Audio super-amphiphobic gauze composite film

A super-amphiphobic, composite membrane technology, applied in synthetic resin layered products, coatings, electrical components, etc., can solve the problem that micron-sized particles and oil pollution cannot be completely protected, the transmission loss of waterproof and breathable membrane sound, and the large mesh aperture. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

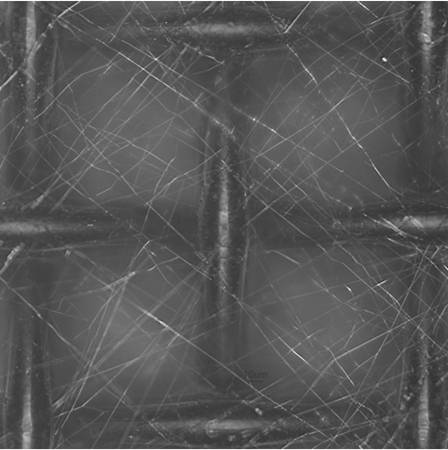

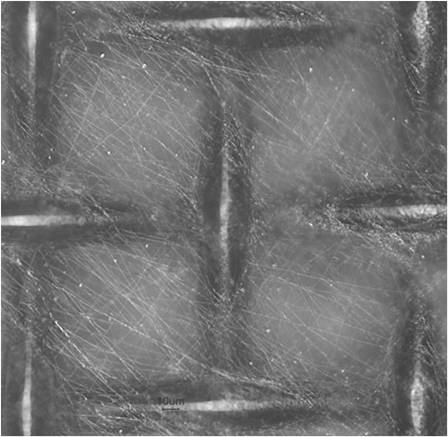

[0020] The audio-frequency super-amphiphobic mesh composite film of the present invention is a compound of three-layer structure, the middle support layer is audio-frequency mesh, and the fiber layer and the super-amphiphobic layer are respectively distributed on both sides of the support layer.

[0021] The audio mesh is selected from the dust-proof mesh in the acoustic field used in the market. It is made of monofilament warp and weft through precision weaving. It has stable mechanical stability and can keep the warp and weft constant, the shape and size of the mesh aperture Invariant, this essentially non-deformable property is very important to maintain the mechanical stability of the composite structure. The selected audio mesh can be made of PET, PA, PP, PBT, PE, PEN, PEEK, cotton or several blends. The diameter of warp and weft is 10-150 microns, preferably 30-90 microns. The opening size is 10-300 microns, preferably 100-200 microns.

[0022] It should be pointed out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com