A kind of impact rebound tester

A tester and scale technology, applied in the direction of testing material hardness, etc., can solve the problems of easy sliding of the pointer, inconvenient reading, easy failure of the locking mechanism, etc., and achieve the effect of convenient zeroing and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

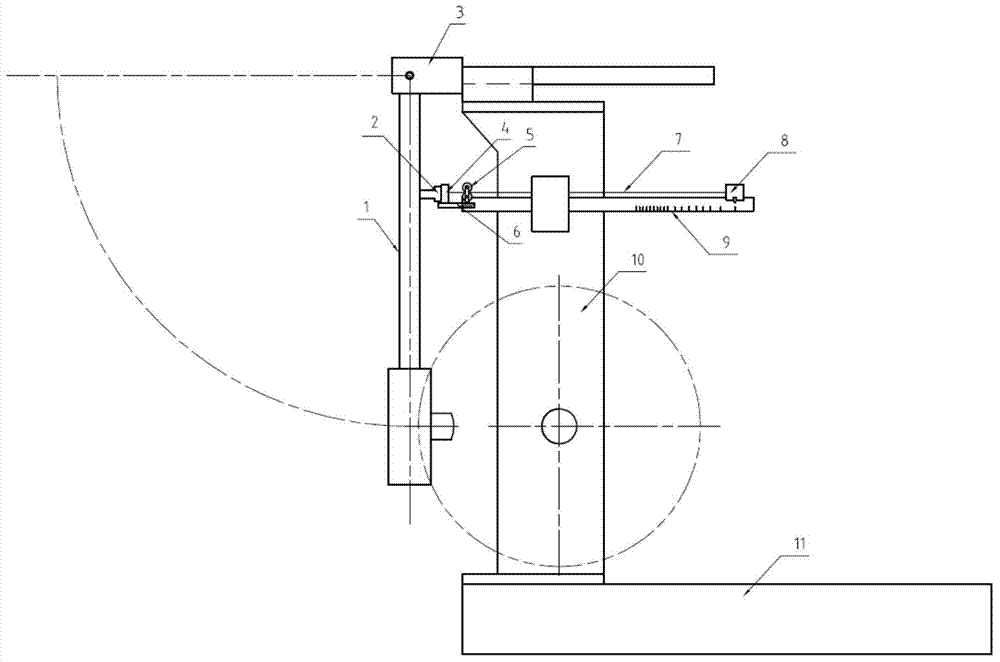

[0021] Such as figure 1 As shown, a kind of impact rebound tester comprises: support 10, scale 9 and pendulum 1; Described support 10 is arranged perpendicular to the horizontal plane and can be installed and fixed by the base 11 below; Described scale 9 is provided with Non-uniformly distributed scales, the scale 9 is horizontally arranged on the support 10, and the scale 9 is also provided with a pointer 8 slidingly connected thereto, and there is a certain friction between the pointer 8 and the scale 9 Coefficient, one end of the scale 9 is also placed with a passive magnet 4, the passive magnet 4 and the pointer 8 are connected by a flexible wire 7; the pendulum 1 includes a hammer head and a connecting rod, and one end of the connecting rod It is hinged with the bracket 10, and the hinge point between the pendulum 1 and the bracket 10 is located above the end of the scale 9 where the passive magnet 4 is placed, and the swing plane of the pendulum 1 is aligned with the sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com