A VCR mining method no-sweep hole blasting charge structure and its construction method

A construction method and technology of mining method, which is applied in the field of mining blasting, can solve the problems of blasting blockage in the back section of the blast hole, and achieve the effect of reducing concentration, reducing negative effects, and eliminating hole plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

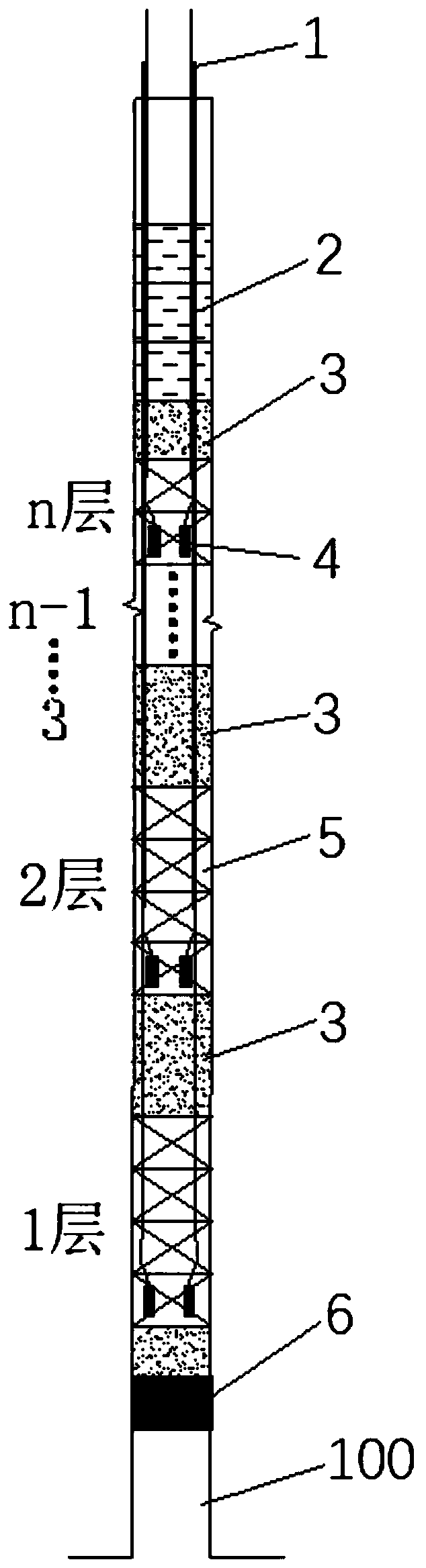

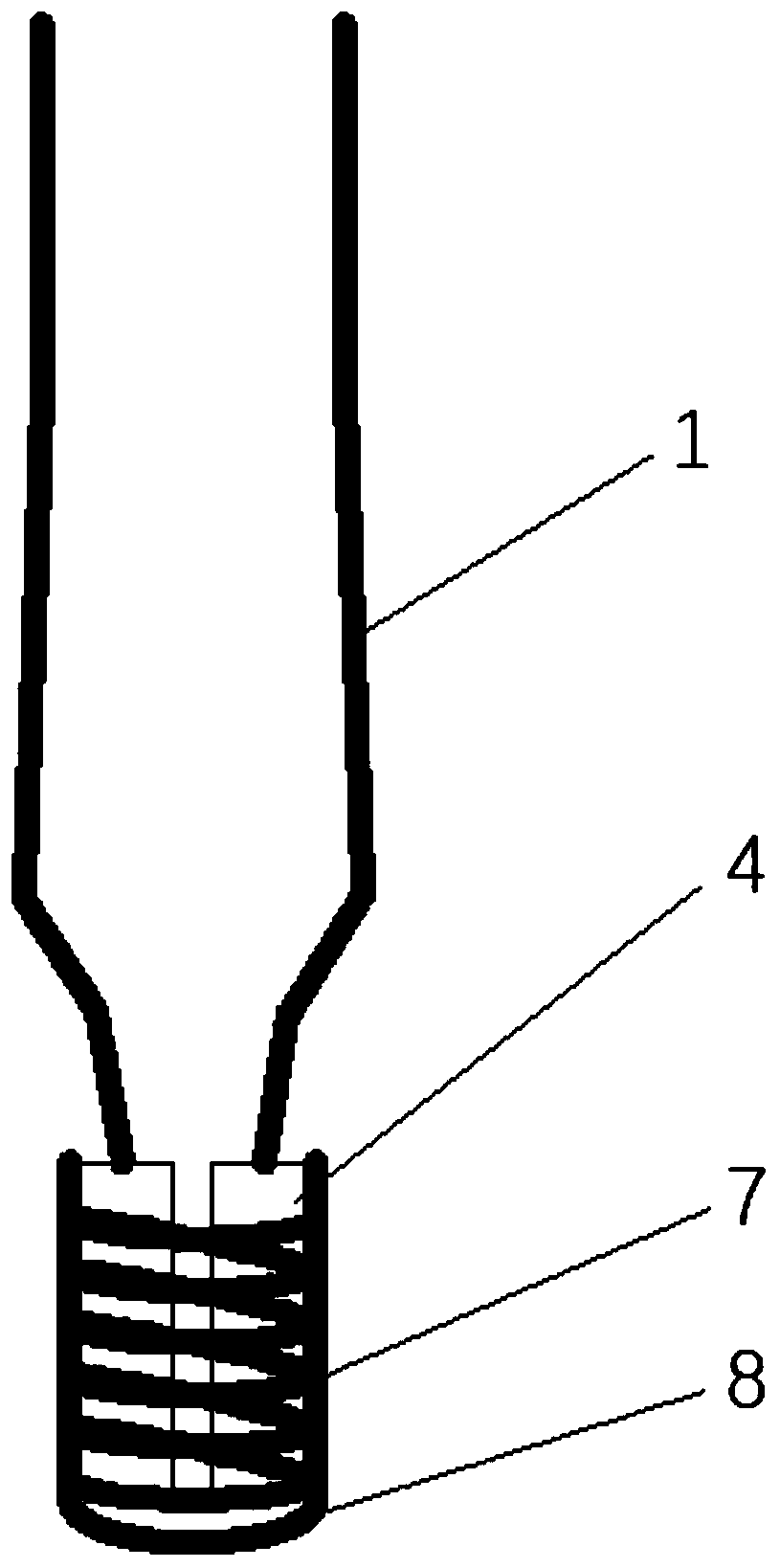

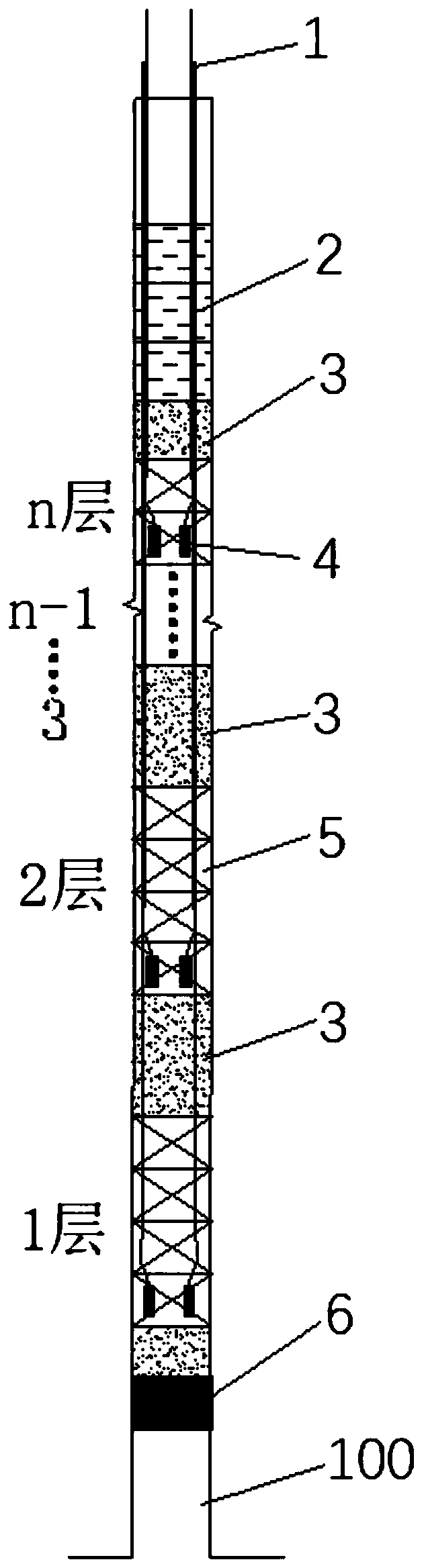

[0032] see figure 1 , the charge structure in the illustration is a preferred solution of the present invention, which is aimed at the sweep-free blasting charge structure of the VCR mining method with a full pass down to the vertical blast hole, and can be applied to a blast hole with a diameter of 90- 250mm downward deep hole. Specifically, it includes several layers of explosives 5 packed in layers within the blasting section of the blasthole 100, and all the explosives 5 are drawn out to the outside of the blasthole through the blasting assembly to connect to the blasting network. Wherein, the explosives are positioned by positioning blocks 6 at the bottom of the blasting section of the blast hole 100 , and each layer of explosives 5 is spaced apart by granular fillers 3 . The bottom explosives 5 and the positioning block 6 are separated by particle fillers 3 , and the top layer of explosives 5 is filled with particle fillers 3 in the blast hole, and the layer of particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com