Equipment and method for measuring brake lever

A technology of brake levers and measuring equipment, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of inaccurate measurement, low measurement efficiency, irregular shape of brake levers, etc., and achieve the effect of efficient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

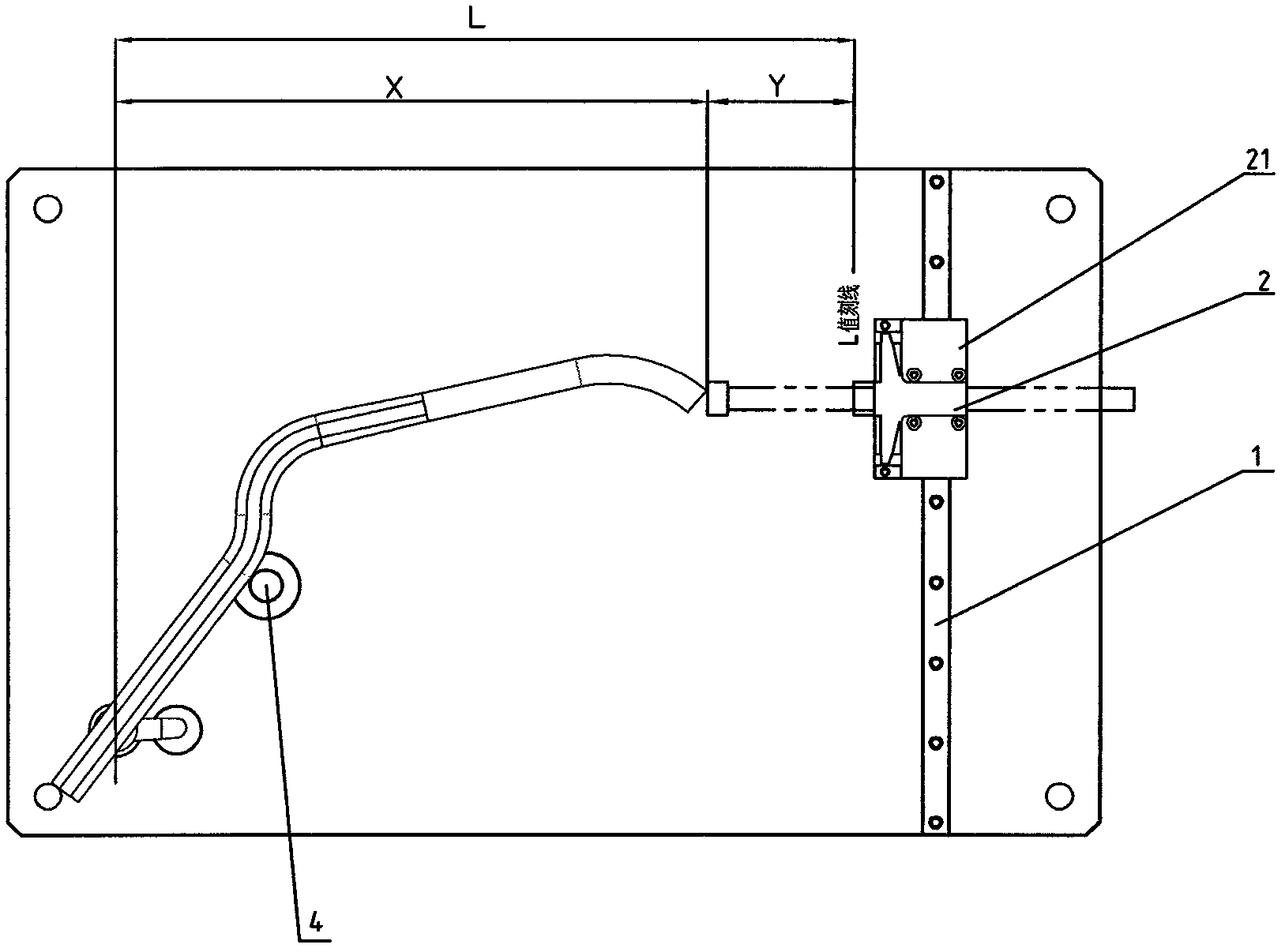

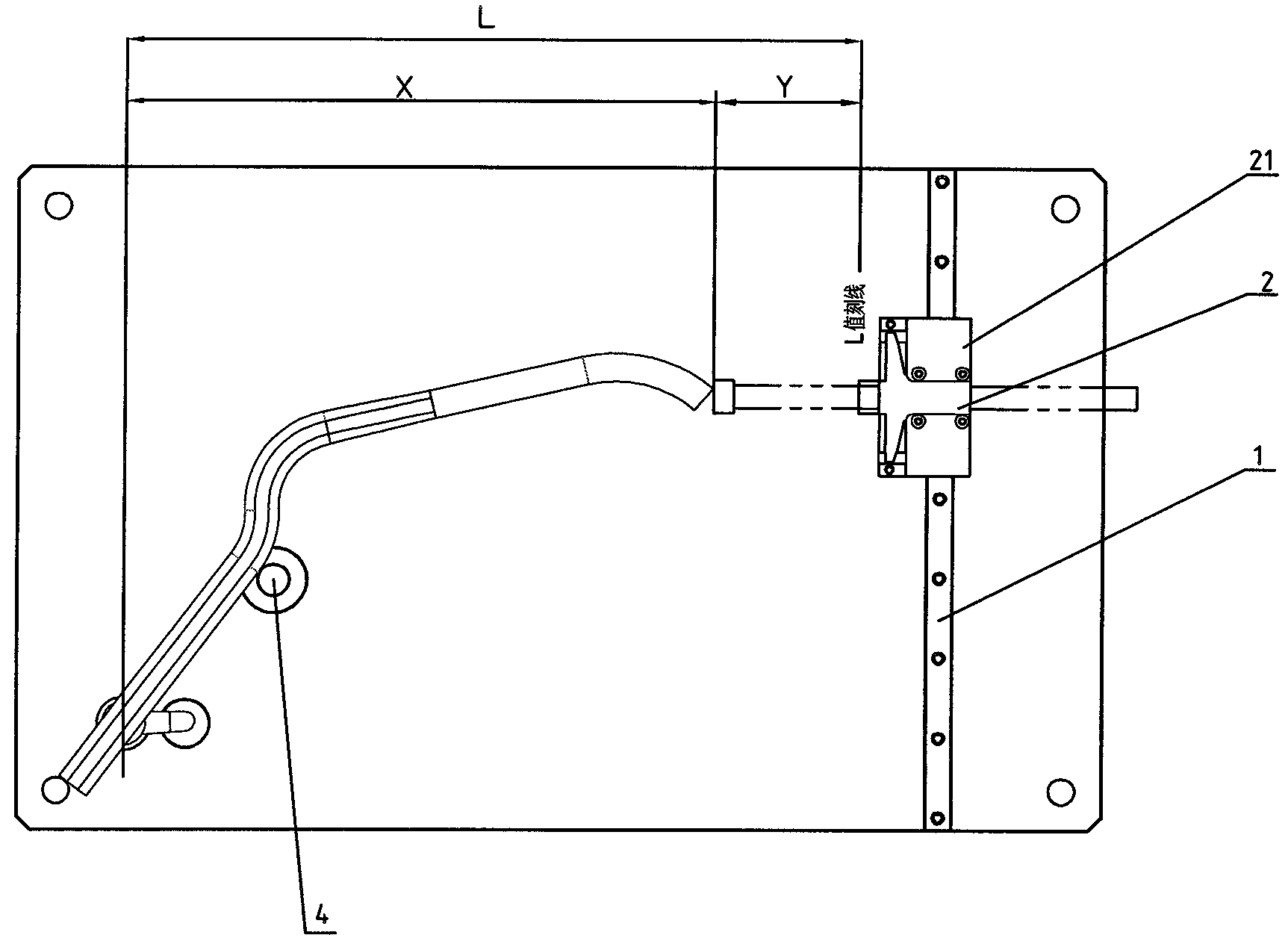

[0028] Embodiment 1. In this embodiment, on the basis of the above disclosure, the measuring ruler 2 is installed on the linear bearing 1 through the measuring ruler base 21. The ruler base 21 can slide along the linear bearing 1, and when the measuring head of the measuring ruler 2 22 is moved to when the end face of ruler base 21 coincides, just in time aligns with L engraved line. This not only facilitates the alignment of the measuring head 22 and the L reticle, but also enables the measurement of brake levers 6 of different specifications.

Embodiment 2

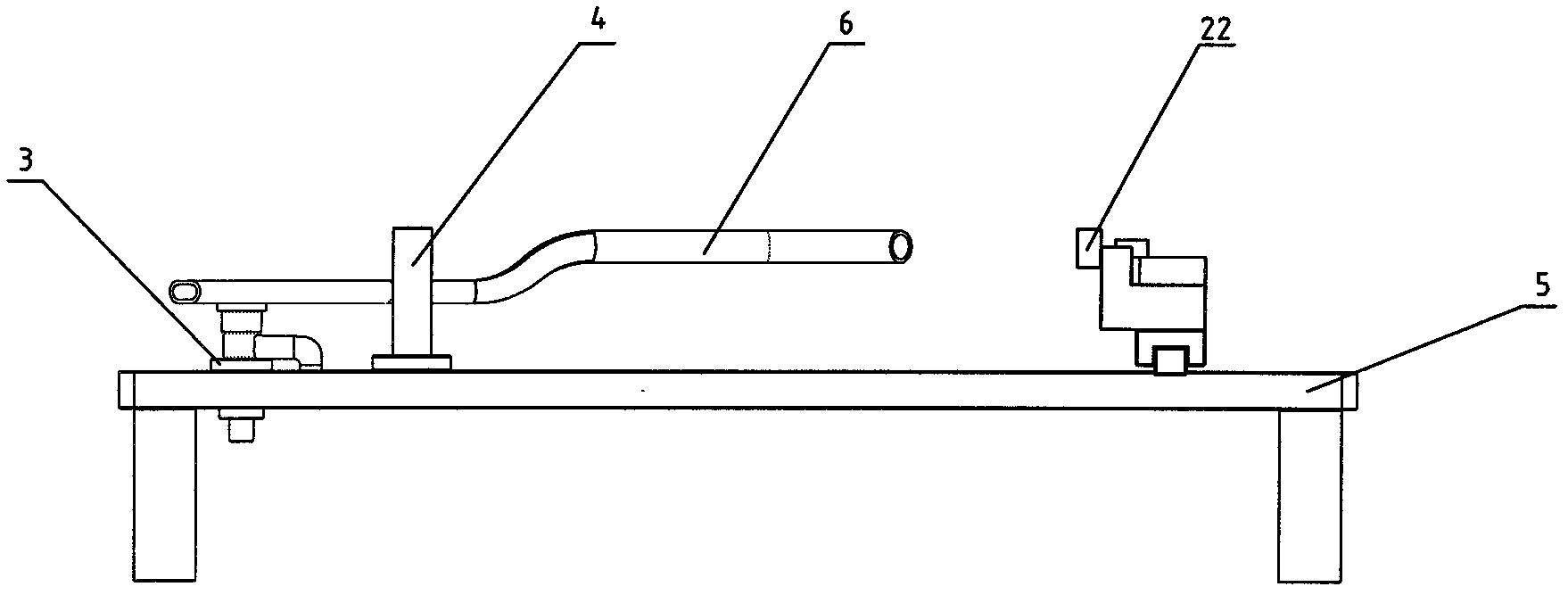

[0029] Example 2, such as figure 1 , figure 2 As shown, in this embodiment, on the basis of Embodiment 1, the fixing sleeve 3 and the positioning column 4 are installed on the bottom plate 5, which can facilitate the fixing and measurement of the brake lever 6 of different specifications by the measuring equipment.

Embodiment 3

[0030] Embodiment 3. On the basis of Embodiment 2, the present embodiment directly displays the reading of the measuring ruler through the digital display.

[0031] The present invention also discloses a measuring method for measuring the brake lever by using the measuring device of any one of the above embodiments, which includes the following steps:

[0032] (1) Determine the length L between the fixed sleeve and the L reticle;

[0033] (2) if figure 2 As shown, fasten the brake lever to the measuring device;

[0034] (3) Align the probe of the measuring ruler with the L reticle, and the reading of the measuring ruler is 0.00mm at this time;

[0035] (4) Move the probe towards the brake lever until the probe touches the high point of the brake lever, and read the reading Y of the measuring ruler at this time;

[0036] (5) Use L-Y to obtain the parameter X to be checked of the brake lever.

[0037] Using the measurement method disclosed in the present invention, the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com