Air bag valve

An air bag valve and valve body technology, which is applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of short service life, small opening and closing torque, and large opening and closing torque, etc. The effect of small closing torque and zero leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

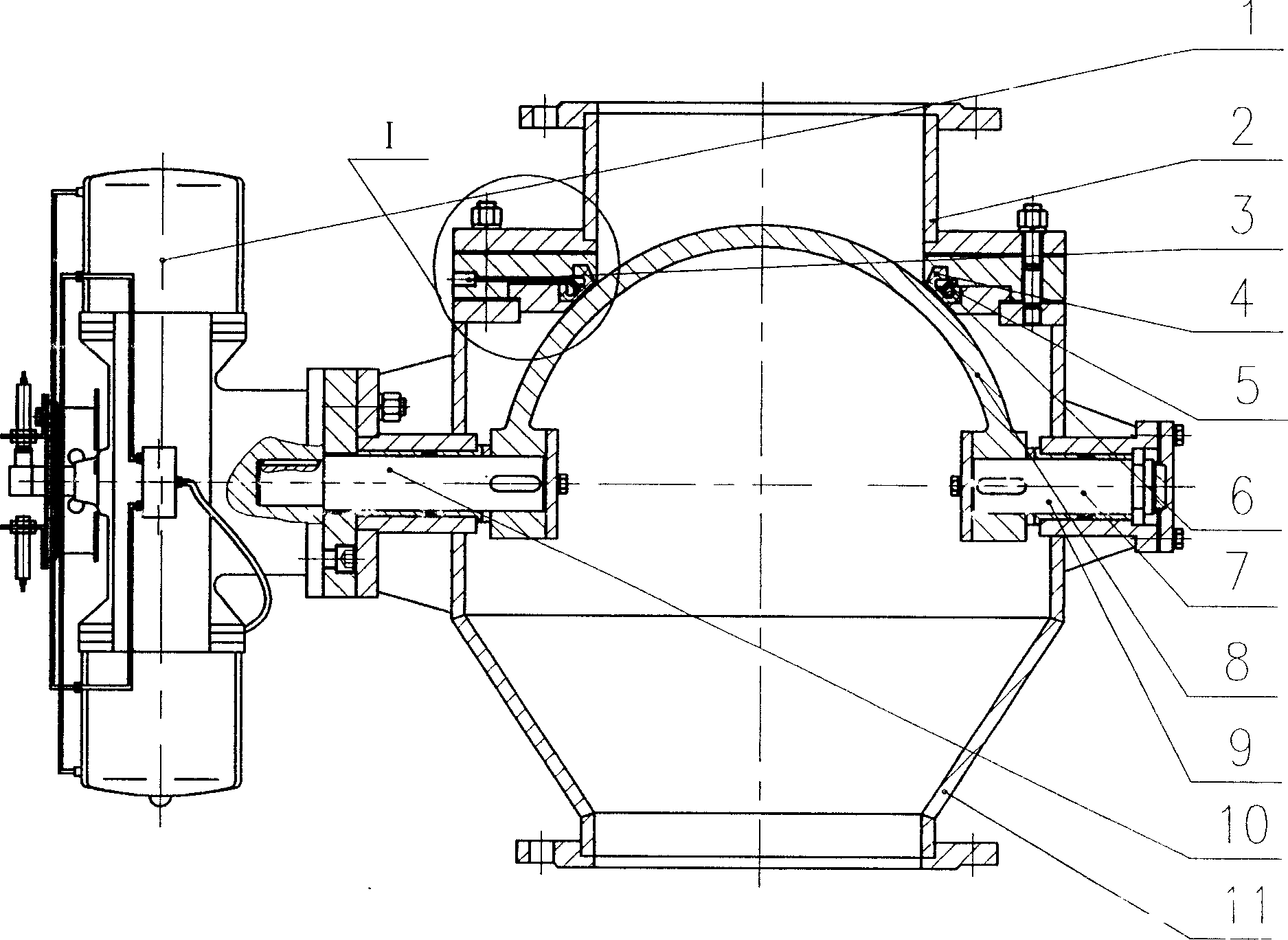

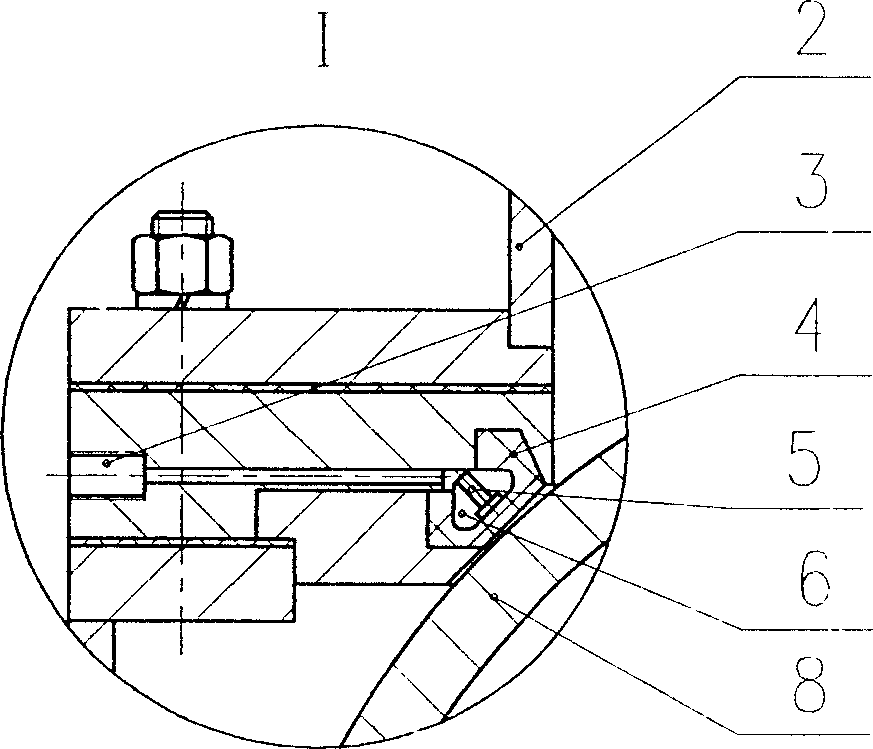

[0011] Such as figure 1 As shown, a kind of airbag valve comprises valve body 11, valve cover 2, upper valve shaft 10, lower valve shaft 9, driving device 1 and end cover 7, valve body 11 and valve cover 2 are connected by bolts, end cover 7 and The valve body 11 is connected by bolts, and the valve core 8 is supported in the valve body 11 through the upper valve shaft 10 and the lower valve shaft 9. The valve body 11 is also equipped with a ring-shaped semi-enclosed rubber sealing ring 4, and the sealing ring 4 is inlaid with There is a metal inner lining 6 with a plurality of radial through holes 5, and an air inlet 3 is also opened on the valve body 11. The air inlet 3 is externally connected to compressed air and communicates with the metal inner lining 6 inside. After assembly, There is a gap of 1 to 1.5 millimeters between the spool 8 and the sealing ring 4. The action principle is as follows: When the valve is closed in place, the compressed air enters the metal inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com