Production process of aluminum sol and aluminum sol prepared by production process

A production process, aluminum sol technology, applied in the direction of alumina/aluminum hydroxide, aluminum compounds, chemical instruments and methods, etc., can solve the problems of low purity of aluminum sol, achieve low impurity content, short reaction cycle, and low reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0090] According to a preferred embodiment of the present invention, the aluminum-chlorine mass ratio of the aluminum sol is 1-1.6, preferably 1-1.4, more preferably 1-1.2.

[0091] According to a preferred embodiment of the present invention, the pH value of the aluminum sol is 3.5-4.5.

[0092] According to a preferred embodiment of the present invention, in the aluminum sol, Al 2 o 3 The calculated aluminum content is 5-30% by weight.

[0093] The present invention will be described in detail below in conjunction with the examples, but the scope of the present invention is not limited thereby.

[0094] In the following examples, the method specified in RIPP34-90 was used to measure the aluminum content in the prepared aluminum sol product, and the ion chromatography method was used to measure the chlorine content in the prepared aluminum sol product.

[0095] The pH value of the aluminum sol was measured with a pH meter (purchased from Mettler-Toledo).

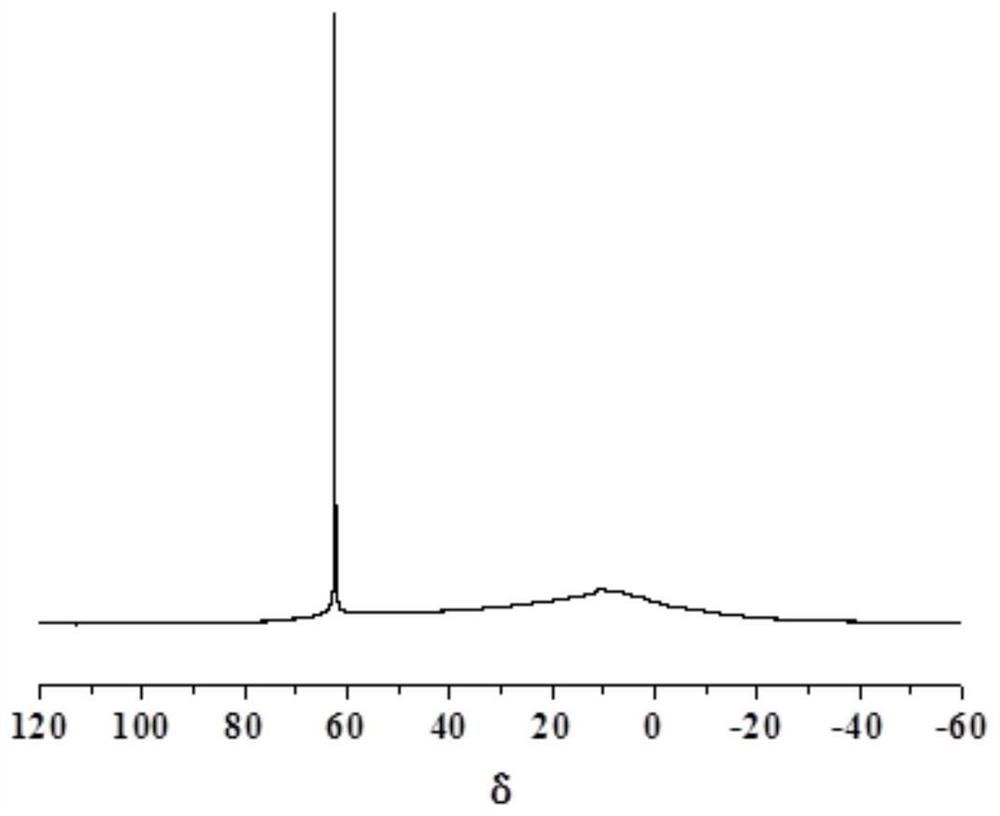

[0096] The exis...

Embodiment 1

[0098] (1) With stirring, at ambient temperature (25°C, the same below), slowly add 515g of ammonia water with a concentration of 15% by weight into 900g of aluminum chloride solution with a concentration of 20% by weight, and stir for 0.5h to obtain pH For the first reaction liquid of 3.4, the temperature of the first reaction liquid was raised to 50° C., and stirred and reacted at this temperature for 0.5 hours.

[0099] (2) With stirring, the heated solution obtained in step (1) is contacted with 160 g of ammonia water at a concentration of 15% by weight to obtain a second reaction solution with a pH of 3.7, and the temperature of the second reaction solution is raised to 70° C. , and the reaction was stirred at this temperature for 6 hours, then cooled to ambient temperature to obtain a concentration of 4.5% by weight (as Al 2 o 3 ) of salt-containing aluminum sol.

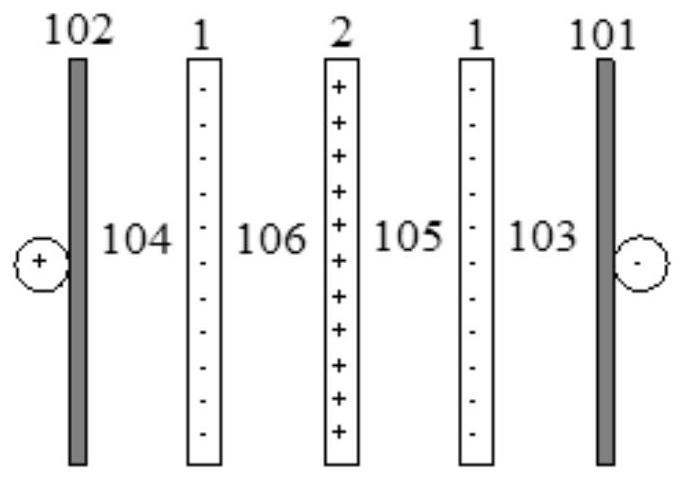

[0100] (3) Ordinary electrodialysis: the salt-containing aluminum sol obtained in step (2) is stored in t...

Embodiment 2

[0107] (1) With stirring, at ambient temperature (25° C., the same below), 660 g of a concentration of 15% by weight of sodium hydroxide aqueous solution is slowly added to 920 g of a concentration of 20% by weight of aluminum chloride solution, and with stirring for 1 h, To obtain a first reaction solution with a pH of 3.3, the temperature of the first reaction solution was raised to 55° C., and stirred and reacted at this temperature for 1 hour.

[0108] (2) With stirring, the heated solution obtained in step (1) is contacted with 110 g of a concentration of sodium hydroxide aqueous solution of 15% by weight to obtain a second reaction solution with a pH of 3.7, and the temperature of the second reaction solution is raised to 80°C, and the reaction was stirred at this temperature for 6.5 hours, then cooled to ambient temperature to obtain a concentration of 4.3% by weight (as Al 2 o 3 ) of salt-containing aluminum sol.

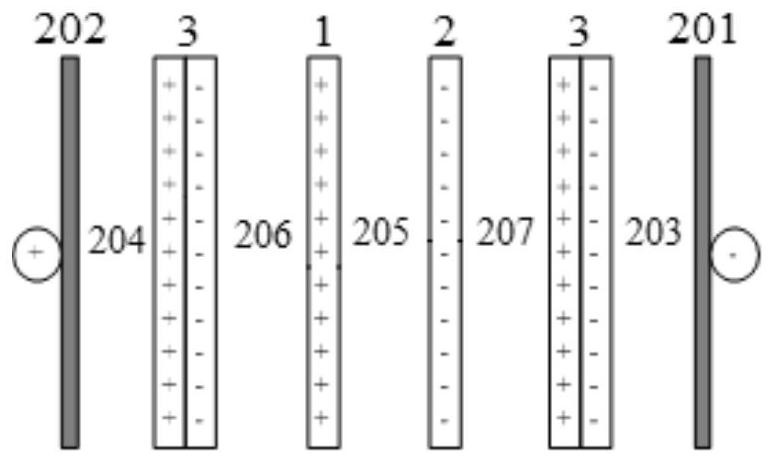

[0109] (3) Ordinary electrodialysis: the salt-contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com