Electronic zeroing method for photoelectric rotary encoder

A shaft angle encoder and electronic technology, applied in the direction of instruments, conversion sensor output, measuring devices, etc., can solve the problems of complex circuit structure, troublesome manual operation, inconvenient zero adjustment, etc., and achieve simple circuit structure, less error-prone and accurate sex high effect

Inactive Publication Date: 2008-02-13

CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

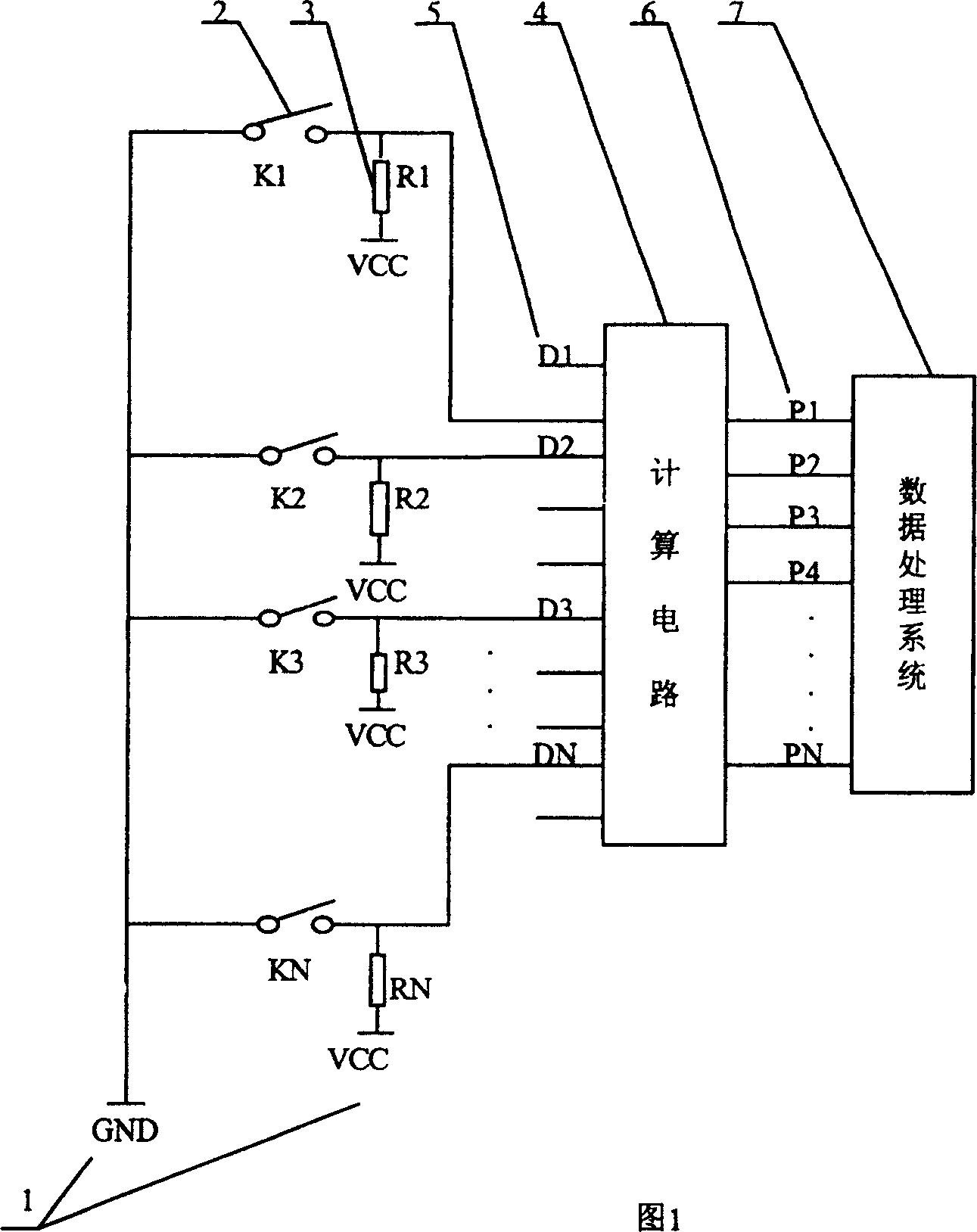

[0004] The structure of the circuit is complex, as many bits as there are encoders, there are as many dial switches and upper resistors as there are. Manual operation is cumbersome, time-consuming, easy to pull wrongly, and zero adjustment is inconvenient.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

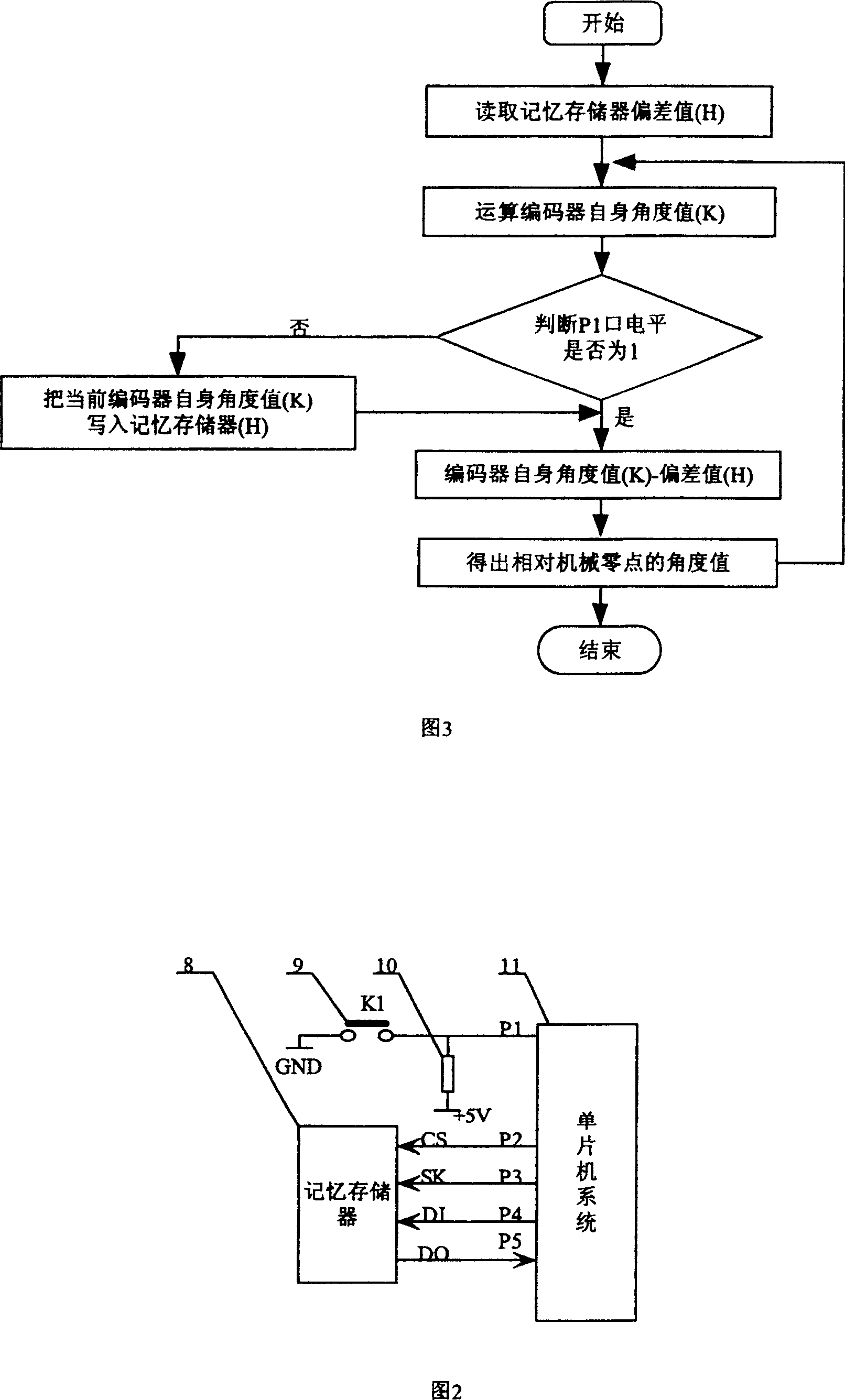

[0010] The method of the present invention designs the circuit according to the structure of the electronic zero-adjustment circuit of the first step, and then controls the circuit according to the control program of the second step. Memory 8 selects 93C66 memory for use, single-chip microcomputer adopts 8751 single-chip microcomputer, the resistance value of pull-up resistor 10 adopts 1-10K, and grounding power supply voltage is 5V.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an electronic zero adjust method of optical-electricity shaft encoder in the field of optical-electricity measuring. First designing a electronic zero adjust circuit which comprises a memory storage device, a reset switch, a upper-pulling resistance and a signal chip computer, wherein the memory storage device possesses chip choosing end CS, clock interface SK, writing end DI and output end DO; one end of the reset switch is connected with the earth, the other end is connected with the P1 port; the upper-pulling resistance is positioned on the P1 port, the other end of the upper-pulling resistance is connected with the 5V power; the signal chip machine possesses input / output (I / O) interface P1 to P5, P1 is connected with the resistance end of the reset switch; P2 to P5 are separately connected with the chip choosing end CS, the clock interface SK, the writing end DI and the output end DO; second controlling the electronic zero adjust circuit by the preset electronic zero adjust program to achieve the clear impact.

Description

1. Technical field [0001] The invention belongs to the technical field of photoelectric measurement and relates to an electronic zeroing method of a photoelectric shaft angle encoder. 2. Technical background [0002] The photoelectric shaft encoder is a representative photoelectric sensor device for photoelectric measurement of angular displacement. When the photoelectric shaft encoder is used for measurement, there are often differences between the zero position of the code disc of the photoelectric shaft encoder and the zero point position of the rotating shaft of the measurement system. There is an angle deviation phenomenon in the misalignment, which leads to inaccurate measured angular displacement of the rotating shaft of the measurement system, making the measurement accuracy meaningless. Therefore, when using a photoelectric shaft-angle encoder to measure the angular displacement of the rotating shaft, it is necessary to first align the zero position of the code disc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01D3/00G01D18/00G01D5/347

Inventor 张泽宇盖竹秋

Owner CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com