A seat for a motor vehicle

A seat and stop technology, applied in vehicle seats, seat frames, special positions of vehicles, etc., can solve the problems of cost removal, high installation cost, rivet cost drilling, etc., and achieves cheap manufacturing and wrong installation. Low-risk, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

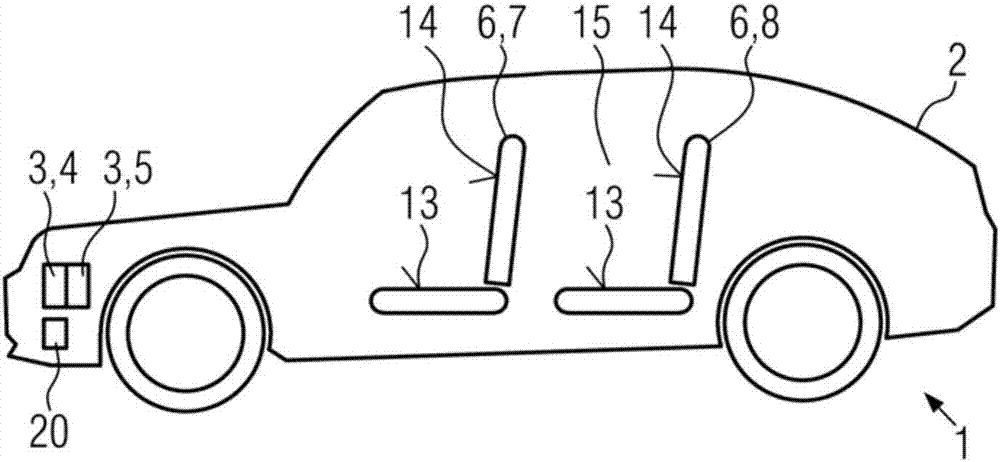

[0043] exist figure 1 The motor vehicle 1 shown in has a body 2 made of metal, in particular steel. Motor vehicle 1 is moved forward by means of drive motor 3 , for example electric machine 4 and / or internal combustion engine 5 . The body 2 defines an interior space 15 in which two front seats 7 as seats 6 and three rear seats 8 as seats 6 are arranged. The three rear seats 8 are combined here to form a row of seats.

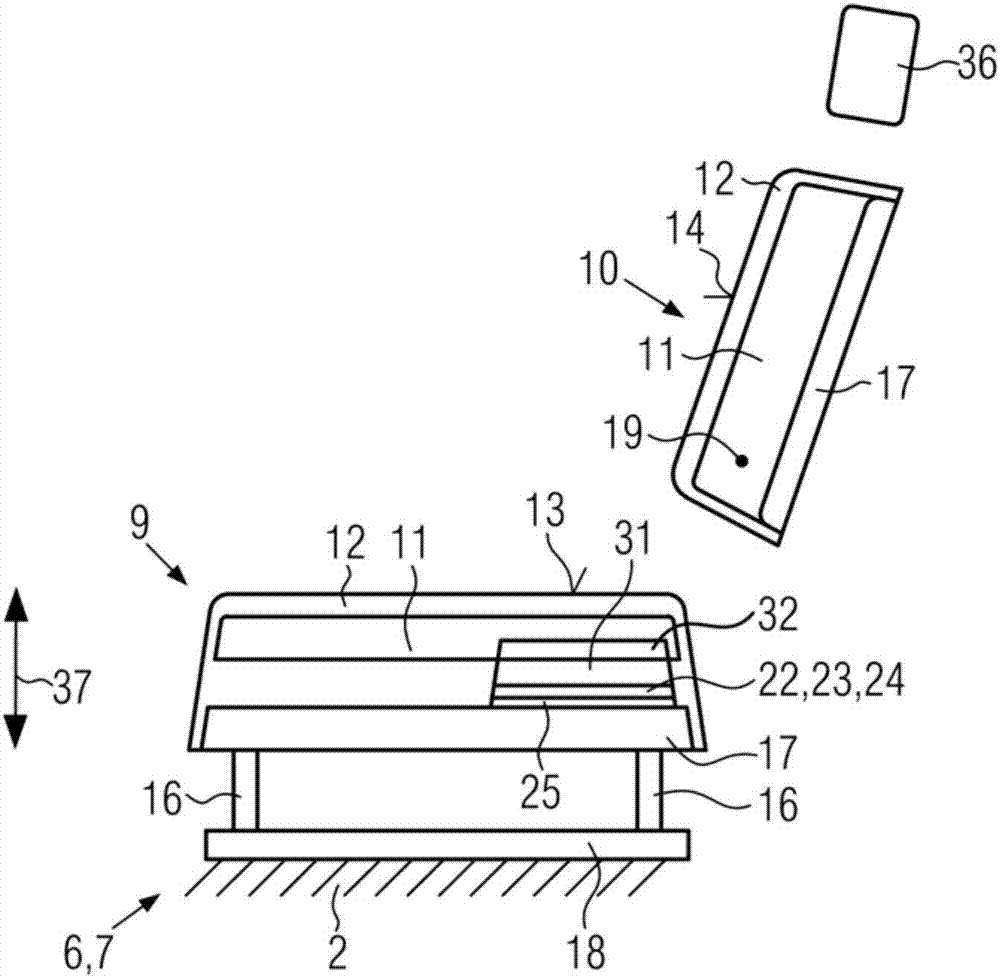

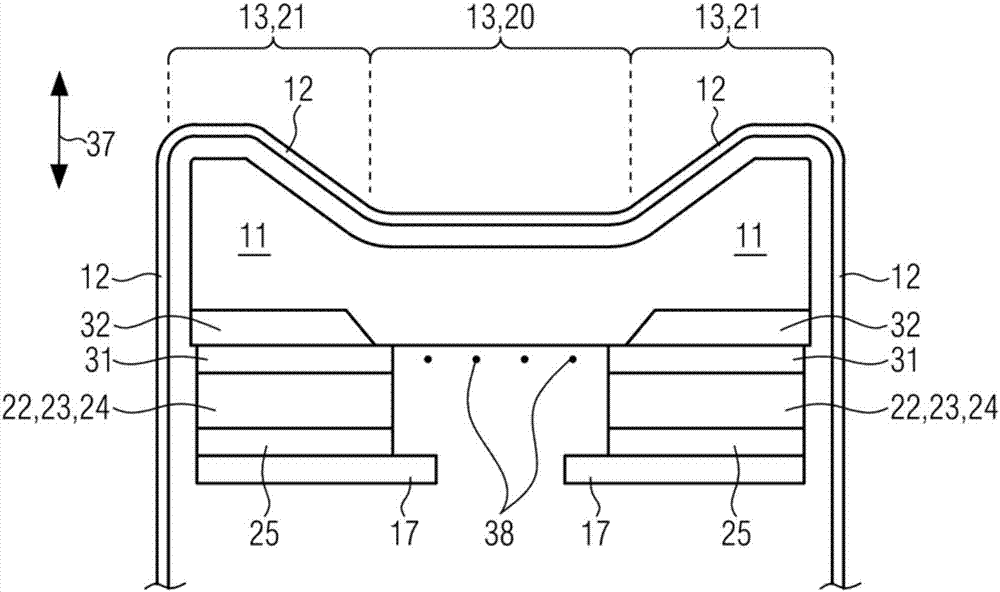

[0044] exist figure 2 A longitudinal section through the front seat 7 is shown in . The front seat 7 includes a seat part 9 and a backrest part 10 . The seat part 9 and the backrest part 10 each have a frame-shaped support structure 17 , to which a cushion 11 made of foam material and a seat cover 12 , for example fabric, leather or plastic, are fastened. A headrest 36 is also fastened to the backrest part 10 . The seat part 9 is fastened by means of feet 16 to a rail 18 which is fastened to the body 2 . In this case, the entire front seat 7 can be moved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com