Alumina continuous feeding equipment

An alumina and equipment technology, applied in the field of electrolysis, can solve the problems of alumina concentration fluctuations, increased energy consumption, large fluctuations in tank heat balance, etc., to reduce temperature and alumina concentration fluctuations, reduce the formation of furnace bottom deposits, and increase current efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

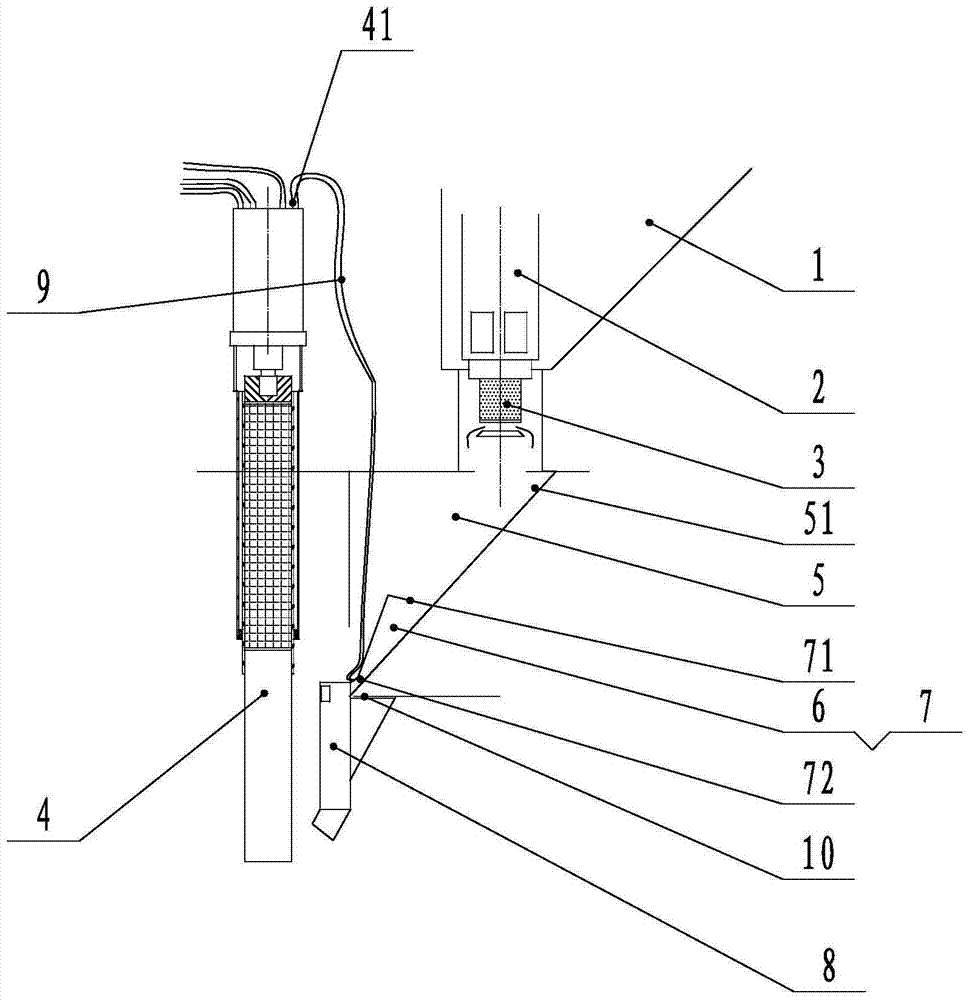

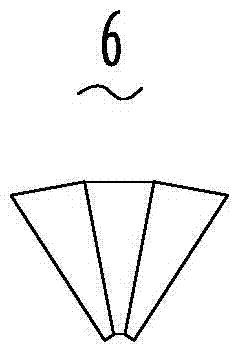

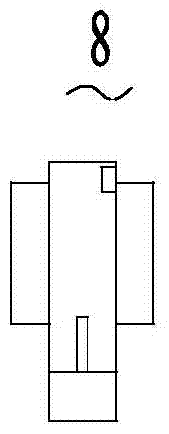

[0022] see Figure 1-Figure 5 , a continuous alumina blanking equipment, comprising: a feeder box 1 for holding alumina powder, a feeder cylinder 2 arranged at the bottom of the feeder box 1, arranged below the feeder cylinder 2 and connected to the feeder cylinder 2 The constant container 3; the alumina continuous feeding device also includes a shelling head 4 for breaking the surface of the material in the electrolytic cell (not shown), and a shelling head 4 and the constant container 3 are provided for alumina from The fixed container 3 enters the material passing frame 5 of the electrolytic cell (not shown), and the material passing frame 5 includes a sloping plate 51, wherein the alumina continuous blanking equipment also includes a buffer 6 arranged in the material passing frame 5, buffering The device 6 and the inclined plate 51 together form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com