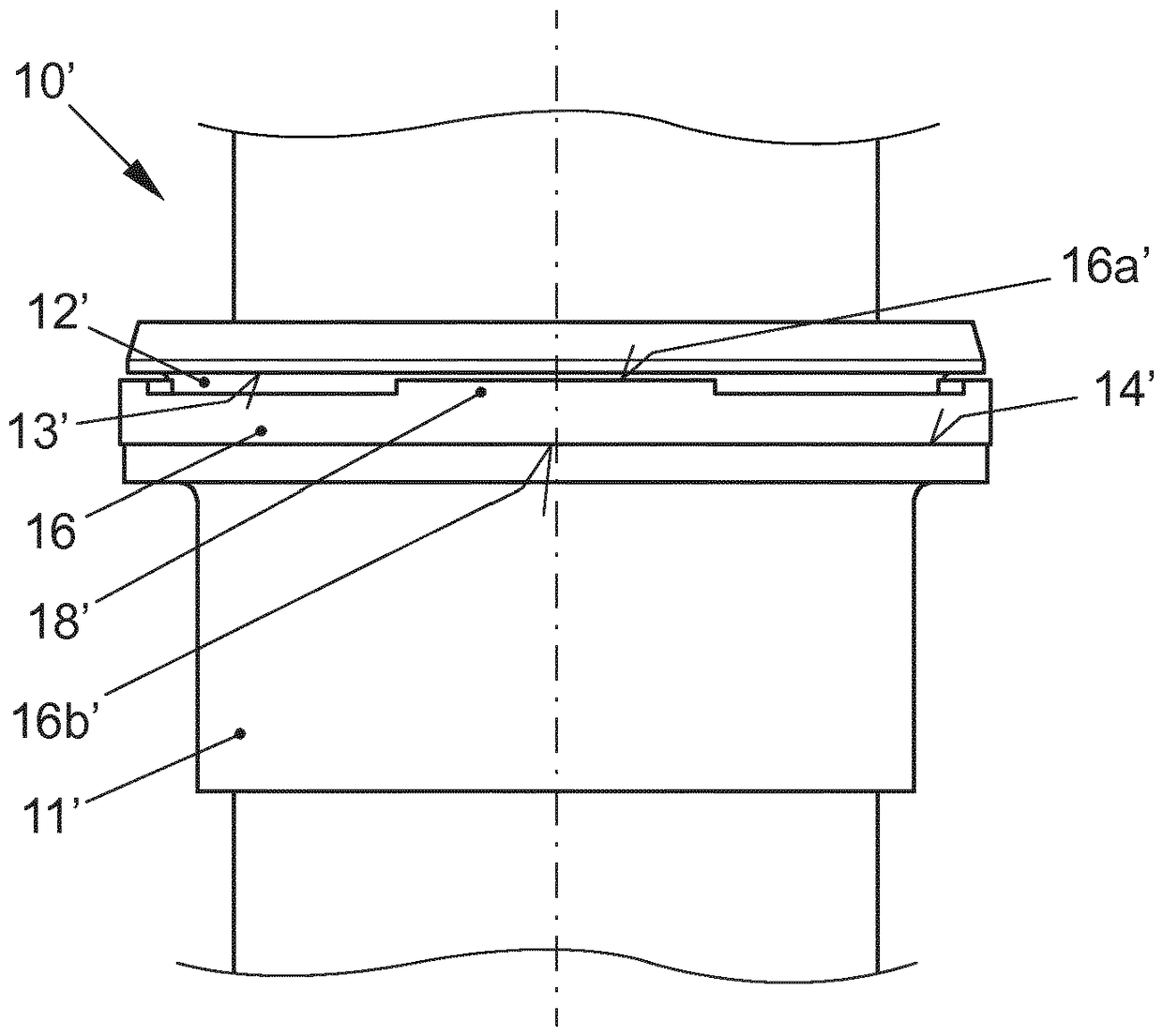

[0046] This exemplary embodiment and other embodiment variants relate to a vibration damper 1 with a hydraulic tension stop, which can be used in a wheel suspension of a motor vehicle.

[0047] exist figure 1 shows an example of a vibration damper 1 with a container tube 2 into which a piston rod 3 is sunk. A piston 4 is fixed rigidly on the piston rod 3 , which divides the interior of the container tube 2 into two chambers 5 and 6 . The two chambers 5 and 6 form an upper working chamber and a lower working chamber of the vibration damper for receiving a hydraulic damping medium.

[0048] The vibration damper 1 also has a hydraulic damping device 10 , which can be used in single-tube shock absorbers as well as in double-tube shock absorbers, and will be explained in more detail below.

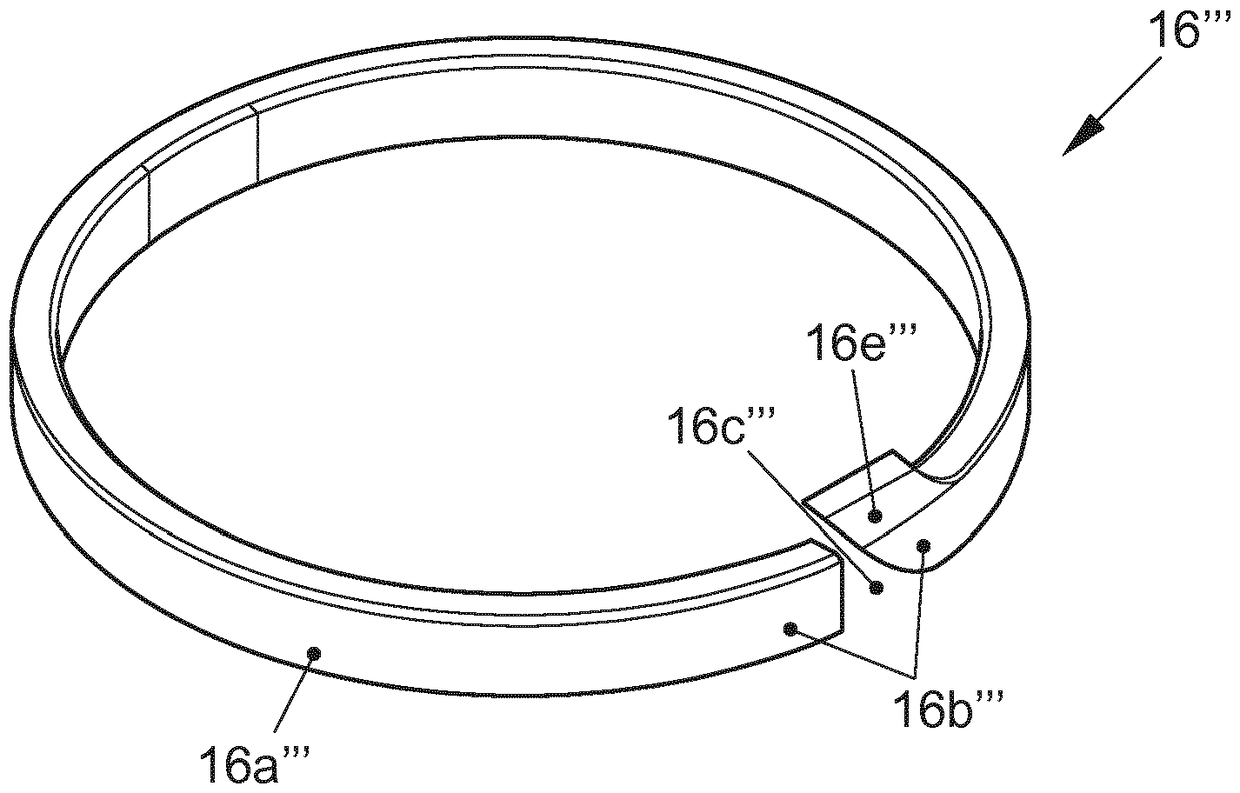

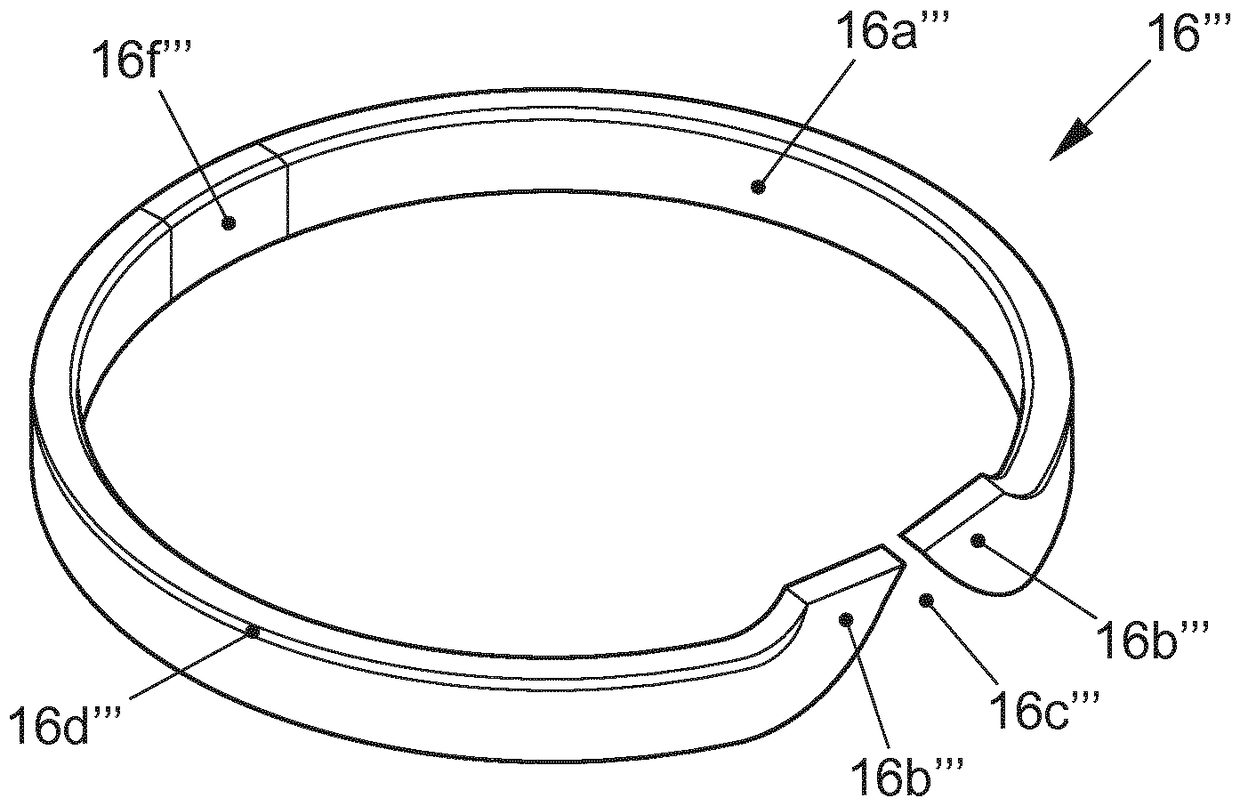

[0049] The hydraulic damping device 10 comprises a damping piston 11 for providing a hydraulic force directed opposite to the pulling movement of the piston rod 3 in the end region of the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com