Electrical machine with preloaded ball race and method for manufacturing the same

A technology of ball bearings and pre-tightening, applied in the direction of ball bearings, rotating bearings, bearings, etc., can solve the problems of reduced service life of rotor bearings, and achieve the effects of avoiding noise, increasing service life, and improving flexibility or bending characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

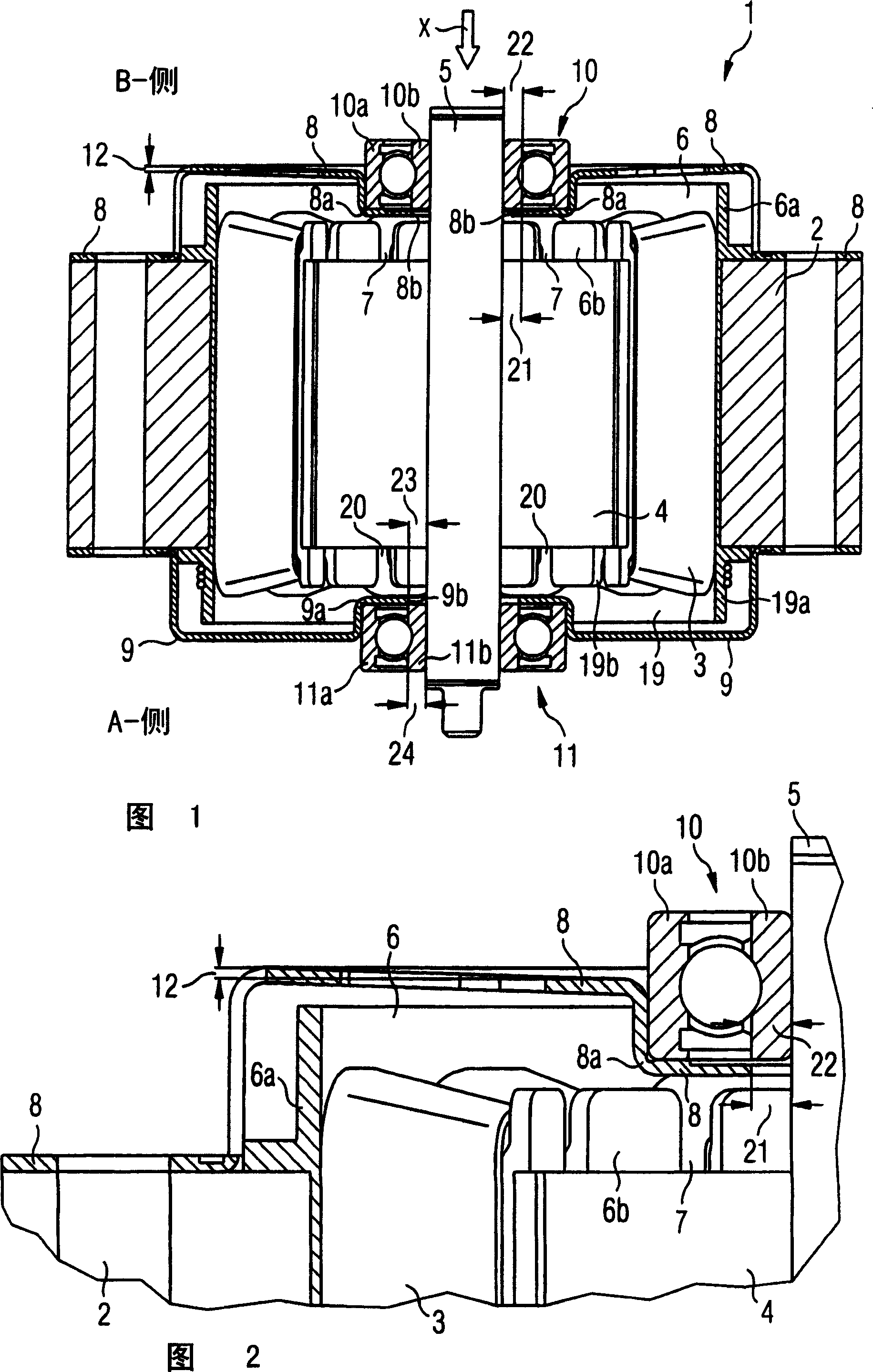

[0019] FIG. 1 shows a sectional view of a motor according to a first embodiment of the invention.

[0020] The electric machine 1 shown has a stator assembly which essentially consists of a stator pack 3 with a stator core 2 and two insulating disks 6 / 19 . Furthermore, the electric machine shown has a rotor assembly which essentially consists of a rotor shaft 5 and a rotor set 4 . The rotor shaft 5 is mounted in a first ball bearing 10 at the B-side end region of the electric machine and in a second ball bearing 11 at the A-side end region of the electric machine.

[0021] The first ball bearing 10 has an outer ring 10a and an inner ring 10b. The inner ring 10b is fixedly connected to the rotor shaft 5 . The second ball bearing 11 has an outer ring 11a and an inner ring 11b. The inner ring 11b is fixedly connected to the rotor shaft 5 .

[0022] An insulating disk 6 is positioned on the B-side end face of the motor. The insulating disc has an outer wall 6a and an inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com